Patents

Literature

325 results about "Macroporus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

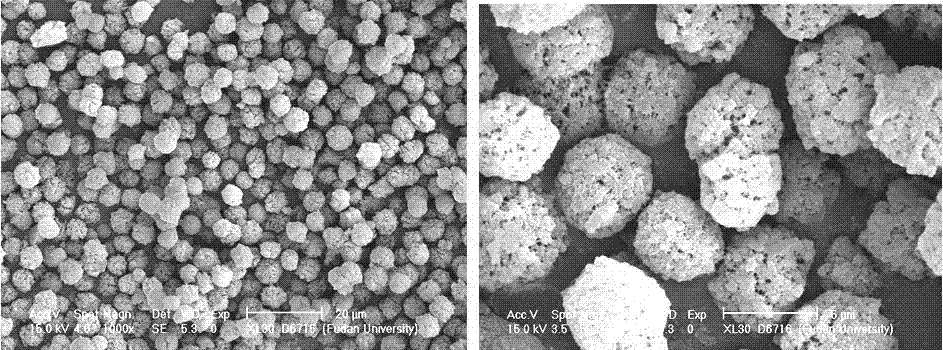

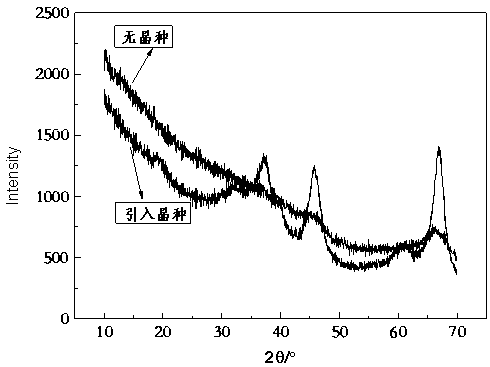

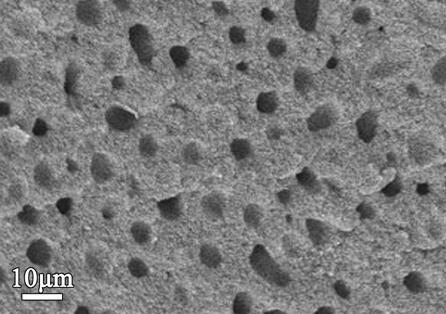

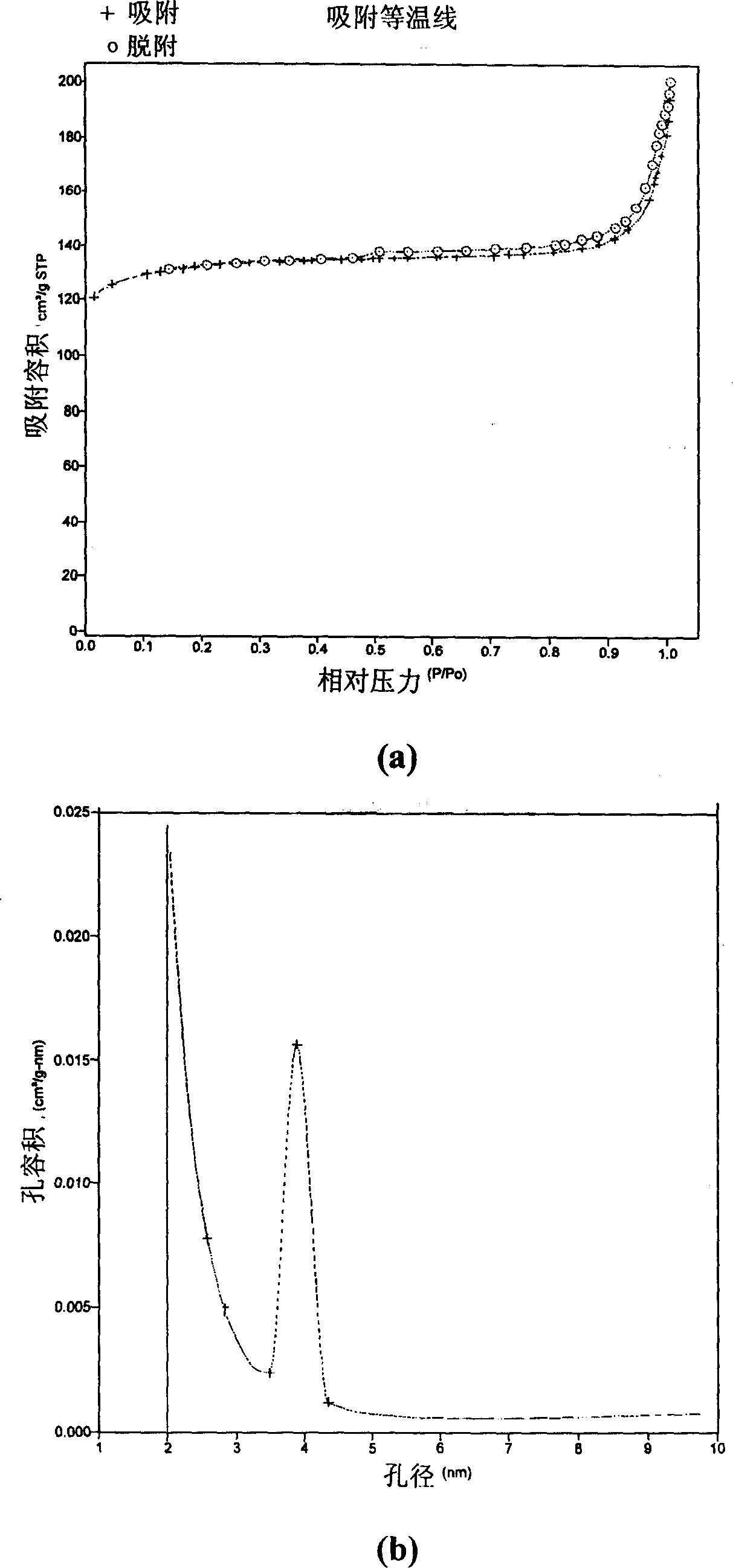

Nano mesoporous and mesoporous-macroporous composite biological glass and its preparing method

InactiveCN1554607AMild reaction conditionsEasy to operateProsthesisSurface-active agentsNanotechnology

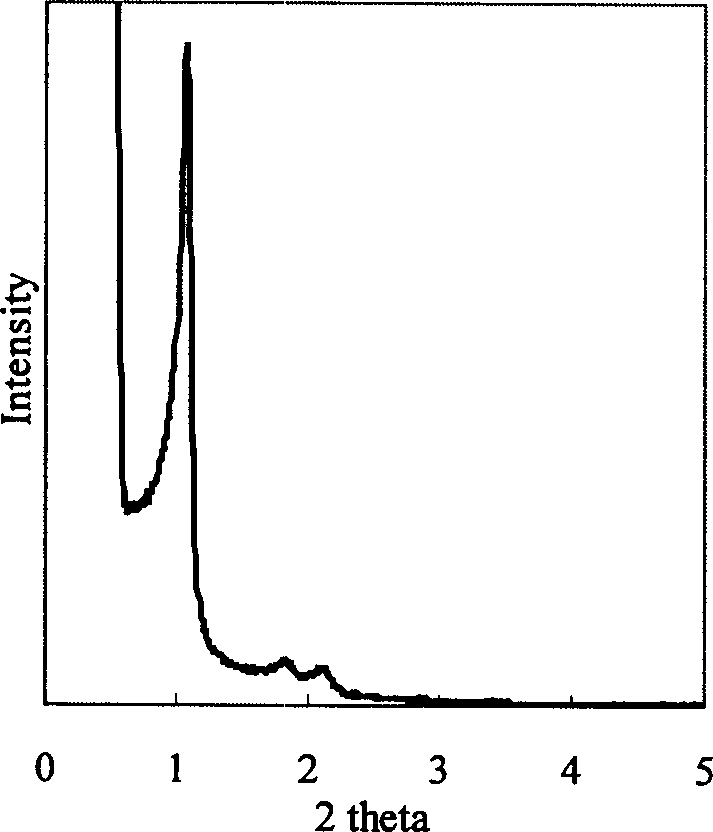

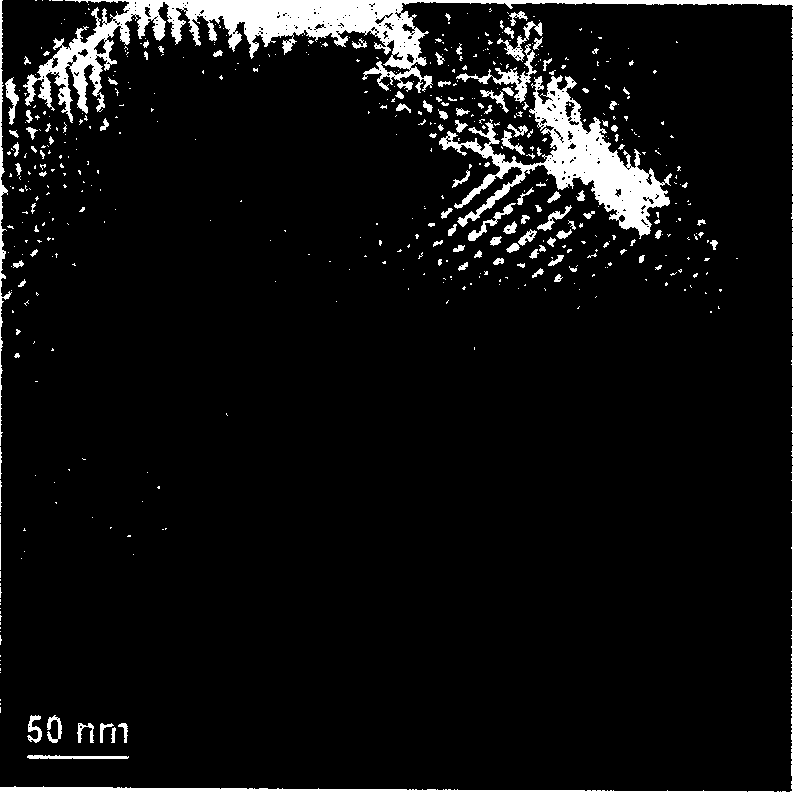

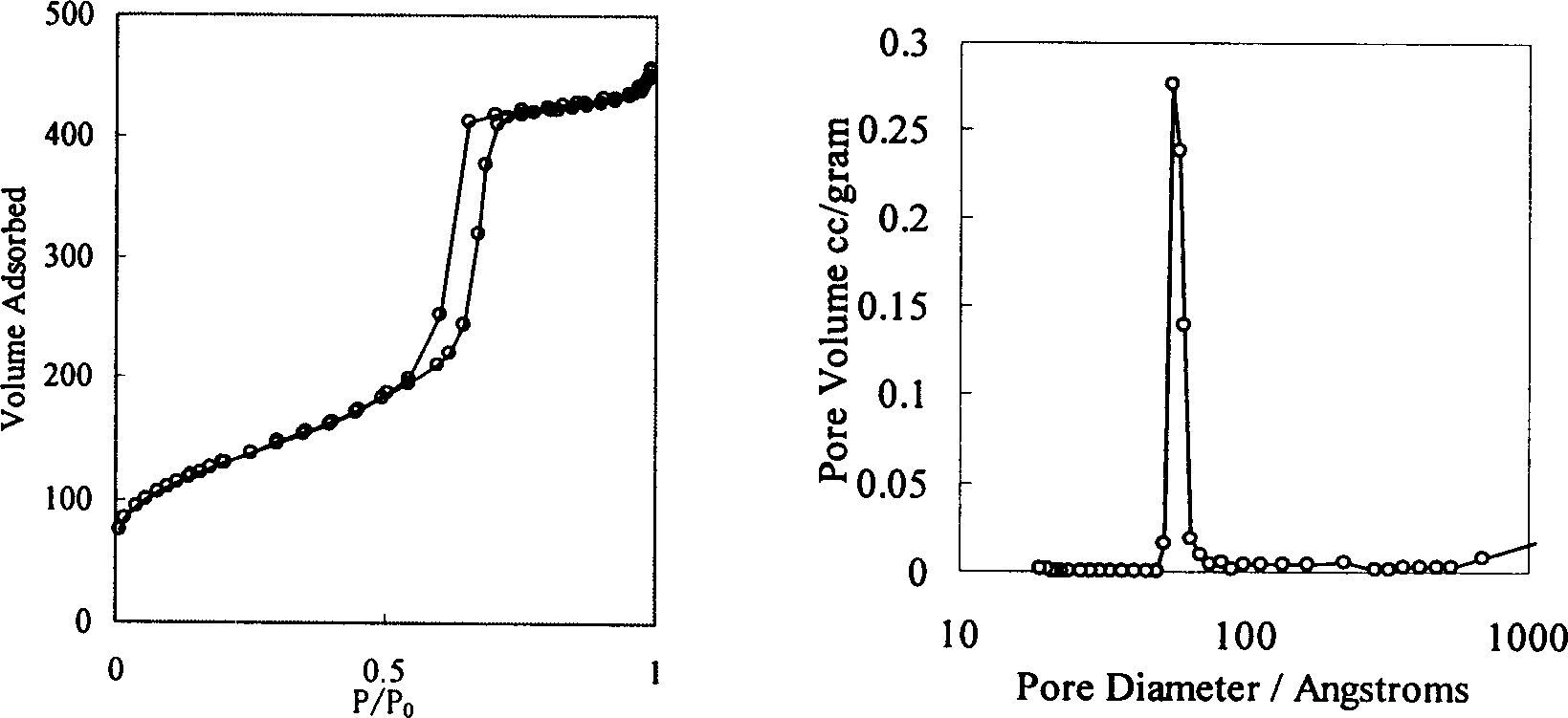

The present invention relates to nano mesoporous and mesoporous-macroporous biological glass produced and through surfactant self-assembling and sol-gel process under mild reaction condition and possessing excellent bioactivity. The new type of biological glass has controllable mesoporous structure, homogeneous and adjustable mesopore distribution, relatively great specific surface area and porosity, macropores with adjustable size and porosity, and controllable shape. The present invention may be used as bone repairing material, dental material and rack material in tissue engineering and for medicine embedding and controlling releasing, etc.

