Patents

Literature

59results about How to "Generation and elimination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel method for reducing generation of malodorous gases in breeding farm

ActiveCN106268287AGood deodorizing effectImprove the governance areaSpecific water treatment objectivesWaste water treatment from animal husbandryLivestockChinese herbs

The invention discloses a novel method for reducing generation of malodorous gases in a breeding farm. The method has the advantages of being simple in production, low in using cost, significant in effect and the like and is beneficial for solving the present existing pig breeding environment pollution problem. The method has the advantages that the synergistic effect of compound Chinese herbs and probiotic fermentation and the strong adsorption effect of an adsorbent are fully utilized, more than 10 kinds of malodorous gases such as NH3, H2S and CH4 in the breeding farm can be effectively removed, and the deodorant effect is good; by adopting the mode of combining a solid deodorant with a liquid deodorant, not only can the control area be increased through the liquid deodorant, but also major control can be conducted on a serious contaminated region through the solid deodorant, and both effectiveness and convenience are achieved; the deodorants are high in infiltration capacity, and therefore the defect that traditional deodorants cannot make full contact with livestock and poultry manure due to the fact that the traditional deodorants are poor in permeability is overcome; the safety is higher, the effect can be continuously achieved for a long time, the maintaining capability is good, and no bad influence is caused to microbial activities in the breeding farm.

Owner:裕龙农牧科技股份有限公司

Exposed concrete pumping agent and preparation method thereof

The invention relates to the field of building materials and discloses an exposed concrete pumping agent and a preparation method thereof. The exposed concrete pumping agent comprises the following raw materials by weight percent: 30%-50% of sulfamate superplasticizer, 0.1%-0.5% of defoaming agent, 1.0%-3.0% of retarder, 0.02%-0.08% of water retaining agent and the balance of water. The preparation method comprises the following steps: after various raw materials are weighed according to weight percent, mixing and stirring the sulfamate superplasticizer, retarder and water retaining agent for30 minutes; and then adding the defoaming agent to stir for 2 hours so as to obtain the exposed concrete pumping agent. By using the exposed concrete pumping agent, the surface of the prepared concrete is smooth and has no honeycomb, pitting skin, holes, stress marks and pollution, and simultaneously the workability and flowability of the exposed concrete can be effectively improved, thus the exposed concrete pumping agent can be widely applied to building elevation decorations such as bridges, houses and the like.

Owner:安徽海螺材料科技股份有限公司

High-chromium alloy wear-proof ball

ActiveCN104141089AImprove performanceImprove liquidityFurnace typesSuperimposed coating processFerrosiliconScrap

The invention discloses a high-chromium alloy wear-proof ball. Raw materials of the high-chromium alloy wear-proof ball comprise, by weight, 70-100 parts of steel scrap, 5-10 parts of ferrochromium, 1-1.5 parts of ferromolybdenum, 1-1.3 parts of ferrovanadium, 0.1-0.3 parts of ferrovanadium, 0.2-0.6 parts of ferrosilicon and 2-5 parts of zinc. The surface of the high-chromium alloy wear-proof ball high-chromium alloy wear-proof ball is processed through the high-frequency induction fusion covering technology and the electric spark deposition technology. The high-frequency induction fusion covering technology comprises the following steps that the vacuum degree is adjusted to be 50-80 Pa, high-frequency induction fusion covering equipment is turned on, the current rises from 500-550 A to 1650-1720 A within 50-80 seconds, heat preservation is carried out for 50-120 s, the current drops to 500-550 A within 30-40 seconds, the high-frequency induction fusion covering equipment is turned off, and cooling is carried out. The electric spark deposition technical parameters comprise the hydrogen flow of 3-7 m<3> / h, the deposition voltage of 150-200V, the deposition frequency of 1450-1560 Hz, the deposition power of 2000-2500 W, the deposition time of 5-6 min / cm<2> and the revolving speed of a rotary deposition gun of 1800-2200 r / min. The high-chromium alloy wear-proof ball is excellent in impact strength, rigidity, heat resistance and wear resistance.

