Heat-insulating and sound-absorbing honeycomb core material and preparation method thereof

A honeycomb core material and sound absorption technology, which is applied in the field of foam composite materials and its preparation, can solve the problems of heat insulation and sound absorption performance, poor temperature resistance of materials that have not been paid attention to, and reduce the flame retardancy and temperature resistance of core materials. Excellent sound absorption and heat insulation performance, the effect of improving the opening degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 120 grams of N,N-dimethylformamide solution of 3,3',4,4'-benzophenone tetraacid dimethyl ester with a solid content of 66%, 6 grams of triethanolamine, polyethylene oxide surface Activator polyethylene glycol 600 and polyether siloxane surfactant AK8805 are mixed according to the mass ratio of 1:1 surfactant 12 grams, deionized water 8 grams in a plastic cup, stir with a glass rod to get The foaming white material is then placed in a thermostat at 10 degrees Celsius and stored for use; accurately weigh 63 grams of polymethylene polyphenyl polyisocyanate at zero degrees Celsius and pour it into the foaming white material, and use a mechanical stirring paddle at 1000 rpm After stirring at a rotating speed for 25 seconds, quickly pour it into a square steel experimental mold with an upper opening with an inner cavity size of 30cm*15cm*5.1cm and scrape it flat; the pre-cut density is 48kg / m 3 , the core grid size is 4.8mm, and the aramid paper honeycomb core material ...

Embodiment 2

[0046] Referring to Example 1, the difference between this example and Example 1 is that the surface activity of the polyoxyethylene surfactant polyethylene glycol 600 and polyether siloxane surfactant L580 mixed at a mass ratio of 1:1 was weighed. 35 grams of agent, 21 grams of deionized water, all the other are identical with embodiment 1.

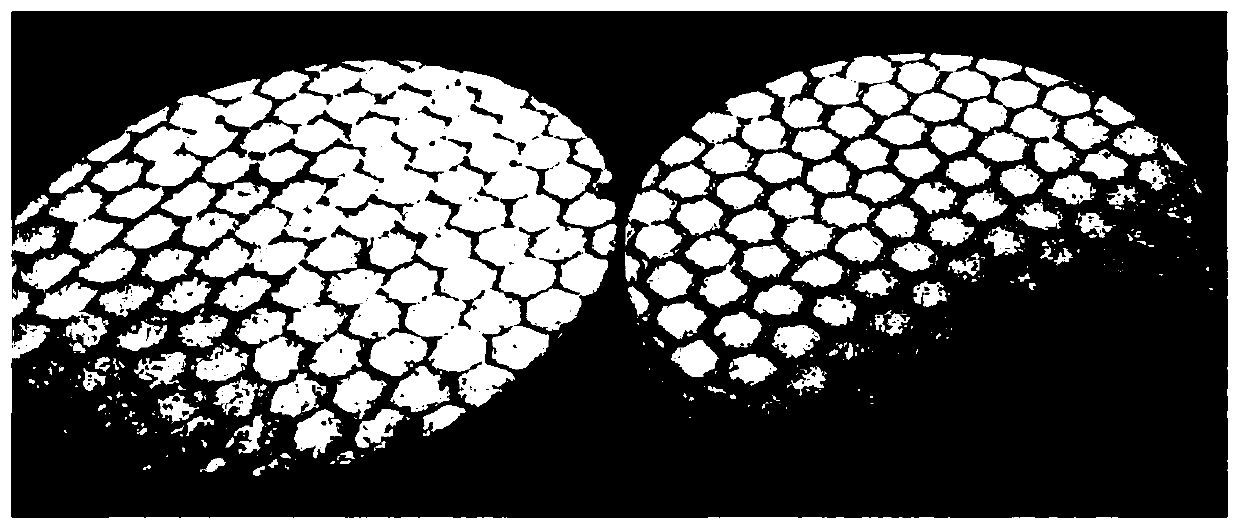

[0047] figure 1 It is a photo of the test sample of the honeycomb core material prepared in Examples 1 and 2 of the present invention. in figure 1 The sample on the right is the sample of embodiment 2.

[0048] The properties of the heat-insulating and sound-absorbing honeycomb core material prepared in this example are as follows:

[0049] The density of filled polyimide foam is 49kg / m 3 ;The opening degree is 53%;The density of the honeycomb core material is 97kg / m 3 ;The thermal conductivity is 0.051W / (m K); the starting frequency of the sound absorption coefficient greater than 0.2 is as low as 166Hz; the average sound absorptio...

Embodiment 3

[0051] Referring to Example 1, the difference between this example and Example 1 is that the weight of various raw materials for preparing foam slurry is half of that in Example 1, and the rest is the same as Example 1.

