Macroporous alumina and preparation method thereof

A technology of macroporous alumina and pore diameter, applied in the field of macroporous alumina and its preparation, can solve the problems of reduced mechanical strength, apparent isolation, and poor spatial continuity, and achieve stress relief, increase specific surface area, and high crushing strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of aluminum sol: Boehmite powder and distilled water are mixed to form a suspension (solid content 3wt%). Under continuous stirring, hydrochloric acid is added dropwise to meet the acid / aluminum molar ratio of 0.07. hours to form a clear aluminum sol.

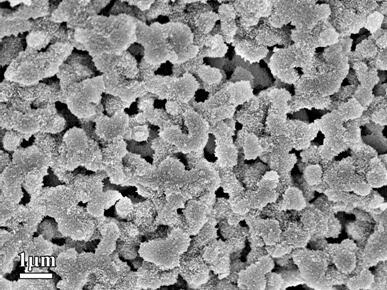

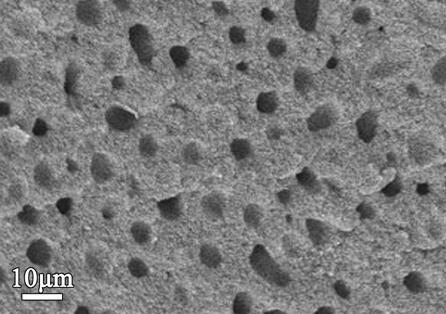

[0040] At room temperature (about 25°C), mix water, absolute ethanol, aluminum chloride, polyethylene glycol, aluminum sol, and formamide evenly, and then add pyridine. The contents of each component of the mixture are by weight: water 22% , ethanol 21%, aluminum chloride 18%, polyethylene glycol (viscosity average molecular weight 1 million) 0.3%, aluminum sol 5%, formamide 1%, pyridine 32.7%. After mixing evenly, the obtained gel was aged at 40°C for 48 hours, and then soaked in 55wt% ethanol aqueous solution for 48 hours. After soaking and removing the liquid phase, it was dried at 40°C until the product no longer showed obvious weight loss. Then calcined at 550° C. for 3 hours, and then cooled to room t...

Embodiment 2

[0042] The preparation of aluminum sol is the same as in Example 1.

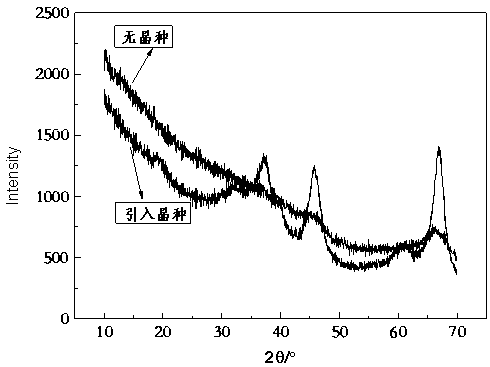

[0043] At room temperature (about 25°C), mix water, absolute ethanol, aluminum chloride, polyethylene glycol, aluminum sol, and acetamide evenly, and then add propylene oxide. The contents of each component of the mixture are by weight: water 23%, ethanol 20%, aluminum chloride 22%, polyethylene glycol (viscosity average molecular weight 1 million) 0.5%, aluminum sol 2%, formamide 2.0%, propylene oxide 30.5%. After mixing evenly, the obtained gel was aged at 40°C for 48 hours, and then the aged mixture was soaked in ethanol for 48 hours. After soaking and removing the liquid phase, it was dried at 40°C until the product no longer lost weight. Then bake at 450° C. for 5 hours, and then cool to room temperature to obtain the macroporous alumina. According to the XRD test, it has a good γ crystal state, the total porosity is 84%, the macropores are evenly distributed, and it has a three-dimensional space. The ...

Embodiment 3

[0045] Preparation of aluminum sol: Boehmite powder and distilled water are mixed to form a suspension (solid content 1.5wt%). Under continuous stirring, acetic acid is added dropwise to meet the acid / aluminum molar ratio of 0.1. After the addition, the temperature is raised to 90°C and refluxed A clear sol formed in 10 hours.

[0046] At room temperature (about 25°C), mix water, absolute ethanol, aluminum chloride, polyethylene glycol, aluminum sol, and N,N-dimethylformamide evenly, and then add pyridine. The components of the mixture are calculated by weight. The contents are: water 20%, ethanol 20%, aluminum chloride 22%, polyethylene glycol (viscosity average molecular weight 1 million) 0.5%, aluminum sol 5%, formamide 2.5%, pyridine 30.0%. After mixing evenly, the obtained gel was aged at 40°C for 48 hours, and then soaked in 80wt% ethanol aqueous solution for 72 hours. After soaking and removing the liquid phase, it was dried at 40°C until the product no longer had obvio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com