Plating solution and method for chemically plating Ni-P on surface of carbon nano tube

A technology of carbon nanotubes and electroless plating, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems such as the inability to form Ni-P coating, achieve excellent economy, suppress excessive formation, Uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

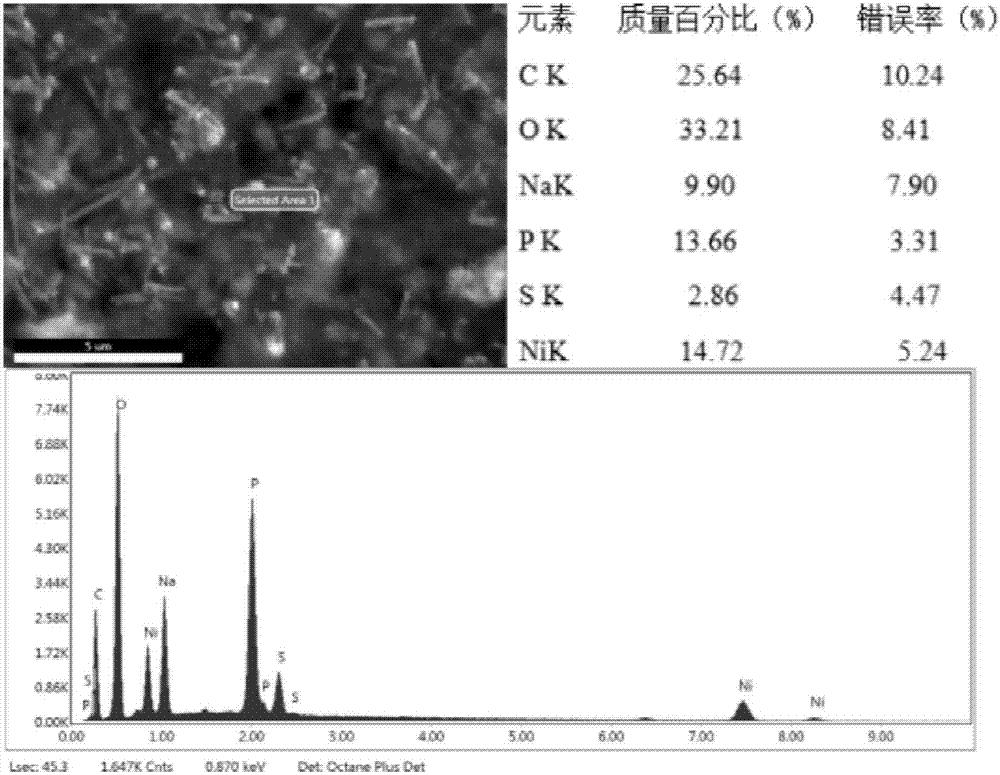

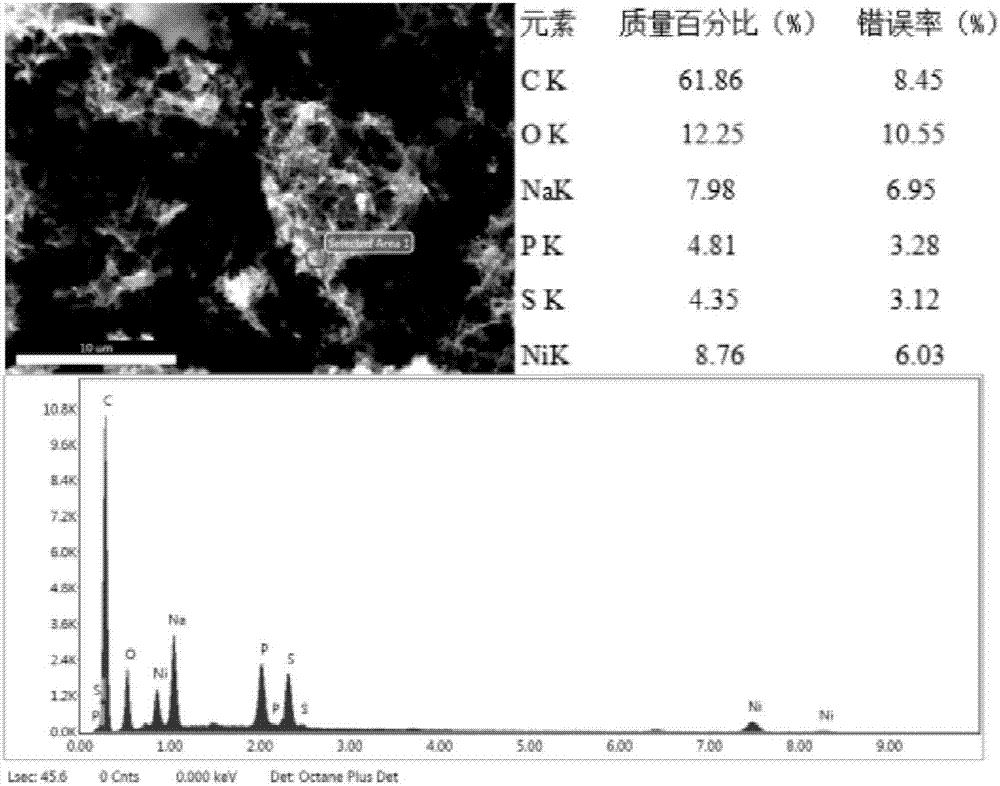

[0028] Such as figure 1 , 2 shown.

[0029] A method for chemically plating Ni-P on the surface of carbon nanotubes, the steps are as follows:

[0030] First, take 1 gram of carbon nanotube powder and dissolve it in 25 milliliters of absolute alcohol, then place it in NaOH solution for cleaning, and then place the sample in sulfuric acid solution for pickling. After washing for many times, the pH value is close to 7. Centrifugal filtration, drying, to be plated;

[0031] The carbon nanotubes are then placed in the following solution for plating:

[0032] Nickel Sulfate (NiSO 4 ·6H 2 O) 25g / L

[0033] Citric acid (C 6 h 8 o 7 ·H 2 O) 13g / L

[0034] Liquid lactic acid (C 3 h 6 o 3 ) 20mL / L

[0035] Anhydrous sodium acetate (CH 3 COONa) 12g / L

[0036] Sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 22g / L

[0037] Anhydrous alcohol (C 2 h 5 OH) 100mL / L

[0038] Deionized water balance.

[0039] The process of configuring the solution is to put a certain amount of...

Embodiment 2

[0048] A method for chemically plating Ni-P on the surface of carbon nanotubes, the steps are as follows:

[0049] First, take 1 gram of carbon nanotube powder and dissolve it in 25 milliliters of absolute alcohol, then place it in NaOH solution for cleaning, and then place the sample in sulfuric acid solution for pickling. After washing for many times, the pH value is close to 7. Centrifugal filtration, drying, to be plated;

