Preparation method of macroporous alumina carrier

A technology of macroporous alumina and alumina powder, which is applied to catalyst carriers, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the complex process of styrene-butadiene rubber emulsion, high cost, and pore-enlarging effect. Not obvious and other problems, to achieve the effect of changing the grain size, improving the pore structure, and increasing the content of macropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

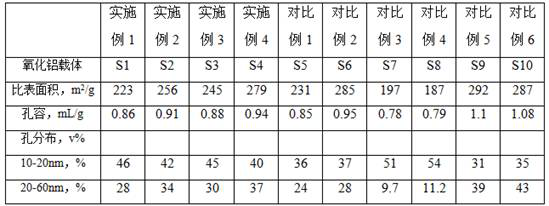

[0032] Weigh an appropriate amount of pseudo-boehmite A1 and pseudo-boehmite B, control the molar ratio of pseudo-boehmite A1 and pseudo-boehmite B to 1:1.5, mix the above materials evenly, and then add them to the mixture Add an appropriate amount of ammonium chloride, control the molar ratio of ammonium ions and aluminum elements to 1:12, mix the above materials evenly, and then place them in a high-temperature furnace and roast at 750°C for 6 hours to obtain alumina powder C1.

[0033] Weigh an appropriate amount of alumina powder C1 and pseudo-boehmite D, control the molar ratio of pseudo-boehmite D and alumina powder C1 to 1:5, then add an appropriate amount of kale powder to the above materials and mix evenly, Add an appropriate amount of nitric acid aqueous solution with a mass concentration of 1.5% to the mixture, knead it evenly, extrude it, dry the molded product at 120°C for 4 hours, and then bake it at 600°C for 4 hours to obtain alumina carrier S1. The properties o...

Embodiment 2

[0035] Same as Example 1, except that the molar ratio of pseudo-boehmite A1 to pseudo-boehmite B is 1:2.5, the molar ratio of ammonium ion to aluminum element is 1:8, and the powder roasting temperature is 700°C. The molar ratio of boehmite D to alumina powder is 1:5.5 to prepare alumina carrier S2. The properties of the carrier are shown in Table 1.

Embodiment 3

[0037] Same as Example 1, except that the molar ratio of pseudo-boehmite A1 to pseudo-boehmite B is 1:2, the molar ratio of ammonium ion to aluminum element is 1:16, and the powder roasting temperature is 800°C. The molar ratio of boehmite D to alumina powder is 1:4.5, and the alumina carrier S3 is prepared. The properties of the carrier are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com