Modified activated carbon composite material and preparation method thereof

A technology of composite materials and activated carbon, applied in separation methods, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve problems such as no antibacterial effect, achieve improved adsorption capacity, effective degradation, enhanced The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

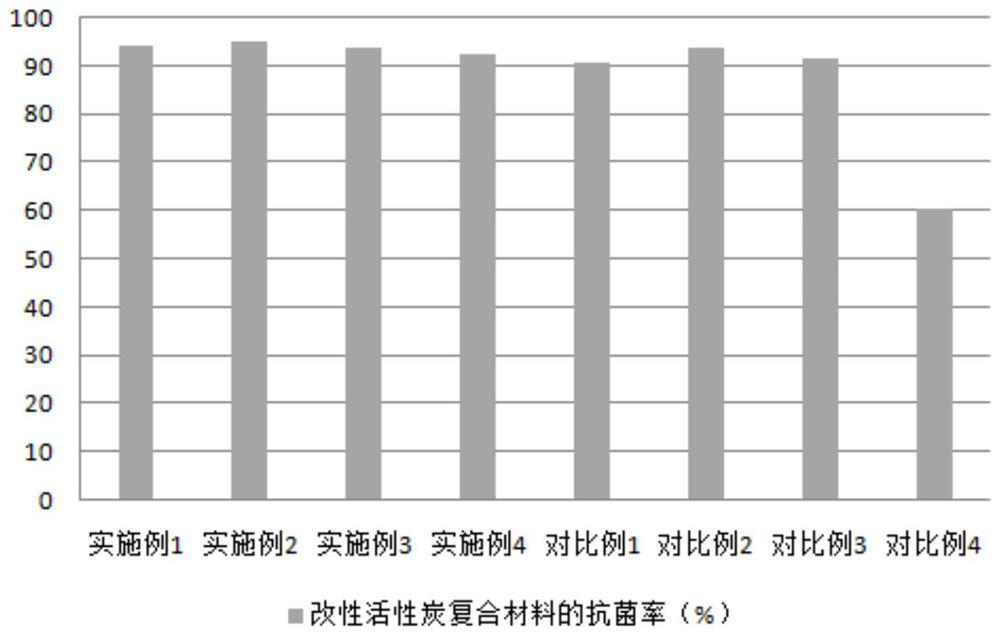

Examples

Embodiment 1

[0029] A preparation method of modified activated carbon composite material, comprising the following steps:

[0030] Step A, put the vermiculite in dilute sulfuric acid with a concentration of 10%, soak it for 14 hours, then put it in an oven and dry it for 20 minutes, then heat treat it at 560°C for 1 hour, crush and screen the particles with a particle size of 100 mesh to 200 mesh, and obtain pre-treated vermiculite;

[0031] Step B, mix coconut shell and sawdust at a weight ratio of 1:4, under the protection of nitrogen, first raise the temperature to 200°C at a rate of 1.0°C / min, keep the temperature for 20min, and then raise the temperature to 650°C at a rate of 3.5°C / min Cracking reaction for 2.5 hours, after crushing to 100 mesh to 200 mesh, biochar is obtained;

[0032] Step C, mixing the biochar obtained in step B with sodium hydroxide at a weight ratio of 1:1.5, treating at 680°C for 90 minutes under a nitrogen atmosphere, washing with water until neutral, and dryi...

Embodiment 2

[0037] A preparation method of modified activated carbon composite material, comprising the following steps:

[0038] Step A, put the vermiculite in dilute sulfuric acid with a concentration of 12%, soak it for 16 hours, then put it in an oven and dry it for 20 minutes, then heat treat it at 500°C for 1 hour, crush and screen the particles with a particle size of 100 mesh to 200 mesh, and obtain pre-treated vermiculite;

[0039] Step B, mix coconut shell and wood chips at a weight ratio of 1:3, under the protection of nitrogen, first raise the temperature to 200°C at a rate of 1.0°C / min, keep the temperature for 35min, and then raise the temperature to 600°C at a rate of 3.5°C / min Cracking reaction for 2.0 hours, after crushing to 100 mesh to 200 mesh, biochar is obtained;

[0040] Step C, mixing the biochar obtained in step B with sodium hydroxide at a weight ratio of 1:1.5, treating at 680°C for 70 minutes under a nitrogen atmosphere, washing with water until neutral, and d...

Embodiment 3

[0045] A preparation method of modified activated carbon composite material, comprising the following steps:

[0046]Step A, put the vermiculite in dilute sulfuric acid with a concentration of 14%, soak it for 12 hours, then put it in an oven and dry it for 20 minutes, then heat treat it at 580°C for 1 hour, crush and screen the particles with a particle size of 100 mesh to 200 mesh, and obtain pre-treated vermiculite;

[0047] Step B, mix coconut shell and wood chips at a weight ratio of 1:2.5, under the protection of nitrogen, first raise the temperature to 200°C at a rate of 1.0°C / min, keep the temperature for 30min, and then raise the temperature to 750°C at a rate of 3.5°C / min Cracking reaction for 3 hours, crushing to 100 mesh to 200 mesh, to obtain biochar;

[0048] Step C, mixing the biochar obtained in step B with sodium hydroxide at a weight ratio of 1:1.5, treating it at 680°C for 60 minutes under a nitrogen atmosphere, washing with water to neutrality, and drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Crystal size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com