Immediately crosslinking technology for preparing macroporous three-dimensional nanofiber bracket

A three-dimensional nano-fiber scaffold technology, applied in fiber processing, prosthesis, filament/wire forming, etc., can solve problems such as complex technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

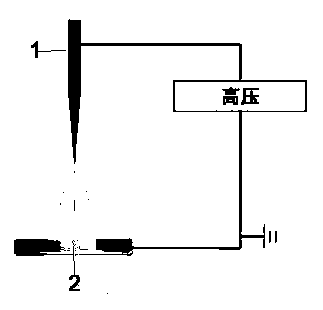

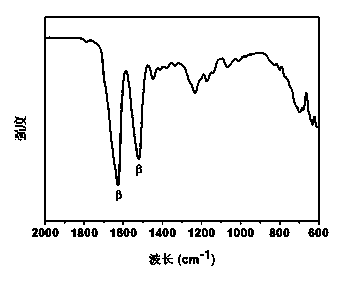

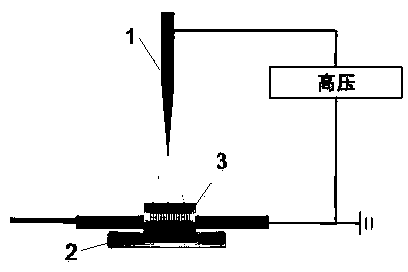

Method used

Image

Examples

Embodiment 1

[0034] 1. Cut silkworm cocoons into 1cm 2 The small pieces were boiled with 500mL of 0.5% sodium carbonate solution for 1.5 hours, cleaned with deionized water, boiled in 500mL of deionized water for 0.5h, washed with deionized water and dried. Add about 60mL of calcium chloride / water / ethanol three-phase solution (the molar ratio of the three substances is 1 / 8 / 2) to the treated silk, stir in a water bath at 70°C for 1 hour to completely dissolve the silk, and then add the obtained The solution was dialyzed for 48 hours. After the dialysis, the solution was centrifuged at 8000r / min for 30 minutes and then filtered. The filtered solution was frozen in liquid nitrogen and then dried for 48 hours to obtain regenerated silk fibroin.

[0035] 2. Dissolve 2 g of regenerated silk fibroin in 8 g of a mixed solution of dichloromethane and trifluoroacetic acid at a mass ratio of 3:7 to prepare a solution for electrospinning with a mass fraction of regenerated silk fibroin of 20%.

[00...

Embodiment 2

[0042] 1. Cut silkworm cocoons into 1cm 2 The small pieces were boiled with 500mL of 0.5% sodium carbonate solution for 1.5 hours, cleaned with deionized water, boiled in 500mL of deionized water for 0.5h, washed with deionized water and dried. Add about 60mL of calcium chloride / water / ethanol three-phase solution (the molar ratio of the three substances is 1 / 8 / 2) to the treated silk, stir in a water bath at 70°C for 1 hour to completely dissolve the silk, and then add the obtained The solution was dialyzed for 48 hours. After the dialysis, the solution was centrifuged at 8000r / min for 30 minutes and then filtered. The filtered solution was frozen in liquid nitrogen and then dried for 48 hours to obtain regenerated silk fibroin.

[0043] 2. Mix and dissolve 0.5g of regenerated silk fibroin and 0.5g of chitosan in 9g of a mixed solution of dichloromethane and trifluoroacetic acid with a mass ratio of 3:7 to prepare a mixture for electrospinning with a mass fraction of 10%. sol...

Embodiment 3

[0050] 1. Cut silkworm cocoons into 1cm 2 The small pieces were boiled with 500mL of 0.5% sodium carbonate solution for 1.5 hours, cleaned with deionized water, boiled in 500mL of deionized water for 0.5h, washed with deionized water and dried. Add about 60mL of calcium chloride / water / ethanol three-phase solution (the molar ratio of the three substances is 1 / 8 / 2) to the treated silk, stir in a water bath at 70°C for 1 hour to completely dissolve the silk, and then add the obtained The solution was dialyzed for 48 hours. After the dialysis, the solution was centrifuged at 8000r / min for 30 minutes and then filtered. The filtered solution was frozen in liquid nitrogen and then dried for 48 hours to obtain regenerated silk fibroin.

[0051] 2. Mix and dissolve 0.75g of regenerated silk fibroin and 0.25g of chitosan in 9g of a mixed solution of dichloromethane and trifluoroacetic acid at a mass ratio of 3:7 to prepare a mixture for electrospinning with a mass fraction of 10%. sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com