Owner:FUDAN UNIV

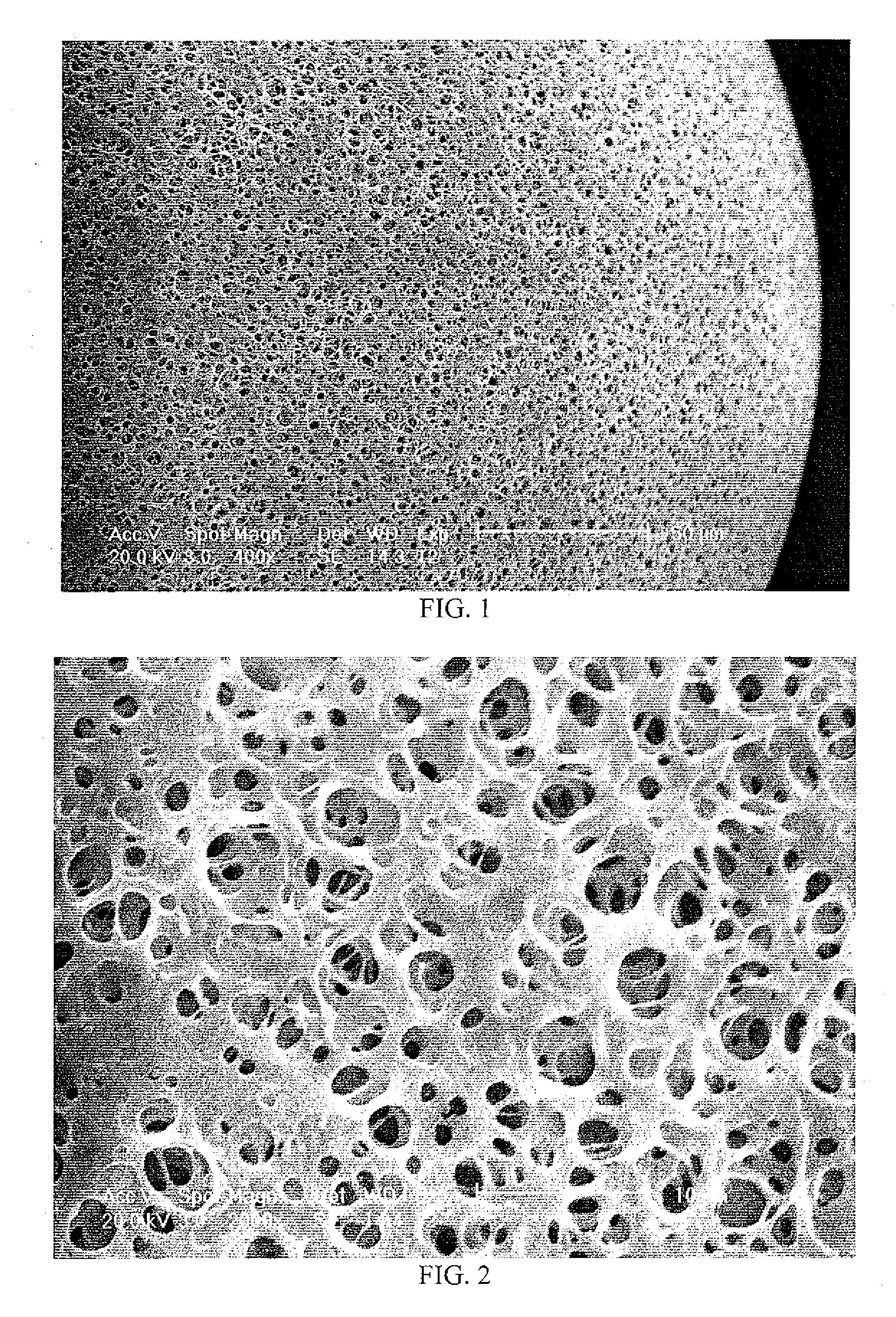

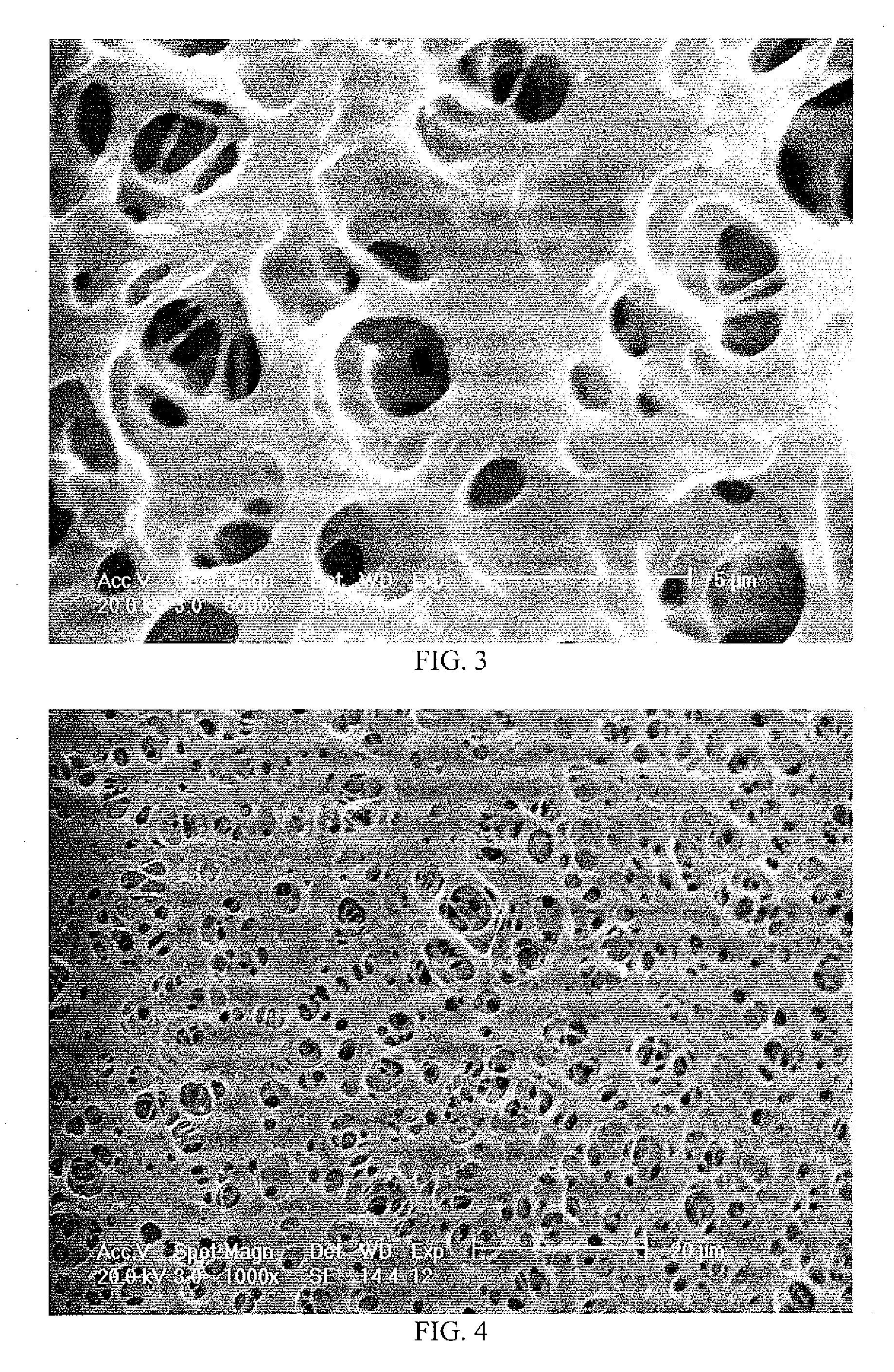

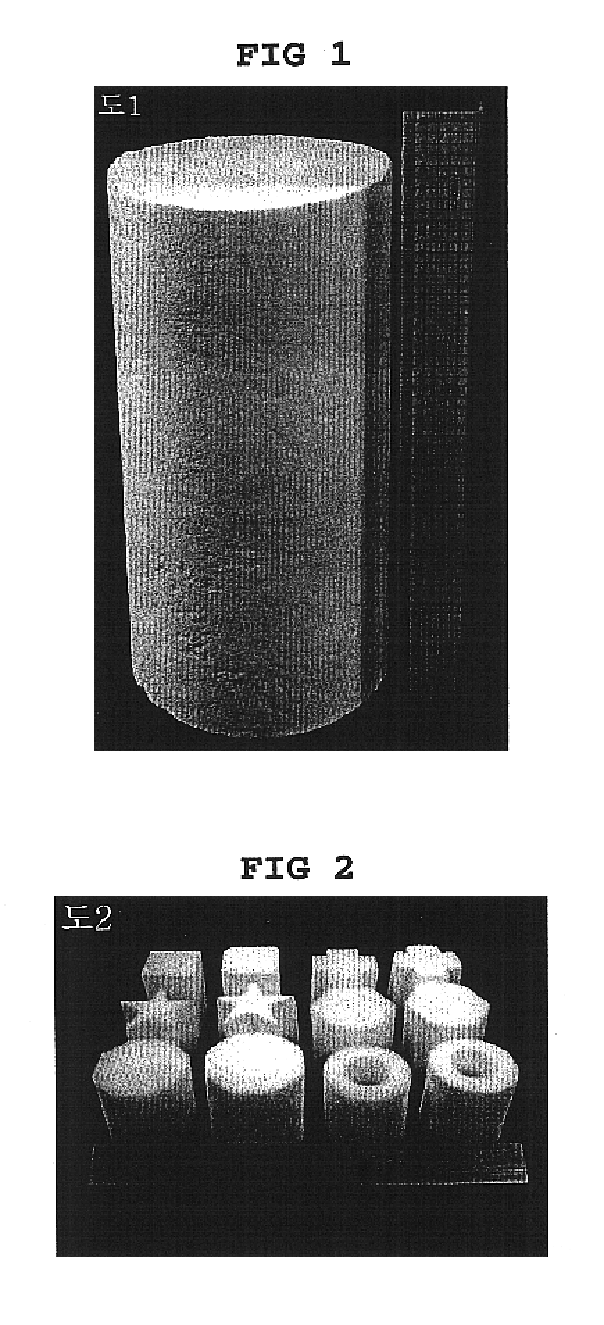

Macroporous 3-D scaffolds for tissue engineering

ActiveUS20140017284A1Density of cell does notHigh mechanical strengthBiocidePharmaceutical delivery mechanismChemistryMacropore

Macroporous 3-D tissue engineering scaffold comprising elastomeric cross-linked polymer units and interconnected macropores containing living cells are produced by step of: in a mixture of the cells and elastomeric polymer units comprising activatable crosslinking groups, activating the crosslinking groups to form the scaffold.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

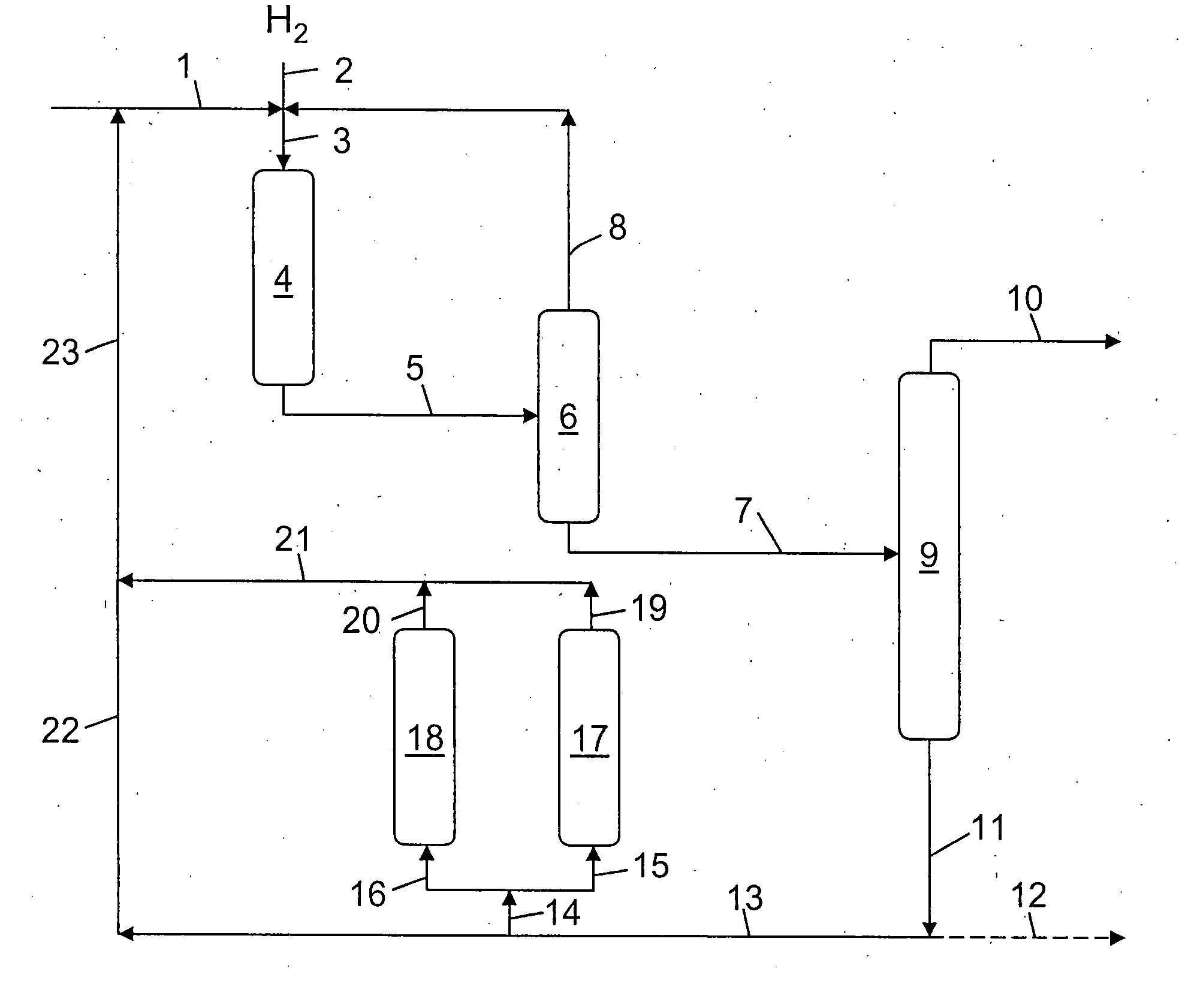

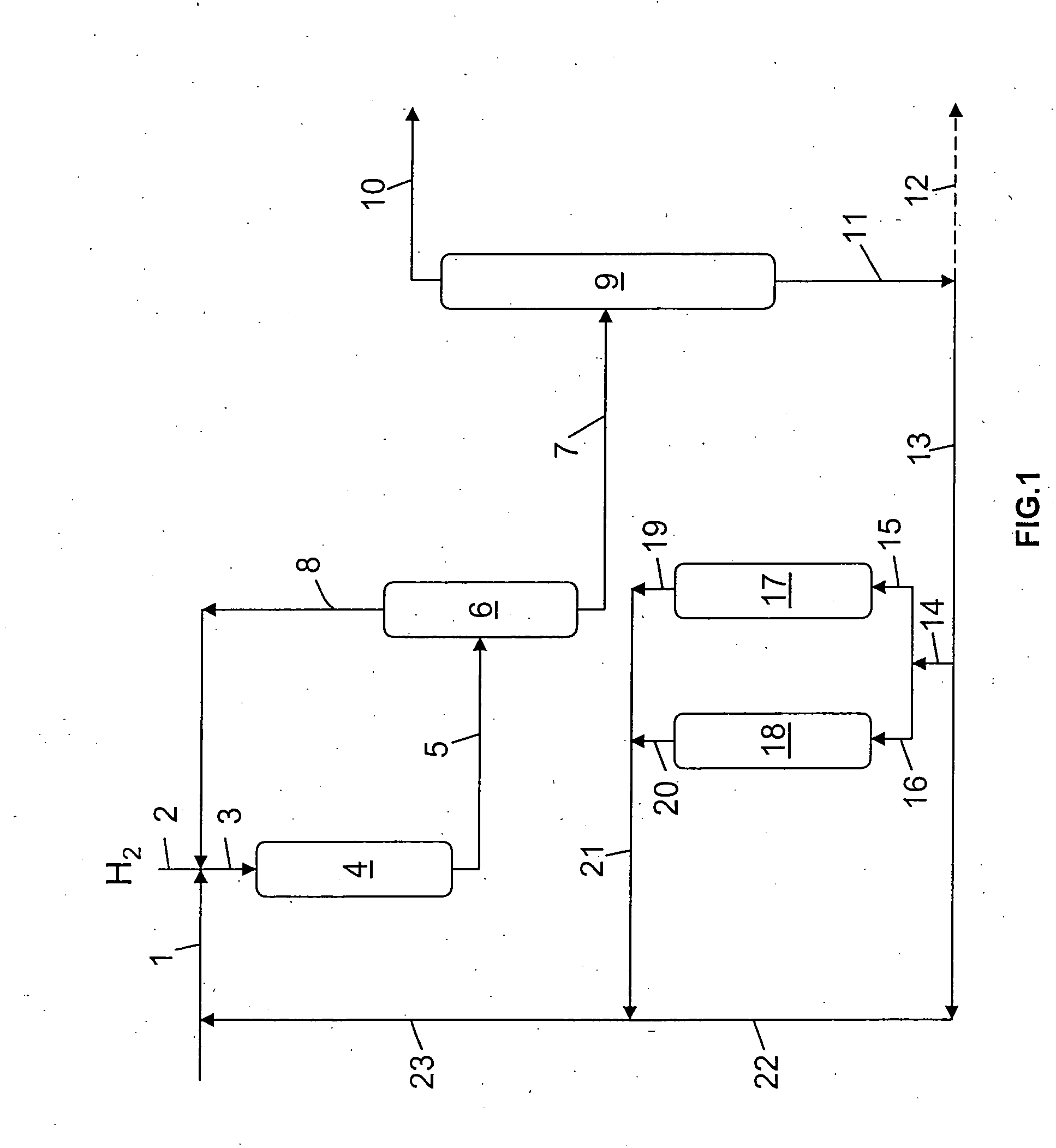

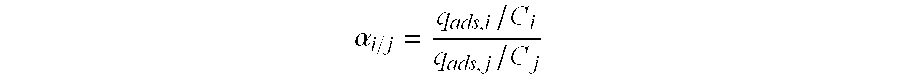

Hydrocracking process with recycle, comprising adsorption of polyaromatic compounds from the recycled fraction on an adsorbant based on silica-alumina with a controlled macropore content

InactiveUS20060213809A1Small sizeEliminate PNAsCatalytic crackingHydrocarbon oil crackingSorbentSilicon dioxide

Owner:INST FR DU PETROLE

Preparation method of macroporous-mesoporous alumina

InactiveCN101863499ASimple processLow cost of preparationAluminium oxides/hydroxidesPetrochemicalAluminum Ion

The invention provides a preparation method of macroporous-mesoporous alumina, which comprises the following steps: a, dissolving reaction assistants and aluminum salts into solution of an organic solvent, wherein the molar ratio of the reaction assistants and aluminum ions is (3-5): 1, dissolving a template agent into the solution, wherein the molar ratio of the aluminum ions and the template agent is 1: (0.015-0.025), and finally controlling the PH value of the solution to be 3.5-6.0; b, aging the solution prepared in Step a to gradually remove the organic solvent and water in the system, thereby obtaining a macroporous-mesoporous alumina precursor; c, calcinating at the temperature of 400-800 DEG C, thereby obtaining macroporous-mesoporous alumina powder. The invention has the advantages of simple process, regular pore canals and centralized pore size distribution, and can realize controlled regulation according to specific application conditions. Therefore, the invention has significant value of application in heterogeneous catalysis and adsorptive separation in the petrochemical industry and the use as the catalyst carrier, energy material and the like.