Owner:宁国市宁武新材料科技有限公司

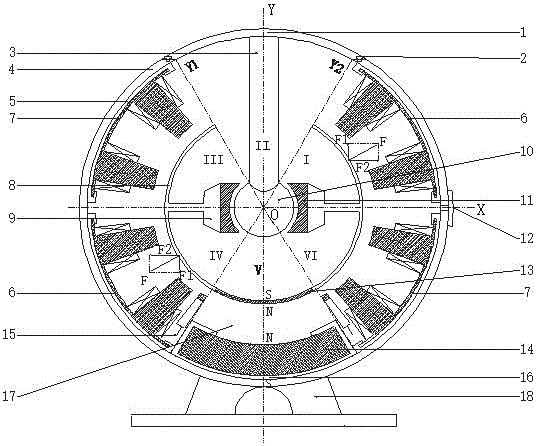

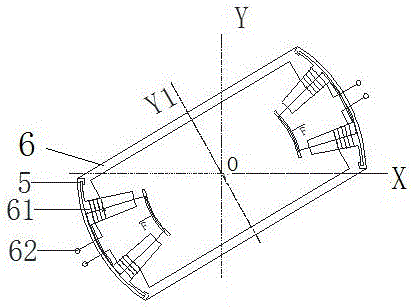

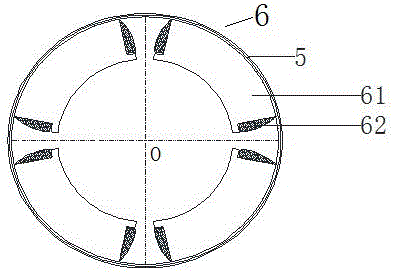

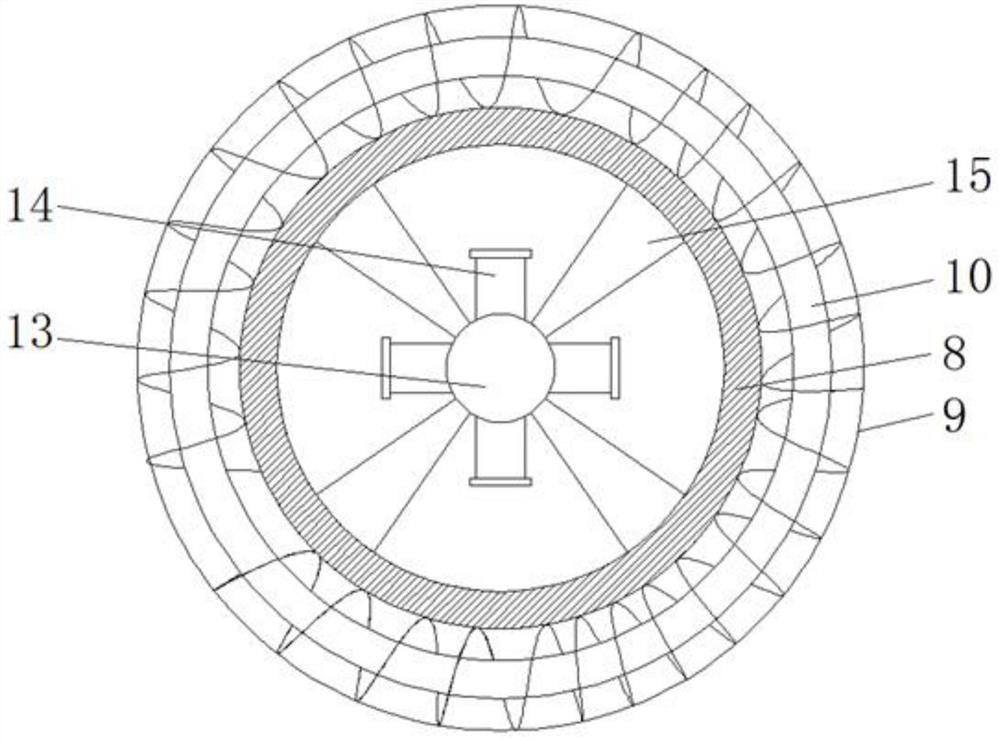

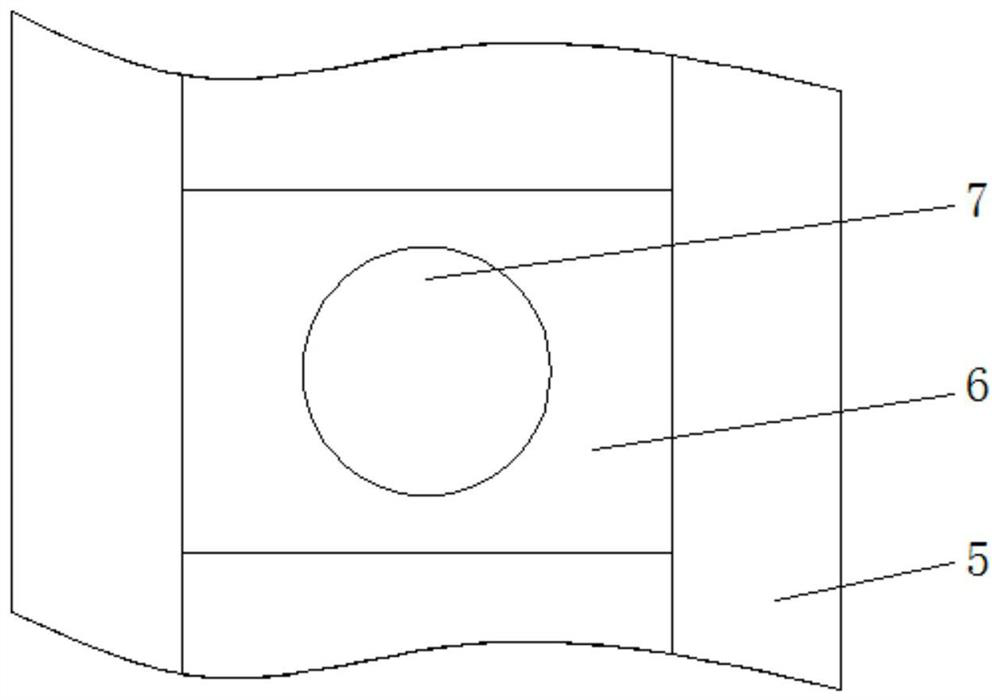

Spherical electric vehicle magnetic suspension flywheel battery

ActiveCN106602788AEliminate lossesSuspension stabilityElectric machinesMechanical energy handlingFriction lossElectrical battery

The invention discloses a spherical electric vehicle magnetic suspension flywheel battery; an inner housing, a spherical stator, a spherical cavity rotor, two permanent magnets and two magnetic suspension spherical surface bearings are arranged in a vacuum cavity; the spherical stator is arranged in the right center of the flywheel housing; the spherical cavity rotor is arranged outside the spherical stator; the spherical cap shape inner housing having the same spherical core is arranged outside the spherical cavity rotor; the bottom opening of the inner housing is seamlessly fixedly connected with the first permanent magnet in a spherical cap shape; the inner housing and the spherical cavity rotor are fixedly connected through a rotor connector; the second permanent magnet in the spherical cap shape is arranged right below the first permanent magnet, and fixedly connected on the inner surface of the flywheel housing; the two magnetic suspension spherical surface bearings are arranged between the flywheel housing and the inner housing, fixedly connected on the inner wall of the flywheel housing, and two central shafts thereof are intersected. The spherical electric vehicle magnetic suspension flywheel battery can eliminate air friction losses on the flywheel, and can increase the gyro control moment scope, thus inhibiting the flywheel gyroscopic effect.

Owner:JIANGSU UNIV

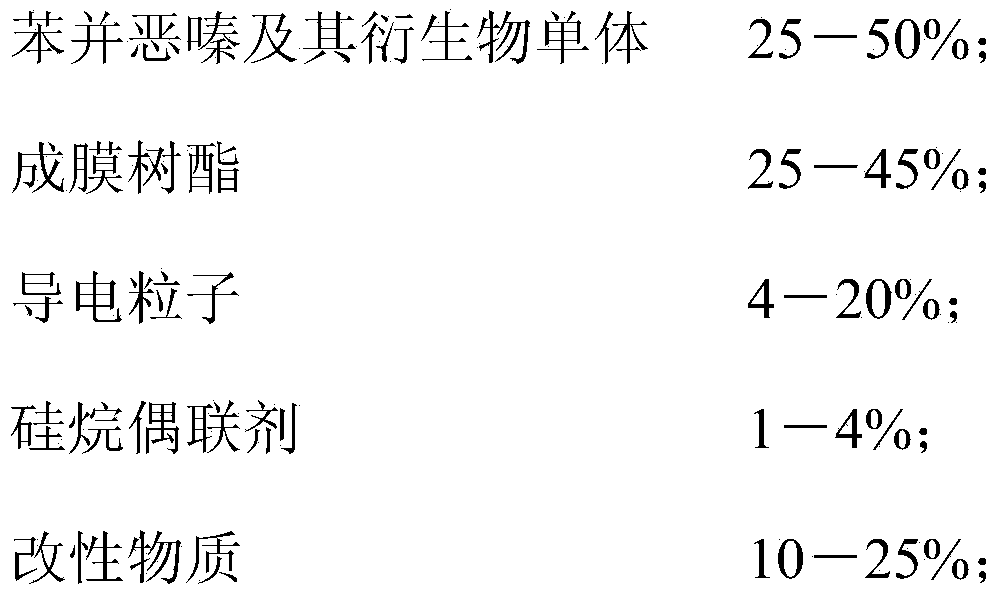

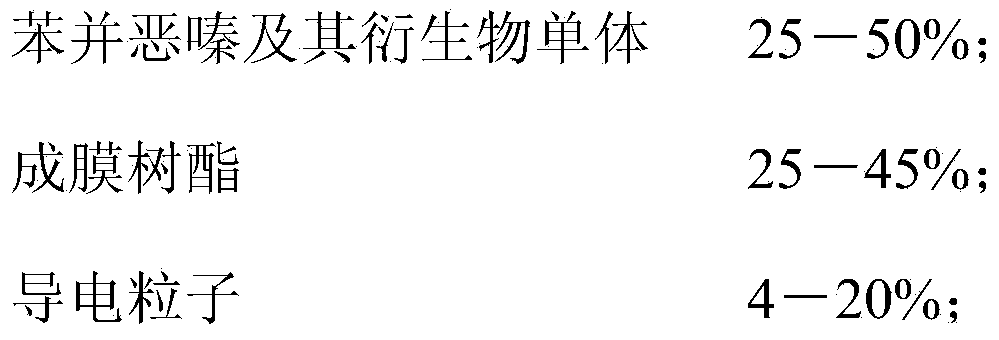

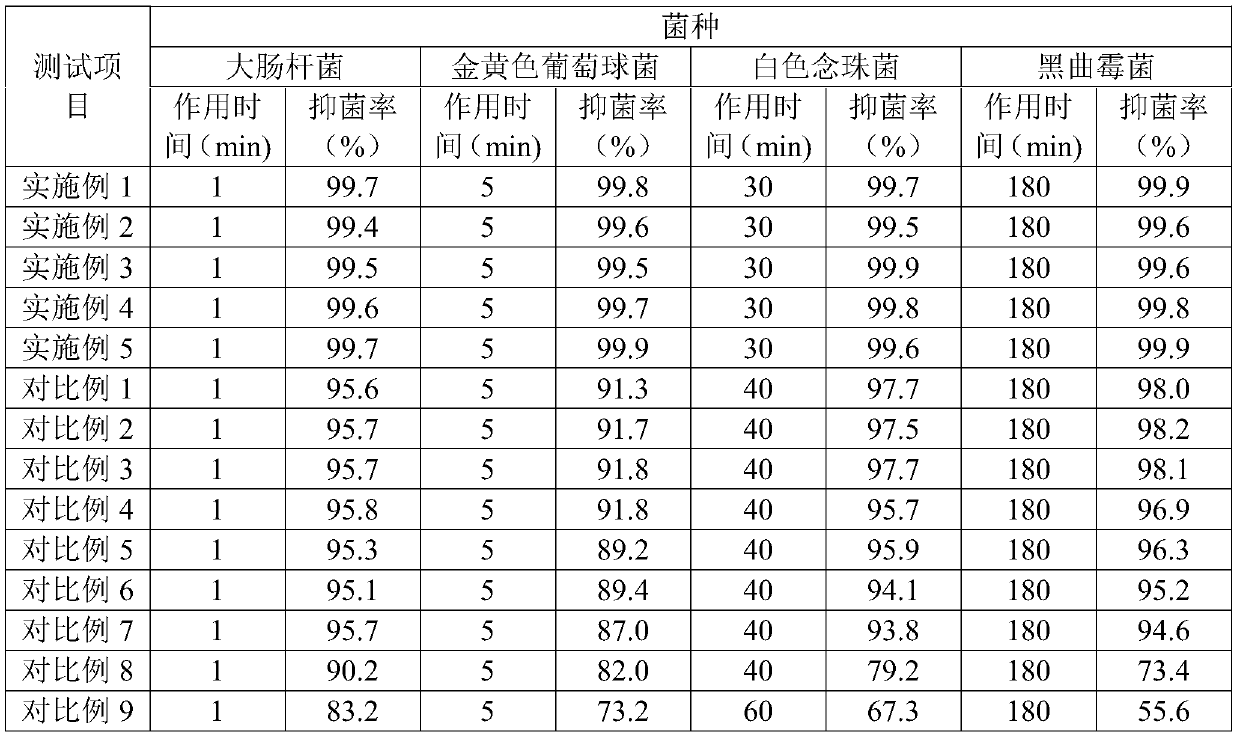

Anisotropic conductive film containing benzoxazine and preparation method of anisotropic conductive film

InactiveCN104312471AEliminate subsequent adverse effectsEliminate unsafe effectsNon-macromolecular adhesive additivesFilm/foil adhesivesAnisotropic conductive filmPorosity

