Preparation method of fly ash chitosan composite adsorbent for treating printing and dyeing wastewater

A composite adsorption, printing and dyeing wastewater technology, applied in water/sewage treatment, chemical instruments and methods, textile industry wastewater treatment, etc., can solve problems such as poor biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

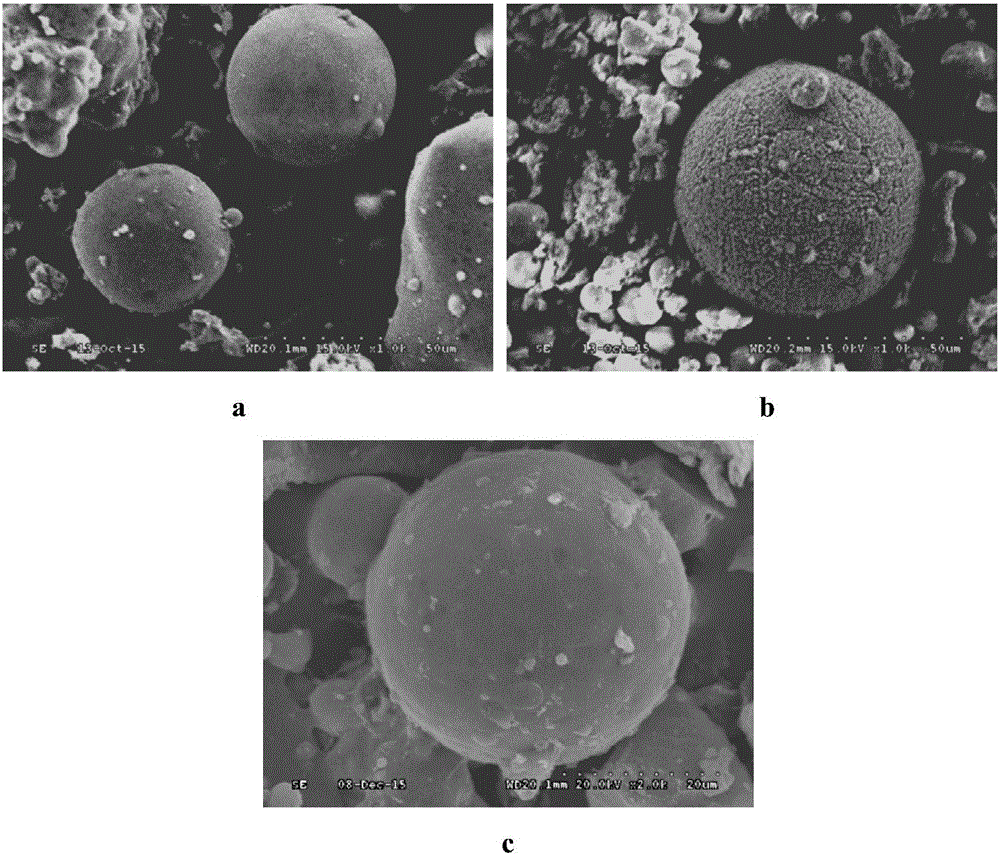

[0031] A method for preparing a fly ash chitosan composite adsorbent for treating printing and dyeing wastewater, comprising the following process steps:

[0032] a. Pass the bottom fly ash through a 300-mesh sieve for later use;

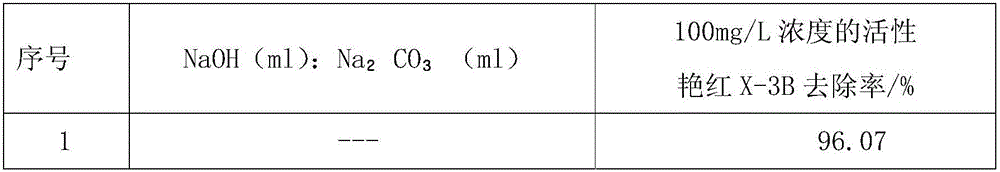

[0033] b. Take 5.0000g spare bottom fly ash, mix with 2mol / L NaOH solution and 1mol / L NaOH 2 CO 3 The mixed solution of the solution or the 2mol / L NaOH solution alone is mixed according to the solid-to-liquid ratio of 1:10, then ultrasonically treated at room temperature for 2 hours, the mixed solution after ultrasonic treatment is washed to neutral, suction filtered, and dried at 80°C for later use , to prepare mixed alkali-modified fly ash;

[0034]c. Take 2.0000g of mixed alkali-modified fly ash, mix fly ash and chitosan at a mass ratio of 1:10, add 20ml of chitosan acetic acid solution after mixing, first stir the mixed solution for 30min quickly, and at the same time use 2mol / LNaOH solution was titrated to pH=9, and then stirred slowly for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com