Owner:CENT SOUTH UNIV

Macroporous copolymers with large pores

ActiveUS20080237133A1Large and extraordinary poreHigh strengthCation exchanger materialsIon-exchanger regenerationPolymer networkMacroporous resin

The present invention provides a macroporous copolymer having large pores, typically in the range of 5,000-200,000 Å and a typical breaking weight of at least 175 g / bead. The macroporous copolymers can be made using an interpenetrating polymer network (IPN) techniques. These macroporous copolymers may also form macroporous resins. The present invention also provides methods of using the macroporous copolymers and resins.

Owner:PUROLITE CORP

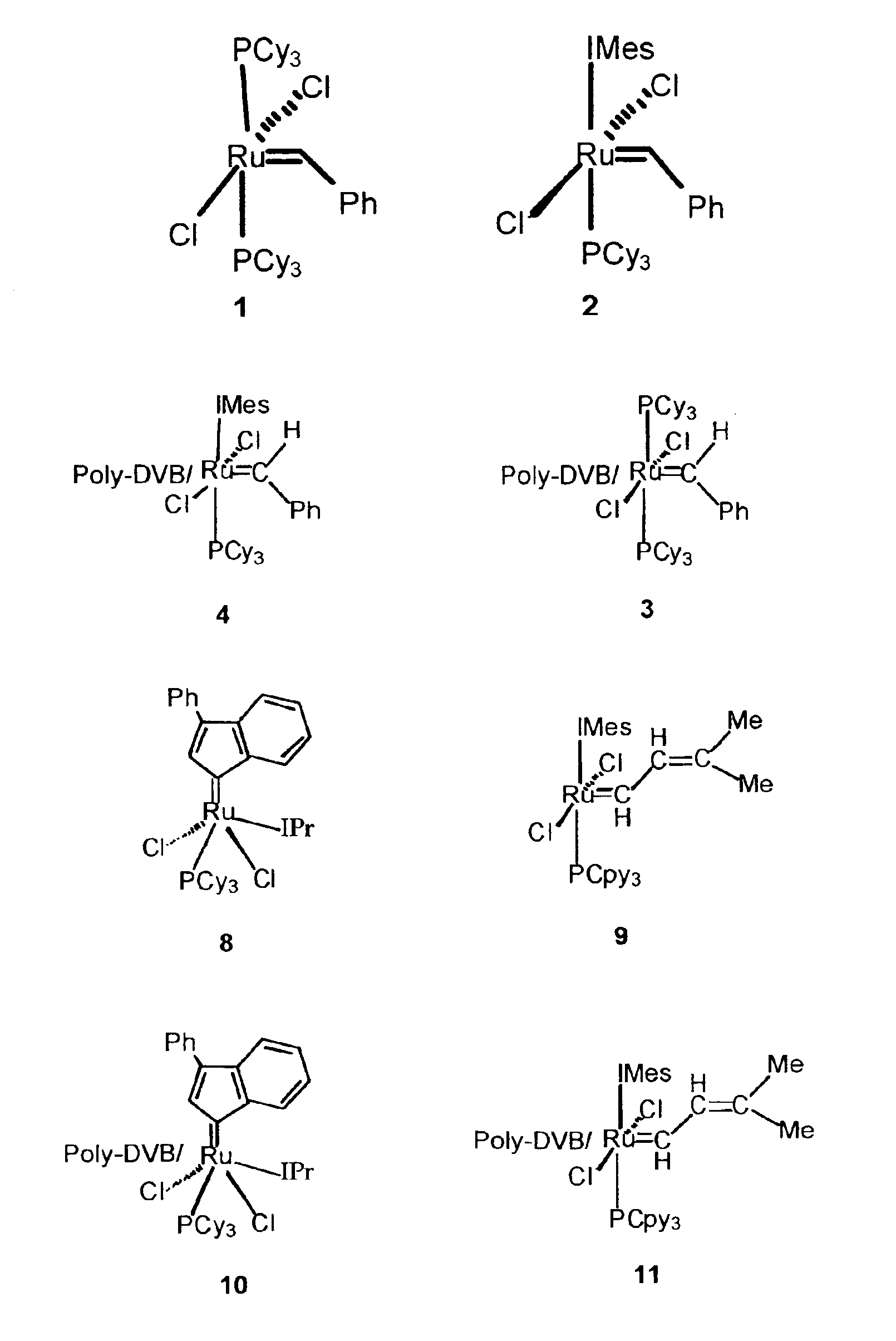

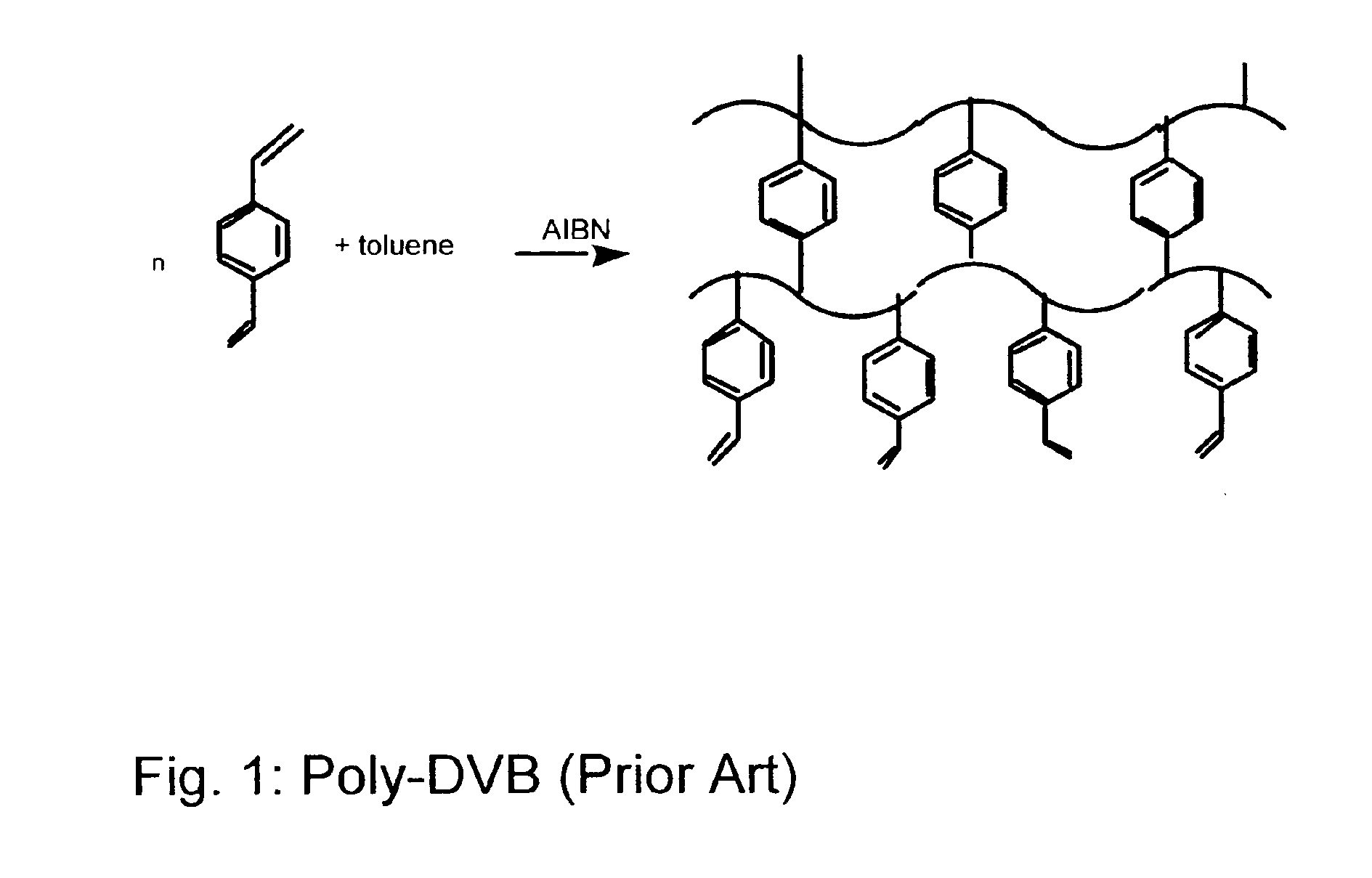

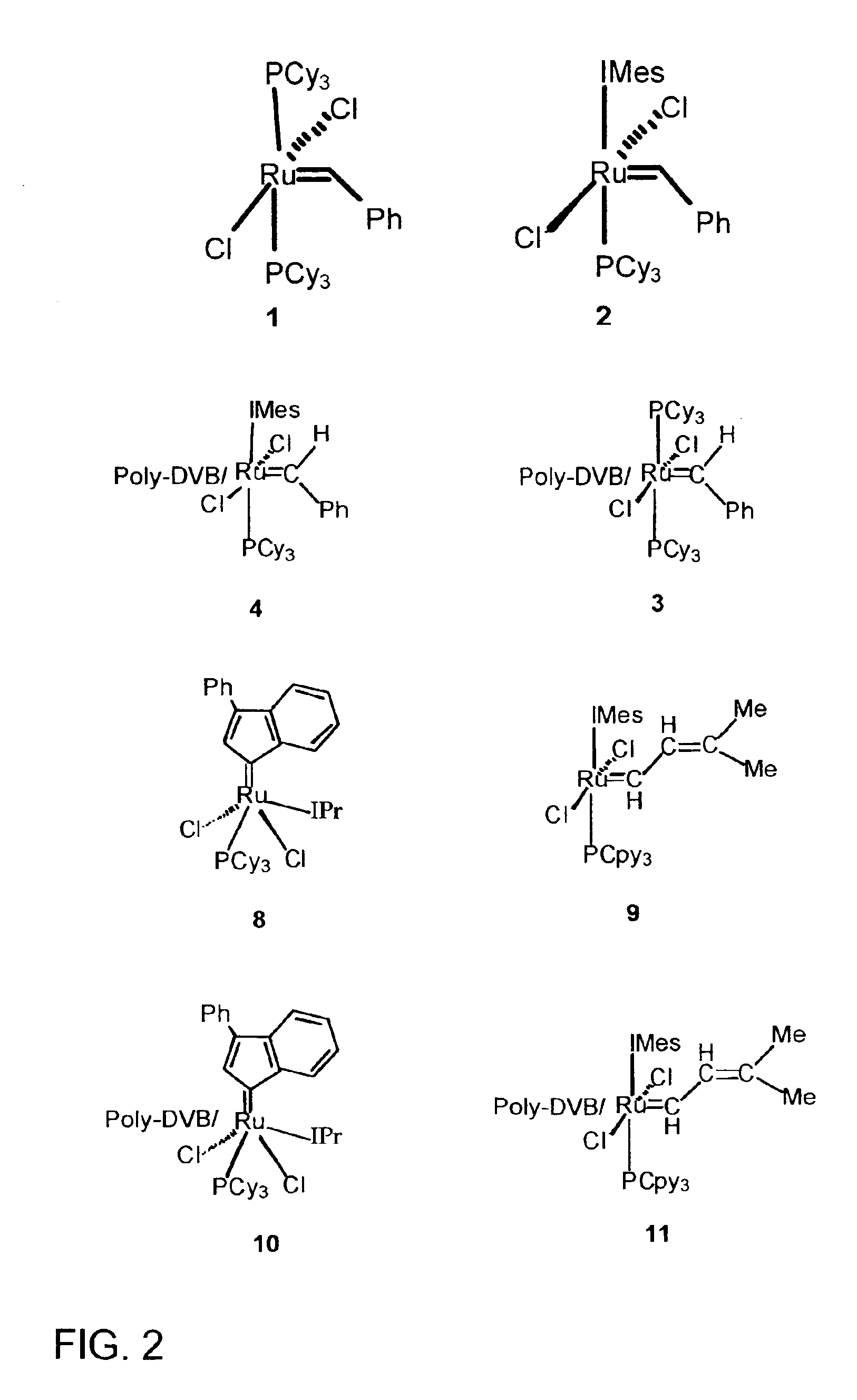

Simply assembled and recyclable polymer-supported olefin metathesis catalysts

InactiveUS6921736B1Ruthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsAlkeneHomogeneous catalysis

Owner:UNIV OF NEW ORLEANS RES TECH FOUND

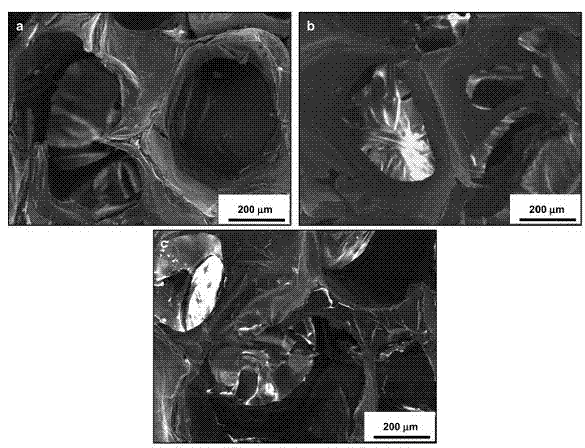

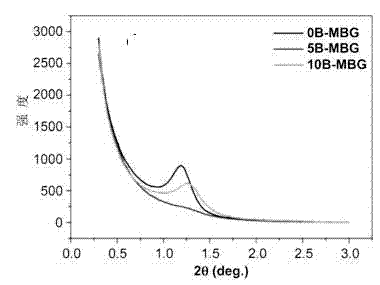

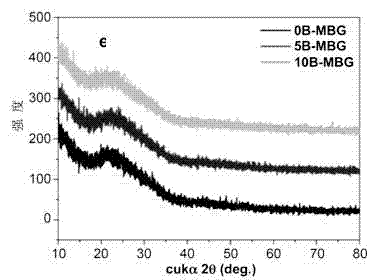

Boron-containing nano-mesoporous and macroporous bioactive glass, and preparation method and application thereof

The invention discloses a boron-containing nano-mesoporous and macroporous bioactive glass, a preparation method thereof and the application thereof to medical supports. The boron-containing mesoporous bioactive glass is prepared by substituting BO33- for part of SiO44- by a sol-gel method. According to the method, controllable porosity (78 to 90 percent) is obtained by adjusting immersion times (2 to 5 times) and aperture (300 to 500 microns). The composite glass material has pores suitable for cell growth; tissue growth and nutrition transmission are facilitated due to the porosity characteristic; and the structural integrity of the supports can be maintained in vitro. When the boron content is 0 to 10 percent, the boron-containing ordered mesoporous bioactive glass support has large surface area of 365 to 194 m<2> / g and is suitable for serving as vectors of medicines and growth factors. The biological material can slowly release boron ions, can serve as a tissue repair material applied to bone and periodontium engineering, and can serve as vectors of medicines or genes.

