Patents

Literature

41results about How to "Increased porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method of intelligence-promoting water chestnut crisp chips

InactiveCN104351686AEliminate astringencyRemove green smellFood thermal treatmentFood shapingFlavorWater Chestnuts

The invention discloses a processing method of intelligence-promoting water chestnut crisp chips. The processing method comprises the following steps: performing steam treatment, stewing and blanching, freezing and unfreezing on fresh water chestnut, then performing zinc enrichment treatment, and finally performing primary drying, microwave puffing treatment and secondary drying to obtain the intelligence-promoting water chestnut crisp chips. According to the processing method of the intelligence-promoting water chestnut crisp chips, disclosed by the invention, new components are provided for the water chestnut crisp chips, and original color, flavor and nutritional components also can be kept; and the prepared zinc-enriched water chestnut crisp chips are less in nutritional component loss, are sweet, fresh and delicious, are crisp in taste, are added with zinc elements so as to be used for supplementing micro elements required for a human body, and have the health effects of promoting the intelligence development of children, improving memories and preventing senile dementia.

Owner:ANHUI SCI & TECH UNIV

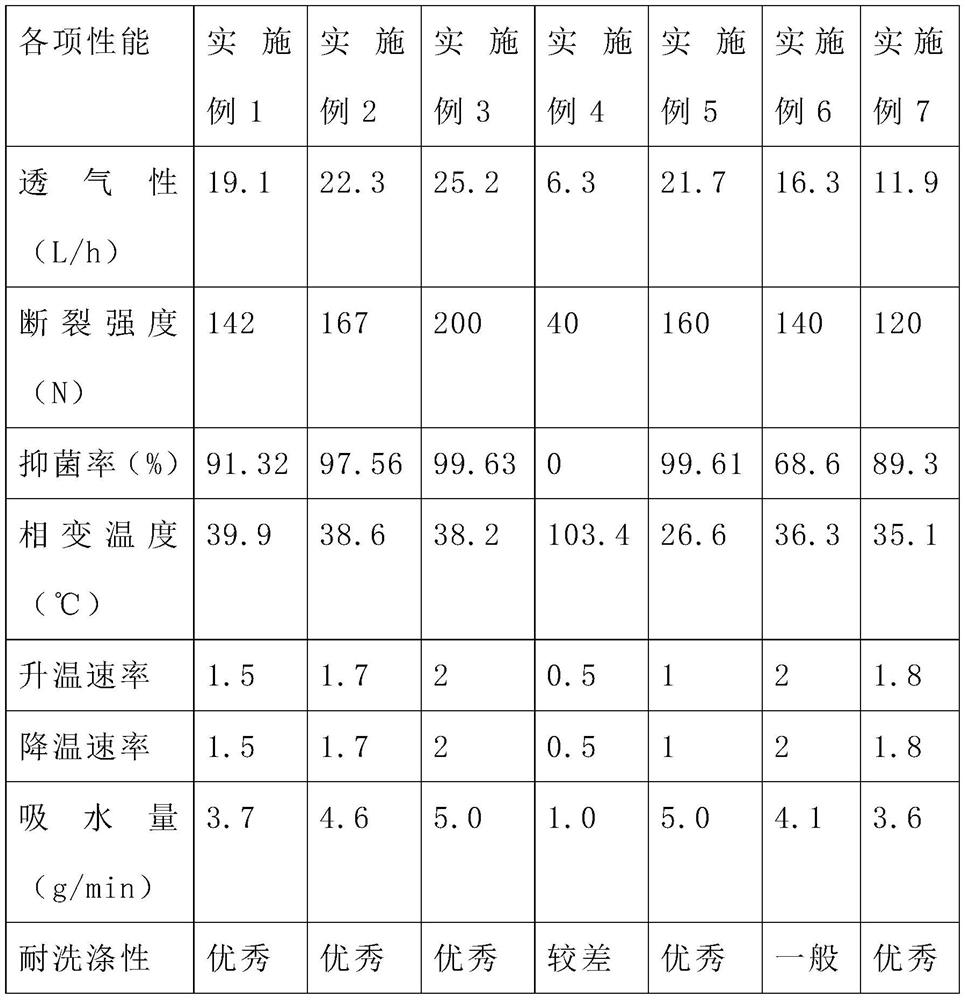

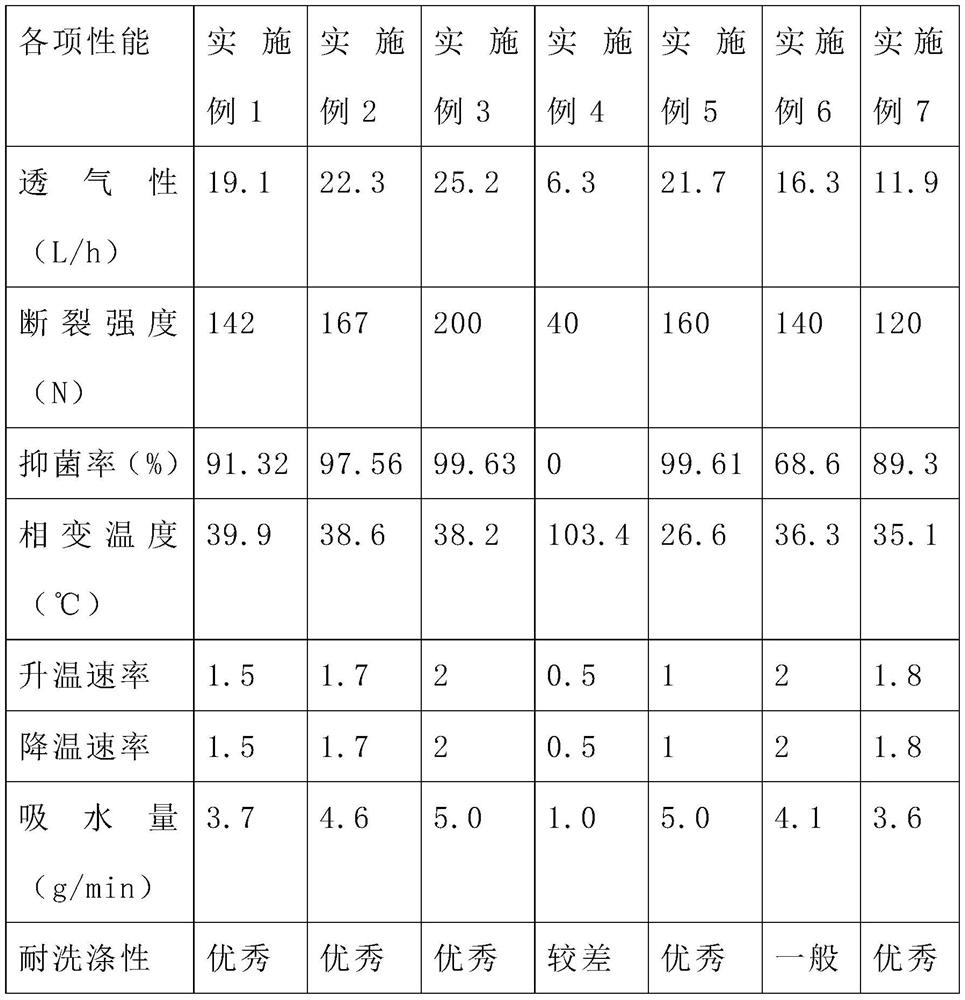

Phase-change temperature-regulating fiber blended yarn

ActiveCN111663214AAvoid reunionPrevent precipitationFilament/thread formingConjugated synthetic polymer artificial filamentsYarnPolymer science

The invention discloses a phase-change temperature-regulating fiber blended yarn and a preparation method thereof. The preparation method comprises the following steps of firstly, mixing paraffin hydrocarbon, graphite powder and methyl-2, 4-diisocyanate, and stirring at a high speed to obtain a phase-change temperature-regulating microcapsule; adding the prepared phase-change temperature-regulating microcapsule into nano-silver hydrogel to obtain modified nano-silver hydrogel; adding chitosan into sodium alginate hydrogel to obtain modified sodium alginate hydrogel; mixing the modified nano-silver hydrogel and the modified sodium alginate hydrogel into a spinning solution, and performing electrostatic spinning to obtain composite fibers; and spirally twisting the composite fibers, wool fibers and combed cotton to obtain the phase-change temperature-regulating fiber blended yarn. According to the phase-change temperature-adjusting fiber blended yarn and the preparation method thereof, the prepared phase-change temperature-adjusting fiber blended yarn has good temperature-adjusting and antibacterial properties, is more washable, keeps good water absorption and air permeability of fabric, and has high practicability.

Owner:JIANGYIN HAOYE TEXTILE

Processing method of selenium and zinc enriched non-fried potato chips

ActiveCN104351695AEliminate astringencyRemove green smellFood ingredient functionsFood preparationVacuum pumpingChipped potatoes

The invention discloses a processing method of selenium and zinc enriched non-fried potato chips. The processing method comprises the following steps: (1) raw material treatment: treating potatoes in steam at 45-55 DEG C for 10-50 minutes, then stewing and blanching for 30-60 minutes in the steam at 80-90 DEG C, and cooling; (2) freezing and unfreezing: cutting the potatoes into slices with the thicknesses of 3-6mm, freezing at the temperature of less than -10 DEG C, and then unfreezing the potato slices in a selenium and zinc enriched solution; (3) selenium and zinc enrichment: performing vacuum pumping on unfrozen potato slices in vacuum equipment at the vacuum degree of 0.085-0.095MPa for 10-20 minutes; (4) pre-drying: performing low-temperature drying on selenium and zinc enriched potato slices until the terminal water content is 15-35%; (5) puffing treatment; (6) after-drying: drying puffed potato slices until the terminal water content is less than 5%; and (7) cooling and packaging. The selenium and zinc enriched non-fried potato chips prepared by using the processing method disclosed by the invention are less in nutritional component loss, good in color and crisp in taste, and are added with selenium and zinc elements so as to have significant health effects.

Owner:ANHUI SCI & TECH UNIV

Production method of high-quality instant rice

The invention discloses a production method of high-quality instant rice, belonging to the technical field of food processing. The method is based on the principle of strong absorption of alcohol water vapor to lipid and moisture (including combined water) in rice, permeation and dissolving promotion of a magnetic field, and cavatition and uniform drying effect of infrared rays with intermediate waves, and can be used for improving the rehydration and preservation performance of the instant rice. The production method mainly comprises the process steps of selecting normal rice as raw materials, immersing at 40-50 DEG C for 25-35 minutes, cooking for 25-30 minutes, adding an aqueous solution of ethanol for dispersion, filtering, braising the rice for 15-20 minutes, drying by alcohol water vapor under a magnetic field of 6000-6500 GS till the water content of the rice is 8%-10%, and drying with infrared rays with the wavelength of 2-4 microns till the water content of the rice is 4%-5%. The instant rice is good in mouthfeel and excellent in rehydration and preservation performance.

