Manufacturing method and application of nano-copper antibacterial and antiviral melt-blown cloth master batch

A manufacturing method and nano-copper technology are applied in the field of materials to achieve the effects of improving particle size and distribution, improving crystallinity and good bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

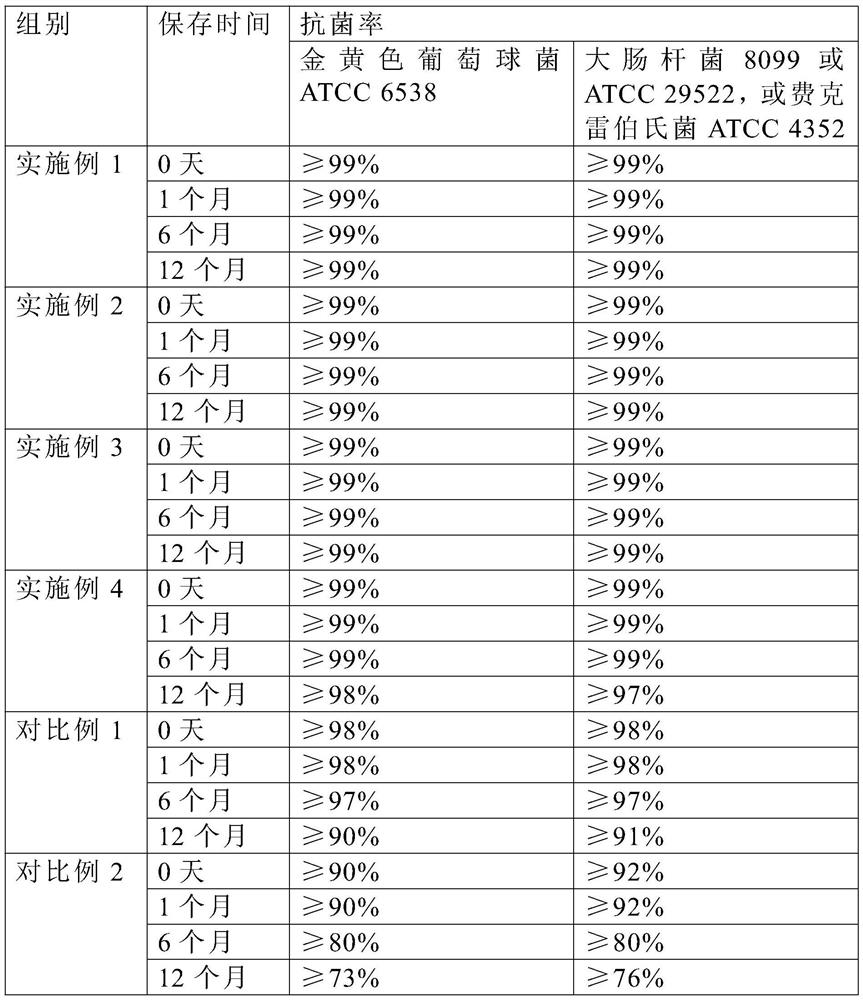

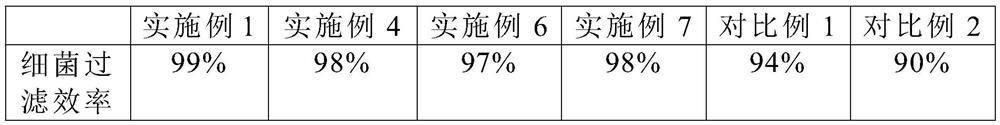

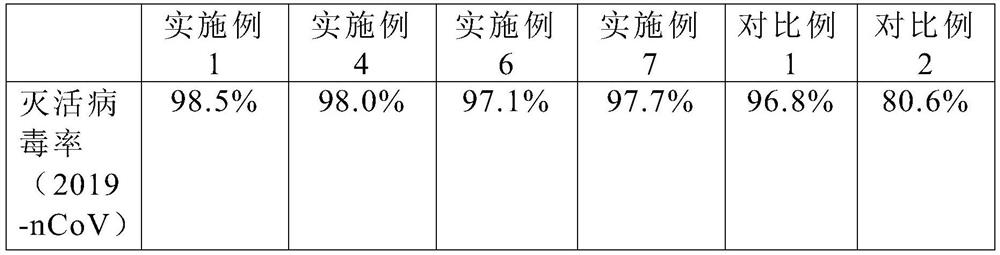

Examples

Embodiment 1

[0034] A method for manufacturing nano-copper antibacterial and antiviral melt-blown cloth masterbatch, comprising the following steps:

[0035] S1 Preparation of nano-copper

[0036] Copper powder is subjected to supersonic particle bombardment treatment with a supersonic particle bombardment device at an air velocity of 600-1000m / s. The microsphere structure diamond hexagonal crystal nano-copper with a particle size of 100-500nm and a positive charge is obtained by mechanical nano-milling.

[0037] S2 Preparation of nano-microcapsule-coated graphene composites

[0038] Mix 1 part by weight of graphene, 0.5 part by weight of microsphere structure diamond hexagonal crystal nano-copper, 0.1 part by weight of microporous silica and 3 parts by weight of polycyanopropenyl alkyl ester to obtain nano-microcapsules Graphene-coated composite material. Specifically as follows, S2-1 prepares graphene-loaded nano-copper particles

[0039] Disperse 1 part by weight of graphene in ethy...

Embodiment 2

[0062] This embodiment is basically the same as Embodiment 1, the difference is:

[0063] (1) In step S2

[0064] 1 part by weight of graphene, 1 part by weight of microsphere structure diamond hexagonal crystal nano-copper, 0.2 part by weight of microporous silicon dioxide and 10 parts by weight of polylactic acid are mixed and hybridized to obtain a nano-microcapsule-coated graphene composite material.

[0065] (2) In step S3-1

[0066] The nano-microcapsule-coated graphene composite material and the polypropylene material were prepared according to a weight ratio of 1:10.

Embodiment 3

[0068] This embodiment is basically the same as Embodiment 1, the difference is:

[0069] (1) In step S2

[0070] 1 part by weight of graphene, 0.8 part by weight of microsphere structure diamond hexagonal crystal nano-copper, 0.15 part by weight of microporous silica and 5 parts by weight of chitosan are mixed and hybridized to obtain a nano-microcapsule-coated graphene composite material .

[0071] (2) In step S3-1

[0072] The nano-microcapsule-coated graphene composite material and the polypropylene material are prepared according to a weight ratio of 1:6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com