A kind of phase change temperature regulating fiber blended yarn

A technology of temperature-regulating fibers and blended yarns, which is applied in the directions of fiber processing, fiber chemical characteristics, and yarns, can solve the problems of unsatisfactory moisture absorption and air permeability, poor temperature-regulating effect, and low mechanical strength, and achieves improved degradability. , good flexibility, avoid the effect of agglomeration and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

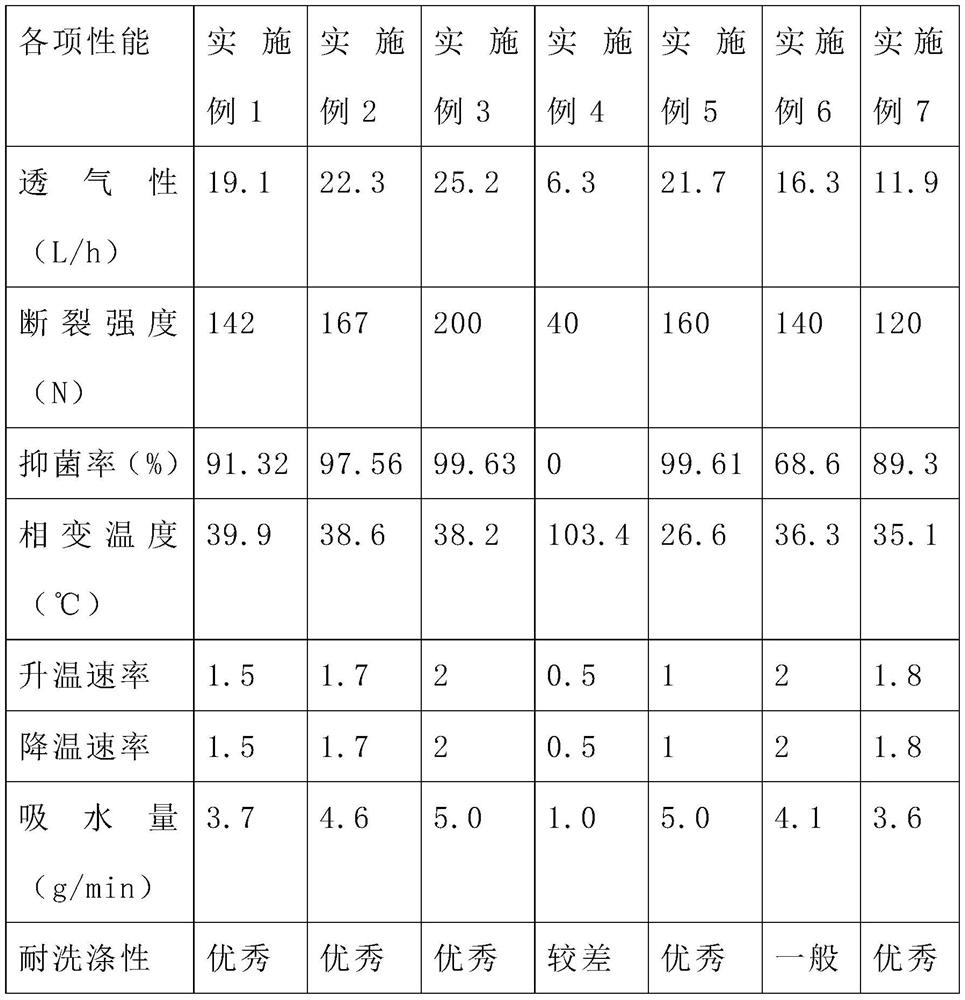

Examples

Embodiment 1

[0047] S1. Preparation of spinning stock solution and related raw materials:

[0048] S2, preparation of phase-change thermoregulation microcapsules:

[0049] Mix paraffin, alkane, superfine iron powder, graphite powder, emulsifier A and add deionized water, keep the constant temperature at 60°C, and disperse at a high speed at 3000r / min; then slowly add 10% citric acid solution to adjust the pH value 3. React for 3 hours, and when the temperature drops to 60°C, emulsion A is obtained;

[0050] Add methyl-2,4-diisocyanate, diethylenetriamine and catalyst to emulsion A, continue to maintain a constant temperature of 60°C, and slowly add piperazine and emulsifier B dropwise, and emulsify at a high speed at 3000r / min. Continue constant temperature for 1h to obtain the phase change thermoregulation microcapsules;

[0051] S3, preparation of modified nano-silver hydrogel:

[0052] Preparation of gel wall: Mix F127 and F68 evenly, slowly add ethylparaben solution while stirring, ...

Embodiment 2

[0065] S1. Preparation of spinning stock solution and related raw materials:

[0066] S2, preparation of phase-change thermoregulation microcapsules:

[0067] Mix paraffin, alkane, superfine iron powder, graphite powder, emulsifier A and add deionized water, keep the constant temperature at 65°C, and disperse at a high speed at 3000r / min; then slowly add 10% citric acid solution to adjust the pH value 4. React for 3 hours, and when the temperature drops to 63°C, emulsion A is obtained;

[0068] Add methyl-2,4-diisocyanate, diethylenetriamine and catalyst to emulsion A, continue to maintain a constant temperature of 63°C, and slowly add piperazine and emulsifier B dropwise, and emulsify at a high speed at 3000r / min. Continue constant temperature for 1.2h to obtain the phase change thermoregulation microcapsules;

[0069] S3, preparation of modified nano-silver hydrogel:

[0070] Preparation of the gel wall: Mix F127 and F68 evenly, slowly add ethylparaben solution while stir...

Embodiment 3

[0083] S1. Preparation of spinning stock solution and related raw materials:

[0084] S2, preparation of phase-change thermoregulation microcapsules:

[0085]Mix paraffin, alkane, superfine iron powder, graphite powder, emulsifier A and add deionized water, keep the constant temperature at 70°C, and disperse at a high speed at 3000r / min; then slowly add 10% citric acid solution to adjust the pH value 5. React for 3 hours, and when the temperature drops to 65°C, emulsion A is obtained;

[0086] Add methyl-2,4-diisocyanate, diethylenetriamine and catalyst to emulsion A, continue to maintain a constant temperature of 65°C, and slowly add piperazine and emulsifier B dropwise, and emulsify at a high speed at 3000r / min. Continue constant temperature for 1.5h to obtain the phase change thermoregulation microcapsules;

[0087] S3, preparation of modified nano-silver hydrogel:

[0088] Preparation of gel wall: Mix F127 and F68 evenly, slowly add ethylparaben solution while stirring,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com