Owner:NANCHANG UNIV

High-strength light ceramic filler

InactiveCN101020606AIncrease Al2O3 contentHigh compressive strengthSustainable biological treatmentCeramicwarePorosityChemical composition

The high strength light ceramic filler is prepared with clay 60-78 wt%, black earth 8-15 wt%, calcium carbonate 8-15 wt%, talcum 3-10 wt% and rice bran powder for the rest. Chemically, it consists of silica 50-60 wt%, alumina 13-20 wt%, calcium oxide 3-8 wt% and magnesia 10-16 wt% except impurity. It has high compression strength, long service life, low impurity content, high whiteness and high porosity.

Owner:杨剑

Planting method of selenium-rich organic rice

InactiveCN106508537AReduce the content of heavy metal ionsIncreased content of heavy metal ionsAnimal corpse fertilisersExcrement fertilisersDiseaseInsect pest

The invention discloses a planting method of selenium-enriched organic rice. The method comprises the steps of 1, field management, wherein a heavy metal adsorbing material with a thickness of 5-10 cm is laid after rice field soil is deeply plowed by 55-70 cm, then soil refilling is carried out, next, underground water is poured to soak the rice field for 20-30 days, again, the soil is exposed under the sun for 3-5 days after the water is drained, the heavy metal adsorbing material is taken out, and finally, an inorganic fertilizer with a thickness of 2-4 cm is buried at the 10-15 cm position of the soil; 2, transplanting management; 3, fertilization management, wherein firstly an active material is sprayed 1-3 hours before a selenium-rich leaf force fertilizer is sprayed, and the spraying quantity of the active material is 10-20 kg / mu. The selenium-rich organic rice planted through the planting method is fine and long in granule, crystal, transparent, soft and non-stick, the content of organic selenium is high, the incidence of diseases and insect pests is low, the content of heavy metal is low, and the selenium-rich organic rice has market competitiveness.

Owner:GUANGXI ZHONGKE QUNYUAN AGRI & FORESTRY SCI & TECH

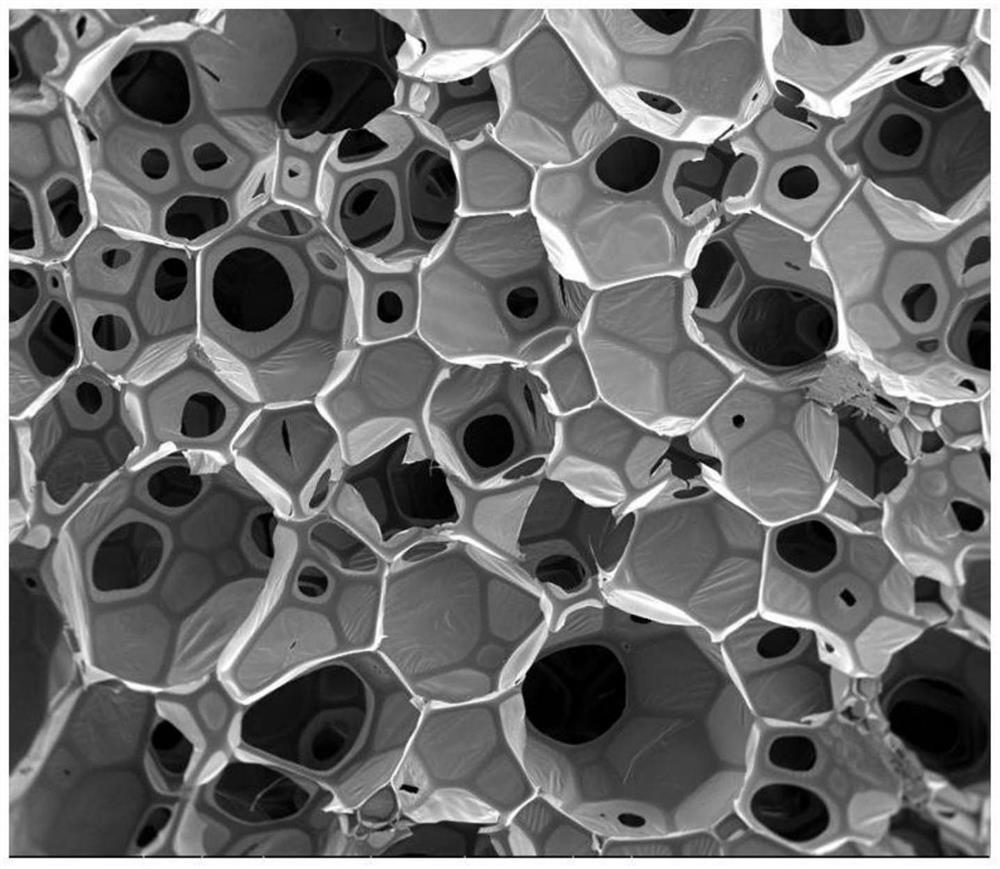

Heat-insulating and sound-absorbing honeycomb core material and preparation method thereof

ActiveCN110734645AExcellent sound absorption and heat insulation performanceIncreased porosityPolymer sciencePtru catalyst

The invention discloses a heat-insulating and sound-absorbing honeycomb core material and a preparation method thereof. The preparation method is characterized in that the dosage weight ratio of an aromatic anhydride derivative solution to a catalyst to a surfactant to a foaming agent to an isocyanate which are dissolved in a polar solvent is controlled; the length, width and depth three-dimensional size of the heat-insulating and sound-absorbing honeycomb core material is controlled by the length, width and depth three-dimensional size ratio of the inner cavity of a mold; and the ratio of themass of a foaming slurry to the volume of the inner cavity of a closed system is controlled, so that the density of polyimide foam compounded with the heat-insulating and sound-absorbing honeycomb core material is 12-100kg / m < 3 >, and the opening degree is 50-60%, and the heat-insulating and sound-absorbing honeycomb core material is obtained. The heat-insulating and sound-absorbing honeycomb core material can achieve the heat-insulating and sound-absorbing performance without being filled with different functional particles, and can be directly applied without post-processing.

