Preparation method of hydrophobic Y-type molecular sieve and hydrophobic Y-type molecular sieve

A molecular sieve, hydrophobic technology, applied in separation methods, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve the problems of restricting the popularization and use of activated carbon, unable to meet environmental protection emissions, difficult to regenerate activated carbon, etc., to prolong the adsorption breakthrough time. , the effect of shortening the modification time and reducing the economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

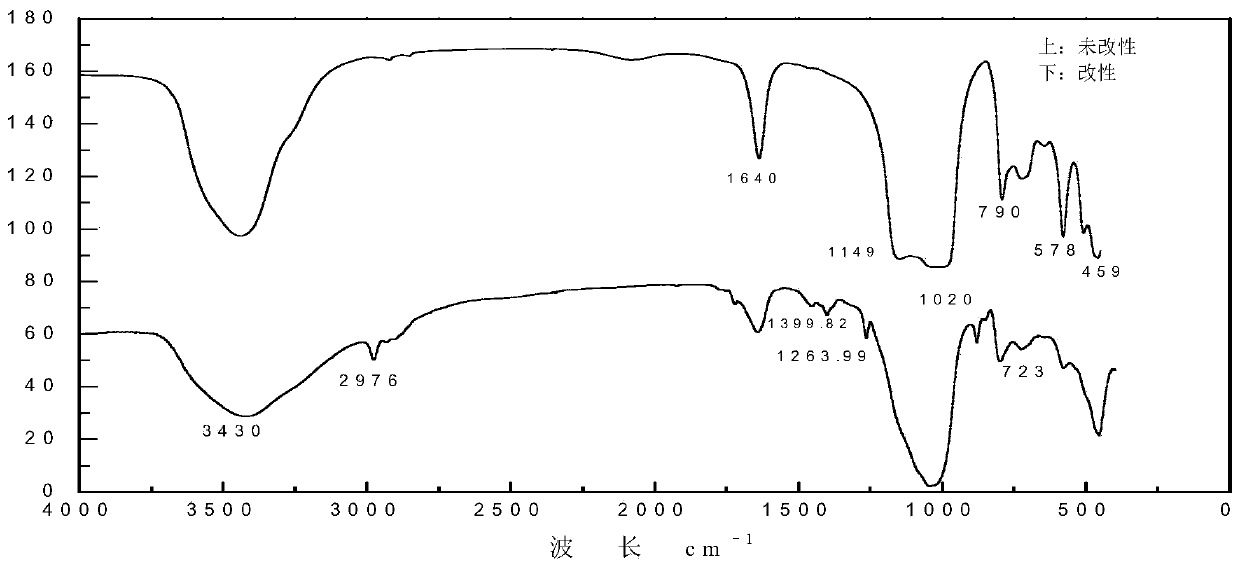

[0035] The present invention relates to a kind of preparation method of hydrophobic Y-type molecular sieve, comprises the following steps:

[0036] S1: Activation pretreatment process

[0037] Crush the NAY molecular sieve through the sieve, the mesh size of the sieve is 40-60 mesh, and roast it under the protection of an inert gas. The inert gas is preferably nitrogen. The roasting time is 1-4 hours, and the roasting temperature is 200-450 ° C. After roasting, it is placed in a desiccator Standby; in this step, the NAY molecular sieve can be any one of spherical, strip and powder, and of course a mixture of two or three of them can also be used.

[0038] S2: Modification process

[0039] Dissolve the NAY molecular sieve prepared in step S1 in an organic solvent, and add the silylating agent drop by drop while ultrasonically dispersing evenly. The ultrasonic time is 10 to 40 minutes, and then fully react in the reaction device with a condensing reflux device , specifically, ...

Embodiment 1

[0047] In this embodiment, by changing a group of comparative experiments of components and reaction parameters, the optimal modification conditions of hydrophobic Y-type molecular sieves are selected, and the specific parameters are shown in Table 1:

[0048] Table 1:

[0049]

[0050] Refer to the components and proportions shown in Table 1, and prepare hydrophobic Y-type molecular sieves according to the above preparation method.