Owner:WUHAN UNIV

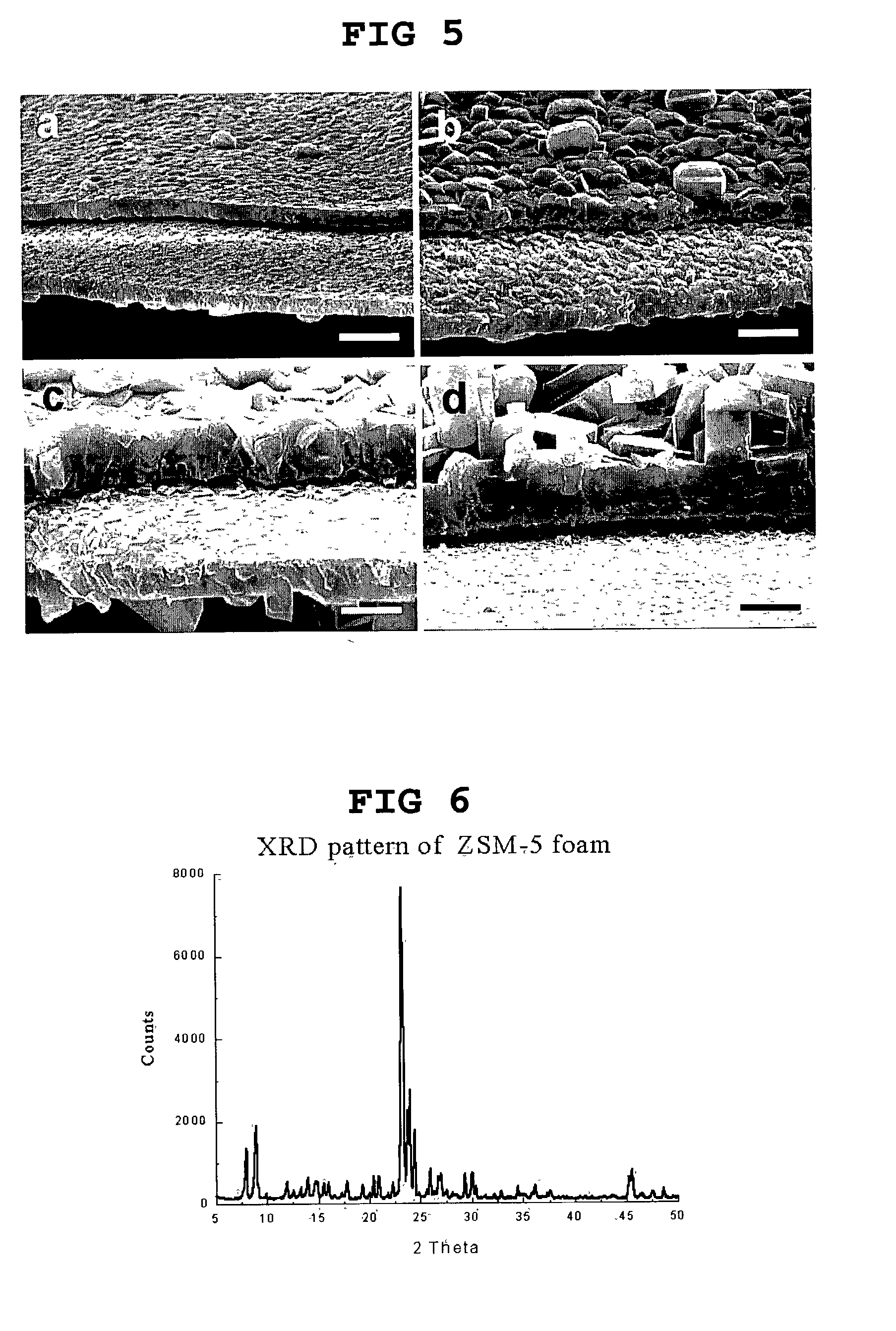

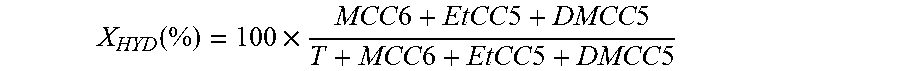

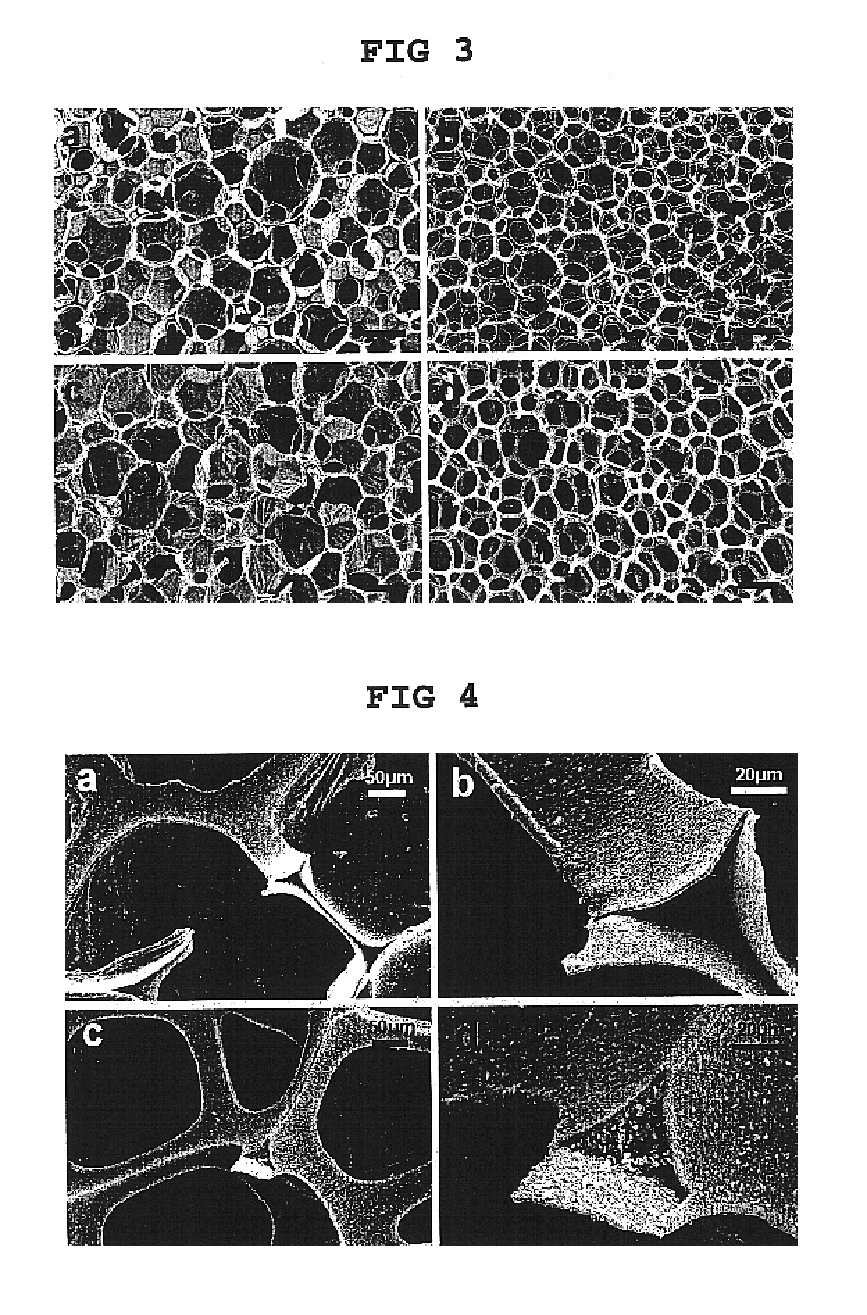

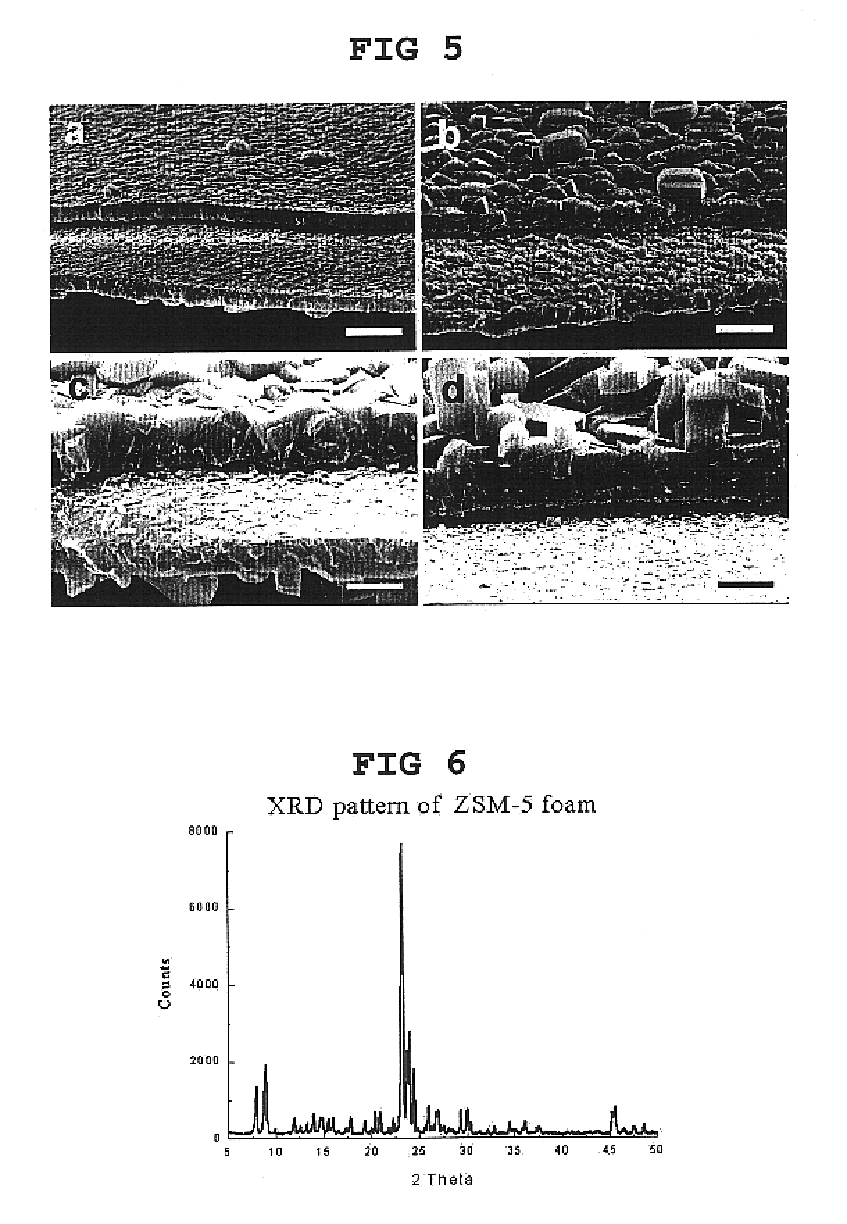

Macroporous foams comprising microporous zeolite or zeotype material and preparation thereof by using polymeric templates having sponge structure

The present invention provides a macroporous foam comprising microporous zeolite or zeotype material and preparation thereof, which comprises dipping a polymeric template capable of releasing an amine which has a sponge or macroporous structure and can be selected from a group consisting of polyurethane, polyamides, aromatic or aliphatic polyimides, polyamideimides, epoxy resins having an amine skeleton, and polymeric materials capable of releasing an organic amine by hydrolysis, in an alkaline or acidic solution, gel or sol of a precursor of said zeolite or zeotype material, and reacting the resultant at a suitable temperature for a period such that all or almost all of the polymeric template can be replaced with zeolite or zeotype material. Said foam comprising zeolite or zeotype material has the outer shape and size and the inner sponge or macroporous structure which are the same or similar to those of the polymeric template used.

Owner:IND UNIV COOP FOUND SOGANG UNIV

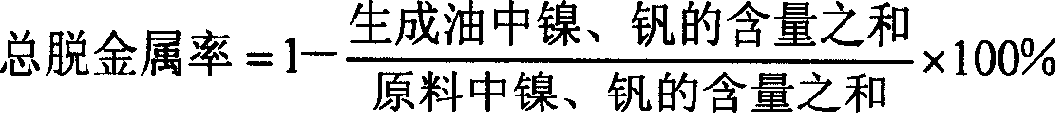

Mesoporous and macroporous catalyst with a co-mixed active phase, the preparation process thereof and the use thereof in hydrotreating of residues

InactiveUS20170137725A1Catalyst activation/preparationAluminium hydroxide preparationPtru catalystOxide matrix

Mesoporous and macroporous hydroconversion catalyst:a predominantly calcined alumina oxide matrix;a hydrogenating-dehydrogenating active phase with at least one VIB metal, optionally at least one VIII metal, optionally phosphorus,said active phase being at least partly co-mixed in said predominantly calcined alumina oxide matrix.Preparation process for a residue hydroconversion / hydrotreating catalyst by co-mixing of the active phase with a particular alumina.Use of the catalyst in hydrotreating processes, in particular hydrotreating of heavy feedstocks.

Owner:INST FR DU PETROLE

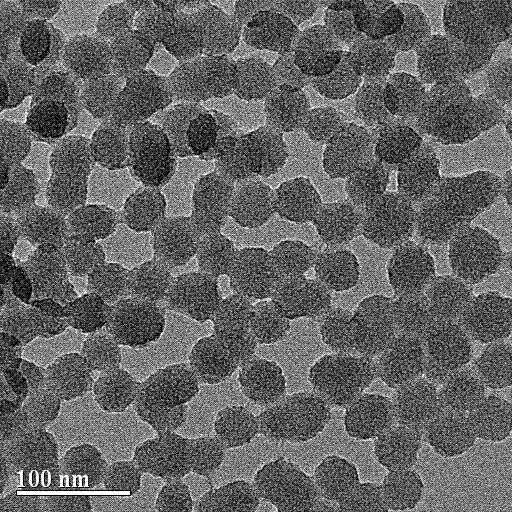

Magnetic macroporous adsorption resin microspheres, and preparation method thereof

InactiveCN103739764AImprove product qualityLow costPharmaceutical non-active ingredientsResin microspherePolyvinyl alcohol

The invention relates to magnetic macroporous adsorption resin microspheres, and a preparation method thereof. The magnetic macroporous adsorption resin microspheres comprise oil phase and water phase; the oil phase comprises following raw materials, by weight, 50 to 70 parts of 55% divinyl benzene, 5 to 10 parts of styrene, 3 to 5 parts of methyl acrylate, 30 to 50 parts of gasoline No.200, 20 to 40 parts of methylbenzene, 1 to 2 parts of dibenzoyl peroxide, and 10 to 20 parts of nano Fe3O4 particle; and the water phase comprises following raw materials, by weight, 600 to 800 parts of deionized water, 5 to 10 parts of sodium chloride, 6 to 8 parts of polyvinyl alcohol, and 2 to 6 parts of gelatin. The magnetic macroporous adsorption resin microspheres are capable of solving a problem of magnetic macroporous adsorption ion exchange resin prepared via existing technology that the magnetic macroporous adsorption ion exchange resin is not microspherical in shape, and is not suitable for applications in the field of medicine. Application range of the magnetic macroporous adsorption resin microspheres is wider, product quality is higher, and cost is relatively low.

Owner:何小刚

Preparation method of macroporous adsorbent resin for toxin substance adsorption

ActiveCN105085829ALarge specific surface areaRich pore structureOther chemical processesPolymer scienceParaquat

The invention provides a preparation method of a macroporous adsorbent resin for toxin substance adsorption, which comprises the following steps: preparing a lower-crosslinking-degree macroporous styrene-divinylbenzene resin, crosslinking the lower-crosslinking-degree macroporous styrene-divinylbenzene resin by a Friedel-Crafts process to obtain an ultrahigh-crosslinked-structure macroporous adsorbent resin, and introducing acylation reaction and grafting reaction in the ultrahigh-crosslinked-structure macroporous adsorbent resin preparation process to successfully prepare the carboxylic-acid-group-containing polyvinylpyrrolidone-grafted ultrahigh-crosslinking-degree macroporous adsorbent resin for toxin substance adsorption. The resin has the advantages of huge specific area and abundant pore structure, contains part of carboxylic acid ion groups, and is grafted by the polyvinylpyrrolidone on the resin surface. Therefore, the adsorption capacity for paraquat, acetochlor and other toxin substances containing cations or basic groups can be enhanced by utilizing the potential energy effect caused by hydrophobicity and huge specific area of the particular polystyrene skeleton of the ultrahigh-crosslinking-degree adsorbent resin, the pore screening action of the abundant pore structure and the charge action of the carboxylic acid groups. Besides, the polyvinylpyrrolidone is grafted on the resin surface to enhance the compatibility of the resin with blood.