Owner:HARBIN ENG UNIV

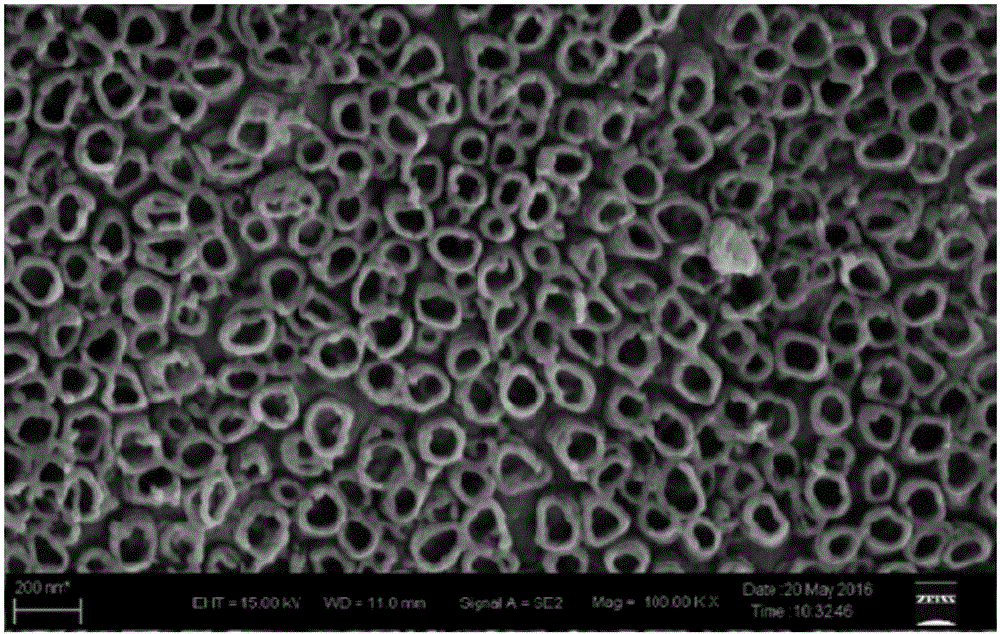

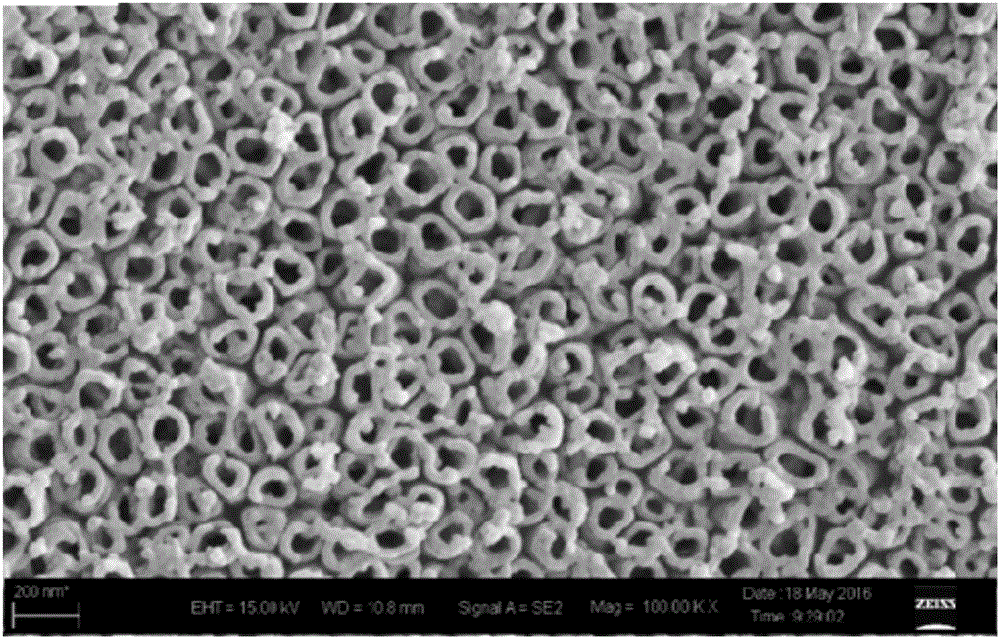

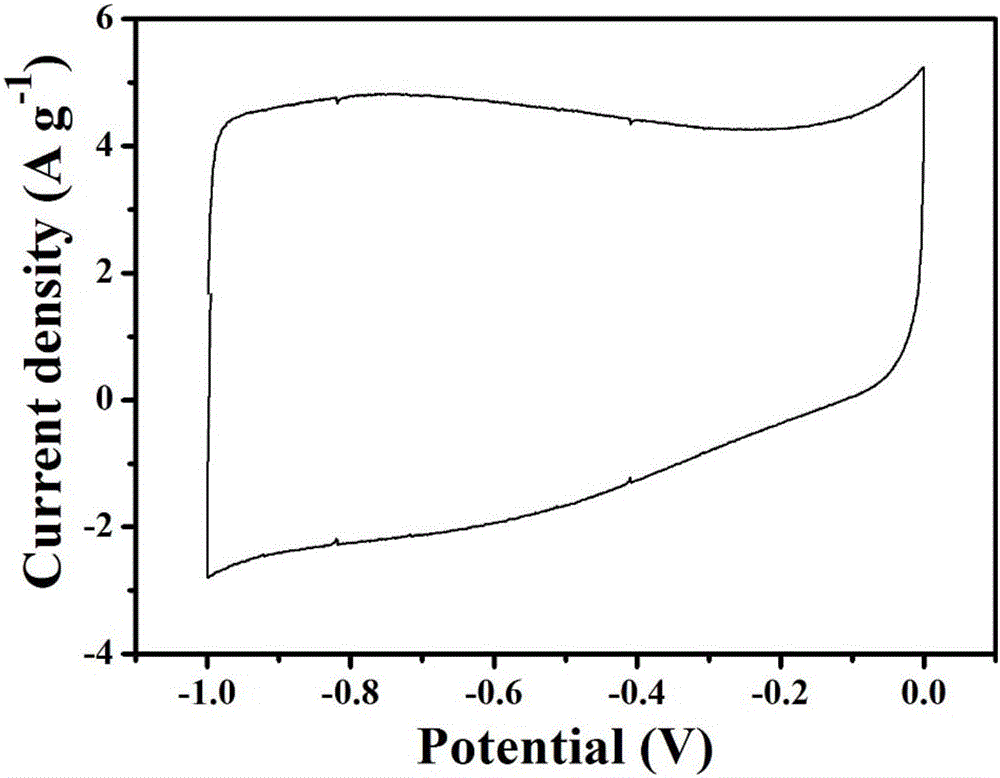

Method for preparing titanium oxide nanotube/carbon/manganese oxide composite material by employing electrochemical reduction method

InactiveCN106206079AIncrease capacitanceLower resistanceElectrolysis componentsHybrid capacitor electrodesTio2 nanotubeSupercapacitor

The invention provides a method for preparing a titanium oxide nanotube / carbon / manganese oxide composite material by employing an electrochemical reduction method, relates to a method for preparing a composite material of a super capacitor, and aims at solving the problem that a titanium oxide nanotube composite material capacitor prepared by an existing method is low in capacity. The method comprises the steps of forming a three-electrode system by a titanium oxide nanotube with carbon loaded on the surface, a Pt electrode and a saturated calomel electrode; and utilizing a CHI660D electrochemical workstation and carrying out chemical deposition by employing a potentionstatic deposition method to obtain the titanium oxide nanotube / carbon / manganese oxide composite material. By the electrochemical reduction method, a layer of manganese oxide is deposited on the surface of the carburized titanium oxide nanotube to prepare the titanium oxide nanotube / carbon / manganese oxide composite material. Compared with a TiO2NT / C composite material, the titanium oxide nanotube / carbon / manganese oxide composite material has higher capacitive performance. The titanium oxide nanotube / carbon / manganese oxide composite material can be obtained.

Owner:HARBIN INST OF TECH

Production method of instant colored rice

ActiveCN103844176AGood rehydrationShorten heat conduction timeFood preparationBound waterWater vapor

The invention relates to a production method of instant colored rice, belonging to the technical field of food processing. According to the method, the rehydration property and the storage performance of the instant colored rice based on the characteristics of high-frequency vibration and cavatition of ultrasonic waves, strong absorption effect of ethanol water vapor to lipids and water including bound water in rice and microwave heating consistence inside and outside can be improved. The production method comprises the main process steps of selecting red rice or black rice as raw materials, soaking for 30-40min at 45-55 DEG C, cooking for 30-40min, adding ethanol water solution for dispersion, filtering and continuously cooking for 20-30min, drying with ethanol water vapor in a 30-50Khz ultrasonic wave field until the water content is 8-10%, and then drying by microwaves with power of 100-200W until the water content is 3-4%. The produced instant colored rice has good mouthfeel, good rehydration property and excellent storage performance.

Owner:XUZHOU JINCHENG PLANET TRANSMISSION

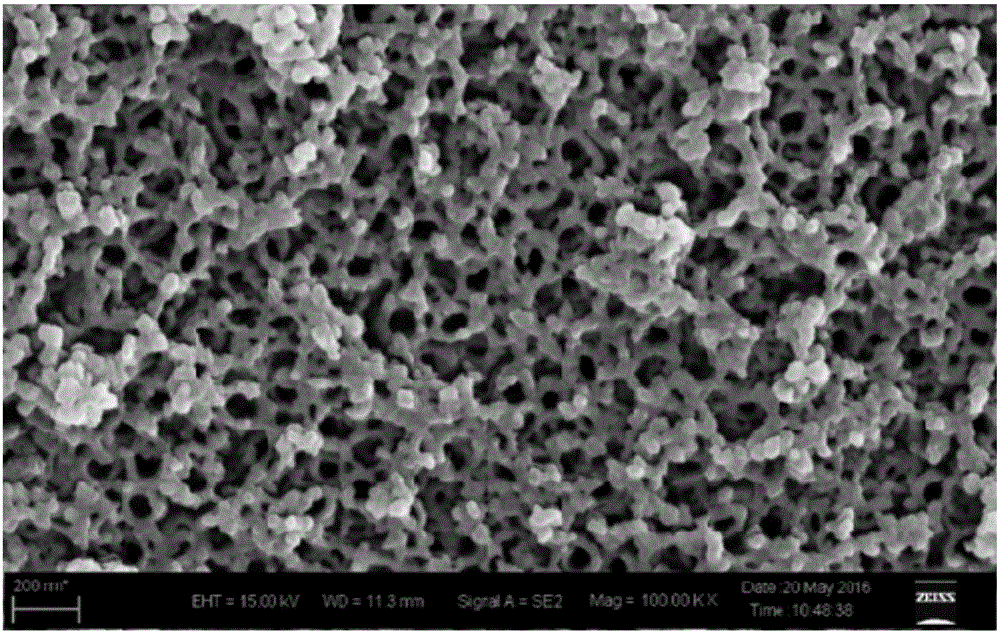

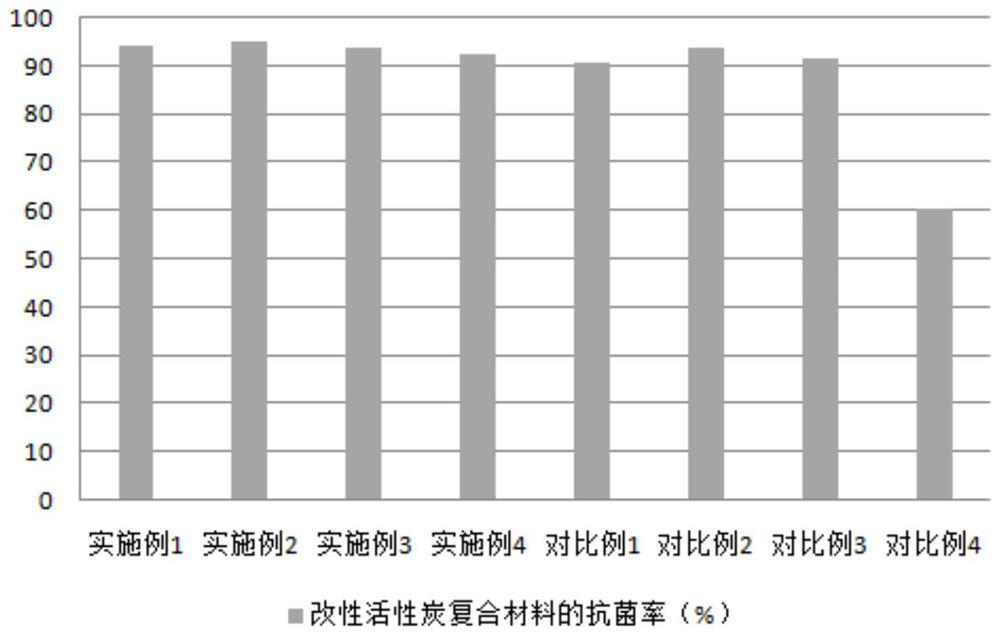

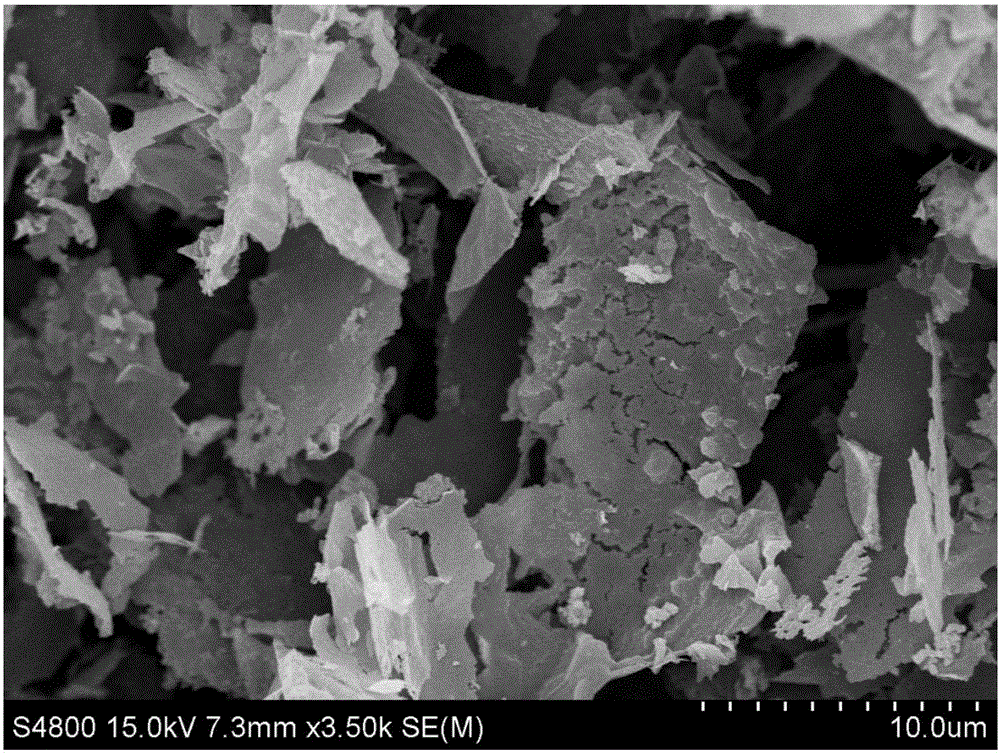

Modified activated carbon composite material and preparation method thereof

InactiveCN111604029AIncreased porosityImprove adsorption capacityMaterial nanotechnologyGas treatmentActivated carbonGraphite

The invention discloses a preparation method of a modified activated carbon composite material. The preparation method comprises the following steps: A, soaking vermiculite in dilute sulfuric acid, drying in an oven, and carrying out heat treatment; B, mixing coconut shells and wood chips, and carrying out heating cracking to obtain charcoal; C, mixing biochar with sodium hydroxide, and performinghigh-temperature treatment to obtain activated carbon; D, mixing and ball-milling the pretreated vermiculite, activated carbon and expanded graphite to obtain mixed powder; E, dropwise adding butyl titanate and nitric acid into absolute ethyl alcohol, stirring for reacting, and then adding the mixed powder to obtain a mixed solution; and F, carrying out vacuum drying on the mixed solution to obtain the modified activated carbon composite material. According to the prepared modified activated carbon composite material, activated carbon is mixed in the process of preparing nanometer titanium dioxide, the adsorption capacity of the activated carbon to harmful gas is enhanced; and in addition, the nanometer titanium dioxide has certain sterilization and bacteriostasis capacity, and the purification effect is improved.