The invention relates to an anisotropic conductive film containing benzoxazine. The anisotropic conductive film comprises a flexible base material and an anisotropic conductive adhesive layer, wherein the anisotropic conductive adhesive layer is prepared by coating anisotropic conductive adhesive on the flexible base material through drying; the anisotropic conductive adhesive consists of the following components in percentage by mass: 25-50% of benzoxazine and derivative monomers thereof, 25-45% of film-forming resin, 4-20% of conductive particles, 1-4% of silane coupling agent and 10-25% of modified materials; the benzoxazine and derivative monomers thereof comprise one or the mixture of more in the following materials: dihydric phenol benzoxazine and derivatives thereof, diamine benzoxazine and derivatives thereof, naphthol benzoxazine and derivatives thereof, benzoxazine with unsaturated bonds and derivatives thereof, silicon-containing benzoxazine and derivatives thereof. The anisotropic conductive film is good in condensate compactness, small in shrinkage factor, small in coefficient of thermal expansion, low in porosity, small in internal stress, high in temperature resistance and moisture resistance, and suitable for electronic equipment used under high temperature and humidity conditions.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Medium chrome multi-component alloy wear-resistant ball

ActiveCN104109794AImprove corrosion resistanceHigh hardnessFurnace typesMetallic material coating processesWear resistantPore water pressure

The invention discloses a medium chrome multi-component alloy wear-resistant ball. The medium chrome multi-component alloy wear-resistant ball comprises the following components of steel scrap, ferrochrome, ferromolybdenum, ferrovanadium, ferromanganese, ferrosilicon and metallic zinc. In the preparation process, the vacuum cladding process parameters are as follows: the temperature is 1050-1250 DEG C, the time is 3-5 hours, the vacuum degree is 5-6*10<-4>Pa, inflow water pressure of cooling water is 0.45-0.55MPa during warming, inflow water pressure 1 minute before temperature reduction is 2.2-2.5MPa and air-cooling is performed at 120-145 DEG C and discharge out of a furnace is performed; the primary laser cladding process parameters are as follows: the laser power is 1800-2300W, the defocusing amount is plus (20-45), the scanning speed is 250-290mm / min, the powder feeding voltage is 5-10V, the powder feeding speed is 5-9.5g / min and the argon flow is 200-280L / h; the secondary laser cladding process parameters are as follows: the output power is 1600-2500W, the scanning speed is 20-50mm / s, the spot diameter is 5-10mm and the thickness of a cladding layer is 2-3mm. The wear-resistant ball is high in hardness, impact toughness, corrosion resistance, heat resistance and wear resistance.

Owner:宁国市宁武新材料科技有限公司

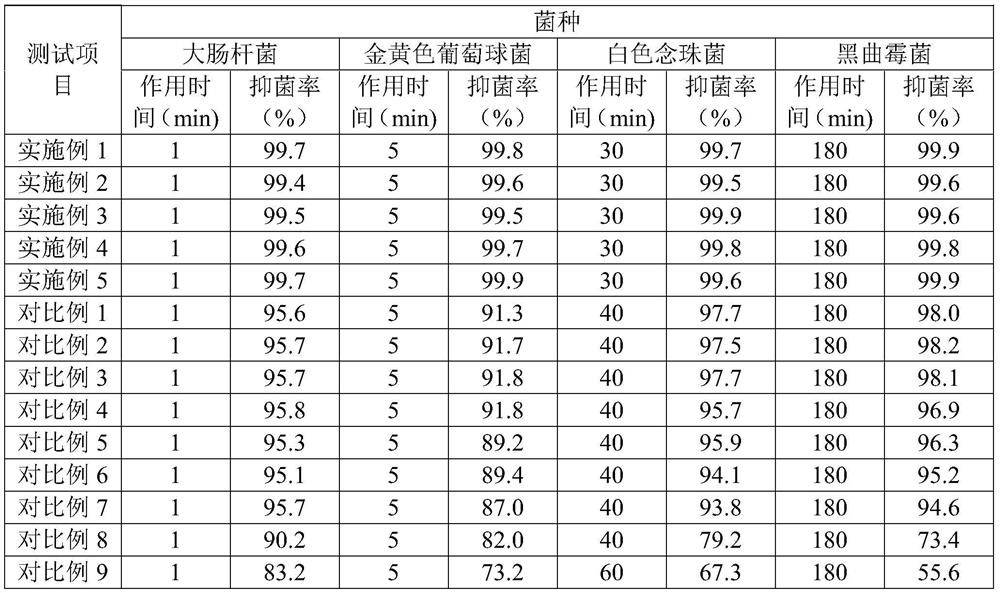

Deodorizing and purifying concentrated solution, and preparation method and application thereof

ActiveCN111249173ACatch quicklyPromote decompositionAntibacterial agentsCosmetic preparationsBiotechnologyArginine

The invention provides a deodorizing and purifying concentrated solution, and a preparation method and an application thereof. The deodorizing and purifying concentrated solution comprises lysine, arginine, glycine, taurine, trehalose, an antibacterial saccharide compound, glycerol monoalkyl ester, a bactericide, a solubilizer and water. The deodorizing and purifying concentrated solution providedby the invention has the following advantages: through mutual cooperation of all components, the synergistic effect is achieved; peculiar smell molecules in the environment can be rapidly captured; organic matter generating odor can be decomposed or neutralized; the source of generated odor gas is reduced; the generated odor gas can be eliminated in time; various common bacteria or fungi can be restrained; the action time is short; the inhibition effect is strong; meanwhile, the deodorizing and purifying concentrated solution can be directly sprayed or diluted and then sprayed onto the body or hair of a pet, and is safe, reliable and low in irritation.

Owner:XIAOPEI NETWORK TECH (SHANGHAI) CO LTD

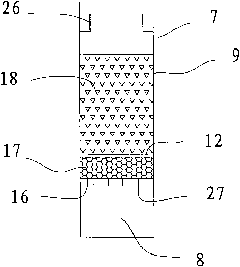

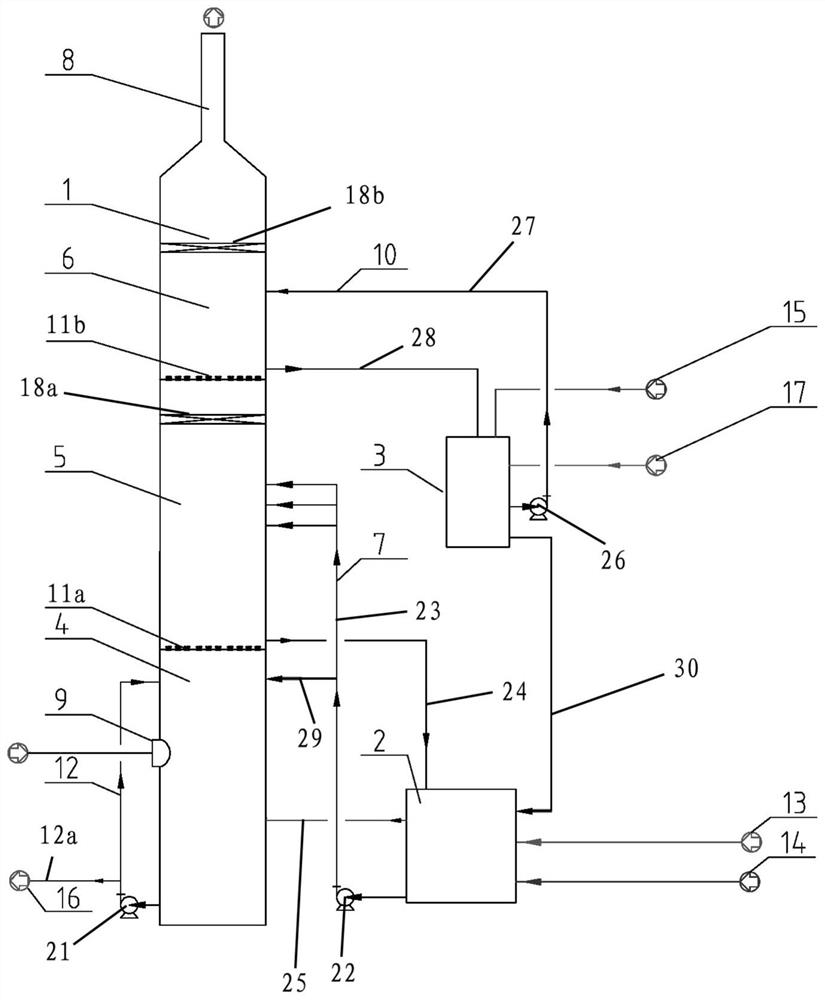

Flue gas desulfurization, purification and recovery process for flue gas desulfurization column