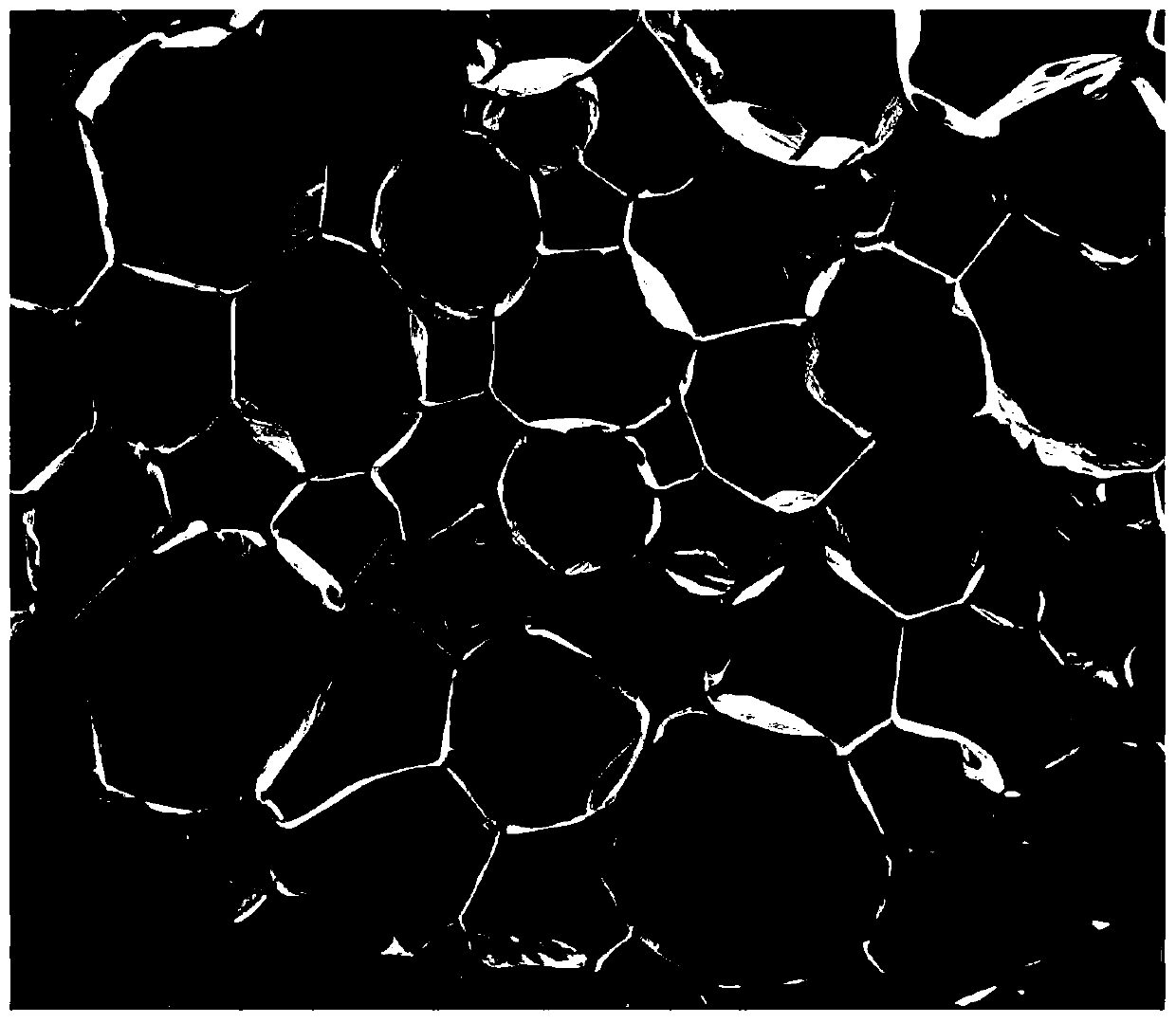

[0052] figure 2 It is a scanning electron micrograph of the polyimide foam in the honeycomb core material prepared in Example 3 of the present invention. From figure 2 The honeycomb structure of the polyimide foam can be seen.

[0053] The properties of the heat-insulating and sound-absorbing honeycomb core material prepared in this example are as follows:

[0054] The density of filled polyimide foam is 27kg / m 3 ; Opening 54%; Honeycomb core material density 75kg / m 3 ;The thermal conductivity is 0.050W / (m K); the starting frequency of the sound absorption coefficient greater than 0.2 is as low as 187Hz; the average sound absorption coefficient in the 100-1000Hz frequency band is 0.41, and the average sound absorption coefficient of each frequency point...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com