Graphite/Cu alloy connector and preparation method thereof

A technology of alloy and graphite, which is applied in the field of graphite/Cu alloy joints and its preparation, can solve problems such as poor wettability, achieve enhanced compatibility, be beneficial to industrial applications, and have good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

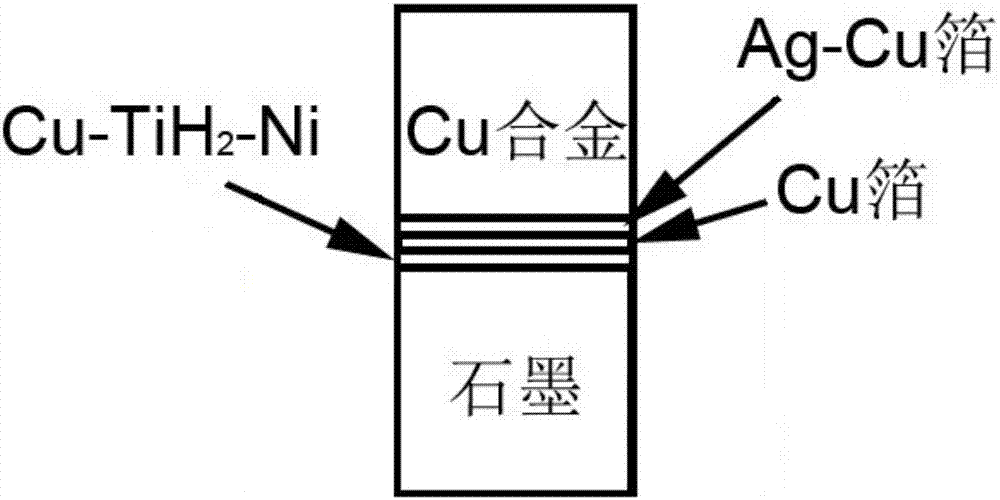

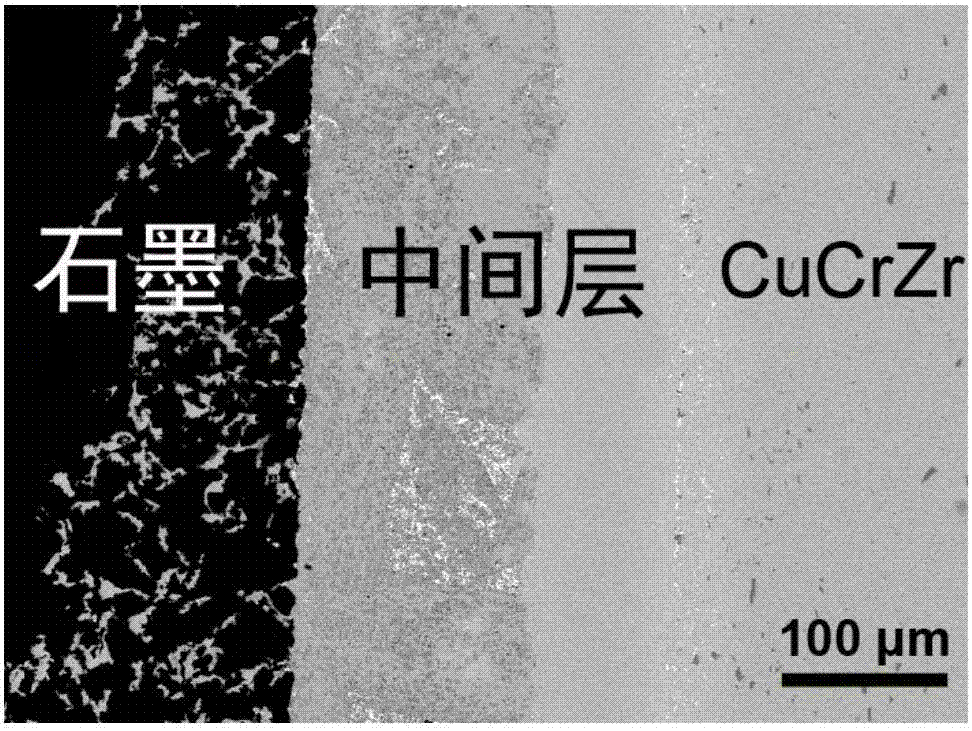

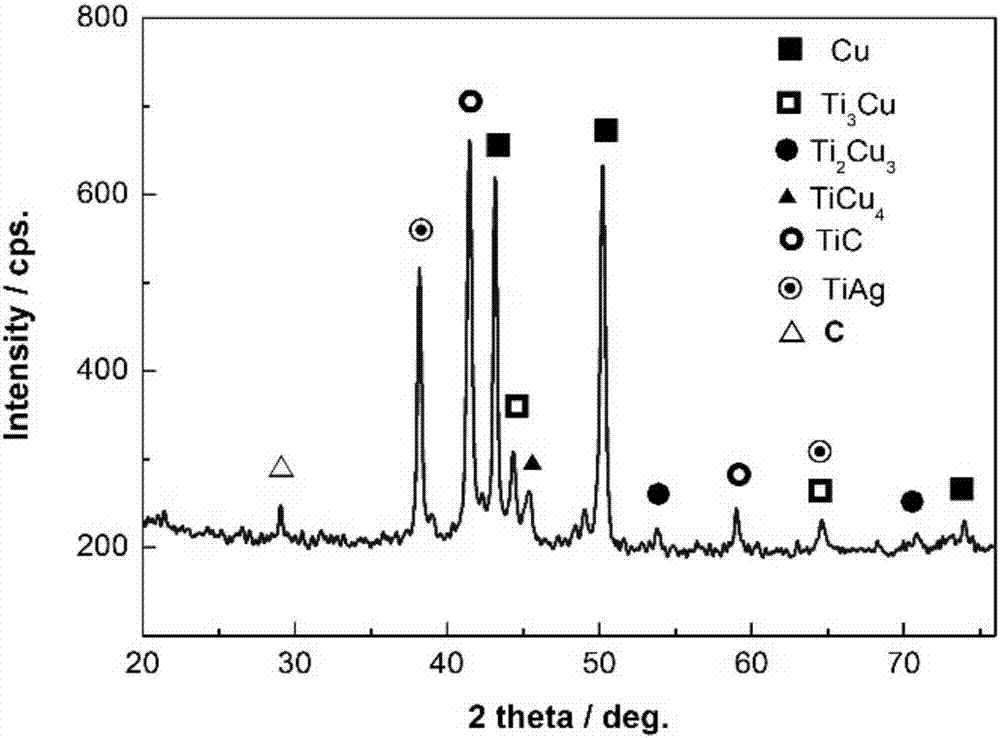

[0035] Using Cu-TiH 2 -Ni / Cu / Ag-Cu composite solder to prepare graphite / CuCrZr alloy joints, the specific steps are as follows:

[0036] 1. Weigh Cu and TiH with a mass ratio of 60:30:10 2 , Ni three powders, and mix them evenly, add alcohol and grind until the alcohol is completely volatilized, and Cu-TiH 2 -Ni mixed powder solder.

[0037] 2. Sand the Ag-Cu foil with a thickness of 100 μm (the mass percentage of Ag is 72%, and the mass percentage of Cu is 28%) and Cu foil with sandpaper to remove the oxide on the surface, and then put it into alcohol for ultrasonic Wash for 30 minutes.

[0038] 3. Grind the end faces of graphite and CuCrZr alloy to be connected step by step with metallographic sandpaper, then put them into an ultrasonic cleaning machine for cleaning for 30 minutes, and then dry them with a hair dryer for later use.

[0039] 4. Take an appropriate amount of Cu-TiH prepared in step 1 2 -Ni mixed powder solder, add a small amount of absolute ethanol and gl...

Embodiment 2

[0050] To prepare graphite / copper joints, the specific steps are as follows:

[0051] 1. Weigh Cu and TiH with a mass ratio of 70:22:8 2 , Ni three powders, and mix them evenly, add alcohol and grind until the alcohol is completely volatilized, and Cu-TiH 2 -Ni mixed powder solder.

[0052] 2. Sand the Ag-Cu foil with a thickness of 100 μm (the mass percentage of Ag is 72%, and the mass percentage of Cu is 28%) and Cu foil with sandpaper to remove the oxide on the surface, and then put it into alcohol for ultrasonic Wash for 30 minutes.

[0053] 3. Grind the end faces of graphite and copper to be connected step by step with metallographic sandpaper, then put them into an ultrasonic cleaning machine for cleaning for 30 minutes, and then dry them with a hair dryer for later use.

[0054] 4. Take an appropriate amount of Cu-TiH prepared in step 1 2 -Ni mixed powder solder, add a small amount of absolute ethanol and glycerol to make a viscous paste solder, then evenly coat the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com