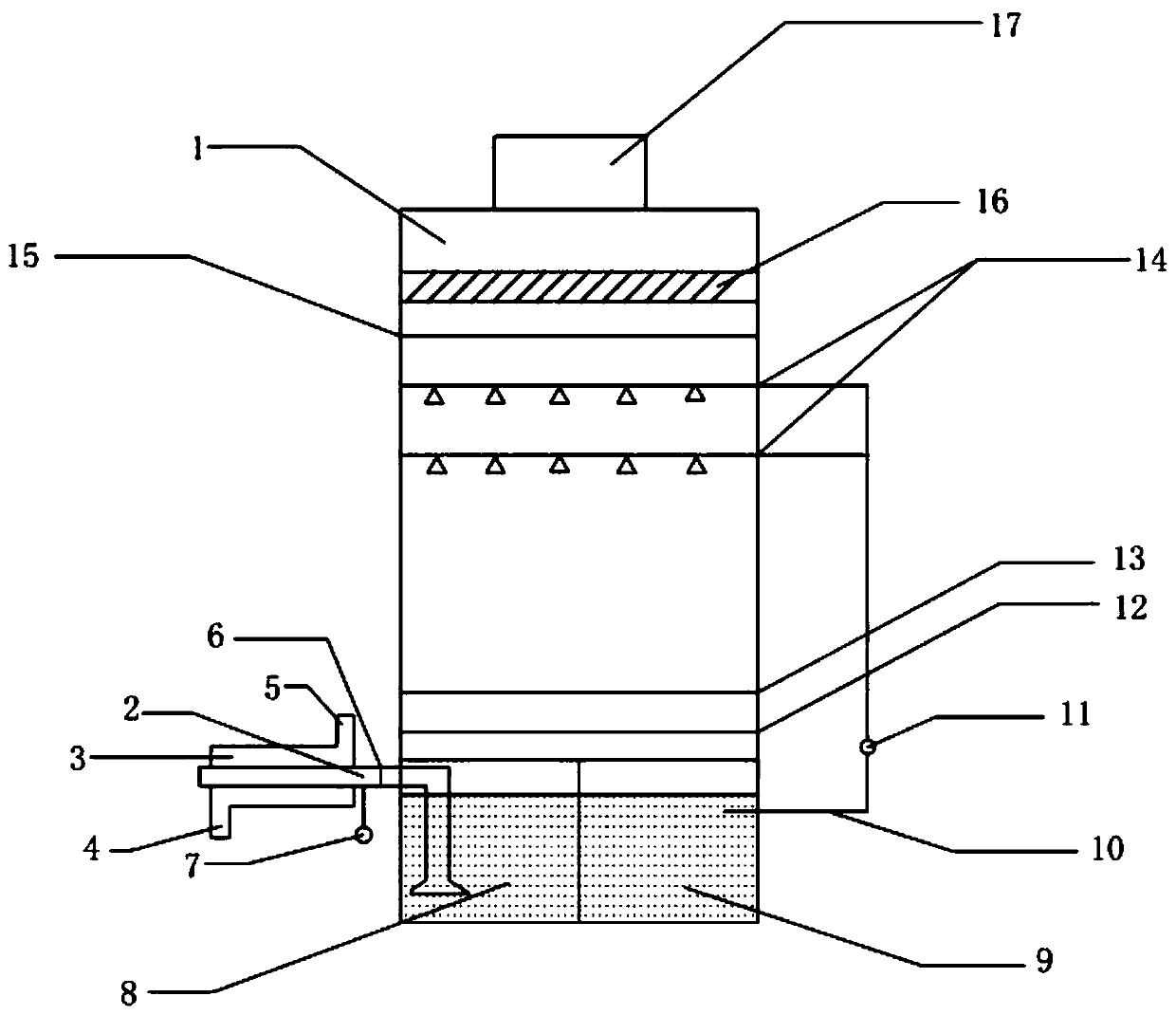

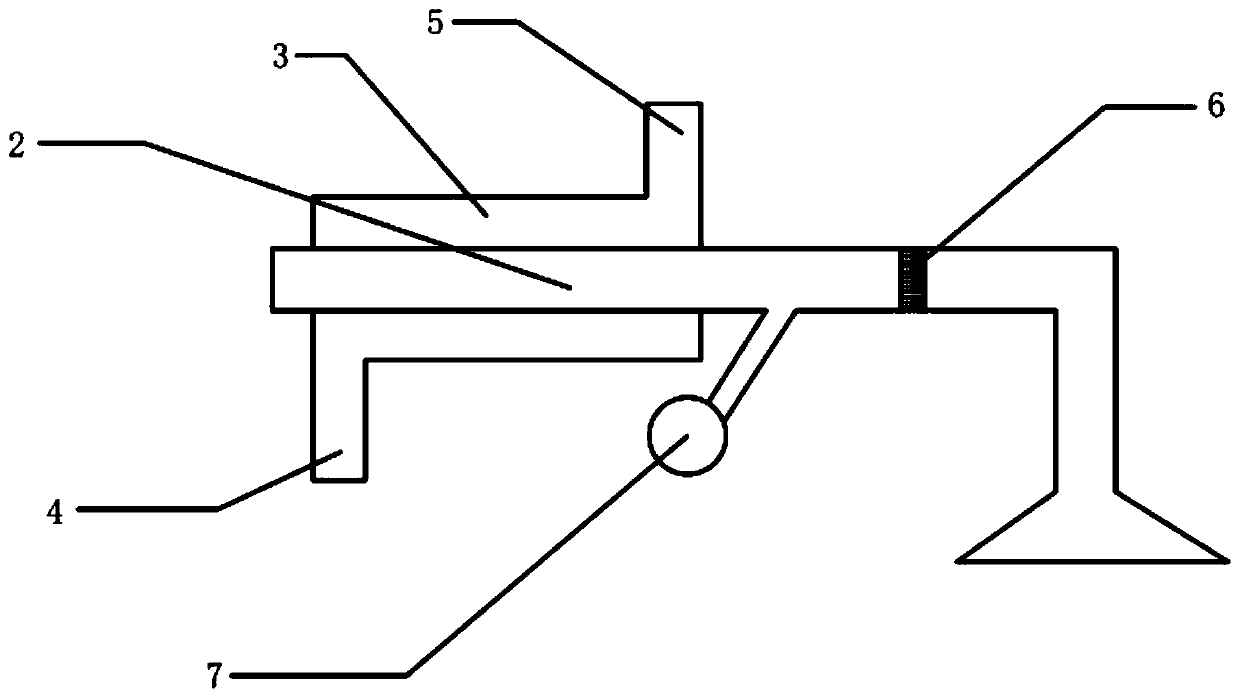

InactiveCN110711469AImprove desulfurization effectImprove environmental performanceCombination devicesGas treatmentSorbentWater circulation

The invention discloses a flue gas desulfurization, purification and recovery process for a flue gas desulfurization column. The desulfurizing column comprises a column body, a smoke inlet, a heat exchanger, a refrigerant inlet, a refrigerant outlet, a first filter screen, an air blower, a gas absorption tank, a circulating liquid tank, a guide pipe, a circulating pump, a second filter screen, a third filter screen, a fourth filter screen, a spraying layer, a demister and a smoke outlet; compared with a traditional flue gas desulfurization, purification and recovery process for a desulfurization column. The adsorbent is contacted with a liquid adsorbent, and then is contacted with an atomized adsorbent. Almost all sulfur-containing substances in the flue gas are removed; the use of the circulating liquid pool recycles the adsorbent which is not reacted in the spraying layer and the water generated by the reaction, and the use of multiple filtering processes and the modified ABS synthetic resin guide pipe prolongs the service life of the equipment, reduces the maintenance frequency of the desulfurization equipment, and has a good market application prospect.

Owner:ANHUI NARADA RENEWABLE RESOURCE TECH CO LTD

Textile printing and dyeing wastewater treatment device and technology

InactiveCN101798159AQuickly and efficiently remove colorImprove biodegradabilityTreatment using aerobic processesMultistage water/sewage treatmentAeration rateSulfide

The invention discloses a textile printing and dyeing wastewater treatment device and technology. The technology comprises the following steps: a first intake pump is used to pump wastewater into the bottom of a biological creeping bed, wastewater passes through a first biological haydite layer from bottom to top, the top effluent enters in a sedimentation and filtration ditch to precipitate, a second intake pump is used to pump the upper clear water into the ozone reaction area on the bottom of an ozone-aeration biological filter while 50-75mg / L of ozone is injected, then the reacted water passes through a second biological haydite layer from bottom to top, the clean water overflowing from the top enters a clear water reservoir, the clear water in the clear water reservoir is sent to the outside for emission or for advanced treatment and reuse. The invention has the advantages that the adhesion of microorganism in the system is good, the aeration rate is enough and enough biological concentration can be maintained, thus the volume load is increased, the sludge load is reduced, the amount of sludge can be obviously reduced; and as ozone is used to remove organics which are difficult to degrade, the entire technology is under the aerobic environment, sulfides generated in the anaerobe treatment process can be avoided and physical and chemical sludge generated in the coagulating sedimentation process can be eliminated.

