Preparation method and application of porous carbon material

A technology of porous carbon materials and products, which is applied in the field of preparation of porous carbon materials, can solve the problem that carbon materials are difficult to have a multi-level pore structure, and achieve the effects of good electrochemical performance, abundant raw material sources, and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

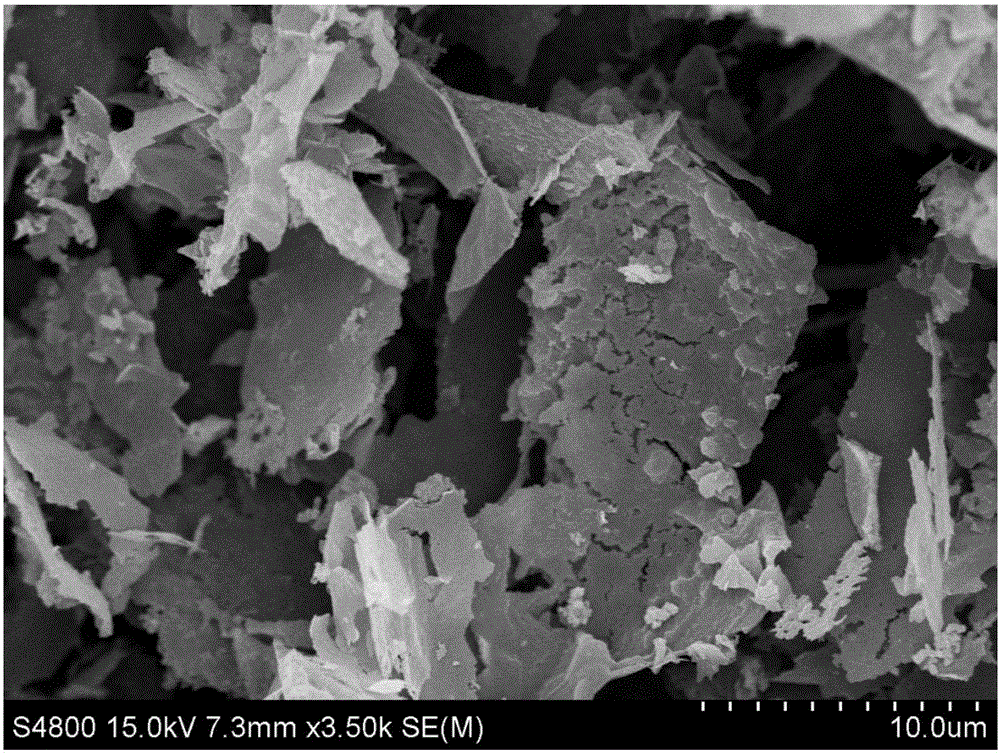

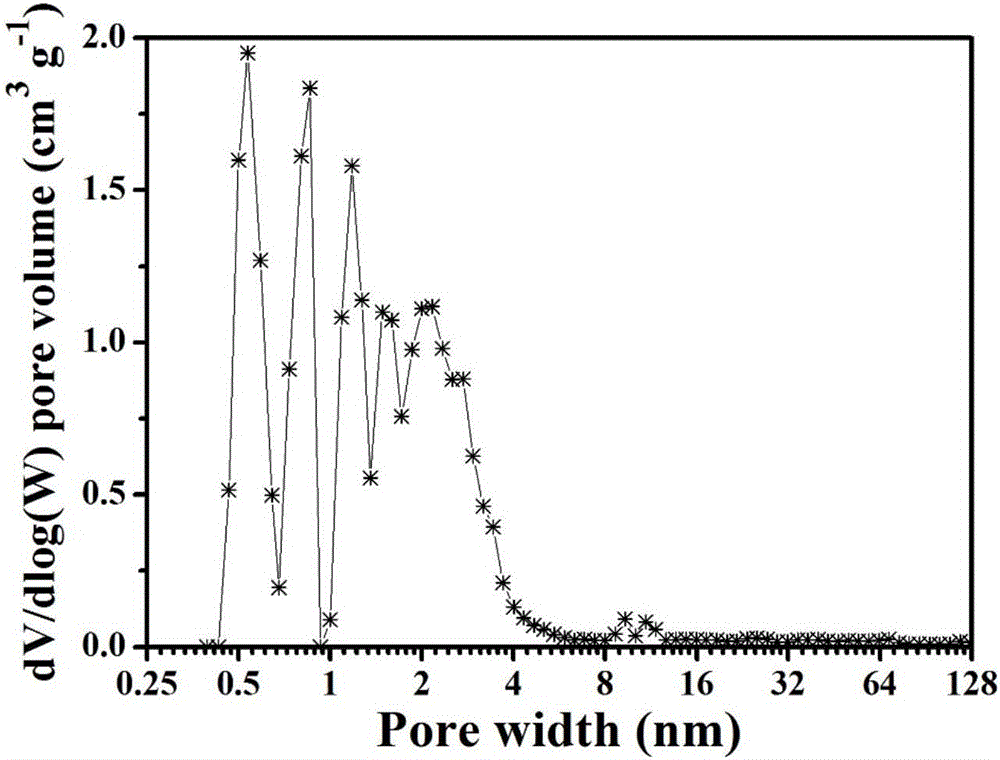

[0024] Weigh 10g of potassium acetate and put it in a nickel crucible, place it in a high temperature quartz tube furnace under the protection of Ar flow (gas flow rate is 40mL / min), raise the temperature to 800°C at a heating rate of 5°C / min, and maintain it for 1.5h Natural cooling, black composite carbon material is obtained after pyrolysis, and then an excess of 10% HNO is added 3 (v / v) solution, immerse the composite carbon material, set the rotating speed at 500r / min, magnetically stir for 3h, then wash with a large amount of deionized water until neutral, and vacuum dry at 80°C for 18h to obtain the porous carbon material.

