Modification method of dietary fibers and product thereof

A dietary fiber and modification technology, applied in the field of modification methods and obtained products, can solve the problems of high cost and large amount of enzyme, achieve the effect of increasing pores, loose and porous structure, and improving the efficiency of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

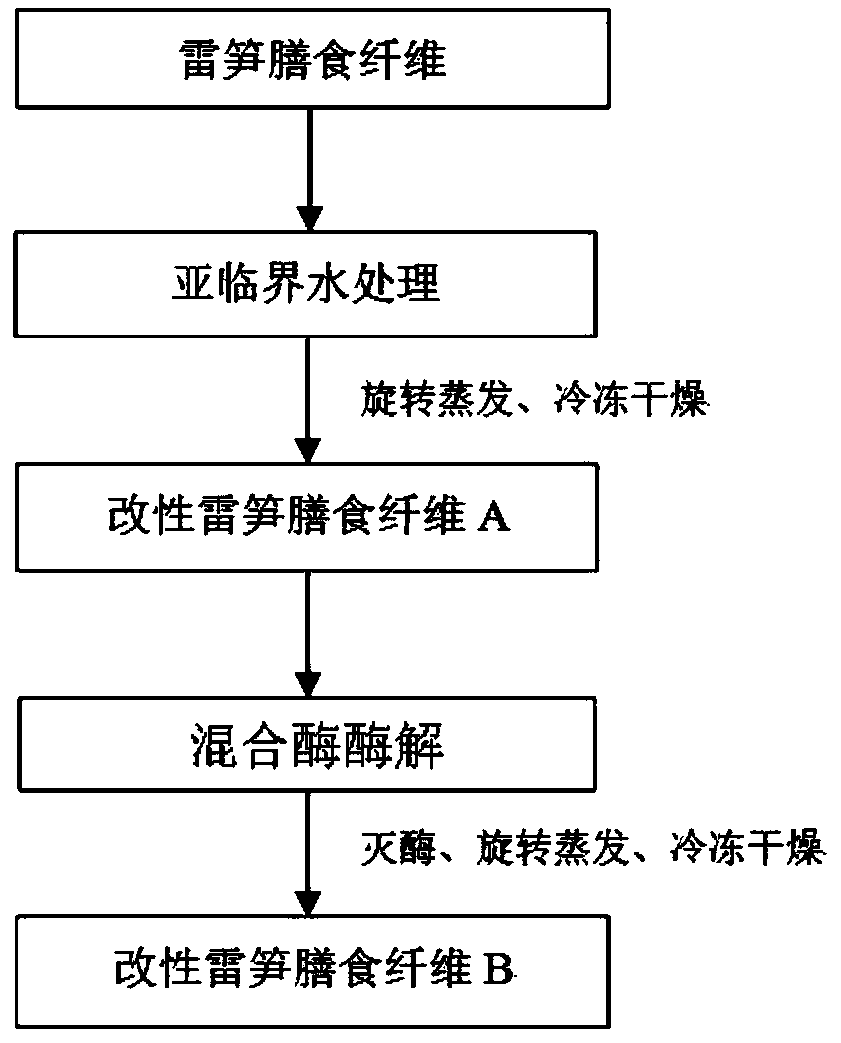

Method used

Image

Examples

Embodiment 1

[0031] Extraction of total dietary fiber of asparagus:

[0032] The extraction of total dietary fiber of bamboo shoots can adopt known techniques in the art, such as acid-base extraction method, ultrasonic extraction method, biological enzyme method, etc. The extraction method of total dietary fiber of bamboo shoots of the present invention is: fresh bamboo shoots raw materials are pulverized, It is obtained by leaching with 10% NaOH solution and 30% acetic acid solution, washing to neutrality, filtering and drying.

Embodiment 2

[0034] (1) Mix the extracted dietary fiber and distilled water at a mass volume ratio of 1:50 (w / v, g / mL), put it into a subcritical water equipment, set the temperature at 135°C, and process for 10 minutes; the process is over Finally, concentrated by rotary evaporation at a temperature of 50°C, and then freeze-dried the concentrated solution and the residue for 48 hours, crushed after freeze-drying, and passed through a 80-mesh sieve to obtain the modified Lei bamboo shoot dietary fiber A;

[0035] (2) Add distilled water to the modified bamboo shoot dietary fiber A obtained in step (1) according to a material-to-liquid ratio of 1:20, adjust the pH to 4.8 with a HCl solution with a concentration of 1mol / L, add cellulase and xylanase Mixed enzymes, the amount of mixed enzymes added is 0.30% of the mass of the dietary fiber A of bamboo shoots (the proportion of cellulase in the mixed enzymes is 30%), and the enzymolysis is stirred at a temperature of 50 ° C for 3 hours to obtai...

Embodiment 3

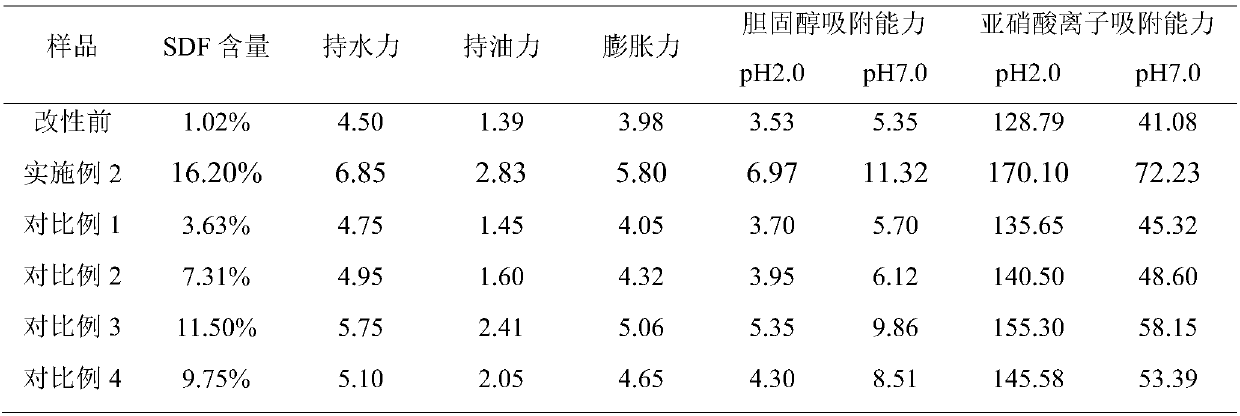

[0063] The test process is the same as in Example 2, except that the subcritical water treatment temperature is 120°C. Prepared the modified Leisun dietary fiber B. After measurement, the soluble dietary fiber content is 12.40%, the water holding capacity is 6.12g / g, the oil holding capacity is 2.38g / g, the swelling force is 5.12mL / g, the cholesterol adsorption capacity is 6.55mg / g (pH2.0), 10.84mg / g (pH7.0), nitrite ion adsorption capacity is 148.32μg / g (pH2.0), 58.12μg / g (pH7.0).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water holding capacity | aaaaa | aaaaa |

| Oil holding power | aaaaa | aaaaa |

| Expansion force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com