Nano mesoporous and mesoporous-macroporous composite biological glass and its preparing method

A bioglass and nano-mesoporous technology, applied in medical science, prosthesis, etc., can solve the problems of macroporous bioglass materials that have not been reported, and achieve excellent biological activity, mild reaction conditions, and strong pore volume adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

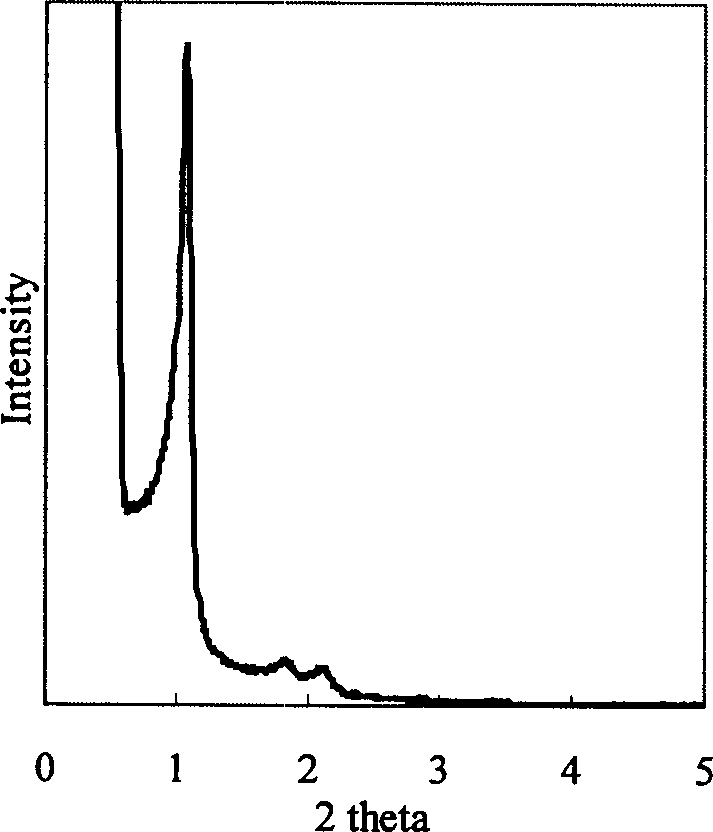

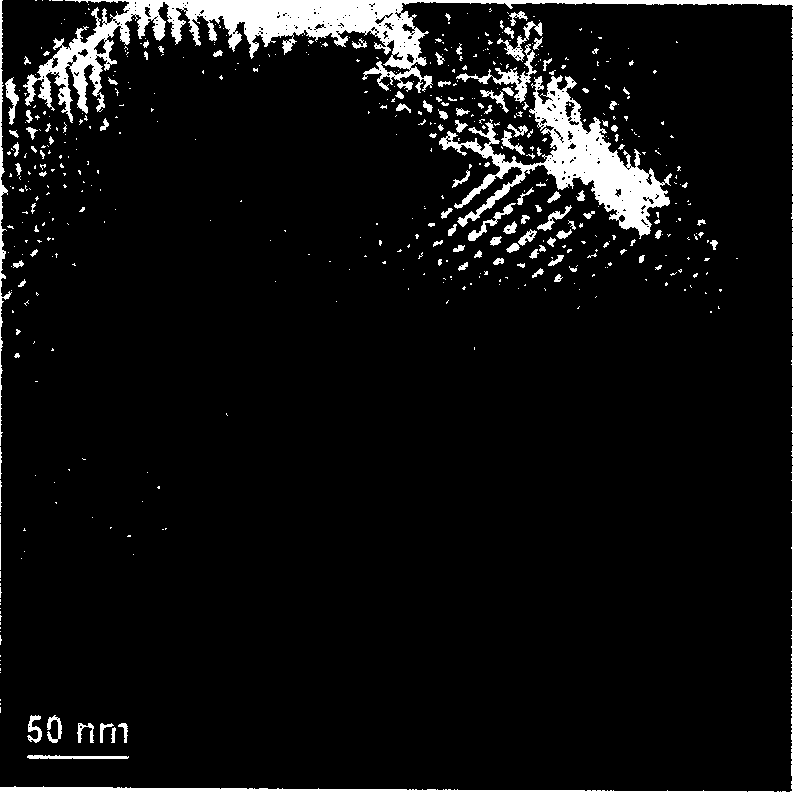

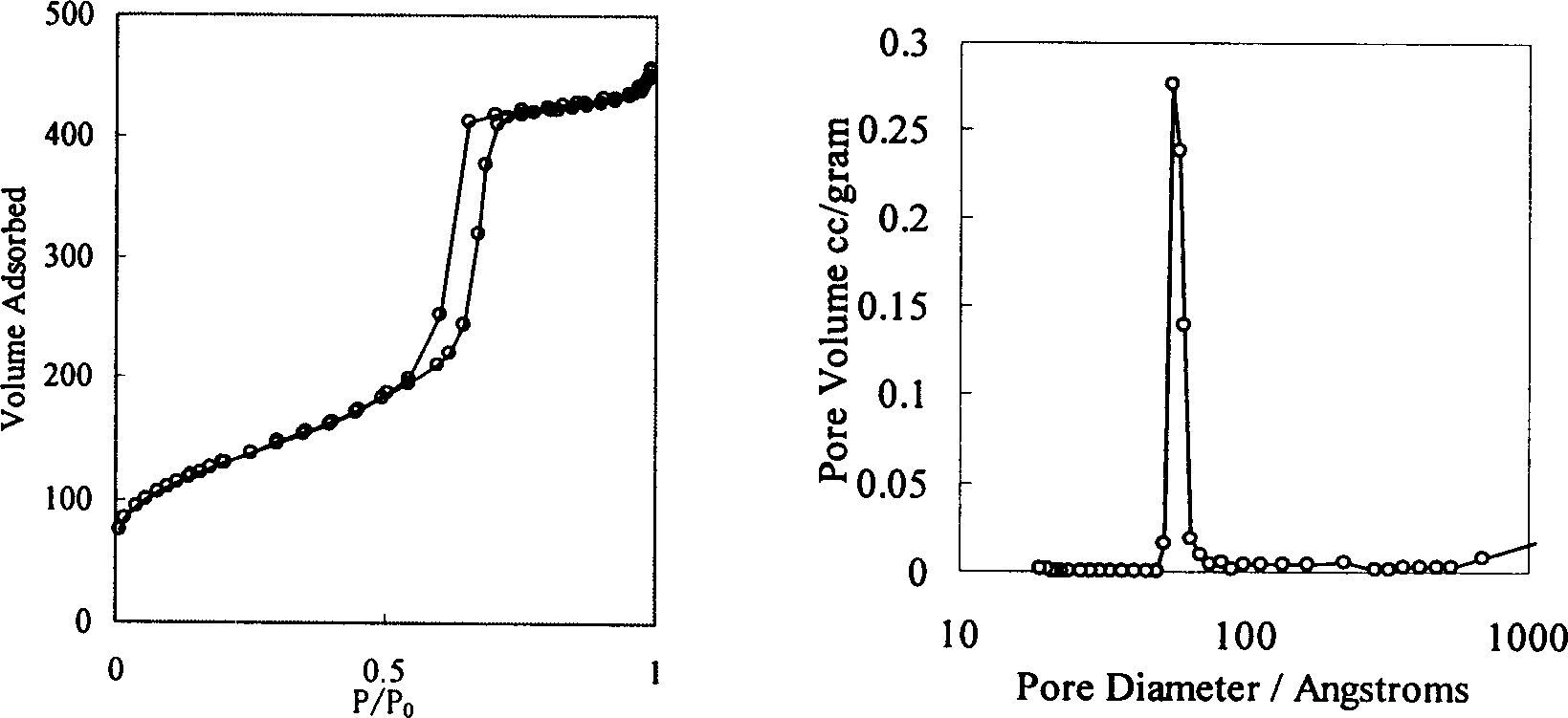

Image

Examples

Embodiment 1

[0031] 2g P123+30g EtOH+1.04g Ca(NO 3 ) 2 4H 2 O+3.12gTEOS+0.18g TEP+0.5g0.5MHCl+0.5gPE was stirred at room temperature for 24h, aged at room temperature for 72h until a dry gel was formed, and baked in a box-type resistance furnace at 550°C for 24h, namely Nano-mesoporous and mesoporous-macroporous composite bioglasses were obtained.

Embodiment 2

[0033] 2g F127+30g EtOH+1.04g Ca(NO 3 ) 2 4H 2 O+3.12g TEOS+0.18g TEP+0.5g0.5MHClg+0.5g PBMA, stirred at room temperature for 48h, aged at room temperature for 72h until a dry gel was formed, and baked in a box-type resistance furnace at 700°C for 10h , that is, nano-mesoporous and mesoporous-macroporous composite bioglass.

Embodiment 3

[0035] 2g F108+30g EtOH+1.04g Ca(NO 3 ) 2 4H 2 O+3.12gTEOS+0.18g TEP+0.5g0.5MHCl was stirred at room temperature for 24h, then aged at room temperature for 48h until a dry gel was formed, and then baked at 600°C for 15h in a box-type resistance furnace to obtain nano-sized media. Hole Bioglass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com