Owner:GUANGDONG ESQUEL TEXTILES

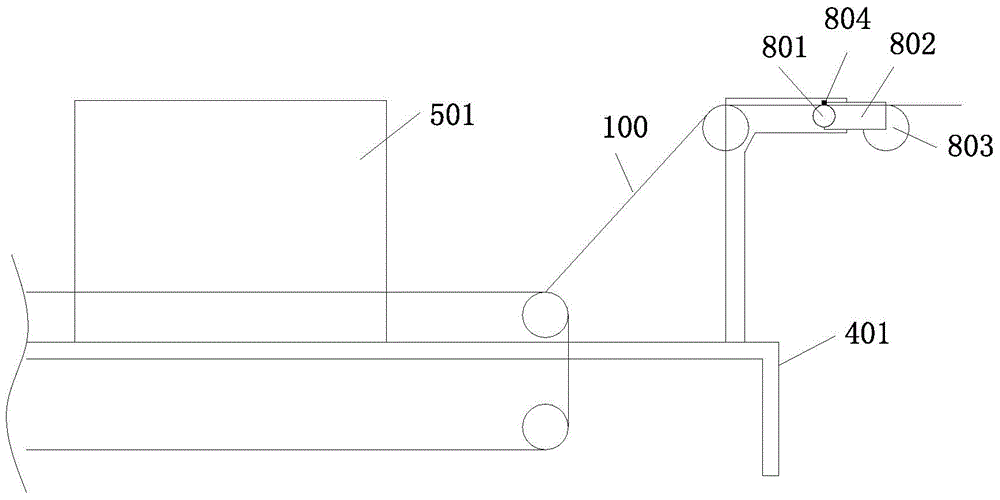

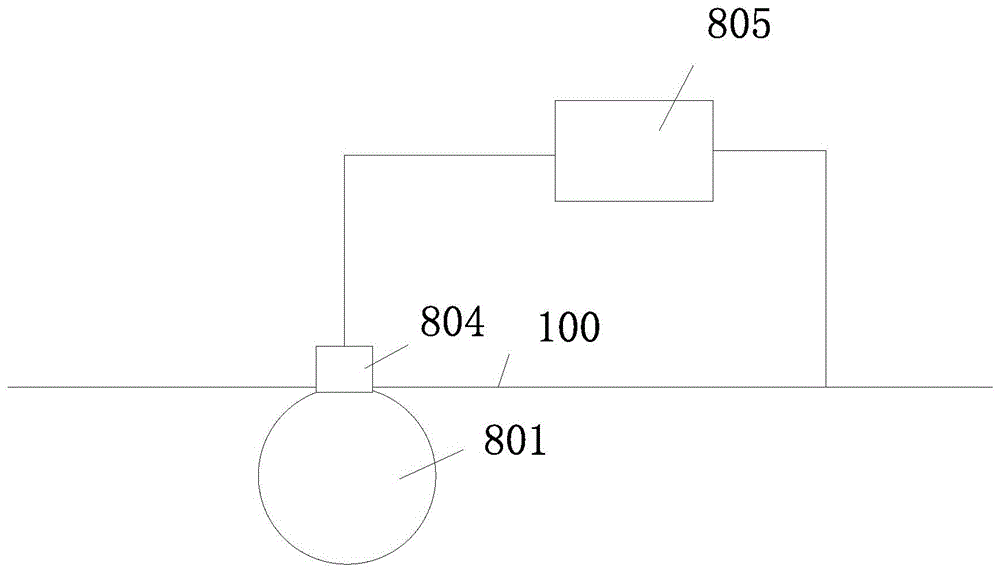

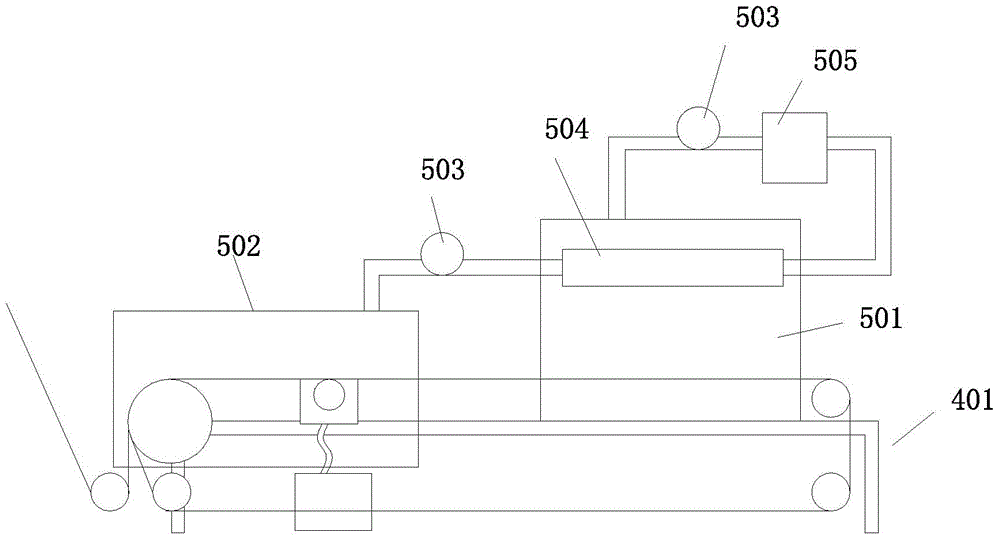

Enameled wire paint breaking alarming method and mechanism of enameling machine

ActiveCN104021890AReduce defective rateImprove performanceAlarmsInsulating conductors/cablesCombustorCombustion chamber

The invention discloses an enameled wire paint breaking alarming method and mechanism of an enameling machine. According to the method, one end of an alarm is connected with a naked end point of an enameled wire; the other end of the alarm is connected with a conductive fixed shaft; the enameled wire is discharged from a drying oven and passes through the fixed shaft in a fitting manner; when a naked section of the paint-broken enameled wire passes through the fixed shaft, a loop is composed of the fixed shaft, the enameled wire and a self power supply and the alarm sends out alarming information including sounds, light and the like to promote a worker to repair or adjust; the method is also used for collecting gas generated by a paint coating mechanism by an outer cover and then introducing the gas into a heat exchanging pipe in the drying oven to be heated; after being heated, the gas is conveyed to a catalytic combustor to be re-heated into hot gas; then the hot gas is introduced into the drying oven to heat and dry the enameled wire. According to the enameled wire paint breaking alarming method and mechanism, when the paint of the enameled wire is broken, the worker can be reminded of repairing or adjusting so that the defective rate is greatly reduced and the performance of products is improved.