Embodiment 2

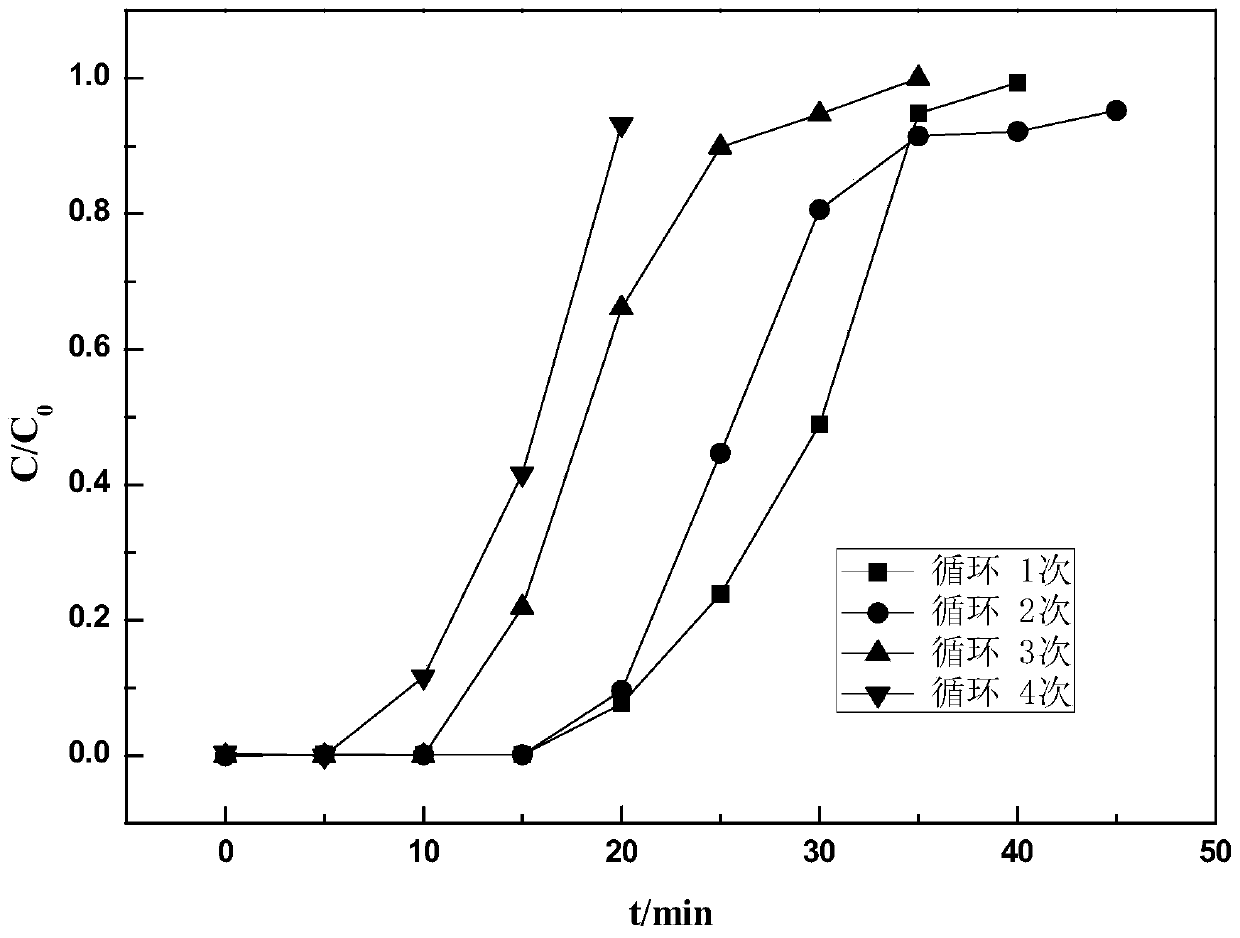

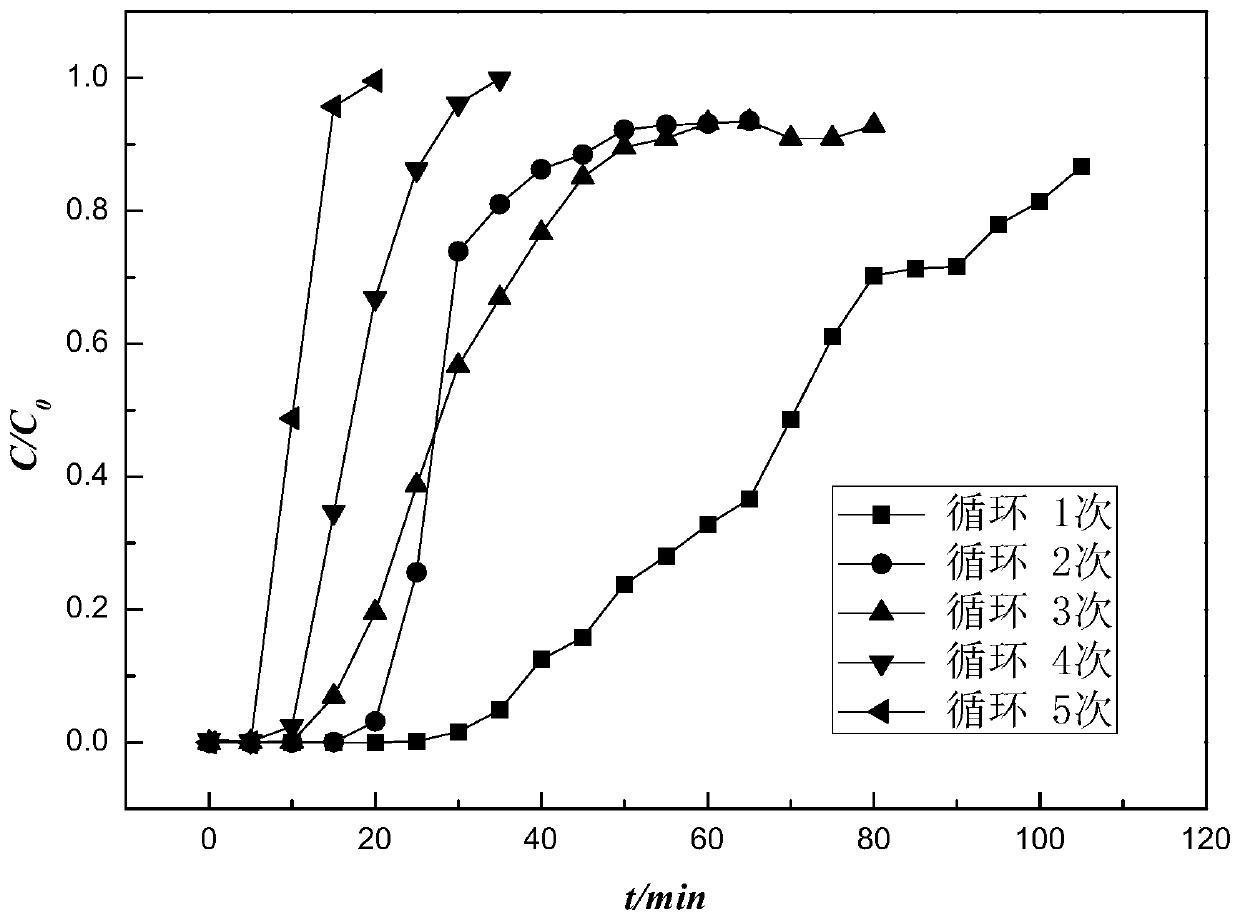

[0052] This example involves the adsorption test of the hydrophobic Y-type molecular sieve prepared in Example 1 under a static saturated water vapor environment. Put the dish together in a closed incubator, let it stand for 24 hours, weigh the weight of the adsorbent, and calculate the water absorption by calculating the difference with that before adsorption.

[0053] The specific experimental parameters and results are shown in Table 2:

[0054] Table 2:

[0055]

[0056]The modification time, temperature, organic solvent, and silanization reagent were orthogonally screened according to four factors and three levels, and the optimal silanization reagent conditions were obtained as condensation reflux temperature 50°C, modification time 8h, organic solvent cyclohexane, silanization Reagent Dimethyldichlorosilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com