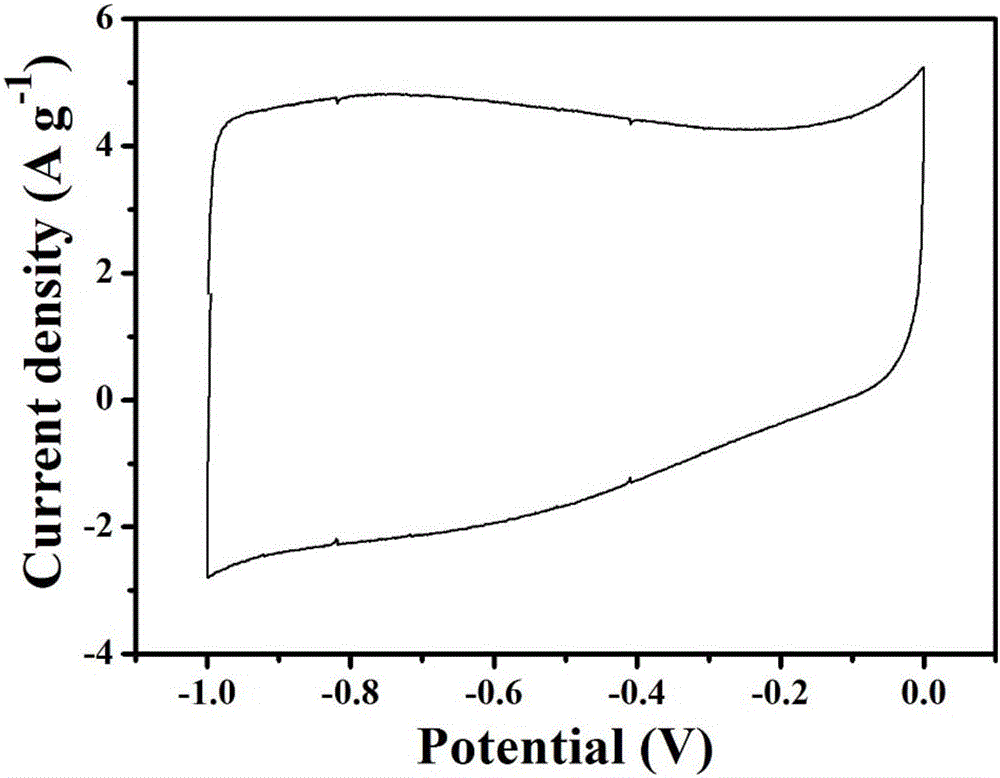

[0025] The test method to use it for supercapacitor electrode material is:

[0026] Firstly, the porous carbon material is ground into a powder with a particle size of less than 30 μm by an agate mortar, and the above-mentioned porous carbon, acetylene black and polyvinylidene fluoride (Poly(vinylidene fluoride), PVDF) are weighed according to a mas...

Embodiment 2

[0029] Weigh 10g of potassium acetate and put it in a nickel crucible, place it in a high temperature quartz tube furnace under N 2 Under the protection of air flow (gas flow rate is 20mL / min), the temperature was raised to 700°C at a heating rate of 3°C / min, kept for 3h, then cooled naturally, and a black composite carbon material was obtained after pyrolysis, and then an excess of 5% HCl was added (v / v) solution, immerse the composite carbon material, set the rotation speed at 1000r / min, magnetically stir for 2h, then wash with a large amount of deionized water until neutral, and vacuum dry at 60°C for 24h to obtain a porous carbon material.

[0030] It was used for electrochemical test, and the specific capacitance was 96.4F / g at a current density of 1A / g.

Embodiment 3

[0032] Weigh 10g of potassium acetate and put it in a nickel crucible, place it in a high temperature quartz tube furnace under N 2 Under the protection of air flow (gas flow rate of 100mL / min), the temperature was raised to 900°C at a heating rate of 8°C / min, maintained for 0.5h and then cooled naturally. After pyrolysis, a black composite carbon material was obtained, and then an excess of 7% HCl ( v / v) solution, immerse the composite carbon material, set the rotating speed to 200r / min, magnetically stir for 6h, then wash with a large amount of deionized water until neutral, and vacuum dry at 110°C for 6h to obtain a porous carbon material.

[0033] It was used for electrochemical test, and the specific capacitance was 102.9F / g at a current density of 1A / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com