Owner:江山三星铜材线缆有限公司

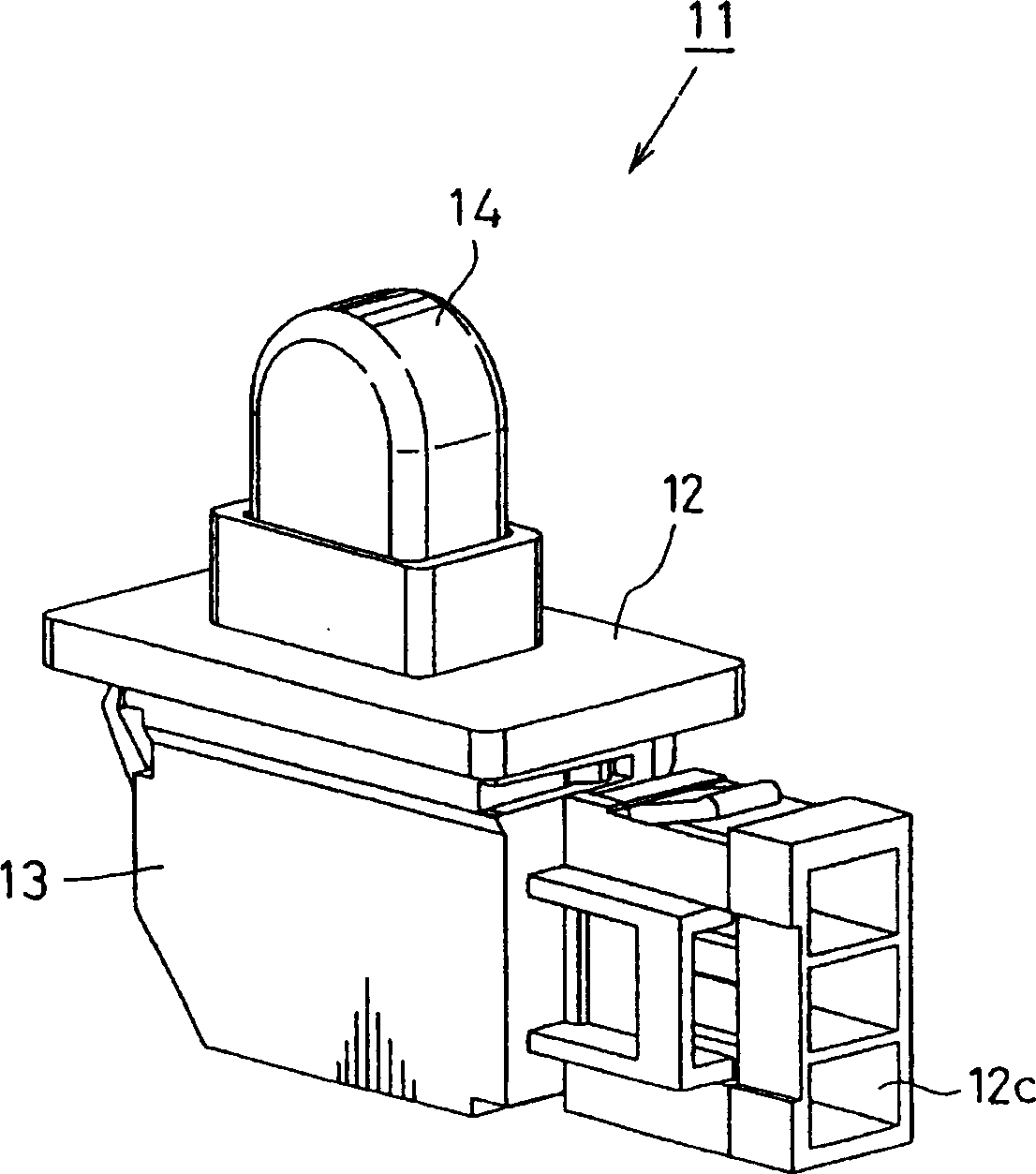

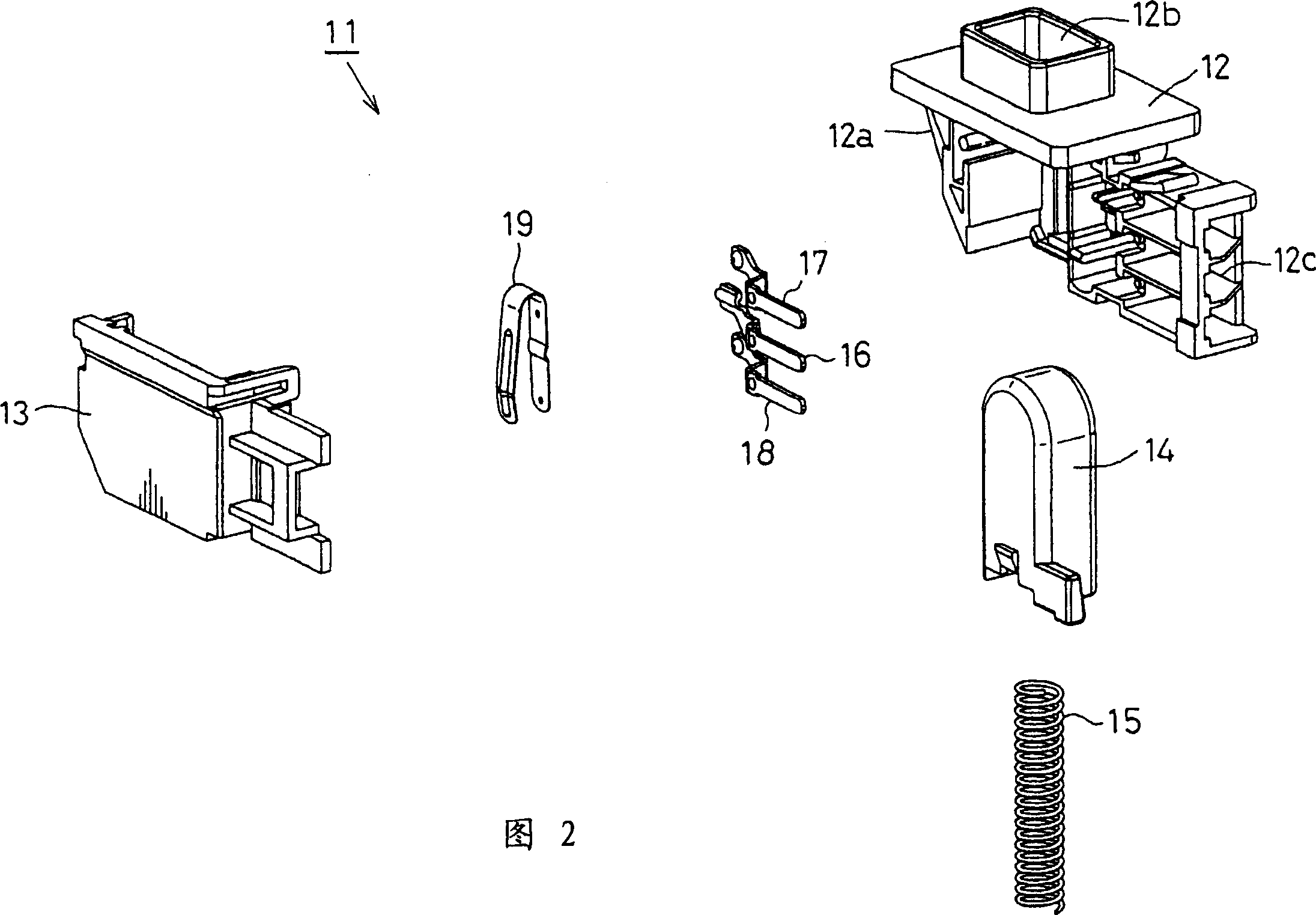

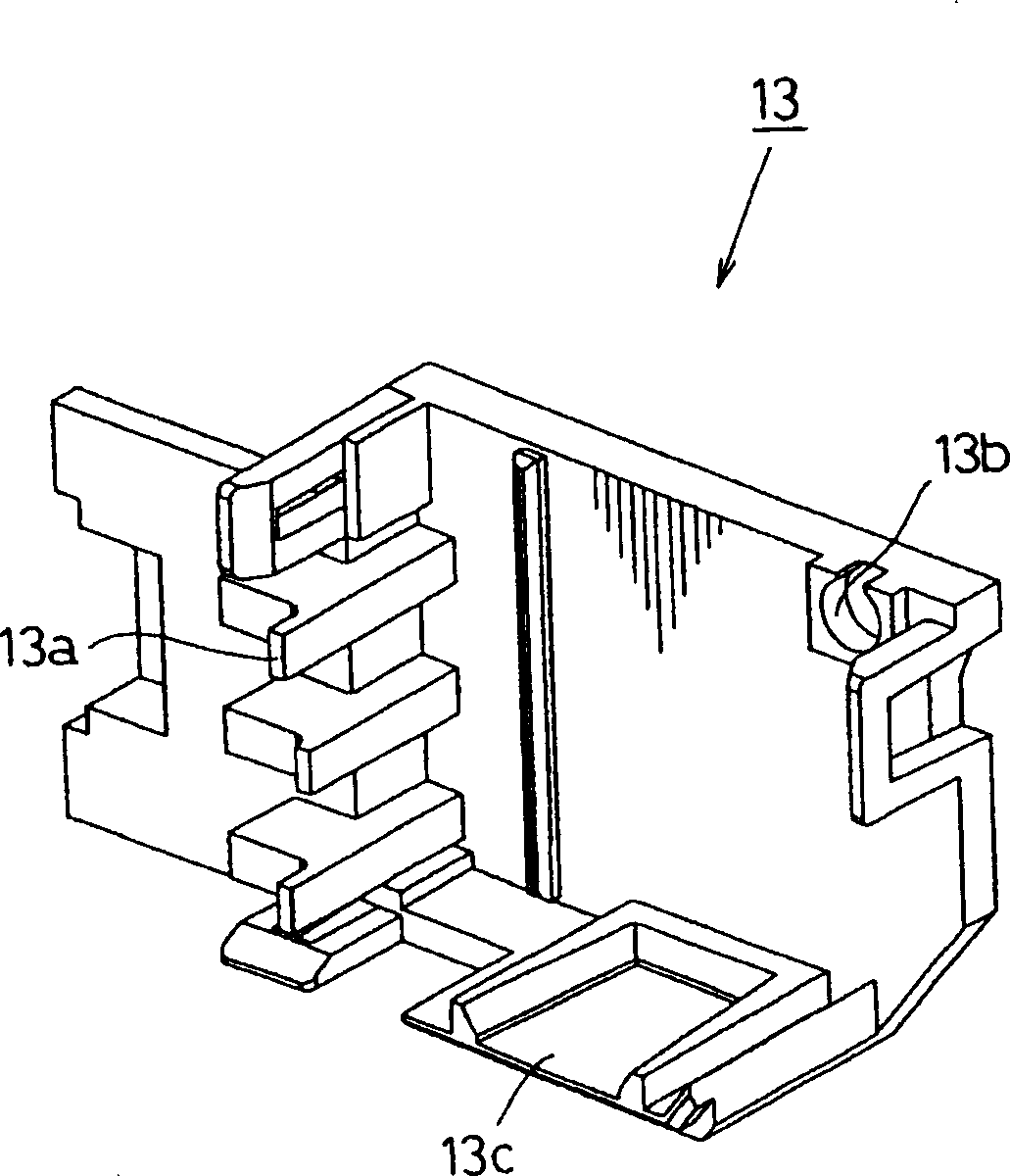

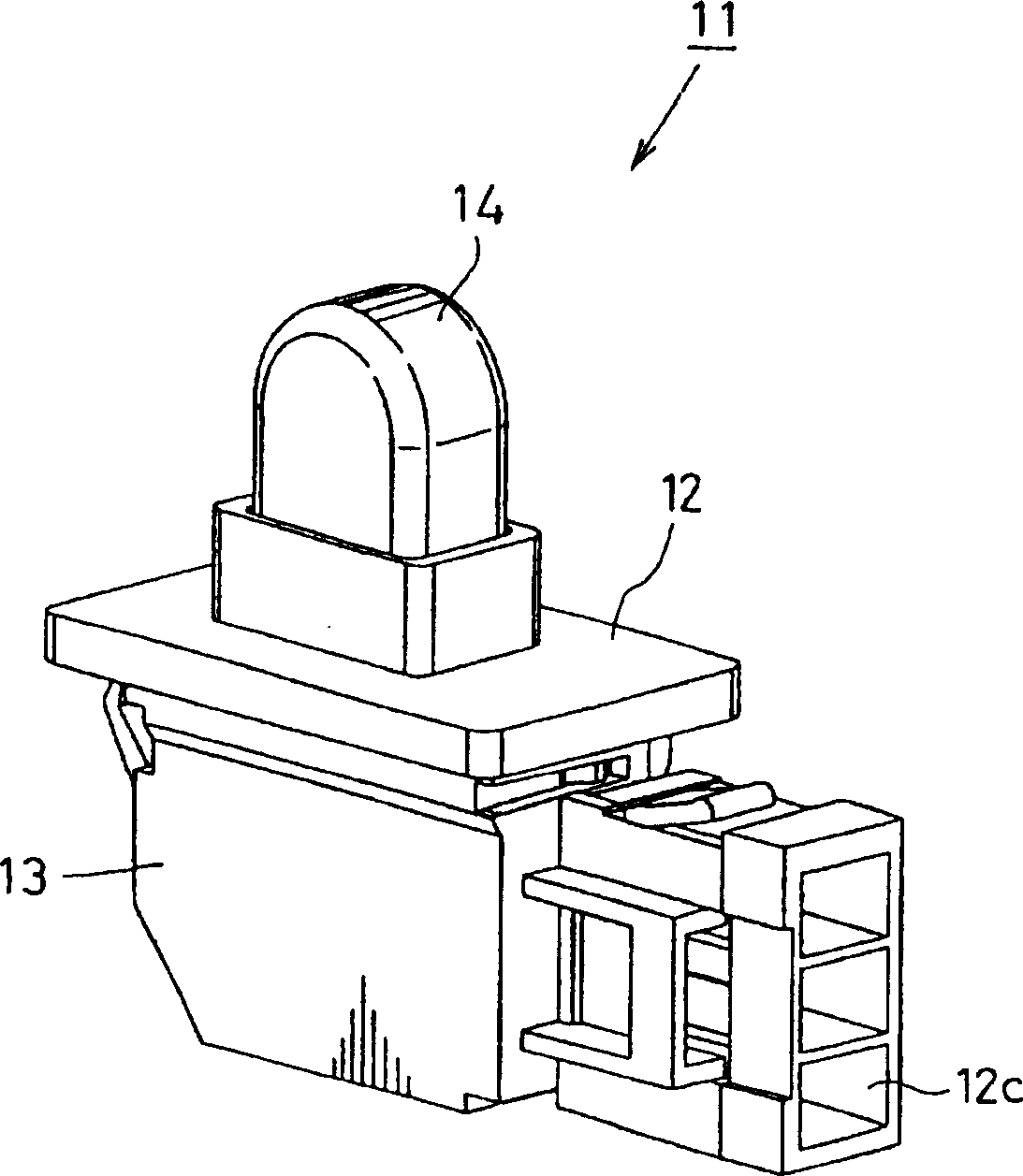

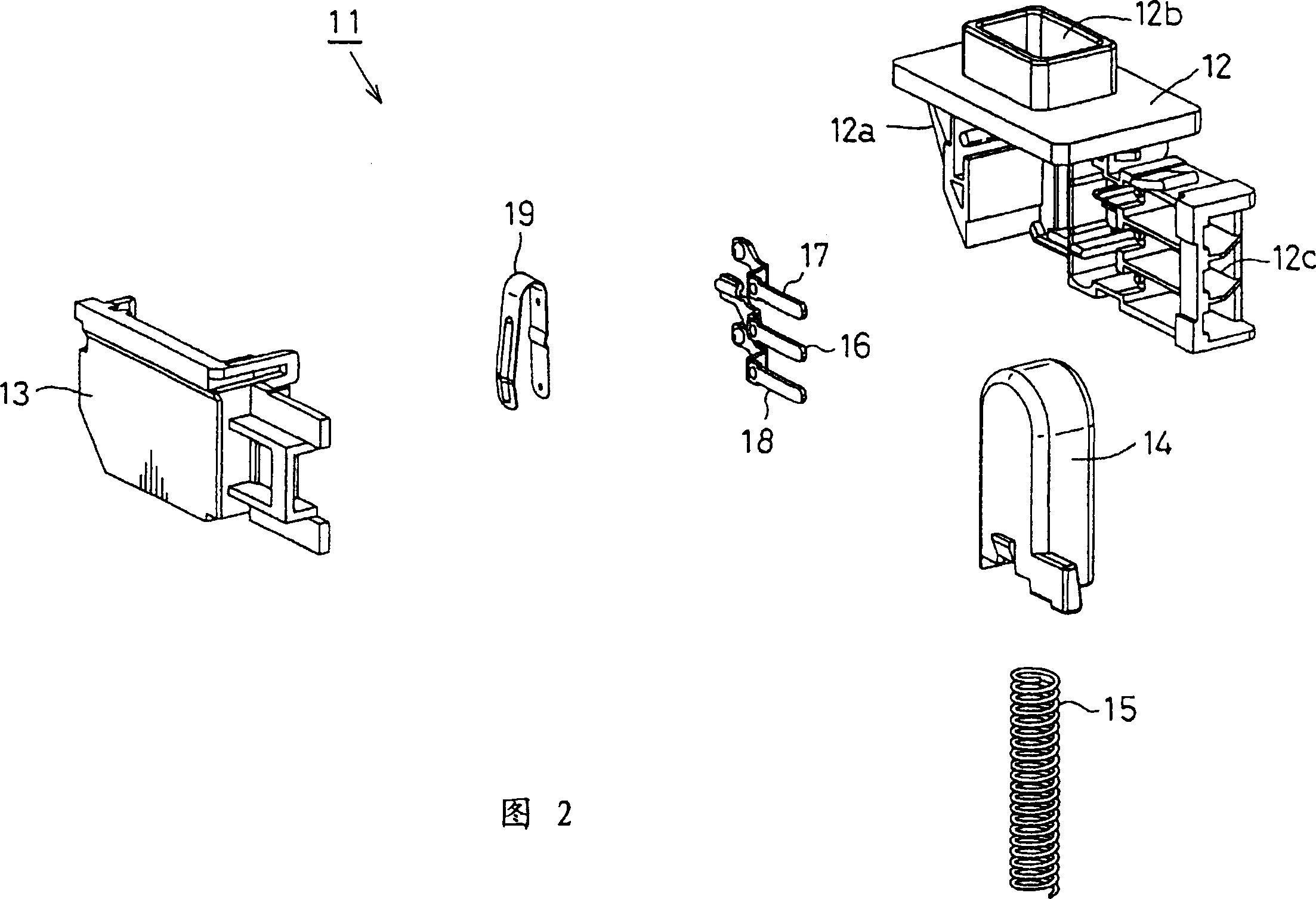

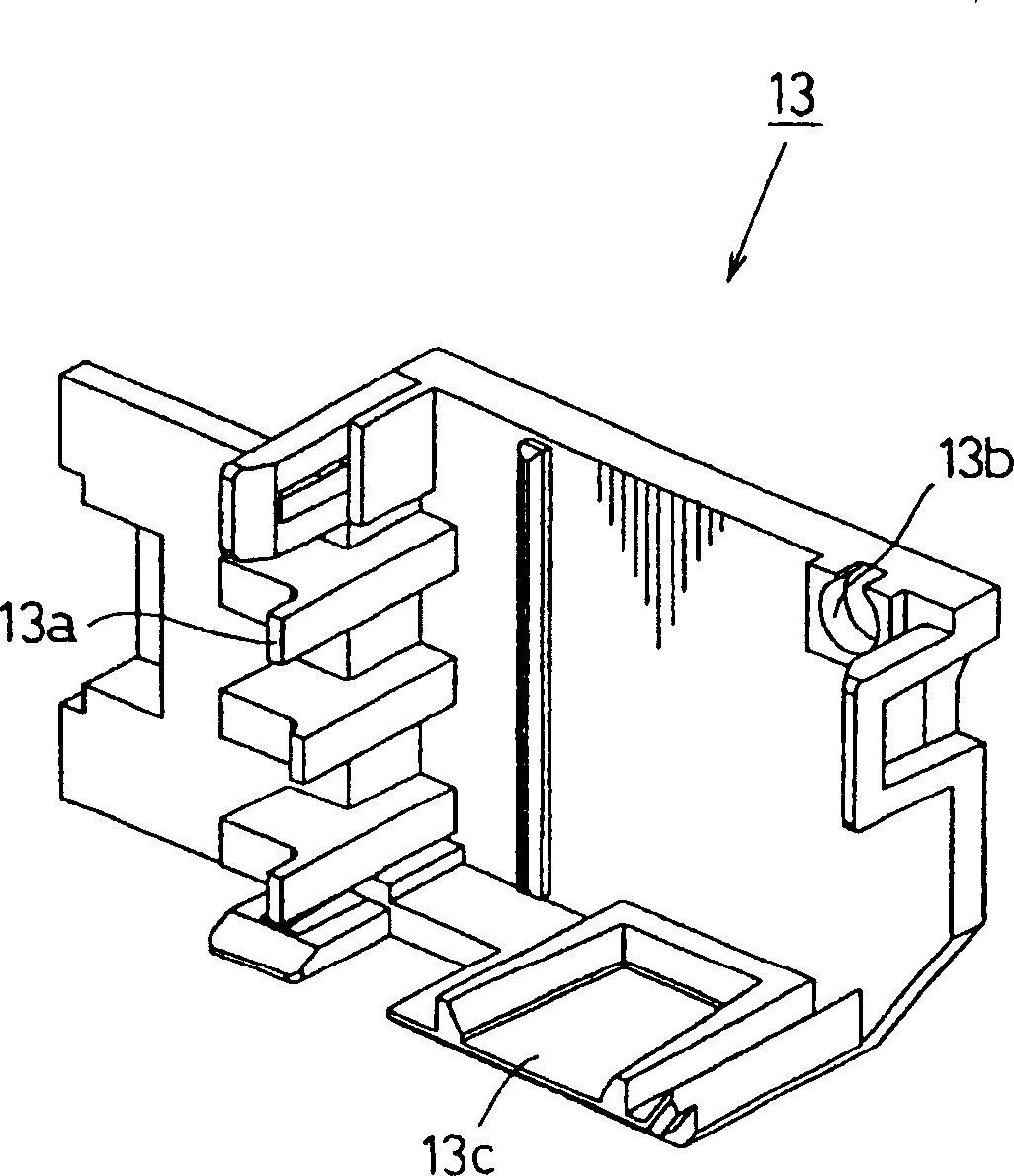

Switch, botton switch and rotation switch

InactiveCN1409337AReduce in quantityReduce assembly man-hoursContact engagementsEngineeringPush switch

The present invention is provided with a contact switching mechanism having