Alloy electrode suitable for Cu<2>SnSe<3>-based thermoelectric element and preparation technology of thermoelectric element

A technology of alloy electrode and preparation process, which is applied in the manufacture/processing of thermoelectric devices, parts and components of thermoelectric devices, etc. It can solve the problems of inapplicable electrodes and connection technology, large heat loss and electrical loss, and affecting the performance of thermoelectric elements, etc., to achieve The effect of easy control of process parameters, good connection and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

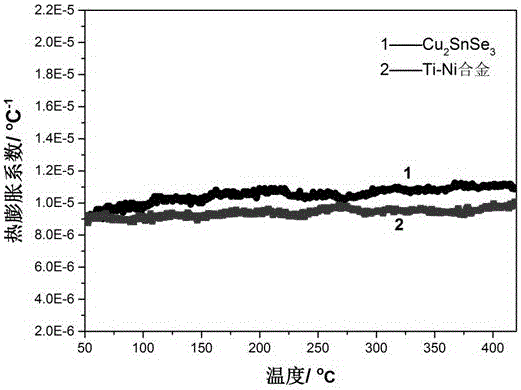

[0032] Cu 2 SnSe 3 Based thermoelectric element, the alloy electrode is Ti-Ni alloy (containing Ni15%, Ti85%), the preparation method is as follows:

[0033] Select the electrode sheet with a thickness of 0.2mm Ti-Ni alloy to perform sandblasting treatment to make the surface roughness Ra of both sides approximately 1.0-2.0μm, then put it in alcohol for ultrasonic treatment for 10 minutes, and dry the Ti-Ni alloy The electrode sheet is placed in a graphite mold; the surface of the electrode is evenly spread with a particle size of 400-500 mesh Cu 2 SnSe 3 Powder, of which Cu 2 SnSe 3 The powder is prepared by ball milling in an argon atmosphere, the ball-to-battery ratio is 12:1, the rotating speed is 300 rpm, and the ball milling time is 24 hours (1 hour for each forward ball mill, 15 minutes of stopping interval, and then reverse Ball milling for 1 hour, stopping at 15 minutes interval, cyclically, the total ball milling time is 24 hours); then, Cu is prepared by rapid hot press...

Embodiment 2

[0036] Cu 2 SnSe 3 Based thermoelectric element, the alloy electrode is Ti-Ni alloy (containing Ni18%, Ti82%), the preparation method is as follows:

[0037] Select a Ti-Ni alloy electrode sheet with a thickness of 2mm to perform sandblasting treatment to make the surface roughness Ra on both sides approximately 1.0-2.0μm, and then put it in alcohol for ultrasonic treatment for 10 minutes, and dry the Ti-Ni alloy The electrode sheet is placed in a graphite mold; the surface of the electrode is evenly spread with a particle size of 400-500 mesh Cu 2 SnSe 3 Powder, of which Cu 2 SnSe 3 The powder is prepared by planetary ball milling under the protection of argon gas. The ball-to-battery ratio is 12:1, the rotating speed is 300 rpm, and the ball milling time is 24 hours (the ball milling method is the same as in Example 1); then it is used under vacuum Preparation of Cu by rapid hot pressing sintering 2 SnSe 3 Based on thermoelectric elements, the sintering temperature for rapid hot...

Embodiment 3

[0040] Cu 2 SnSe 3 Based thermoelectric element, the alloy electrode is Ti-Ni alloy (containing Ni15%, Ti85%), the preparation method is as follows:

[0041] Select a Ti-Ni alloy electrode sheet (containing 15% Ni) with a thickness of 1.0mm, and the treatment process is the same as that in Example 1. Place it in a graphite mold, and spread 400-500 mesh Cu uniformly on the electrode surface 2 SnSe 3 Powder, of which Cu 2 SnSe 3 The preparation process of the powder is the same as in Example 1, and then the Cu is prepared by rapid hot pressing sintering under vacuum conditions 2 SnSe 3 Based on thermoelectric elements, the sintering temperature for rapid hot press sintering is 550°C, the sintering pressure is 55MPa, the pressure is applied at 350°C, the vacuum degree is 5Pa, the heating rate is 90°C / min, and the heat preservation time is 15min.

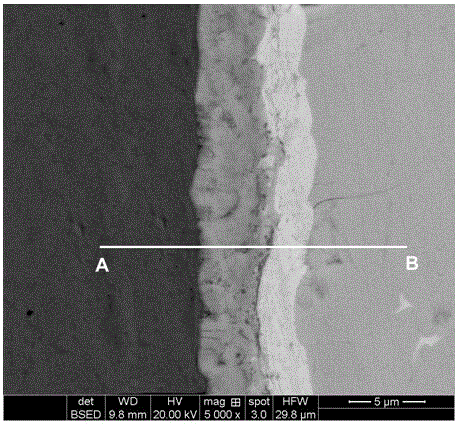

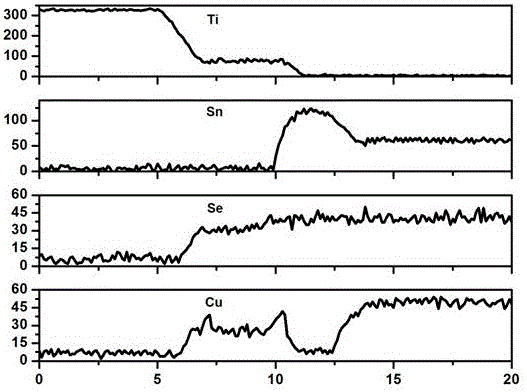

[0042] Ti-Ni electrode / Cu obtained 2 SnSe 3 The thermoelectric element is observed by scanning electron microscope, the interface is well bon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com