Owner:TIANJIN STANDARD BIOLOGICS CO LTD +1

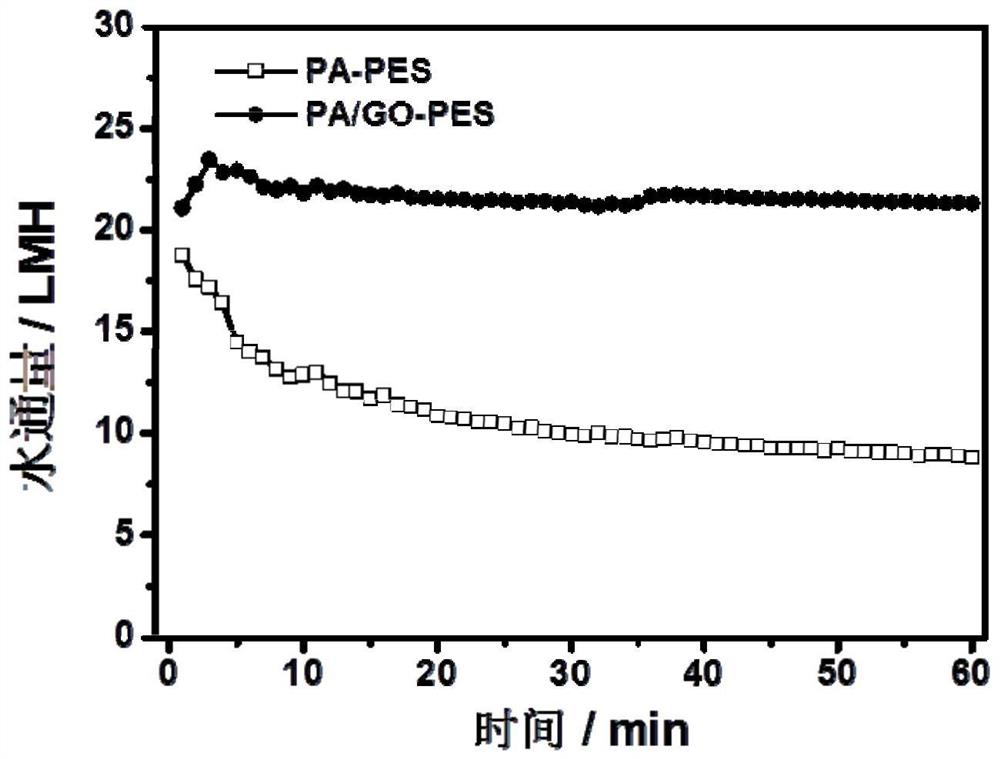

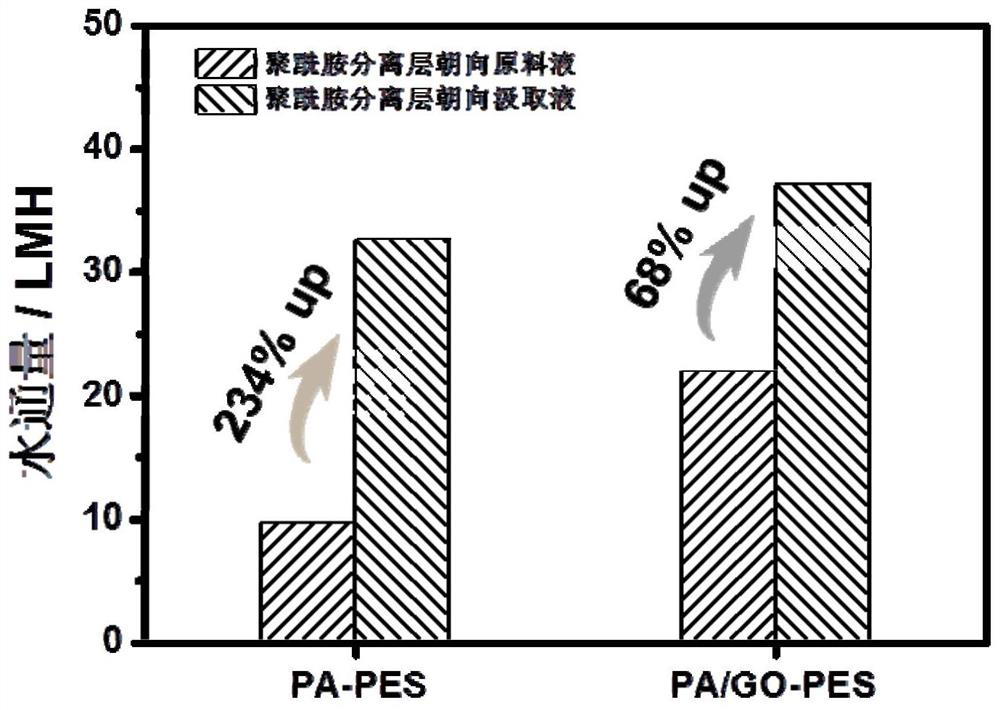

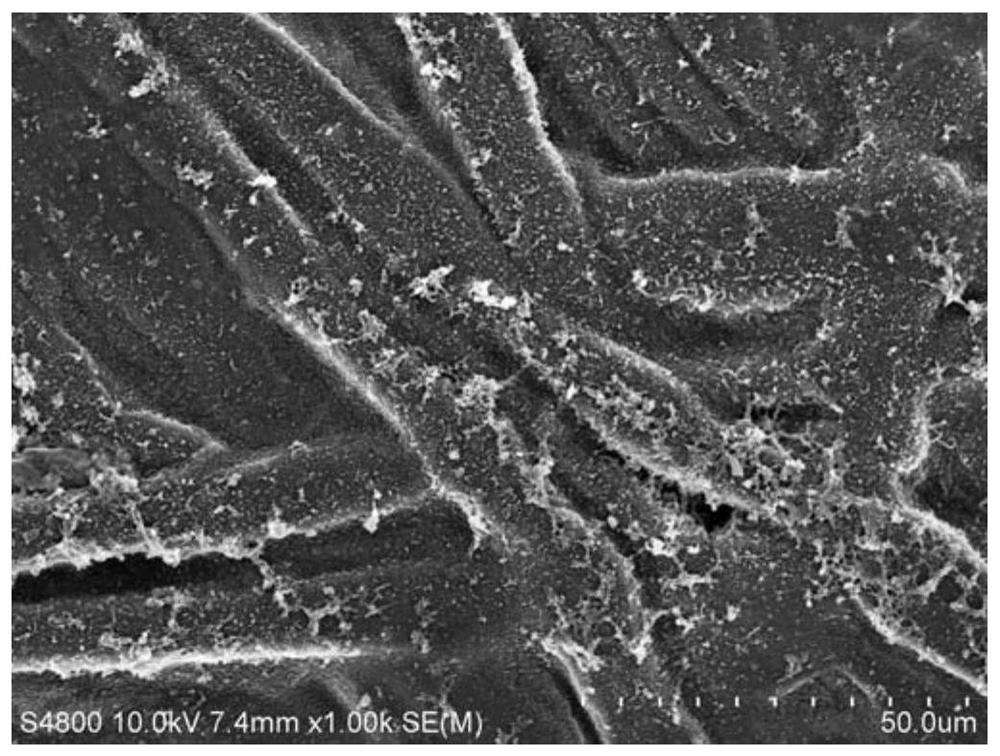

Forward osmosis composite membrane and preparation method and application thereof

ActiveCN112023732AReduce mass transfer resistanceIncrease water fluxSemi-permeable membranesGeneral water supply conservationPolymer scienceConcentration polarization

The invention belongs to the technical field of membrane separation, and particularly relates to a forward osmosis composite membrane based on a two-dimensional nano material and a macroporous substrate and a preparation method and application of the forward osmosis composite membrane. According to the composite membrane, a two-dimensional nano material is deposited on the surface of a macroporoussubstrate to serve as a middle layer, a polyamide separation layer is formed on the surface of the middle layer, and the composite membrane is obtained. The two-dimensional nano material middle layerin the composite membrane prevents polyamide from permeating into the macroporous substrate to damage the original macroporous and mutually communicated pore structure, reduces the mass transfer resistance, and effectively relieves the internal concentration polarization phenomenon in the forward osmosis process, thereby greatly enhancing the separation performance of the polyamide composite membrane and prolonging the service life of the composite membrane. The forward osmosis composite membrane can be widely applied to seawater desalination, juice concentration and other fields.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

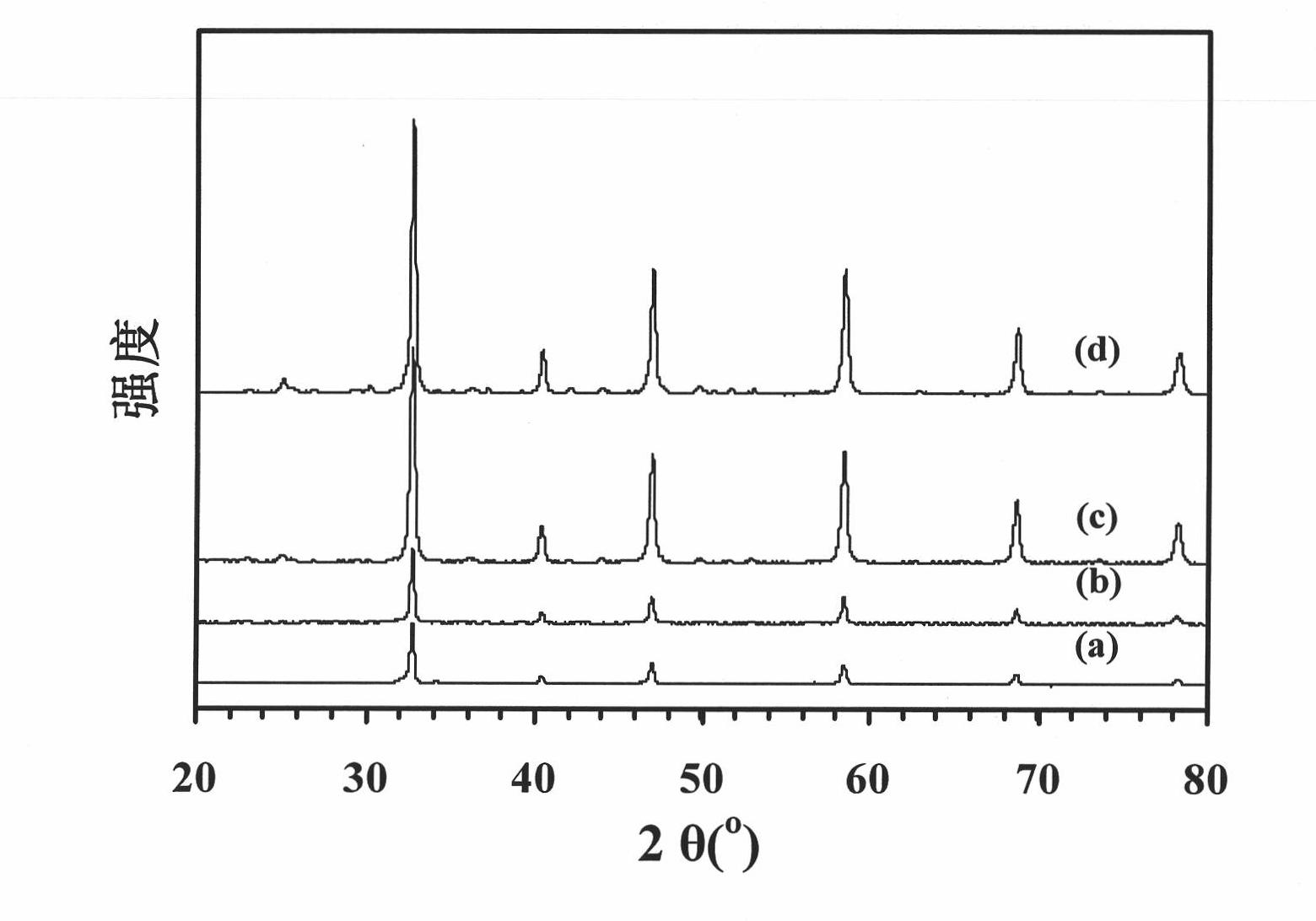

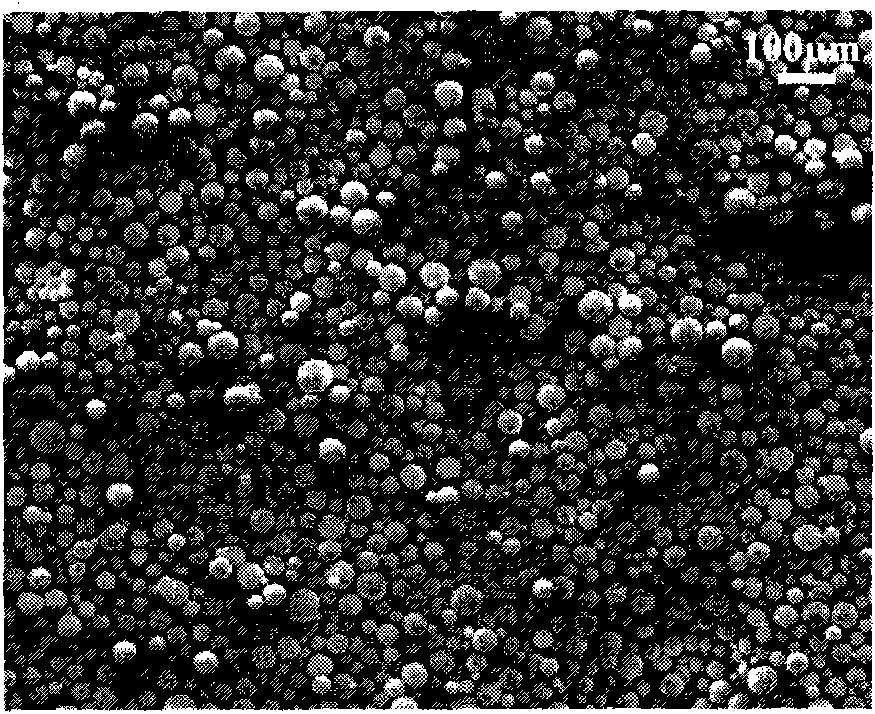

New method for preparing polycrystalline SrFeO3 with three-dimensional ordered macroporous structure

InactiveCN102010011AThe macroporous structure hasHigh crystallinityIron compoundsAir atmosphereFiltration

The invention discloses a new method for preparing polycrystalline SrFeO3 with a three-dimensional ordered macroporous structure. The new method comprises the following steps of: dissolving strontium nitrate and iron nitrate in water according to the molar ratio of 1 to 1, adding citric acid to form complexing solution, and controlling metal ion concentration to be about 1.5mol / L, wherein an additive or a carbon source such as lysine, sugar or the like can be introduced into the solution; pouring a polymethyl methacrylate (PMMA) microsphere template into the solution, impregnating, performingsuction filtration and drying; placing the mixture into a tubular furnace; and heating to the temperature of 600 DEG C in a nitrogen atmosphere at the rate of 1 DEG C per minute, keeping the constanttemperature for 2 hours, switching to an air atmosphere after cooling to below 70 DEG C, heating to the temperature of 300 DEG C at the rate of 1 DEG C per minute, keeping the constant temperature for 1 hour, continuously heating to the temperature of 750 DEG C and keeping the constant temperature for 3 hours to obtain the perovskite type polycrystalline oxide SrFeO3 with the three-dimensional ordered macroporous structure. The prepared polycrystalline oxide SrFeO3 material with the three-dimensional ordered macroporous structure has the advantages of high crystallinity, cheap and readily available raw materials and high thermal stability of a product.

Owner:BEIJING UNIV OF TECH

Diffusively light reflective paint composition, method for making paint composition, and diffusively light reflective articles

ActiveUS20110064939A1Economical and simpleLayered productsDiffusing elementsMicrosphereOptoelectronics

A diffusively reflective paint composition is disclosed for use in reflectors in lighting fixtures. The paint is formed by blending macroporous polymeric particles with a paint carrier. The macroporous polymeric particles are formed by reducing a reflective macroporous sheet material. The paint can further comprise solid or hollow microspheres. The paint can be applied to a variety of substrates to form diffusely reflective articles.

