Modified asphalt and preparation method and application thereof

A technology for modifying asphalt and asphalt, which is applied in building components, building insulation materials, buildings, etc., can solve problems such as affecting the forming speed of the coil, affecting the yield of the product, and groove marks on the coil product, so as to avoid adverse effects and shorten the Modification time, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a kind of modified asphalt, the preparation method of described modified asphalt comprises the steps:

[0051] (1) Mix asphalt at 110°C, asphalt regenerant at 55°C, and white oil at 25°C according to the formula, and keep warm at 160°C for 60 minutes to obtain premixed asphalt;

[0052] (2) Shearing and grinding mixing the modifying agent and the premixed asphalt obtained in step (1) for 60 minutes according to the formula to obtain the first shearing material; the shearing and grinding is mixed in a colloid mill, and the grinding gap is 0.2 mm;

[0053] (3) Add talcum powder to the first shearing material obtained in step (2), after stirring and mixing, keep it warm at 180°C for 60min, and then perform shearing, grinding and mixing for 30min in a colloid mill with a grinding gap of 0.1mm to obtain the modified Sexual asphalt.

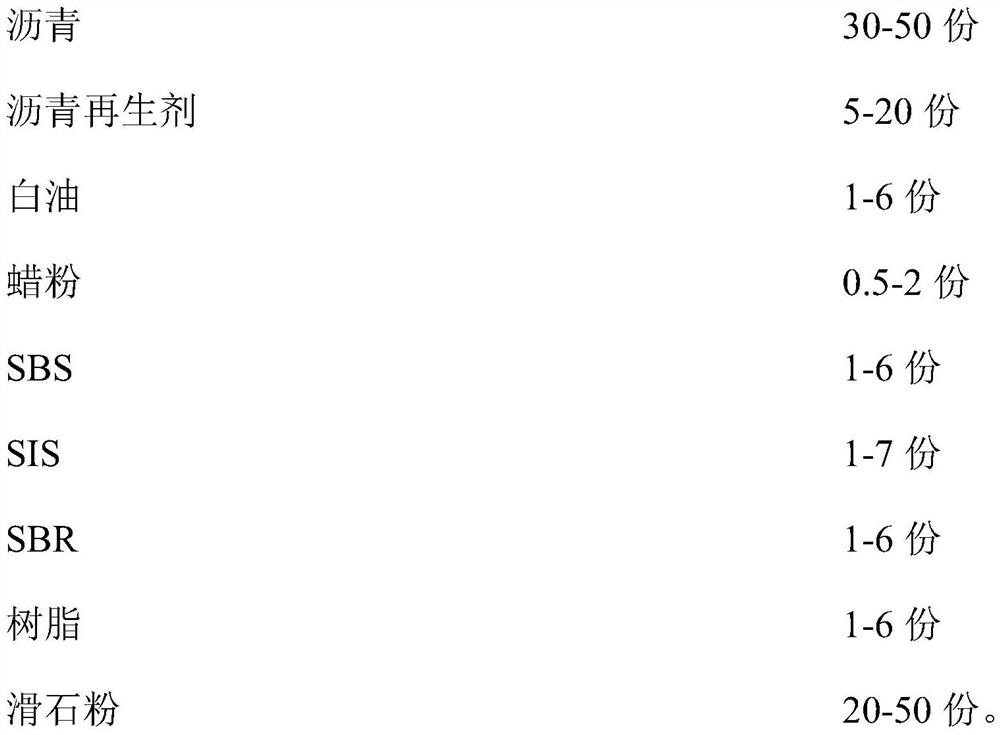

[0054] In parts by weight, the raw materials for preparing the modified asphalt include: 40 parts of asphalt (70#), 1...

Embodiment 2

[0056] This embodiment provides a kind of modified asphalt, the raw material composition of described modified asphalt is identical with embodiment 1, and the preparation method of described modified asphalt comprises the following steps:

[0057] (1) Mix asphalt at 100°C, asphalt regenerant at 50°C and white oil at 20°C according to the formula, and keep warm at 150°C for 70 minutes to obtain premixed asphalt;

[0058] (2) Shearing and grinding mixing the modifying agent and the premixed asphalt obtained in step (1) for 50 minutes according to the formula amount to obtain the first shearing material; the shearing and grinding is mixed in a colloid mill, and the grinding gap is 0.18mm;

[0059] (3) Add talcum powder to the first shearing material obtained in step (2), after stirring and mixing, keep it warm at 175°C for 70min, and then shear, grind and mix for 25min in a colloid mill with a grinding gap of 0.08mm to obtain the modified Sexual asphalt.

Embodiment 3

[0061] This embodiment provides a kind of modified asphalt, the raw material composition of described modified asphalt is identical with embodiment 1, and the preparation method of described modified asphalt comprises the following steps:

[0062] (1) Mix asphalt at 120°C, asphalt regenerant at 60°C and white oil at 30°C according to the formula, and keep warm at 170°C for 50 minutes to obtain premixed asphalt;

[0063] (2) Shearing and grinding mixture modifier and step (1) gained premixed asphalt 70min according to formula quantity, obtains the first shearing material; Said shearing and grinding is mixed and carried out in colloid mill, and grinding gap is 0.24mm;

[0064] (3) Add talcum powder to the first shearing material obtained in step (2), after stirring and mixing, keep it warm at 185°C for 50min, then perform shearing, grinding and mixing for 35min in a colloid mill with a grinding gap of 0.12mm, to obtain the modified Sexual asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com