Wollastonite/polypropylene composite material and preparation method thereof

A technology of composite materials and wollastonite, which is applied in the field of high-strength and high-flow anti-impact wollastonite/polypropylene composite materials and its preparation, can solve the problems of poor fluidity and mechanical properties of composite materials, and improve impact resistance , Shorten modification time and improve fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

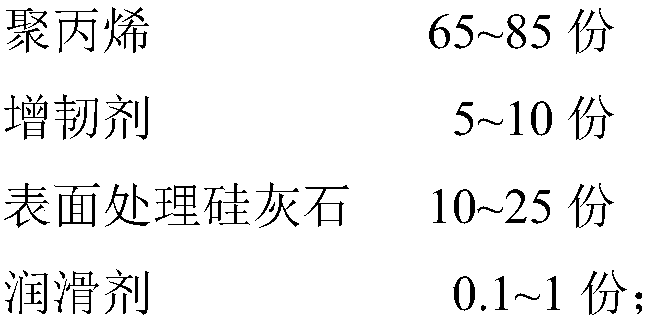

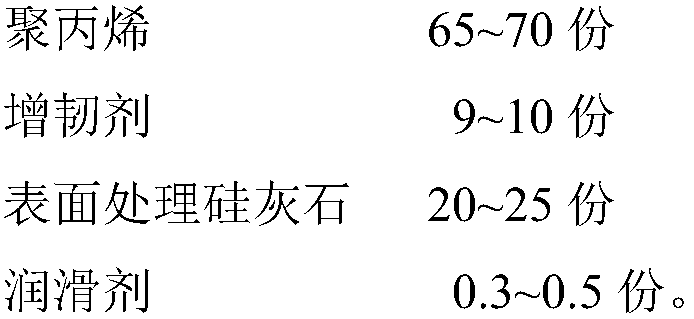

Method used

Image

Examples

Embodiment 1

[0040] 100Kg nano-calcium carbonate coated wollastonite (length-to-diameter ratio 12:1), 1Kg suberic acid is used for surface treatment of wollastonite in CLG-200D powder surface modification machine (treatment temperature: 150°C, treatment time 10min). Then the treated nano-calcium carbonate coated wollastonite, PP (EA5076), POE, polyethylene wax according to the ratio of PP / POE / wollastonite / polyethylene wax=70:10:20:0.4 Extrusion granulation is carried out on the extruder, and then injection molded into a standard sample for a series of performance tests.

Embodiment 2

[0042] 100Kg nano-calcium carbonate coated wollastonite (length-to-diameter ratio 16:1), 1Kg suberic acid is used for surface treatment of wollastonite in CLG-200D powder surface modification machine (treatment temperature: 150°C, treatment time 10min). Then the treated nano-calcium carbonate coated wollastonite, PP (EA5076), POE, polyethylene wax according to the ratio of PP / POE / wollastonite / polyethylene wax=70:10:20:0.4 Extrusion granulation is carried out on the extruder, and then injection molded into a standard sample for a series of performance tests.

Embodiment 3

[0044] 100Kg nano-calcium carbonate coated wollastonite (length-to-diameter ratio 12:1), 1Kg phthalic acid in CLG-200D powder surface modification machine for surface treatment of wollastonite (treatment temperature: 150 ° C, treatment time 10min). Then the treated nano-calcium carbonate coated wollastonite, PPEA (5076), POE, and polyethylene wax are proportioned according to the mass and number of PP / POE / wollastonite / polyethylene wax=70:10:20:0.4 Extrusion granulation is carried out on the extruder, and then injection molded into a standard sample for a series of performance tests.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com