Owner:吴丹妮

Method for producing nutritional instant rice through restrictive red-yeast fermentation

The invention relates to a method for producing nutritional instant rice through restrictive red-yeast fermentation, belonging to the technical field of food processing. The principle of the method disclosed by the invention is as follows: the nutritive value, reconstitution properties and storage performance of the instant rice are improved based on the transformation effect of red yeast fermentation, the strong moisture and lipid absorption effect of alcohol, the cavitation effect of ultrasonic waves and the uniform inside-outside drying effect of medium wave-short wave infrared rays. The method comprises the main process steps of screening rice, elutriating, immersing for 14-20 hours at the temperature of 30-40 DEG C, cooking for 25-30 minutes, pouring with cool water to disperse, filtrating, then, stewing for 15-25 minutes, carrying out restrictive red-yeast fermentation, drying rice with ultrasonic-alcohol water vapor until the moisture content is 15-18%, and then, drying with infrared rays with the wavelength of 2-4 microns until the moisture content is 3-5%. The produced instant rice is rich in nutrition and good in reconstitution properties and storage performance.

Owner:ZHEJIANG QIANCAOSU BIOTECH CO LTD

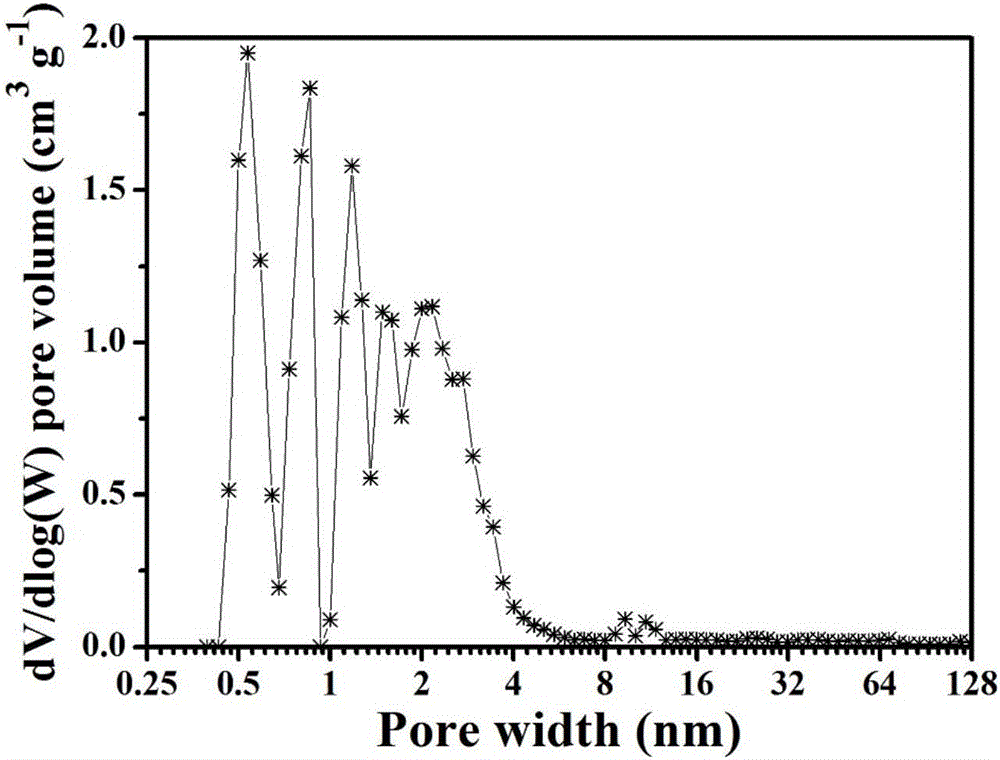

Preparation method and application of porous carbon material

InactiveCN105845457ARich sourcesLow priceHybrid capacitor electrodesHybrid/EDL manufacturePorous carbonCrucible

The invention provides a preparation method and application of a porous carbon material. The preparation method is carried out according to the following steps of placing potassium acetate in a nickel crucible, placing the nickel crucible in a high-temperature quartz tubular furnace, carrying out high-temperature pyrolysis under the protection of an inert gas, obtaining a product after pyrolysis, removing impurities in the product with an acid solution, immersing the product in the acid solution for magnetic stirring, washing the product with a large amount of deionized water to a neutral condition, and carrying out vacuum drying to obtain the porous carbon material. The prepared material is favorable in porous structure, high in specific area, large in pore volume and favorable in electrochemical performance, and also can be applied to other aspects.