Owner:ABL IP HLDG

Method for preparing macropore strong acid cation exchange resin with high specific surface area

ActiveCN102716770AIncrease the degree of cross-linkingLarge specific surface areaCation exchanger materialsPolymer scienceDivinylbenzene

The invention discloses a method for preparing macropore strong acid cation exchange resin with a high specific surface area, and belongs to the field of the preparation for organic macromolecule compounds. The method comprises the following steps: copolymerizing styrene and a divinylbenzene monomer under the coexistence of porogen and a dispersion agent by taking low-carbon alcohol as the porogen, preparing a macropore copolymer white ball, performing macropore purification and high-temperature sulfonation to obtain the cation exchange resin. The crosslinking degree of the polymer white ball is increased by increasing the using amount of the divinylbenzene; the sulfonation temperature is increased at the same time; the specific surface area of the prepared cation exchange resin is large; the cation exchange speed is high; and the special requirement of a novel device such as a simulated mobile bed on the cation exchange resin can be met.

Owner:山东德川化工科技有限责任公司

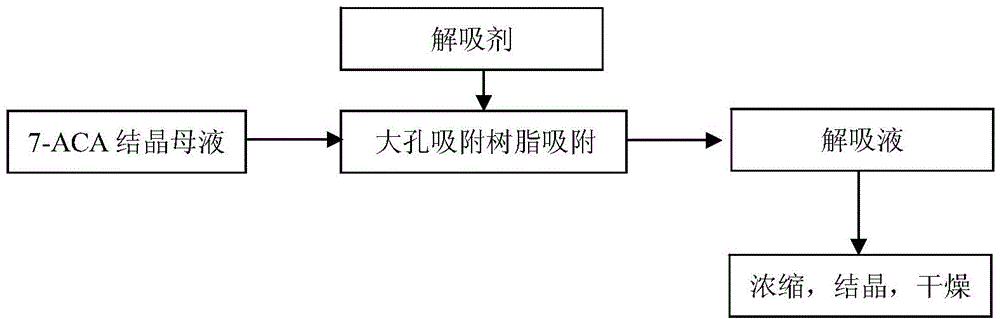

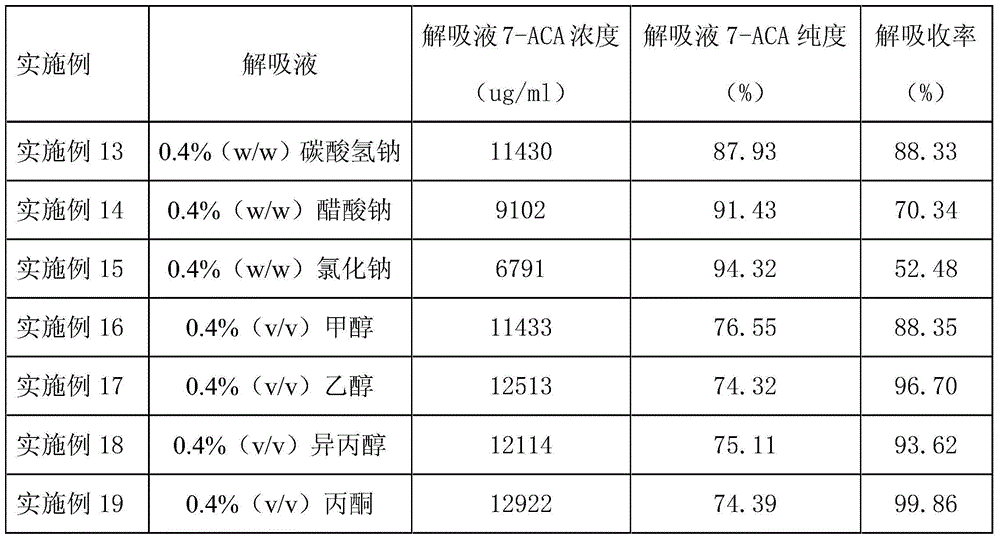

Process for recovering 7-ACA (aminocephalosporanic acid) crystallization mother liquor

The invention provides a process for recovering a 7-ACA (aminocephalosporanic acid) product from mother liquor through macroporous adsorption resin. The process mainly comprises the following steps: performing resin adsorption, performing resin desorption, concentrating and the like, wherein in the resin absorption step, the pH value of 7-ACA crystallization mother liquor is adjusted, the crystallization mother liquor passes through a macroporous adsorption resin layer from top to bottom at a certain flow speed, and when the valence of 7-ACA contained in effluent of a resin column is 1% of that of the crystallization mother liquor at an inlet, resin adsorption is stopped. According to the method, the qualified 7-ACA product with the purity of greater than or equal to 98% and the color grade of greater than 4 can be obtained; the extraction yield of the resin is greater than or equal to 90% and the total process yield is greater than or equal to 40%; based on estimation of 200t of the mother liquor produced each day, the economic benefit of a year can reach more than ten million yuan.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

Method for preparing high-purity nemadectin

The invention discloses a method for preparing high-purity nemadectin and belongs to the field of medicinal chemistry. The nemadectin is a sixteen-member macrolide type anthelmintic antibiotic and mainly used for synthesizing moxidectin with the better anthelmintic effect. According to the method for preparing the high-purity nemadectin, the nemadectin is extracted through an ethanol-water solution, and an extract is obtained, decolorized through ion exchange resin, deproteinized and desugared through macroporous adsorption resin and finally adsorbed and separated through the appropriate macroporous adsorption resin, so that nemadectin products with the purity higher than 90% can be prepared. The method is high in pertinency through matched usage of the resin, and the prepared high-purity nemadectin has great significance in synthesis of the high-purity moxidectin.

Owner:DALIAN JOIN KING FINE CHEM CO LTD

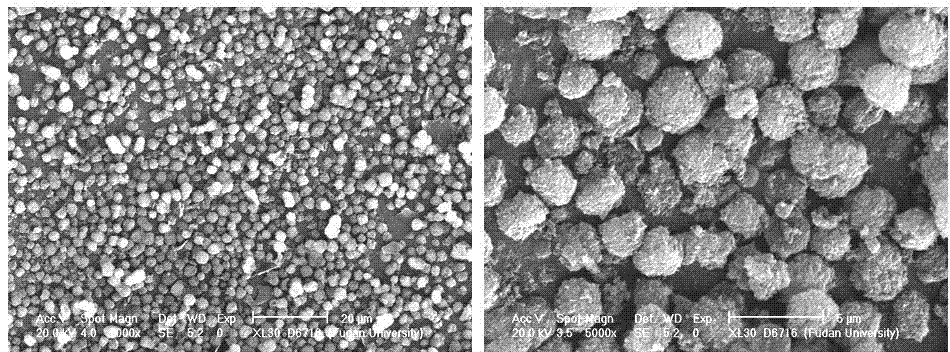

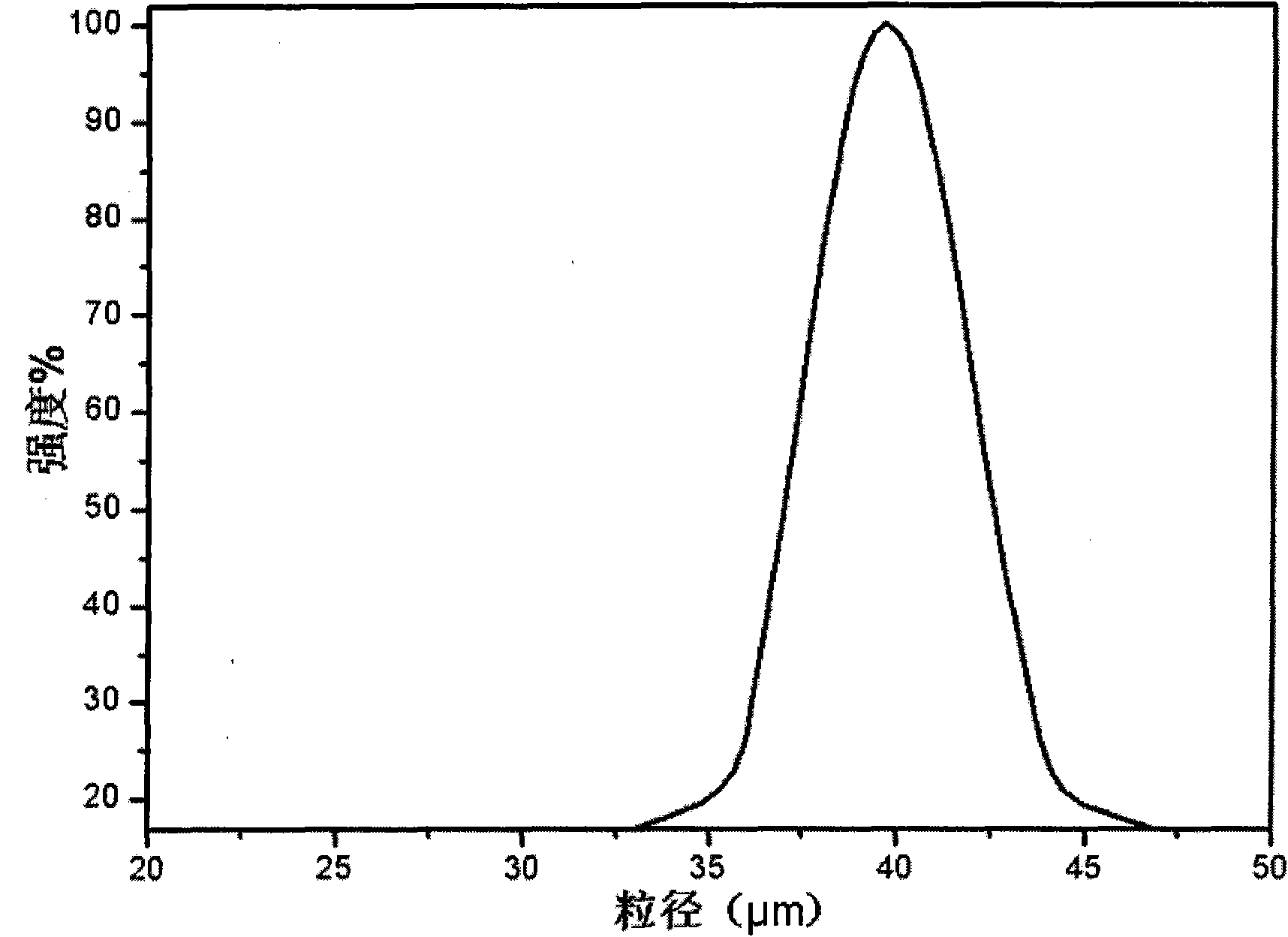

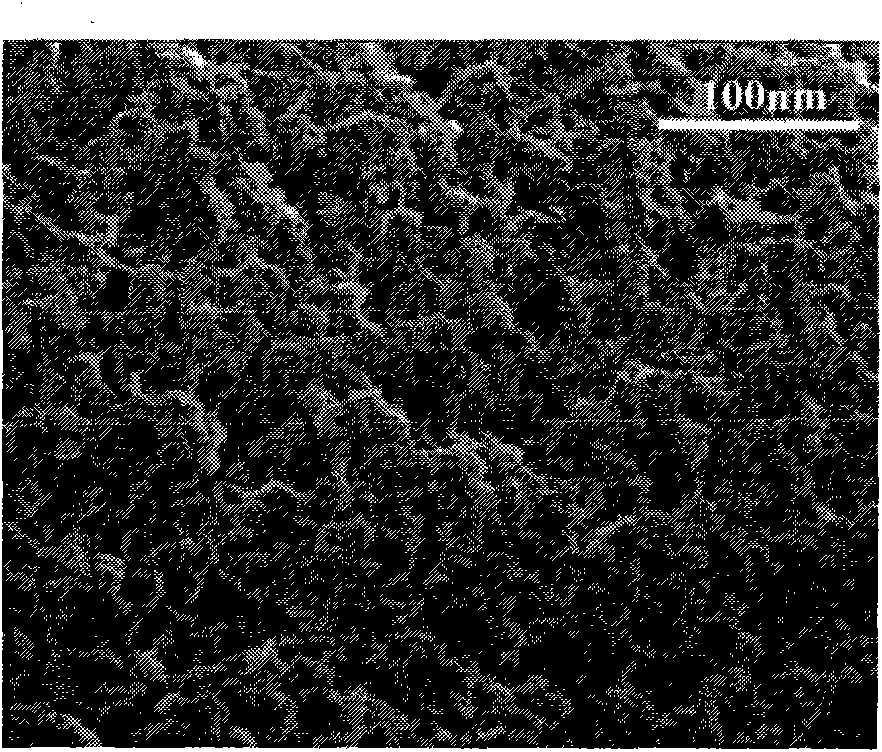

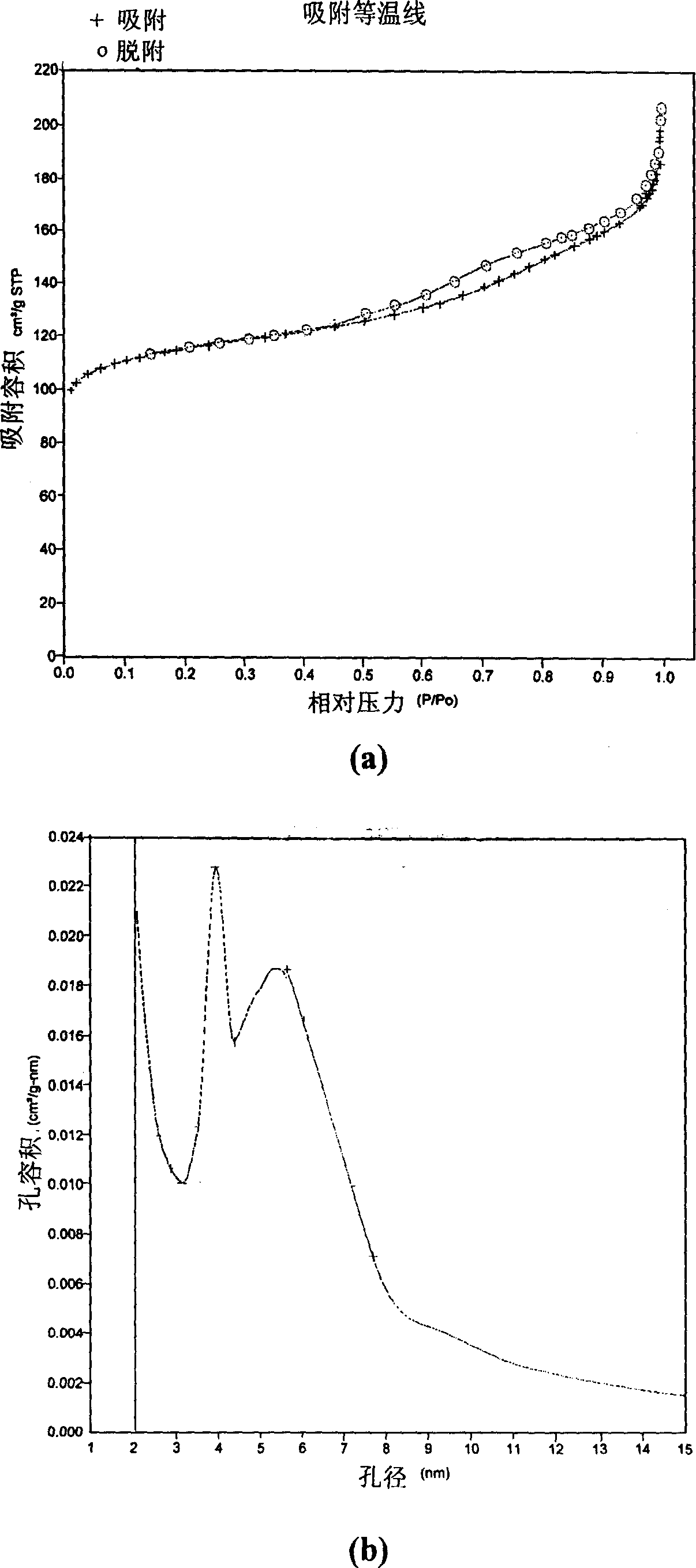

Mesoporous-macroporous multilevel ordered monodisperse micron sphere and preparation method thereof

InactiveCN102849749AEasy to makeOther chemical processesSilicon compoundsMolecular sieveHydrothermal synthesis

The invention belongs to the field of materials, and particularly relates to a mesoporous-macroporous multilevel ordered monodisperse micron sphere and a preparation method thereof. The method includes: using a nanoscale mesoporous molecular sieve obtained by means of hydrothermal synthesis as a multilevel structure construction unit, obtaining a silicon dioxide / urea resin composite micro sphere through the PICA (polymerization-induced colloid aggregation method), performing azeotropic dewatering, and removing urea resin through high-temperature calcinations to prepare the mesoporous-macroporous multilevel ordered monodisperse micron sphere. Dimension of the micron sphere can be adjusted by adjusting usage and proportion of urea and formaldehyde and the pH of solution. The multilevel ordered monodisperse micron sphere prepared by the method is uniform in size and has wide application to adsorption, separation and the like.

