Phase-change temperature-regulating fiber blended yarn

A technology of blended yarn and temperature-regulating fiber, which is applied in fiber treatment, fiber chemical characteristics, yarn, etc., can solve problems such as unsatisfactory moisture absorption and air permeability, poor temperature-regulating effect, and low mechanical strength, so as to improve biocompatibility Good stability and degradability, avoiding agglomeration and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

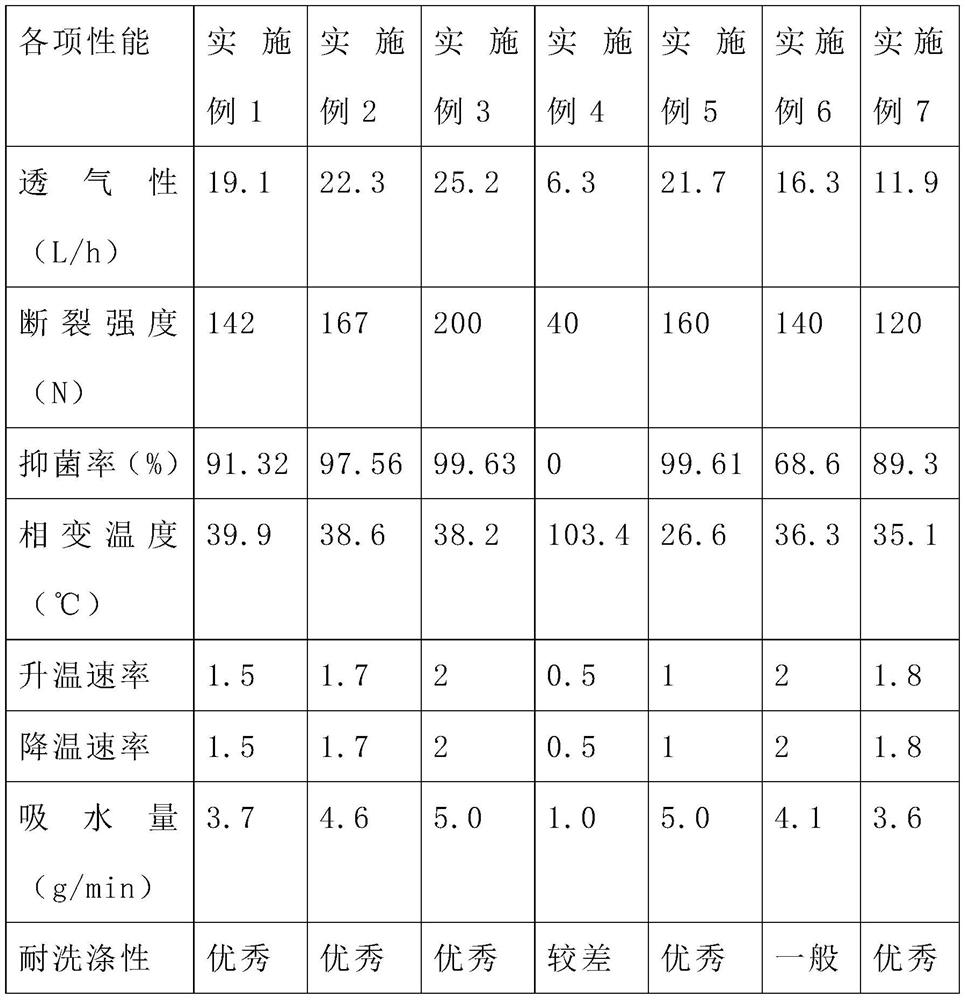

Examples

Embodiment 1

[0047] S1. Preparation of spinning stock solution and related raw materials:

[0048] S2, preparation of phase-change thermoregulation microcapsules:

[0049] Mix paraffin, alkane, superfine iron powder, graphite powder, emulsifier A and add deionized water, keep the constant temperature at 60°C, and disperse at a high speed at 3000r / min; then slowly add 10% citric acid solution to adjust the pH value 3. React for 3 hours, and when the temperature drops to 60°C, emulsion A is obtained;

[0050] Add methyl-2,4-diisocyanate, diethylenetriamine and catalyst to emulsion A, continue to maintain a constant temperature of 60°C, and slowly add piperazine and emulsifier B dropwise, and emulsify at a high speed at 3000r / min. Continue constant temperature for 1h to obtain the phase change thermoregulation microcapsules;

[0051] S3, preparation of modified nano-silver hydrogel:

[0052] Preparation of gel wall: Mix F127 and F68 evenly, slowly add ethylparaben solution while stirring, ...

Embodiment 2

[0065] S1. Preparation of spinning stock solution and related raw materials:

[0066] S2, preparation of phase-change thermoregulation microcapsules:

[0067] Mix paraffin, alkane, superfine iron powder, graphite powder, emulsifier A and add deionized water, keep the constant temperature at 65°C, and disperse at a high speed at 3000r / min; then slowly add 10% citric acid solution to adjust the pH value 4. React for 3 hours, and when the temperature drops to 63°C, emulsion A is obtained;

[0068] Add methyl-2,4-diisocyanate, diethylenetriamine and catalyst to emulsion A, continue to maintain a constant temperature of 63°C, and slowly add piperazine and emulsifier B dropwise, and emulsify at a high speed at 3000r / min. Continue constant temperature for 1.2h to obtain the phase change thermoregulation microcapsules;

[0069] S3, preparation of modified nano-silver hydrogel:

[0070] Preparation of the gel wall: Mix F127 and F68 evenly, slowly add ethylparaben solution while stir...

Embodiment 3

[0083] S1. Preparation of spinning stock solution and related raw materials:

[0084] S2, preparation of phase-change thermoregulation microcapsules:

[0085]Mix paraffin, alkane, superfine iron powder, graphite powder, emulsifier A and add deionized water, keep the constant temperature at 70°C, and disperse at a high speed at 3000r / min; then slowly add 10% citric acid solution to adjust the pH value 5. React for 3 hours, and when the temperature drops to 65°C, emulsion A is obtained;

[0086] Add methyl-2,4-diisocyanate, diethylenetriamine and catalyst to emulsion A, continue to maintain a constant temperature of 65°C, and slowly add piperazine and emulsifier B dropwise, and emulsify at a high speed at 3000r / min. Continue constant temperature for 1.5h to obtain the phase change thermoregulation microcapsules;

[0087] S3, preparation of modified nano-silver hydrogel:

[0088] Preparation of gel wall: Mix F127 and F68 evenly, slowly add ethylparaben solution while stirring,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com