Owner:JIANGSU UNIV

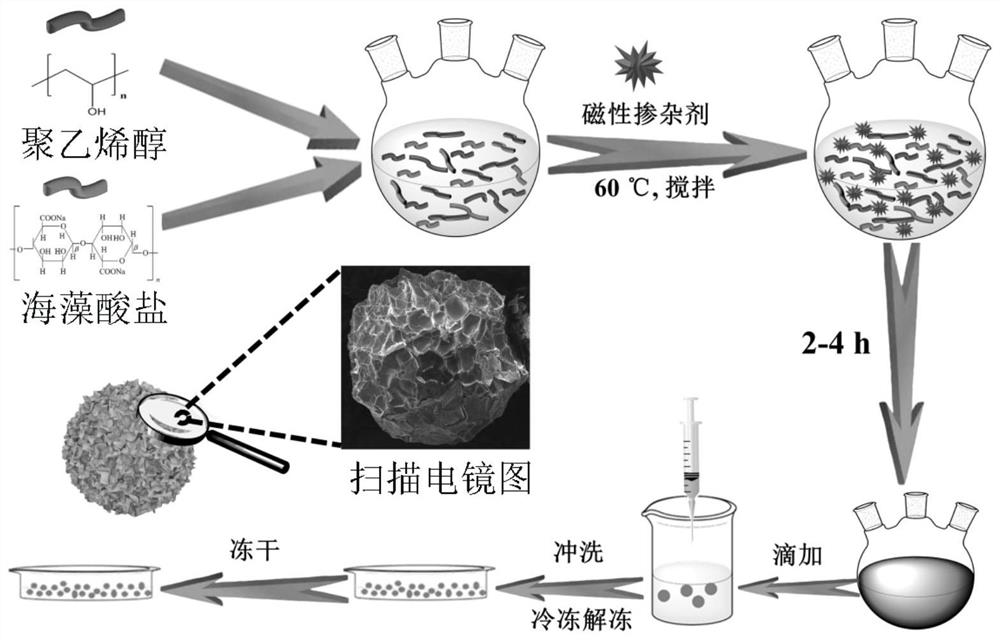

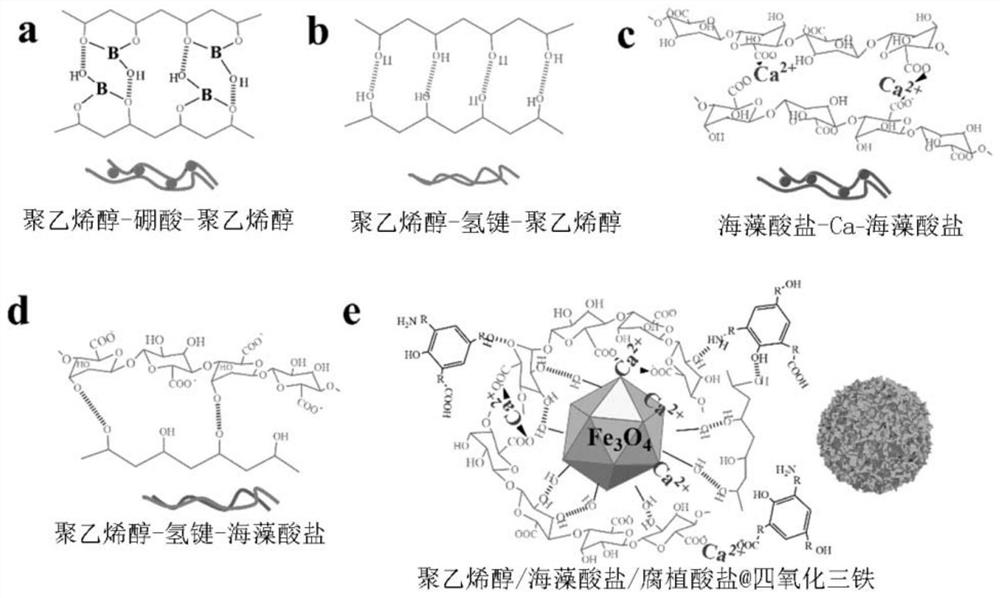

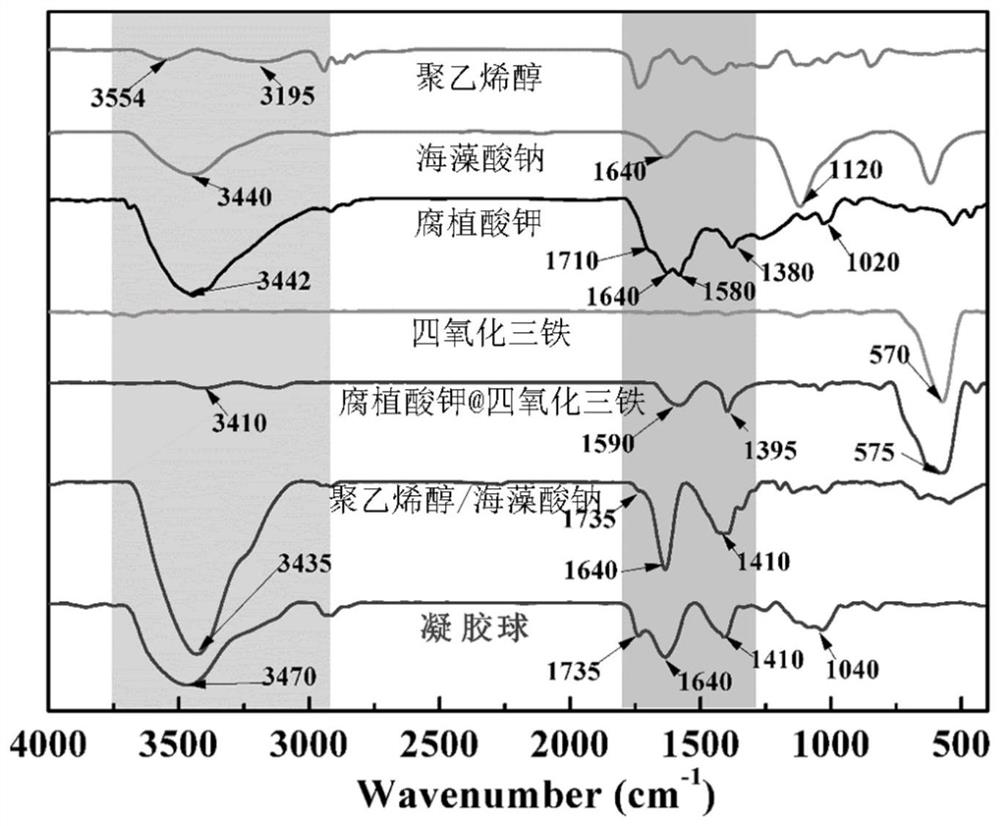

Magnetic gel ball adsorption material and preparation method thereof

PendingCN112755979ACheap and easy to getThe preparation process is matureOther chemical processesCombustible gas purificationPolyvinyl alcoholPhysical chemistry

The invention discloses a magnetic gel ball adsorption material and a preparation method thereof, polyvinyl alcohol and boric acid as well as alginate and soluble calcium salt are respectively cross-linked to form a three-dimensional double-cross-linked structure in a physical double-cross-linking manner under the condition that boric acid and soluble calcium salt are used as double-cross-linking agents; and a humate doping agent is doped into the double-crosslinking network structure, and finally the magnetic gel ball adsorption material is generated. The magnetic gel ball adsorption material synthesized by adopting the method has the advantages of green and environment-friendly synthetic raw materials, simple preparation process, low operation requirement and low cost, and the prepared adsorption material has the advantages of high removal rate, easiness in separation, good stability and recyclability, and can meet the requirements of actual production.

Owner:SHAANXI UNIV OF SCI & TECH

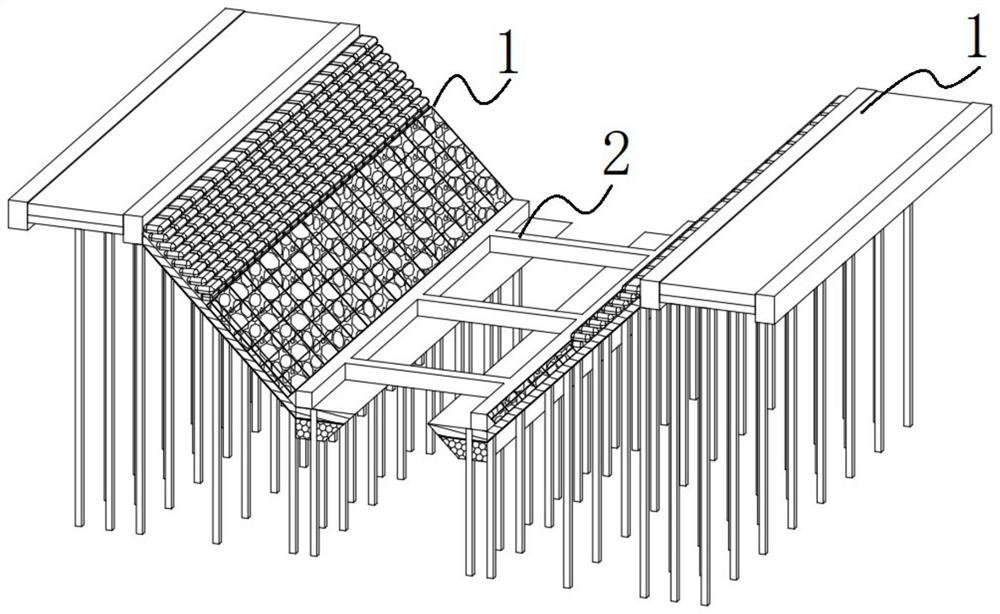

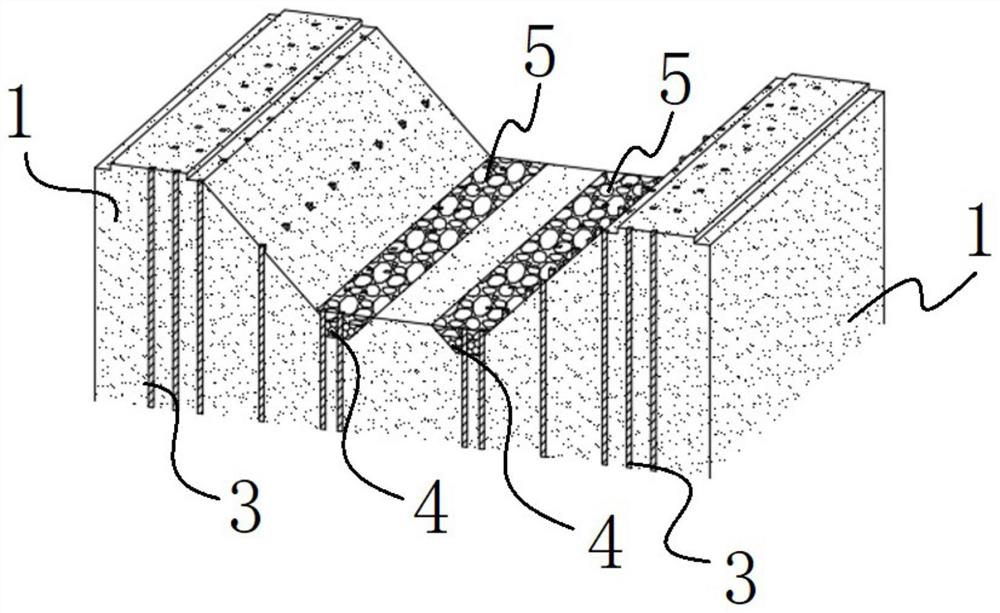

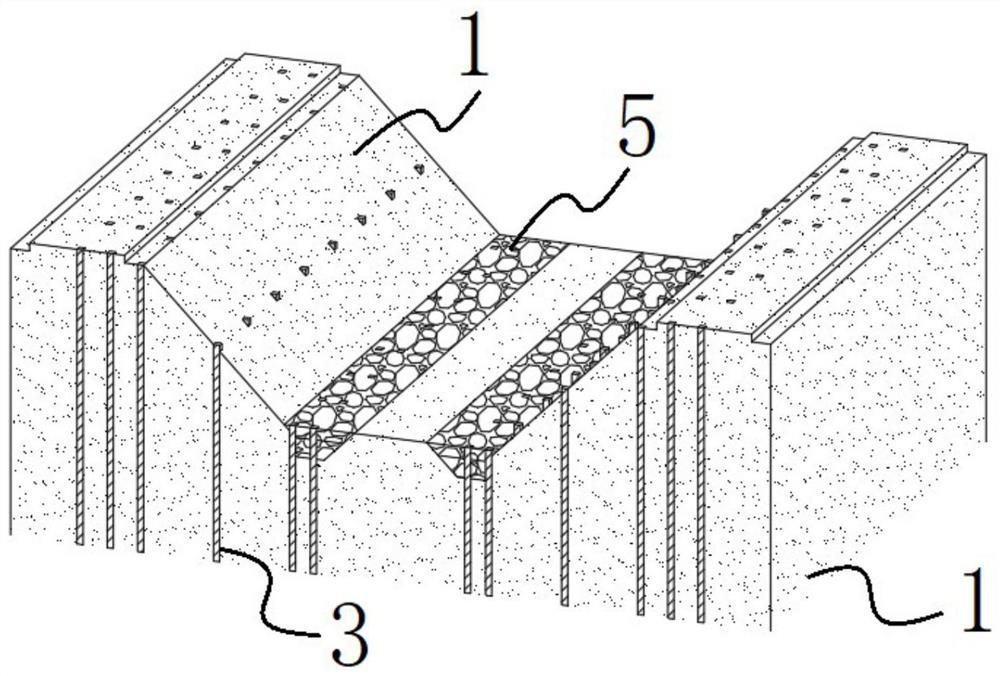

Slope protection supporting structure for slope water ecological management and construction method of slope protection supporting structure

PendingCN113605416APromote eco-environmental protectionImprove aestheticsExcavationsReceptacle cultivationEcologyEnvironmental resource management

The invention discloses a slope protection supporting structure for slope water ecological management. The slope protection supporting structure comprises slope protection structures arranged oppositely and a supporting structure arranged between the two slope protection structures; each slope protection structure comprises a slope toe, a slope and a slope top; a plurality of supporting piles are arranged on the slope protection structures; the supporting piles are arranged on the slope toes, the slope tops and the slopes correspondingly; one ends of the slopes are connected with the slope toes; an anchoring layer and a leveling layer are sequentially arranged on each slope toe from bottom to top; one ends of the slopes are connected with the slope tops; each slope top is provided with a maintenance channel or a road; a protection base layer and a protection reinforcing layer are sequentially arranged on each slope from bottom to top; a lower protection layer is arranged on the lower part of each protection reinforcing layer; and an upper protection layer is arranged on the upper part of each protection reinforcing layer. Through reasonable design, an ecological and natural slope structure is formed, the protection effect and the ecological management effect are good, meanwhile, construction is convenient and fast, the construction effect is improved while construction safety is guaranteed to the maximum extent, time and labor are saved, and efficient construction is achieved.