Owner:FUDAN UNIV

Method of the preparation of macroporous foam comprising zeolite or zeotype material

The present invention provides a macroporous foam comprising microporous zeolite or zeotype material and preparation thereof, which comprises dipping a polymeric template capable of releasing an amine which has a sponge or macroporous structure and can be selected from a group consisting of polyurethane, polyamides, aromatic or aliphatic polyimides, polyamideimides, epoxy resins having an amine skeleton, and polymeric materials capable of releasing an organic amine by hydrolysis, in an alkaline or acidic solution, gel or sol of a precursor of said zeolite or zeotype material, and reacting the resultant at a suitable temperature for a period such that all or almost all of the polymeric template can be replaced with zeolite or zeotype material. Said foam comprising zeolite or zeotype material has the outer shape and size and the inner sponge or macroporous structure which are the same or similar to those of the polymeric template used.

Owner:IND UNIV COOP FOUND SOGANG UNIV

Preparation method and application of macroporous polyacryamide resin

InactiveCN101899130AEasy to prepareLow reaction temperatureOn/in organic carrierReaction temperaturePolyacrylamide

The invention relates to a preparation method of macroporous polyacryamide resin. The method comprises the following steps of: preparing an aqueous phase, preparing an oil phase, preparing the macroporous polyacryamide resin and carrying out after-treatment on products. The preparation method of the macroporous polyacryamide resin has simplicity and low reaction temperature, and the prepared macroporous polyacryamide resin has macroporous structure from the surface to the interior, uniform and dense aperture, relatively larger specific surface area and strong water absorbability and adsorbability, can be used as a carrier of an immobilized enzyme and can greatly improve the capacity of the enzyme.

Owner:SHAANXI NORMAL UNIV

Tuckahoe extract and preparation method thereof

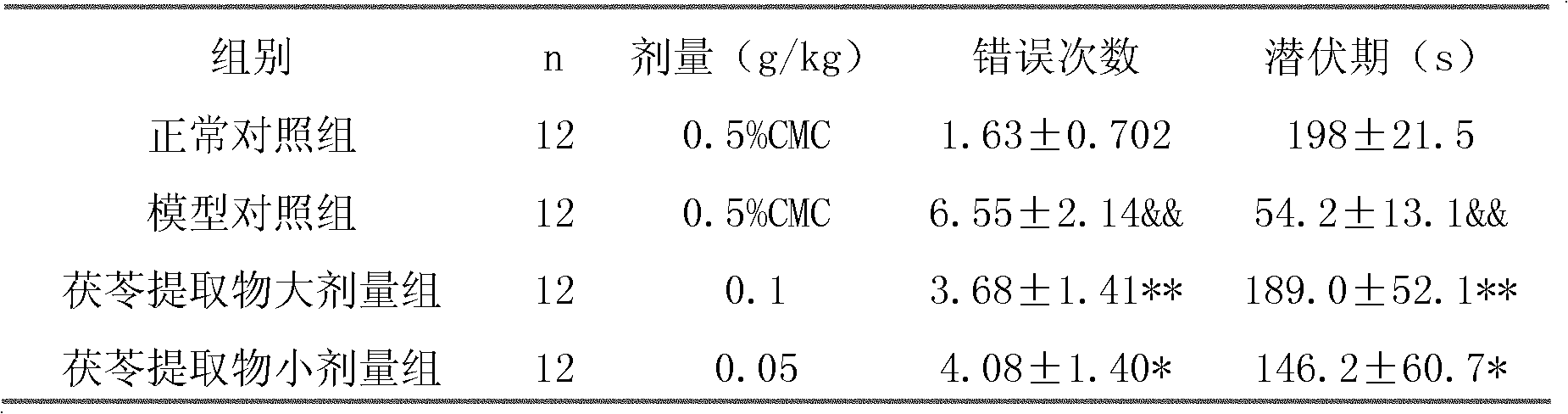

ActiveCN102133242AEnrichmentReduce errorsNervous disorderPlant ingredientsMemory disorderMemory retention disorder

The invention discloses a tuckahoe extract which is prepared through ethanol extraction and macroporous absorption resin purification. The tuckahoe extract enriches more effective parts. Moreover, a rat memory disorder model test proves that the tuckahoe extract can improve the learning and memory capacity of a model rat, so that the number of errors of the model rat is reduced and the latent period is prolonged.

Owner:BEIJING UNIV OF CHINESE MEDICINE

Three-dimensional sequential macroporous Co3O4 loaded nanometer Au catalyst as well as preparation method and application thereof

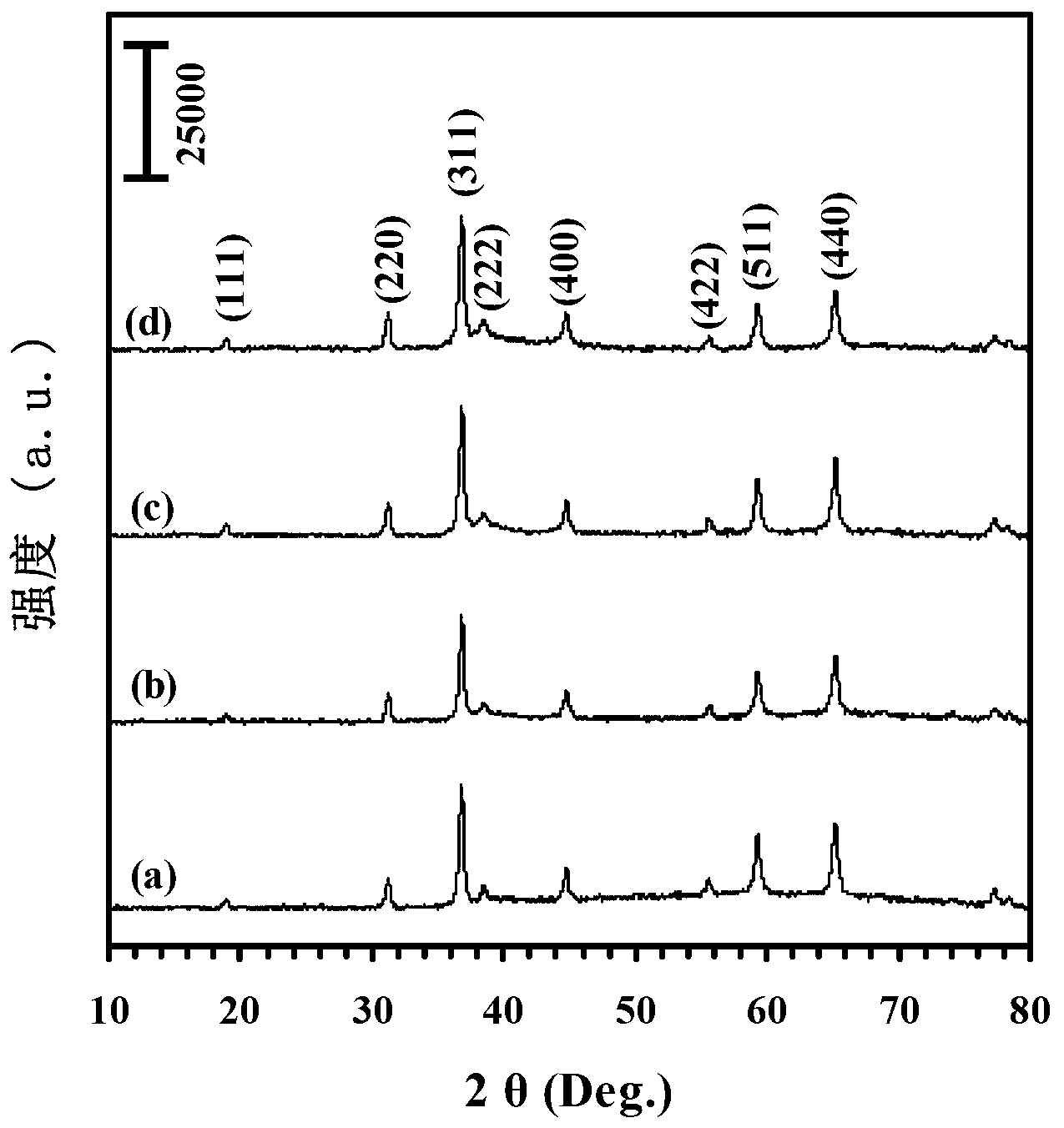

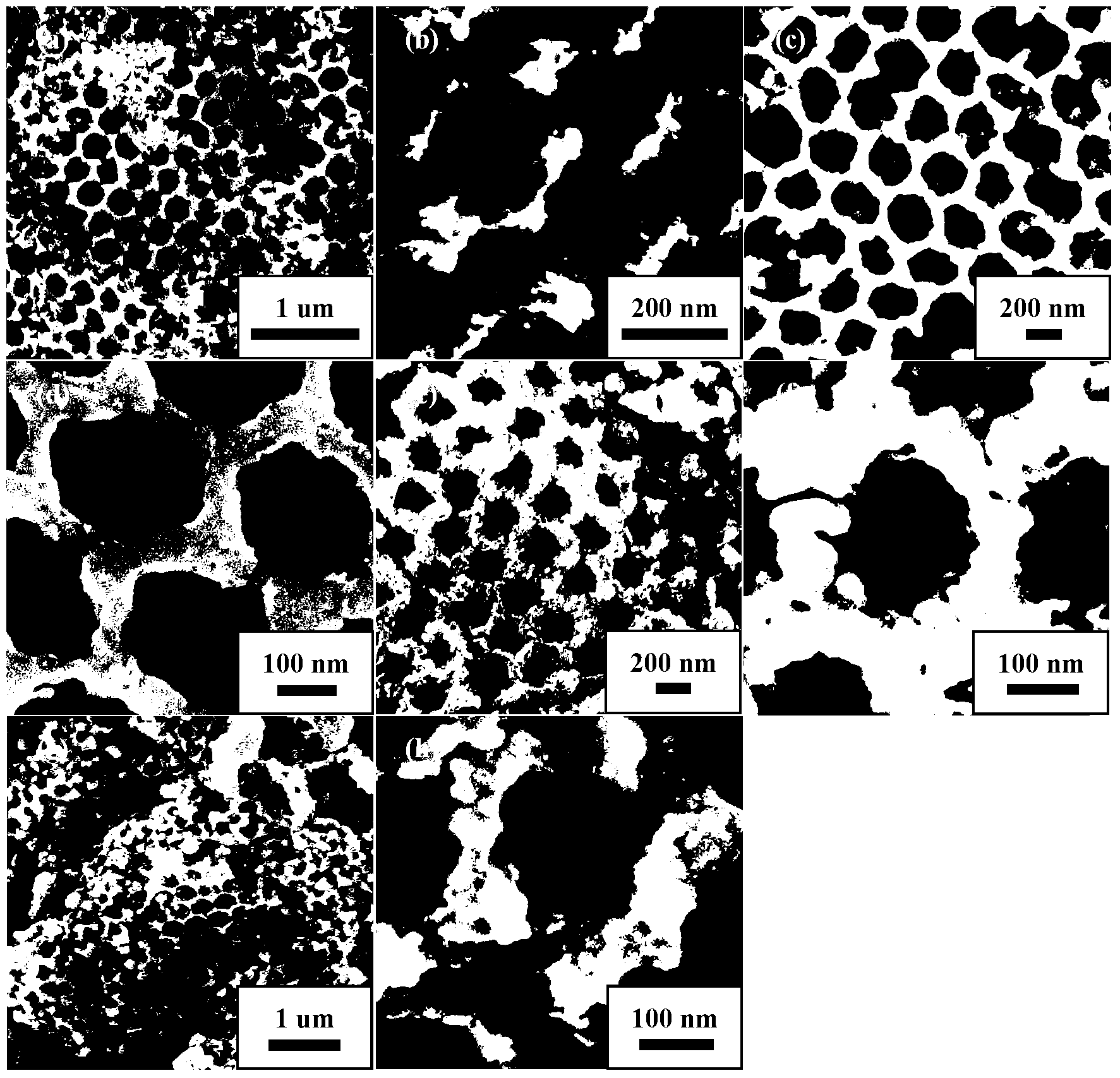

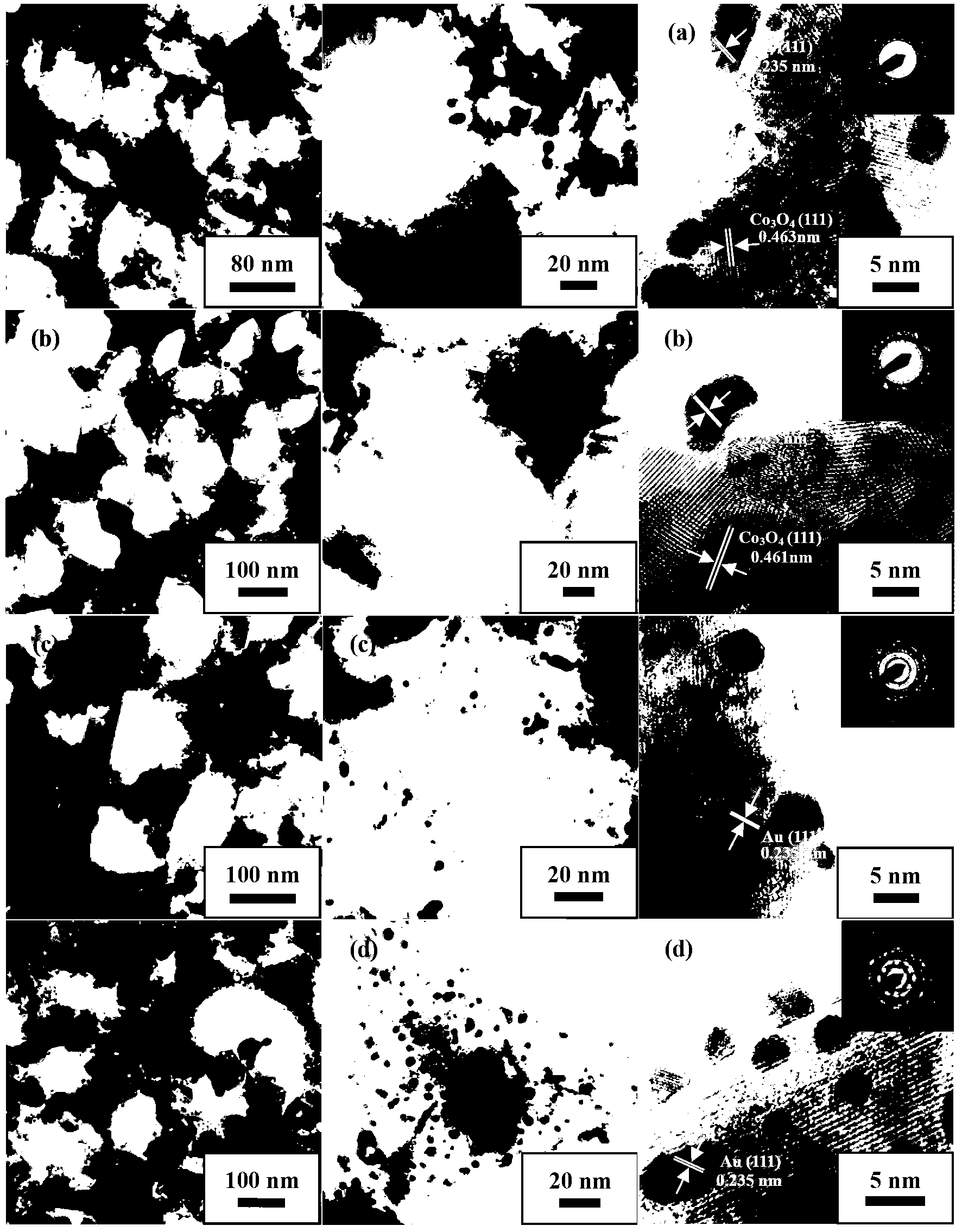

InactiveCN103301850AShape is easy to controlControllable particle sizeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryOxide

The invention relates to a three-dimensional sequential macroporous Co3O4 loaded nanometer Au catalyst as well as a preparation method and an application thereof, and belongs to a transition metal oxide loaded nanometer noble metal catalyst. The pore wall of Co3O4 with a 3DOM structure is supported with cubic phase Au nanometer particles. According to the preparation method, 3DOM Co3O4 is prepared by a polyethyleneglycol 400 assisted PMMA (polymethyl methacrylate) colloidal crystal template method, and then a gold nanometer adhesive is loaded on 3DOM Co3O4 by using a polyvinyl alcohol protection bubble reduction method, so that Au / 3DOM Co3O4 is obtained. The raw materials of the three-dimensional sequential macroporous Co3O4 loaded nanometer Au catalyst is cheap in price and can be easily obtained, the preparation process is simple, and the product obtained by the preparation method is controllable in shape, size and pore diameter.

