Method for recycling CBN (Cubic Boron Nitride) abrasive from waste product obtained by producing ceramic bonding agent CBN grinding wheel

A vitrified bond and grinding wheel technology, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of difficulty in recycling CBN abrasives, high strength and chemical stability, and achieve uniform structure and good bonding of grinding wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

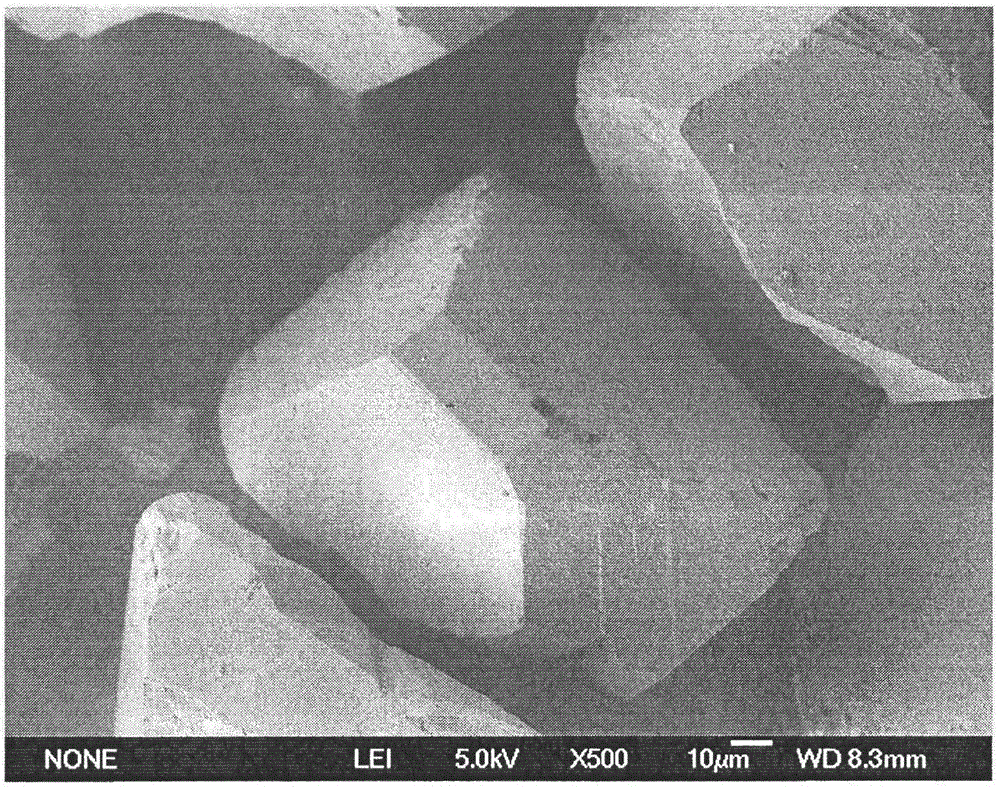

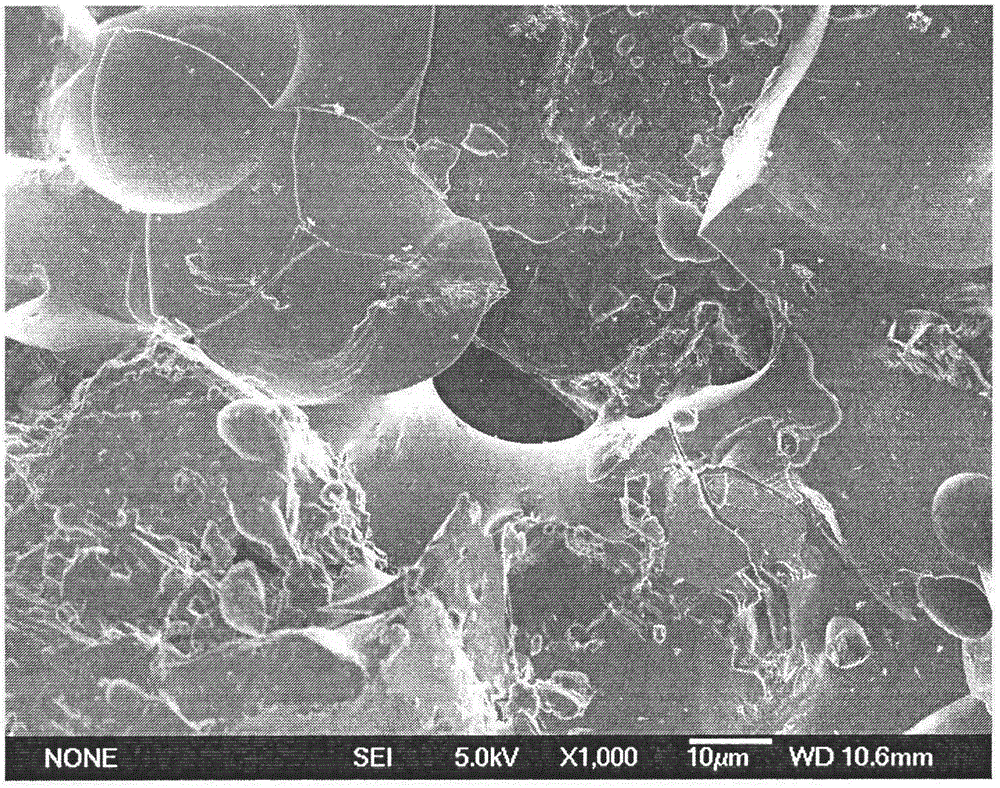

[0014] The specific steps for recovering the CBN abrasive in the vitrified bond CBN grinding wheel are:

[0015] (1) Put the waste CBN grinding wheel into the electric furnace, raise the temperature to 500°C at a heating rate of 5°C / min in the air atmosphere, and keep it at 500°C for 1.5 hours. After the furnace is closed, the grinding wheel is cooled with the furnace. When the temperature is below 60°C, the grinding wheel is taken out from the furnace, and the working layer of the grinding wheel is peeled off from the metal substrate to obtain the working layer of the CBN grinding wheel.

[0016] (2) Soak the CBN grinding wheel working layer obtained in step (1) in absolute ethanol, clean the CBN working layer for 1 hour with an ultrasonic frequency of 60KHZ, and then put the CBN working layer into an electric furnace at a heating rate of 3 Raise the temperature to 550°C at a rate of °C / min, keep the temperature at 550°C for 0.5 hours, open the furnace, take out the CBN worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com