Owner:YUNNAN CONSTR INVESTMENT HLDG GRP CO LTD +1

A kind of phase change temperature regulating fiber blended yarn

ActiveCN111663214BReduce churnEnsure stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsYarnPolymer science

Owner:JIANGYIN HAOYE TEXTILE

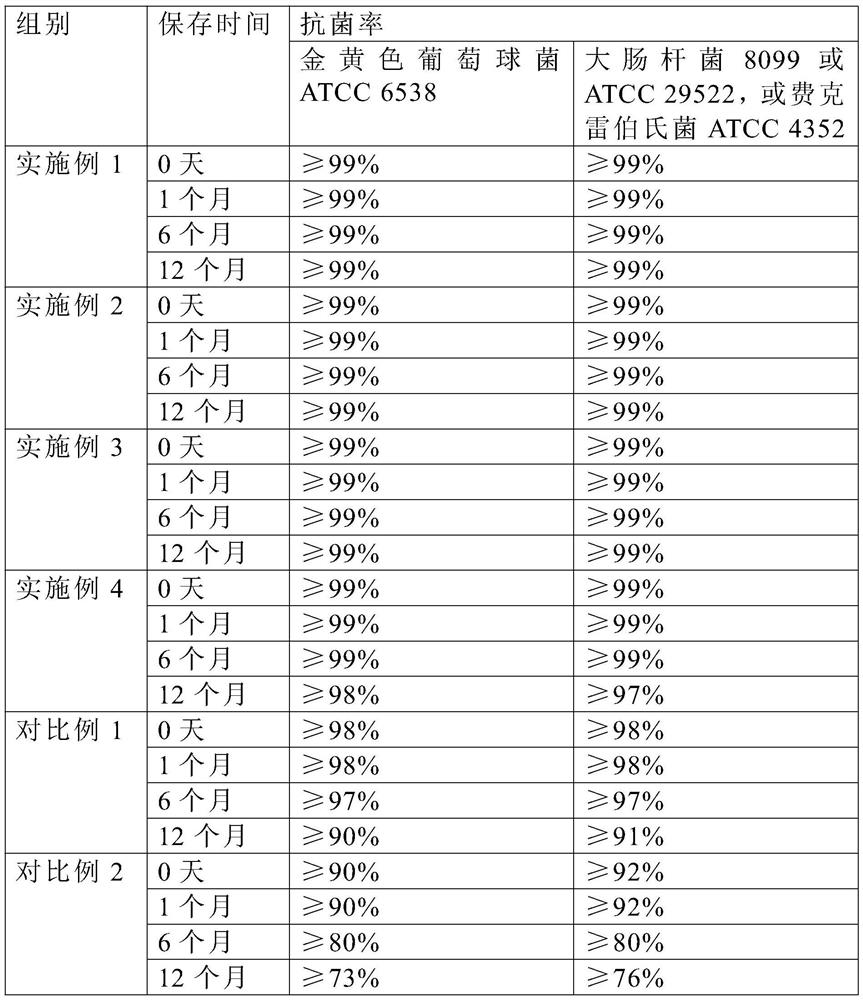

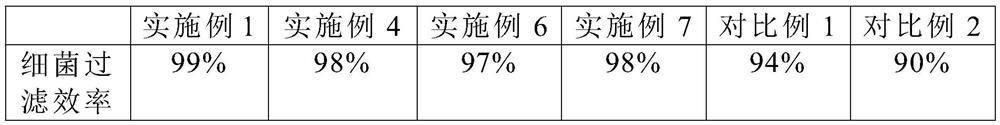

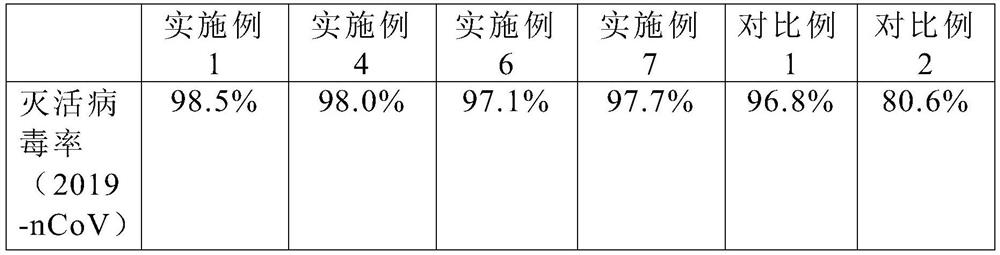

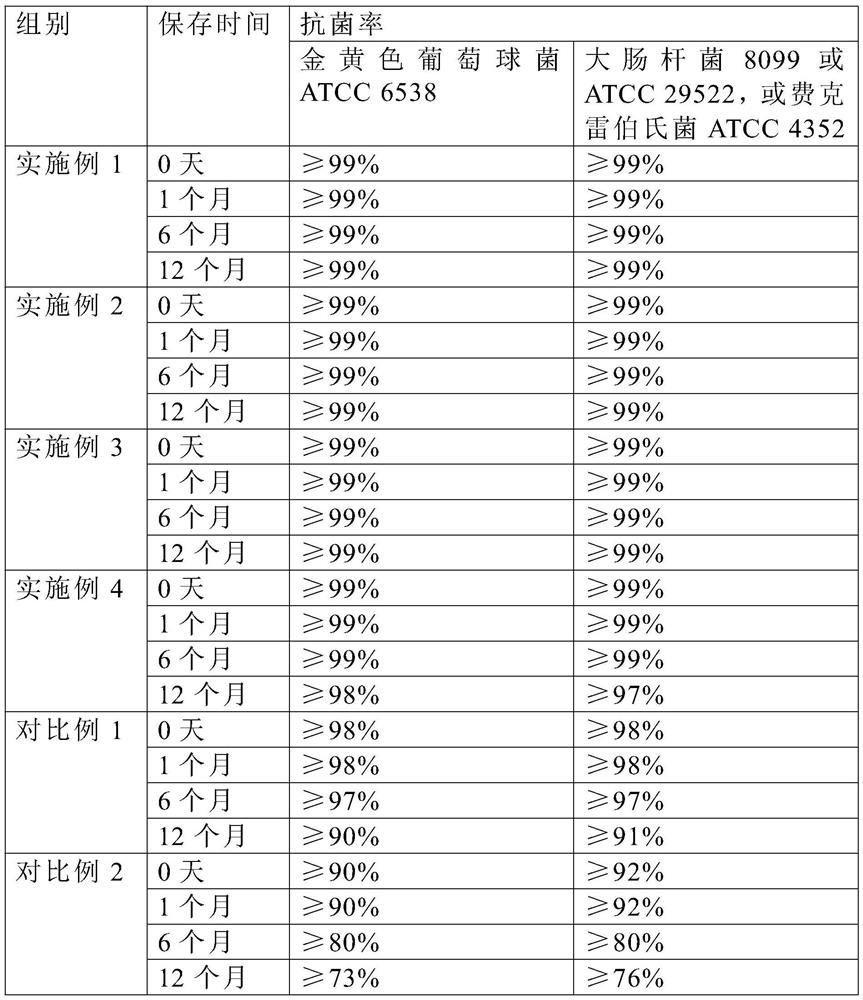

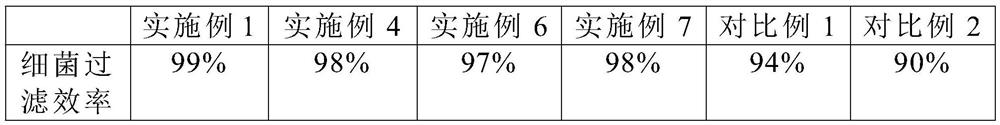

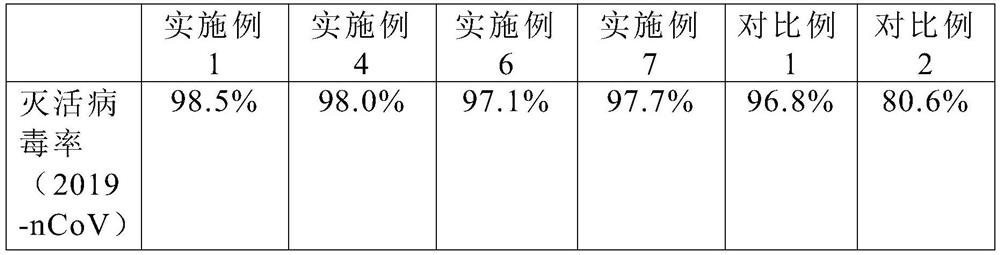

Manufacturing method and application of nano-copper antibacterial and antiviral melt-blown cloth master batch

ActiveCN113334611AImproved particle size and distributionWell combinedNanotechnologyPolypropylenePolyester

The invention belongs to the technical field of materials, and relates to a manufacturing method of nano-copper antibacterial and antiviral melt-blown cloth master batch. The method comprises the following steps of mixing and hybridizing graphene, nano-copper, microporous silicon dioxide and a nano-microcapsule wrapping material to obtain a nano-microcapsule-coated graphene composite material; and mixing and melting the nano-microcapsule-coated graphene composite material and a polypropylene material, and carrying out extrusion granulation to obtain the nano-copper antibacterial and antiviral melt-blown cloth master batch. The invention also relates to application of the nano-copper antibacterial and antiviral melt-blown cloth master batch obtained by the preparation method in melt-blown cloth with antibacterial and virus-inactivating properties. According to the method and application, the nano-copper is used as an antibacterial auxiliary agent to form the nano-microcapsule-coated graphene composite material, and the nano-microcapsule-coated graphene composite material and the polypropylene material form the melt-blown non-woven fabric master batch so that the nano-copper can be firmly embedded in a polyester fiber molecular structure to form a non-dissolution type antibacterial fiber, and then the fiber and the non-woven fabric obtain continuous antibacterial property.

Owner:SHANGYOU JINGHE NANO TECH CO LTD +3

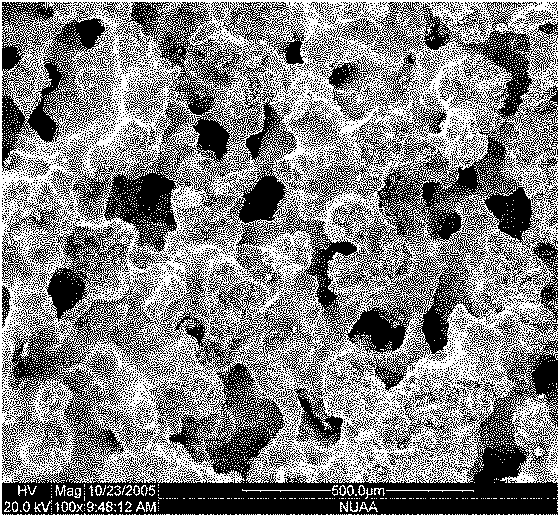

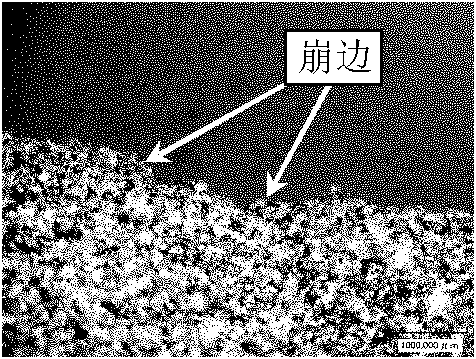

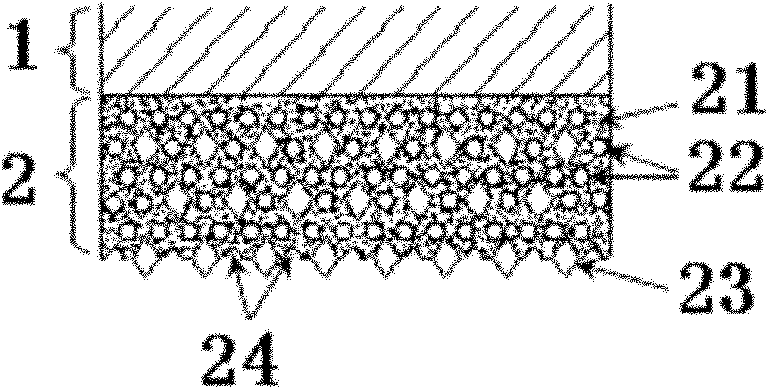

Ceramic hollow sphere composite binder cubic boron nitride grinding wheel working layer and manufacturing method thereof

