Method for improving activated carbon performances by self-assembling low-temperature plasma modification

A low-temperature plasma, activated carbon technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of increasing energy consumption of activated carbon modification, uneven discharge, prolonging discharge time, etc., to achieve balanced surface chemical properties and shorten modification. time, the effect of improving the efficiency of modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

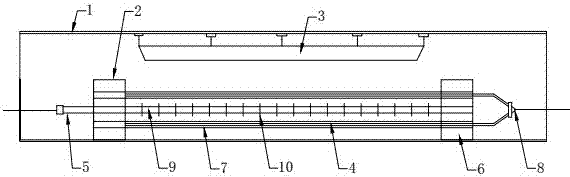

[0024] as attached figure 1 As shown, a self-assembled low-temperature plasma modified reactor to improve the performance of activated carbon mainly includes a box 1, a plasma generator 2, a gas distribution and tail gas treatment system, and auxiliary facilities. The box body 1 is rectangular. The plasma generator 2 is mainly composed of a cathode frame 4, an anode frame 5, and a high-voltage insulator 6; the cathode frame 4 is arranged in a rectangular shape by 4 groups of small quartz tubes, 7 sets of stainless steel wires, and 8 negative poles; the anode frame 5 is made of stainless steel rods 9. An octagonal star 10 is placed along the axial direction to form a serrated positive pole; the high-voltage insulator 6 is made of polytetrafluoroethylene, which mainly fixes the cathode frame and the anode frame, and plays the role of insulating high voltage. The gas distribution and tail gas treatment system is a background gas source, a flow meter, a gas buffer device, and an ...

Embodiment 2

[0035] A method for self-assembled low-temperature plasma modification to improve the performance of activated carbon, same as embodiment 1, wherein:

[0036] (1) Activated carbon sieving treatment

[0037] In the (1) step, the activated carbon is sieved and separated for use.

[0038] (2) Reactor detection and setting

[0039] After completing step (1), first open the pressure reducing valve of the steel cylinder to 0.4 MPa, and introduce background gas with a flow rate of 2.0 L / min through the rotameter, and wait for stable and continuous bubbles to appear in the tail gas recovery device, indicating that the reactor is ventilated smoothly. Turn on the power supply, adjust the voltage to 9.0 kV, and after 30 s of power-on, the ozone analysis instrument detects O in the reactor. 3 When generated, it indicates the generation of energetic particles in the reactor. After setting the voltage range value to 9.0 kV, turn off the power. The background gas is air.

[0040] (3) Ac...

Embodiment 3

[0045] A method for self-assembled low-temperature plasma modification to improve the performance of activated carbon, same as embodiment 1, wherein:

[0046] (1) Activated carbon sieving treatment

[0047] In the (1) step, the activated carbon is sieved and separated for use.

[0048] (2) Reactor detection and setting

[0049] After completing step (1), first open the pressure reducing valve of the steel cylinder to 0.4 MPa, and introduce background gas with a flow rate of 2.0 L / min through the rotameter, and wait for stable and continuous bubbles to appear in the tail gas recovery device, indicating that the reactor is ventilated smoothly. Turn on the power supply, adjust the voltage to 10.0 kV, and after 30 s of power-on, the ozone analysis instrument detects O in the reactor. 3 When generated, it indicates the generation of energetic particles in the reactor. After setting the voltage range value to 10.0 kV, turn off the power. The background gas is air.

[0050] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| loss rate | aaaaa | aaaaa |

| loss rate | aaaaa | aaaaa |

| loss rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com