[0050] The carbon nanotubes are then placed in the following solution for plating:

[0051] Nickel Sulfate (NiSO 4 ·6H 2 O) 18g / L

[0052]Citric acid (C 6 h 8 o 7 ·H 2 O) 10g / L

[0053] Liquid lactic acid (C 3 h 6 o 3 ) 25mL / L

[0054] Anhydrous sodium acetate (CH 3 COONa) 8g / L

[0055] Sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 30g / L

[0056] Anhydrous alcohol (C 2 h 5 OH) 120mL / L

[0057] Deionized water balance.

[0058] The process of configuring the solution is to put a certain amount of distilled water (deionized water) in the ...

Embodiment 3

[0062] A method for chemically plating Ni-P on the surface of carbon nanotubes, the steps are as follows:

[0063] First, take 1 gram of carbon nanotube powder and dissolve it in 25 milliliters of absolute alcohol, then place it in NaOH solution for cleaning, and then place the sample in sulfuric acid solution for pickling. After washing for many times, the pH value is close to 7. Centrifugal filtration, drying, to be plated;

[0064] Then place the carbon nanotubes into the following solution for plating:

[0065] Nickel Sulfate (NiSO 4 ·6H 2 O) 34g / L

[0066] Citric acid (C 6 h 8 o 7 ·H 2 O) 20g / L

[0067] Liquid lactic acid (C 3 h 6 o 3 ) 15mL / L

[0068] Anhydrous sodium acetate (CH 3 COONa) 16g / L

[0069] Sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 20g / L

[0070] Anhydrous alcohol (C 2 h 5 OH) 80mL / L

[0071] Deionized water balance.

[0072] The process of configuring the solution is to put a certain amount of distilled water (deionized water) in the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com