ActiveCN102001053BIncreased porosityHigh porosityAbrasion apparatusGrinding devicesPorosityActive matrix

The invention discloses a ceramic hollow sphere composite binder cubic boron nitride grinding wheel working layer and belongs to the field of manufacture of superhard abrasive tools. A ceramic hollow sphere composite binder is prepared by the following steps of: uniformly mixing 5 to 15 percent of alumina ceramic hollow sphere granules as a pore-forming material and enhancement phase and 85 to 95percent of Cu-Sn-Ti active matrix alloy (10 percent of Ti, 60 percent of Cu and 30 percent of Sn) serving as a matrix material of a grinding wheel working layer, and performing solid phase sintering and furnace cooling to room temperature. The composite binder cubic boron nitride grinding wheel working layer is prepared from the following steps of: mechanically and uniformly mixing 15 to 25 weight percent of cubic boron nitride abrasive particles, 5 weight percent of graphite particles and 70 to 80 weight percent of composite binder layer, pressing into blanks, putting the blanks into a vacuum furnace and performing high-temperature liquid-phase sintering. The prepared composite binder cubic boron nitride grinding wheel working layer has the characteristics of high porosity and high strength.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

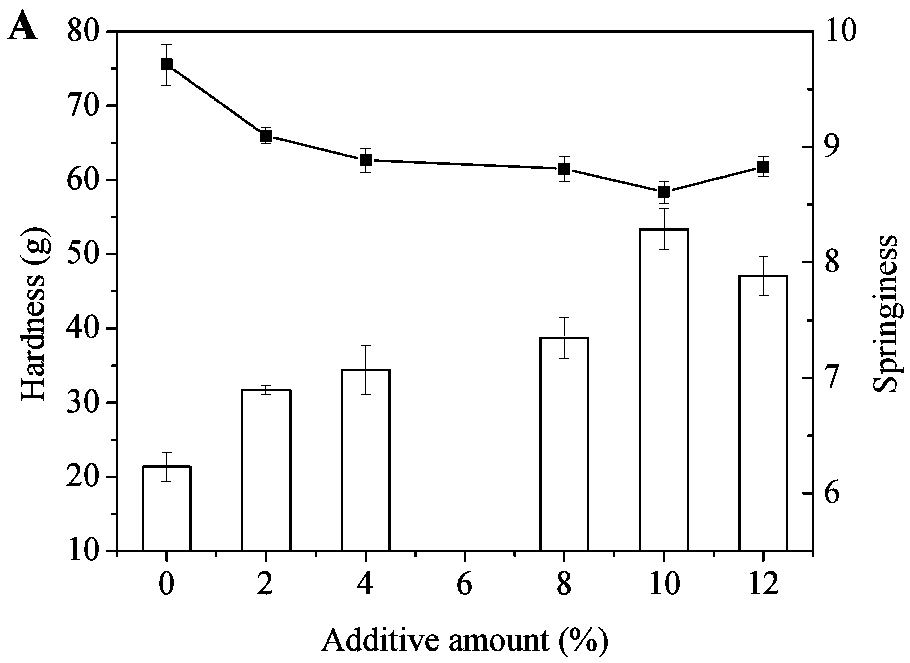

Preparation method of modified edible fungus composite mantou powder rich in amino acids

ActiveCN108783212AFast dryingGuaranteed sensory propertiesFood preservationFood ingredient as mouthfeel improving agentAmylaseSolubility

The present invention discloses a preparation method of a modified edible fungus composite mantou powder rich in amino acids. The method is characterized by comprising the following steps: cleaning edible fungi; conducting blanching for 2-3min; drying the edible fungi until a moisture content is 5% or below; conducting refining treatment; compounding edible fungus powder with wheat flour accordingto a certain proportion; and adding modifying agents such as wheat gluten, monostearin, fungal amylase and xylanase so as to obtain edible fungus composite mantou with good sensory properties. According to the invention, the vacuum microwave drying and superfine grinding of the edible fungi retains the nutrient components in the edible fungi to a great extent, and enables the edible fungus powderto have good fluidity, adsorbability, solubility and absorptivity; and secondly, the combination of the edible fungus powder and the wheat flour improves the protein and fiber content of the flour, and the edible fungus composite mantou powder with high amino acid score is obtained, and the addition of the modifying agents also enables the prepared edible fungus composite mantou to have good sensory properties.

Owner:GUANGXI UNIV

Seaweed polysaccharide anti-transpiration paste leaf fertilizer additive specially used for pear tree

InactiveCN106631536APromote differentiationPromote growthCalcareous fertilisersMagnesium fertilisersDipotassium hydrogen phosphateSodium Bentonite

The invention discloses a seaweed polysaccharide anti-transpiration paste leaf fertilizer additive specially used for a pear tree. The additive is prepared from the following raw materials in parts by weight: 0.8-1 part of surfactin, 6-7 parts of cytokinin, 31-34 parts of methanol, 1.2-1.3 parts of pesticide emulsifier 602, 0.3-0.31 part of anhydrous calcium chloride, 0.139-0.14 part of anhydrous magnesium chloride, a right amount of deionized water, 0.15-0.18 part of isopropanol, 3-4 parts of hydroxyethyl methyl cellulose, 3-4 parts of seaweed polysaccharide, 4-5 parts of biochemical fulvic acid, 1-2 parts of ammonium molybdate, 3-4 parts of bentonite, 0.8-1 part of sodium lauryl sulfate, 29-32 parts of urea, 15-17 parts of potassium humate, 9-11 parts of dipotassium hydrogen phosphate, a right amount of ammonium sulfate and 2-3 parts of white sugar. When the paste leaf fertilizer prepared from the additive disclosed by the invention is used for spraying pear leaves, the yield of the pear tree can be improved, and occurrence of plant diseases and insect pests can be reduced.

Owner:汤广顺

Paste-state pear tree leaf fertilizer additive capable of inhibiting heavy metal absorption by sulfydryl humin

InactiveCN106748214APromote differentiationPromote growthCalcareous fertilisersMagnesium fertilisersTrace elementPear tree

The invention discloses a paste-state pear tree leaf fertilizer additive capable of inhibiting heavy metal absorption by sulfydryl humin. The sulfhydrylation modification is performed on humin by a series of process steps, the number of sulfydryls is increased on the surface of the humin, the toxicity of multiple metals can be coupled and antagonized, a chelated humic acid synergist is added, the absorption of pear trees on heavy metals can be inhibited, and by addition of the produced product into a paste-state pear tree leaf fertilizer, rich nutrients are provided for pear trees, and activities of trace elements and major elements are enhanced, so that the immunity of the pear trees is enhanced, the yield is increased, and the application prospect is good.

Owner:汤广顺

Production method of instant colored rice

The invention relates to a production method of instant colored rice, belonging to the technical field of food processing. According to the method, the rehydration property and the storage performance of the instant colored rice based on the characteristics of high-frequency vibration and cavatition of ultrasonic waves, strong absorption effect of ethanol water vapor to lipids and water including bound water in rice and microwave heating consistence inside and outside can be improved. The production method comprises the main process steps of selecting red rice or black rice as raw materials, soaking for 30-40min at 45-55 DEG C, cooking for 30-40min, adding ethanol water solution for dispersion, filtering and continuously cooking for 20-30min, drying with ethanol water vapor in a 30-50Khz ultrasonic wave field until the water content is 8-10%, and then drying by microwaves with power of 100-200W until the water content is 3-4%. The produced instant colored rice has good mouthfeel, good rehydration property and excellent storage performance.

Owner:XUZHOU JINCHENG PLANET TRANSMISSION

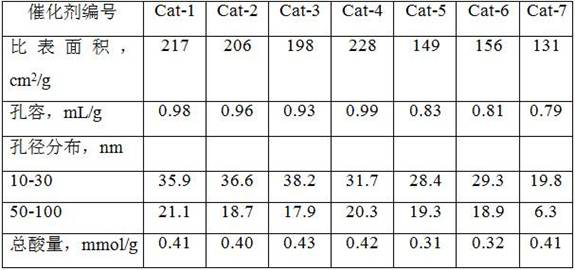

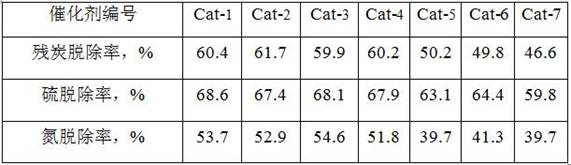

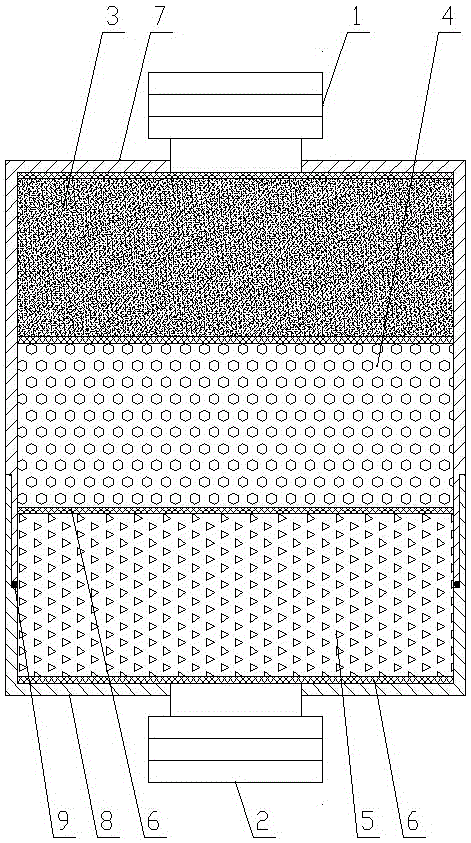

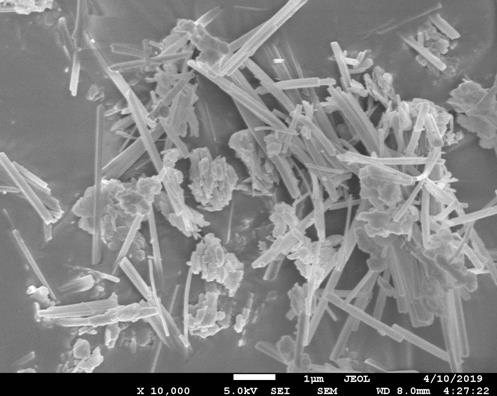

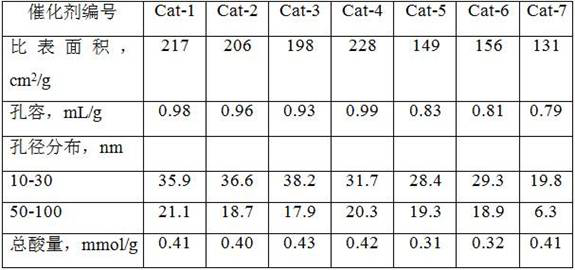

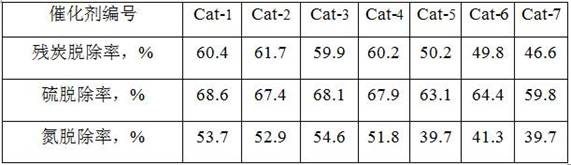

Preparation method of hydrogenation and residual carbon removal catalyst

ActiveCN111821986AIncreased porosityIncrease acidityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetakaolinChemistry

The invention discloses a preparation method of a hydrogenation and residual carbon removal catalyst. The method comprises the following steps: (1) mixing a pore-enlarging agent with pseudo-boehmite to obtain a mixture A; (2) mixing metakaolin, ammonium bicarbonate and water, carrying out sealed crystallization, and carrying out drying, roasting, dealumination treatment and drying on the crystallized material to obtain a material B; (3) carrying out ball-rolling molding on the mixture A to obtain a precursor I; and (4) mixing the material B with the precursor I, carrying out ball-rolling molding, drying, roasting, and loading an active component to obtain the hydrogenation and residual carbon removal catalyst. The catalyst prepared by the method has relatively high macroporous content andproper surface acidity, and has relatively high hydrogenation desulfurization and denitrification activity while having relatively high residual carbon removal activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Special paste-shaped leaf fertilizer additive with rare-earth modified chitosan for pear trees

InactiveCN106748215APromote differentiationPromote growthAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersRare earthPear tree

The invention discloses a special paste-shaped leaf fertilizer additive with rare-earth modified chitosan for pear trees. Formula reaction is carried out on functional groups of lanthanum nitrate, high-lanthanum rare-earth and flaky chitosan, then the rare-earth modified chitosan is prepared, the rare-earth modified chitosan is added when a product is prepared, the prepared product is added when a paste-shaped leaf fertilizer is prepared, the fertilizer is sprayed to the pear trees, then the concentration of sugar of the pear trees can be increased directly after the fertilizer is absorbed by leaves, growth of root systems of the pear trees can be promoted, and meanwhile as the additive is rich in multiple nutrient elements, absorption of nutrition by the leaves can be promoted, the stress resistance of the pear trees can be improved, the disease and insect resistance of the pear trees can be improved, and the yield of the pear trees can be increased.

Owner:汤广顺

Shower purification device with beautifying function and manufacturing method thereof

ActiveCN105152451ASimple structureLight structureMultistage water/sewage treatmentHazardous substanceProtection layer

A shower purification device with a beautifying function comprises a cylindrical shell. A water inlet pipe connector and a water outlet pipe connector are arranged at the two ends of the shell respectively. The shell is filled with a magnetism water purification layer, an adsorption water purification layer and a beautifying and healthcare warm bath layer in sequence from the water inlet pipe connector to the water outlet pipe connector. A supporting protection layer is arranged between the water inlet pipe connector and the magnetism water purification layer, a supporting protection layer is arranged between the magnetism water purification layer and the adsorption water purification layer, a supporting protection layer is arranged between the adsorption water purification layer and the beautifying and healthcare warm bath layer, a supporting protection layer is arranged between the beautifying and healthcare warm bath layer and the water outlet pipe connector, and the circumferential edges of the supporting protection layers are in sealing fit with the inner wall of the shell. The shower purification device is simple in structure, easy to manufacture, convenient to install, light, flexible and convenient to use, good in water purification effect, long in service life and low in cost, can effectively remove residual chlorine, bacteria and other hazardous substances in water and has the functions of flowing water, pure water and healthcare water.

Owner:郑州源致和环保科技有限公司

A kind of preparation method of hydrogenation carbon residue removal catalyst

ActiveCN111821986BIncreased porosityIncrease acidityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrodesulfurization

The invention discloses a preparation method of a hydrogenation carbon removal catalyst, which comprises the following contents: (1) mixing a pore-enlarging agent with pseudo-boehmite to obtain a mixture A; (2) mixing metakaolin, ammonium bicarbonate and Mix with water, seal and crystallize. After crystallization, the material is dried, roasted, dealuminated, and dried to obtain material B; (3) Mixture A is ball-shaped to obtain precursor I; (4) Material B and precursor I Mixing, ball forming, drying, calcining, and loading of active components to obtain a hydrogenation carbon removal catalyst. The catalyst prepared by the method has relatively high macropore content and suitable surface acidity, and the hydrogenation carbon removal catalyst has high carbon removal activity and high hydrogenation desulfurization and denitrogenation activities.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method and application of nano-copper antibacterial and antiviral meltblown masterbatch

ActiveCN113334611BImprove stabilityExtended storage timeTransportation and packagingMetal-working apparatusPolyesterFiber

The application belongs to the technical field of materials, and relates to a method for manufacturing nano-copper antibacterial and antiviral melt-blown cloth master batches, comprising the following steps: mixing graphene, nano-copper, microporous silica and nano-microcapsule wrapping materials to obtain Nano-microcapsule-coated graphene composite material; nano-microcapsule-coated graphene composite material and polypropylene material are mixed, melted, extruded and granulated to obtain nano-copper antibacterial and antiviral melt-blown cloth masterbatch. It also relates to the application of the nano-copper antibacterial and antiviral meltblown cloth masterbatch obtained by the above manufacturing method in a meltblown cloth with antibacterial and virus inactivation properties. Using nano-copper as an antibacterial additive to form nano-microcapsule-coated graphene composite material, and forming a melt-blown non-woven fabric masterbatch with polypropylene material, can make nano-copper firmly embedded in the molecular structure of polyester fiber to form a non-dissolving type Antibacterial fibers, so that fibers and nonwovens can obtain continuous antibacterial properties.

Owner:SHANGYOU JINGHE NANO TECH CO LTD +3

A kind of processing method of non-fried potato chips rich in selenium and zinc

ActiveCN104351695BEliminate astringencyRemove green smellFood ingredient functionsChipped potatoesVacuum pumping

The invention discloses a processing method of selenium and zinc enriched non-fried potato chips. The processing method comprises the following steps: (1) raw material treatment: treating potatoes in steam at 45-55 DEG C for 10-50 minutes, then stewing and blanching for 30-60 minutes in the steam at 80-90 DEG C, and cooling; (2) freezing and unfreezing: cutting the potatoes into slices with the thicknesses of 3-6mm, freezing at the temperature of less than -10 DEG C, and then unfreezing the potato slices in a selenium and zinc enriched solution; (3) selenium and zinc enrichment: performing vacuum pumping on unfrozen potato slices in vacuum equipment at the vacuum degree of 0.085-0.095MPa for 10-20 minutes; (4) pre-drying: performing low-temperature drying on selenium and zinc enriched potato slices until the terminal water content is 15-35%; (5) puffing treatment; (6) after-drying: drying puffed potato slices until the terminal water content is less than 5%; and (7) cooling and packaging. The selenium and zinc enriched non-fried potato chips prepared by using the processing method disclosed by the invention are less in nutritional component loss, good in color and crisp in taste, and are added with selenium and zinc elements so as to have significant health effects.

Owner:ANHUI SCI & TECH UNIV

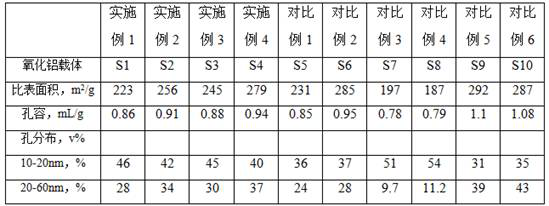

Preparation method of macroporous alumina carrier

ActiveCN114426300AWell mixedHigh pore contentCatalyst carriersAluminium compoundsAluminium oxidesMaterials science

The invention discloses a preparation method of a macroporous alumina carrier. The preparation method comprises the following steps: (1) uniformly mixing a proper amount of pseudo-boehmite powder A and a proper amount of pseudo-boehmite powder B; (2) adding a proper amount of ammonium chloride into the mixed material in the step (1), uniformly mixing, and roasting to obtain aluminum oxide powder C; (3) uniformly mixing a proper amount of pseudo-boehmite D with the aluminum oxide powder C obtained in the step (2), then adding a peptizing agent and an extrusion aid, uniformly mixing and kneading, and carrying out extrusion molding; and (4) drying and roasting the strip-shaped material in the step (3) to obtain the macroporous alumina carrier. The method is simple in process and easy for industrial production, and the prepared alumina carrier has high pore volume and high pore content of 10-20 nm and 20-60 nm.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-strength light ceramic filler

InactiveCN100443439CIncrease Al2O3 contentHigh compressive strengthSustainable biological treatmentCeramicwarePorosityHigh intensity

The high strength light ceramic filler is prepared with clay 60-78 wt%, black earth 8-15 wt%, calcium carbonate 8-15 wt%, talcum 3-10 wt% and rice bran powder for the rest. Chemically, it consists of silica 50-60 wt%, alumina 13-20 wt%, calcium oxide 3-8 wt% and magnesia 10-16 wt% except impurity. It has high compression strength, long service life, low impurity content, high whiteness and high porosity.

Owner:杨剑

A heat-insulating and sound-absorbing honeycomb core material and its preparation method

ActiveCN110734645BExcellent sound absorption and heat insulation performanceIncreased porosityImidePolymer science

The invention discloses a heat-insulating and sound-absorbing honeycomb core material and a preparation method thereof. The preparation method focuses on controlling the dosage and weight of aromatic acid anhydride derivative solution dissolved in a polar solvent, catalyst, surfactant, foaming agent and isocyanate Ratio; control the length, width and depth three-dimensional dimensions of the honeycomb core material to the ratio of the length, width and depth three-dimensional dimensions of the mold cavity; and control the quality of the foamed slurry to the inner cavity volume ratio of the closed system, so that the poly The density of imide foam is 12‑100kg / m 3 Between, the opening degree is 50%-60%, and the heat-insulating and sound-absorbing honeycomb core material is obtained. The heat-insulating and sound-absorbing honeycomb core material does not need to be filled with different functional particles, can achieve heat-insulating and sound-absorbing performance, and can be directly applied without post-processing.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com