Owner:BEIJING UNIV OF TECH

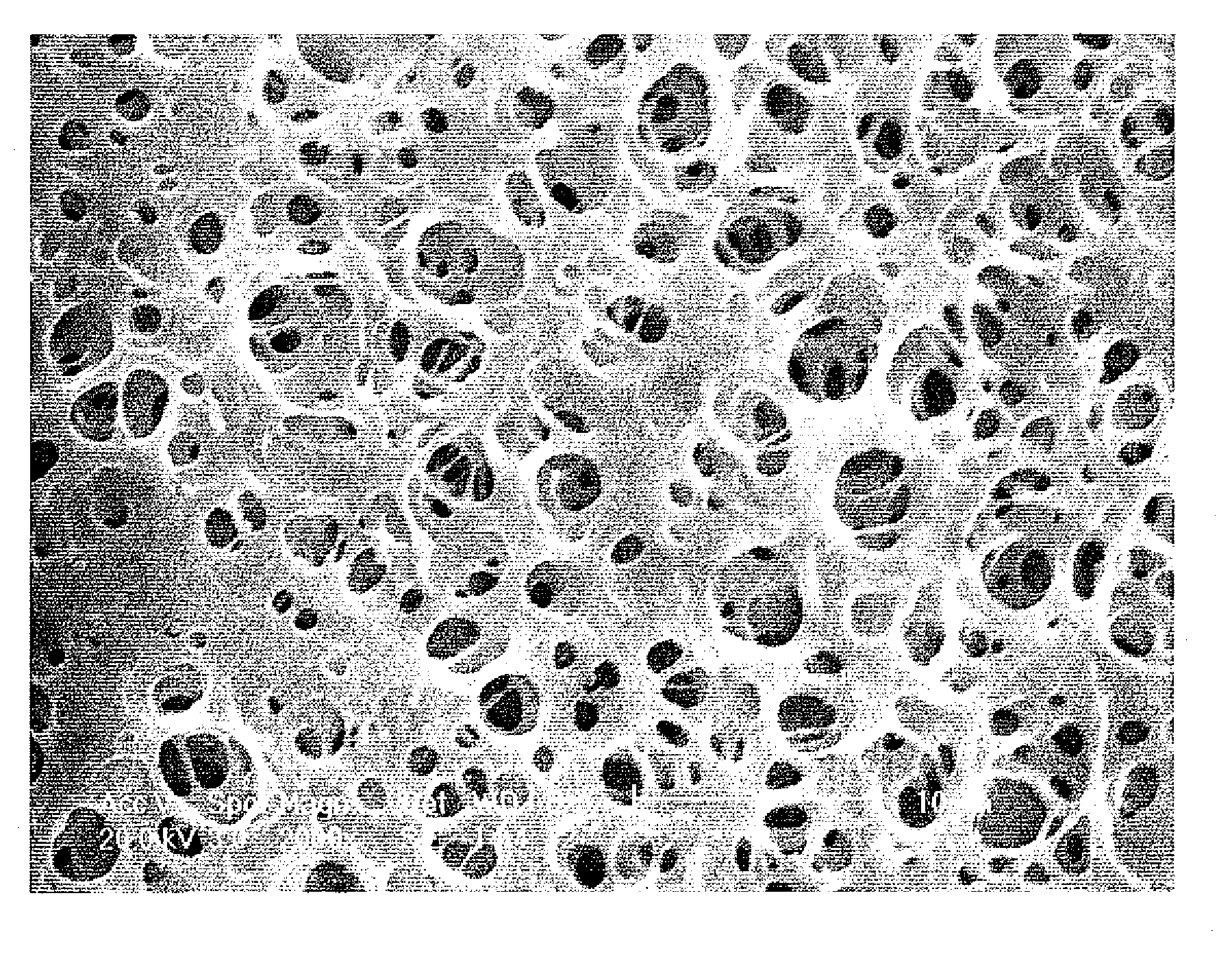

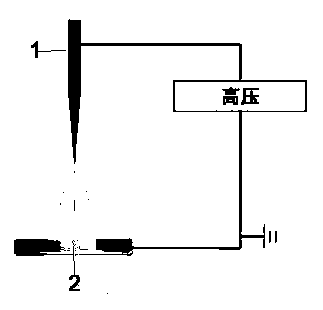

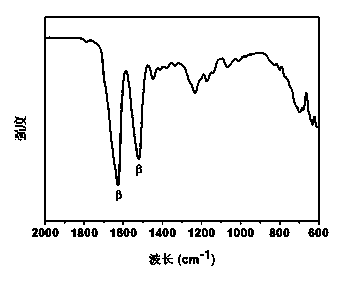

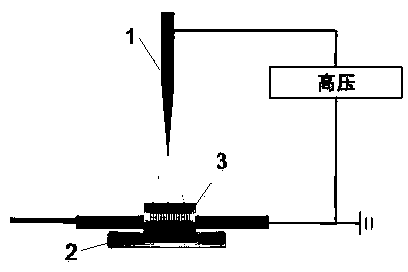

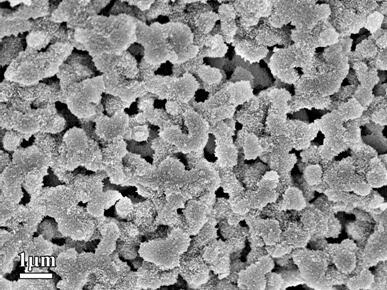

Immediately crosslinking technology for preparing macroporous three-dimensional nanofiber bracket

ActiveCN103861145AStable structureSimple and fast operationFilament/thread formingNon-woven fabricsFiberElectrospinning

The invention provides a method of preparing a three-dimensional nanofiber bracket by combining an immediately crosslinking technology and an electrostatic spinning technology. The bracket prepared according to the invention is of a three dimension solid structure, the thickness of the bracket is 0.05-10mm, the interfibrous gap is 0-30 microns, and the pore size is adjustable. With the adoption of the method, the operation is simple, the relevant immediately crosslinking method solves the problems that fibers are dissolved and the structure is damaged caused by crosslinking after natural biomolecules with poorer mechanical and processing performances carry out electrostatic spinning, so that the nanofiber bracket which has a stable structure, is in three dimension solid and is loose and porous can be obtained, and a platform used for carrying cells, cell factors and drugs is prod for tissue regeneration and repair.

Owner:WUHAN UNIV

Macroporous alumina and preparation method thereof

ActiveCN110467206AEvenly distributedUniform concentrationCatalyst carriersAluminium oxides/hydroxidesPolyethylene glycolOrganic compound

The invention discloses macroporous alumina and a preparation method thereof. The macroporous alumina of the invention has the properties that the macroporous alumina is a gamma crystalline state, thetotal porosity is 60%-85%, the macropore diameter is 100 nm-1000 nm, the proportion of macropores to the total porosity is 40%-75%, the macropores are evenly distributed and three-dimensionally penetrated, a ratio of the wall thickness to the pore diameter of the macropores is 0.7-3.0, and the side crushing strength is 8-25 N / mm. The preparation method of the macroporous alumina includes the following steps: (1) preparing aluminum sol; (2) evenly mixing inorganic aluminum salts, polyethylene glycol, the aluminum sol obtained in the step (1), organic compounds containing amide groups and a low-carbon alcohol aqueous solution; (3) adding epoxypropane and / or pyridine into the mixture obtained in the step (2), evenly mixing the mixture to obtain gel, and carrying out aging to obtain an agingproduct; and (4) immersing the aging product by using the low-carbon alcohol aqueous solution, carrying out solid-liquid separation, and drying and roasting a solid phase to obtain the macroporous alumina.

Owner:CHINA PETROLEUM & CHEM CORP +1

Previous concrete

InactiveCN102976680AHigh compressive strengthGood water permeabilityCeramicwareGlycidyl methacrylateAdhesive

The invention belongs to the technical field of concrete, and particularly provides a previous concrete. The previous concrete comprises cement, aggregate, macroporous resin and adhesive, wherein the macroporous resin is one of GMA-EGDMA (Glycidyl Methacrylate / Ethyleneglycol Dimetacrylate) macroporous resin, GMA-MBAA ((Glycidyl Methacrylate / Methylene-Bis(Acrylamide)) or macroporous resin or GMA-DVB (Glycidyl Methacrylate-Divinylbenzene) macroporous resin; and the adhesive is one of polyvinyl acetate, polyving akohol or butadiene styrene rubber. The previous concrete is high in compressive strength and permeation coefficient, can meet various construction demands on permeability of concrete, and is beneficial for maintaining ecological balance and realizing sustainable development.

Owner:福建九鼎建设集团有限公司

Preparation method of macroporous alumina support

ActiveCN103055948AHigh carbon contentPromote decompositionCatalyst carriersPtru catalystPhysical chemistry

The invention discloses a preparation method of a macroporous alumina support. The method is characterized by taking light ash generated through combustion of crop stems and husks as a pore-enlarging agent, simultaneously adding a triethanolamine water solution and adopting a kneading method to prepare the macroporous alumina support. The method has the beneficial effects that the pore-enlarging agent is small in dosage, wide in source and low in cost, so the preparation cost of the alumina support can be effectively reduced; and the prepared macroporous alumina has the characteristics of double pore distribution, more concentrated pore distribution and higher mechanical strength, is used for preparing heavy / residual oil hydrogenation catalysts and is very favorable for delaying the increase of diffusion resistance in heavy / residual oil hydrogenation, thus being favorable for maintaining the apparent activities of the hydrogenation catalysts and lengthening the running period of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

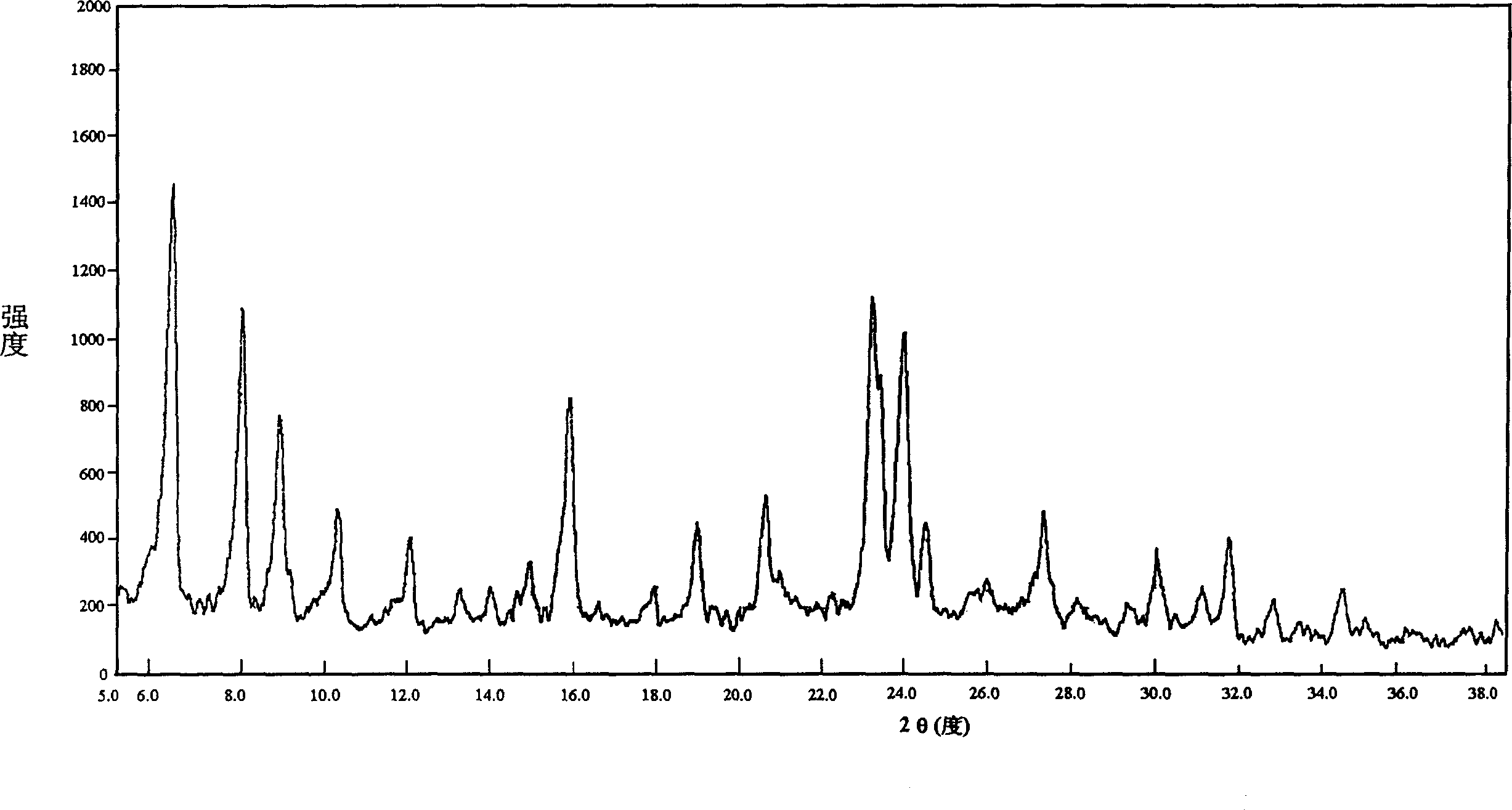

Macroporous zeolite absorbent and preparation method thereof

InactiveCN1806908AFacilitated DiffusionLarge average pore sizeOther chemical processesSorbentORGANIC IODIDE

The invention provides the large aperture zeolitic adsorbent and preparing method. The method comprises the following steps: hydrothermal synthesizing the zeolitic in Na2O-SiO2-Al2O3-H2O colloidal system, possessing the X-ray spectrum, removing the sodium with positive ion exchange, forming with binding agent and modifying with aqueous vapor. The average pore size of adsorbent is 11 nanometers, and the adsorbent is used to remove micro inorganic or organic iodide and iodine from acid medium.

Owner:FUDAN UNIV +1

Chelate resin and its synthesis method

InactiveCN1478807AHigh synthesis efficiencyLarge coordination and complexing abilityComplex ion-exchangersSorbentSynthesis methods

Owner:NO 718 INST NO 7 RES INST CHINA SHIPPING HEAVY IND GRP

Method for preparing macroporous adsorbent resin special for separating valine

ActiveCN101721979AOvercome purityOvercome efficiencyOrganic compound preparationOther chemical processesCross-linkTert-leucine

The invention relates to a method for preparing macroporous adsorbent resin special for separating valine, and belongs to the technical field of chemical and biological product processing. In the method, the types and proportions of an aqueous phase matter, cross-linking agents, polar monomers and pore-foaming agents are controlled in the process of synthesizing the resin, so that the resin can be bonded with di-tert-butyl dicarbonate effectively, and the synthesized macroporous adsorbent resin can separate the valine, alanine and leucine; and simultaneously, the macroporous adsorbent resin adopts pure water as a mobile phase, so that the pollution of a separation process on environment can be lightened effectively. The resin synthesized by the method can be effectively used for separating valine fermentation liquor and removing impurities with similar properties such as the alanine and the leucine in the valine fermentation liquor, and overcomes the defects of low purity, low efficiency, severe pollution and the like which exist in the conventional process for separating and purifying the valine, so that the purity of products reaches over 99 percent, reaches medicinal standards, and has high recovery rate and production strength.

Owner:XINTAI JIAHE BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com