a movable contact member that is bent into a U shape, allowed to press and contact a fixed contact member side, and supported so as to freely tilt and move thereon. In this mechanism, a switching operation is carried out between contacts by reversing the movable contact member in a see-saw manner, with a tilt-movement fulcrum portion of the movable contact member being always in contact with the contact portion of the common fixed contact member. The movable contact member is allowed to have a spring function conformed to elastically shift in response to a switching operation in addition to a contact function that is inherent to the movable contact member so that it is possible to provide a switch having high reliability, such as a push-button switch and a rotary-lever switch, which can cut costs by reducing the number of parts, and ensure a superior contacting property.

Owner:ORMON CORP

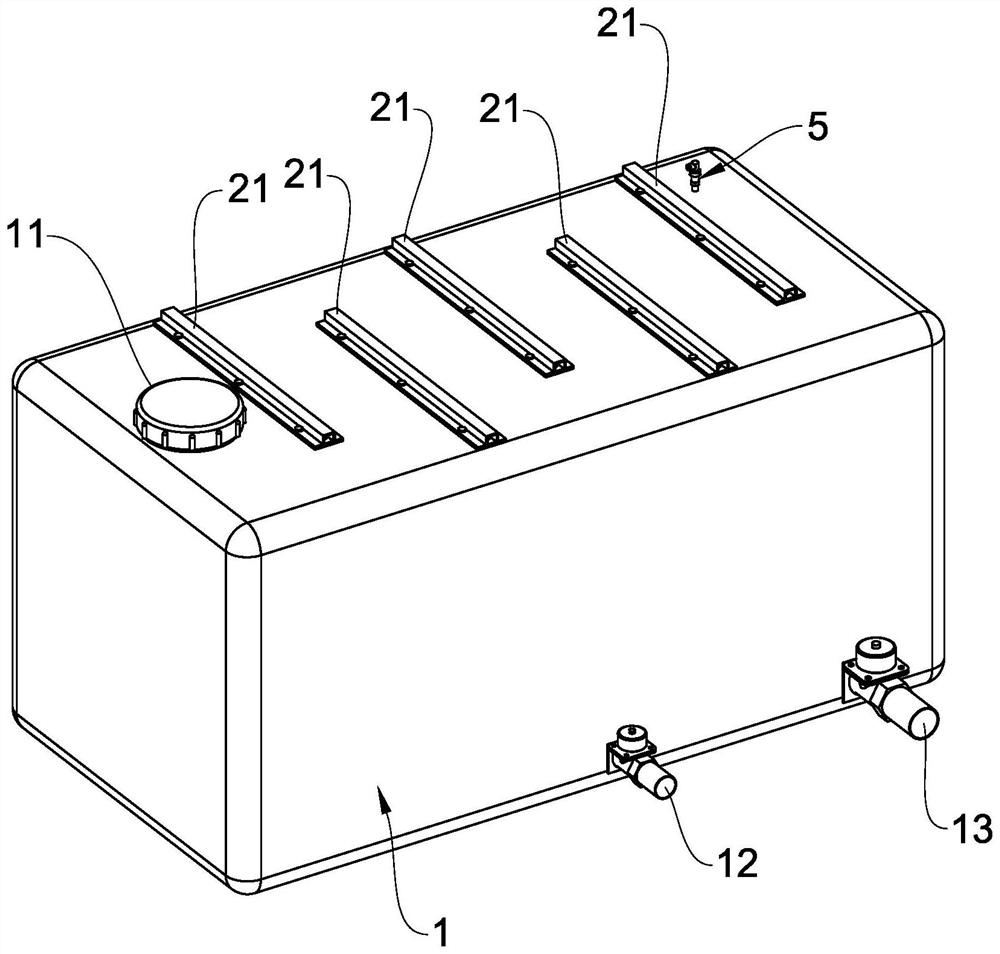

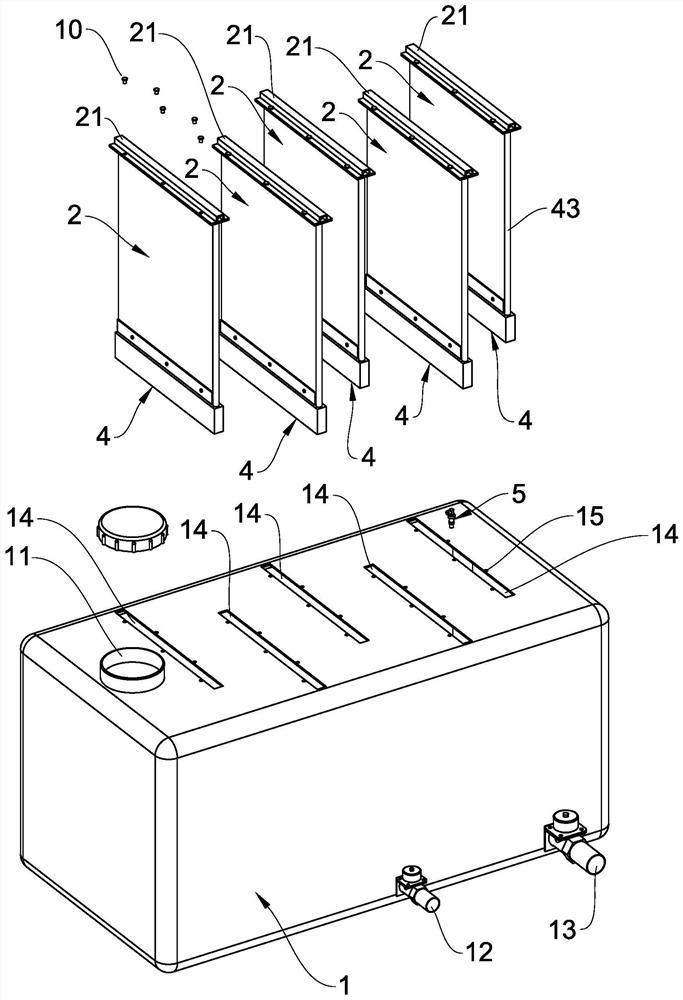

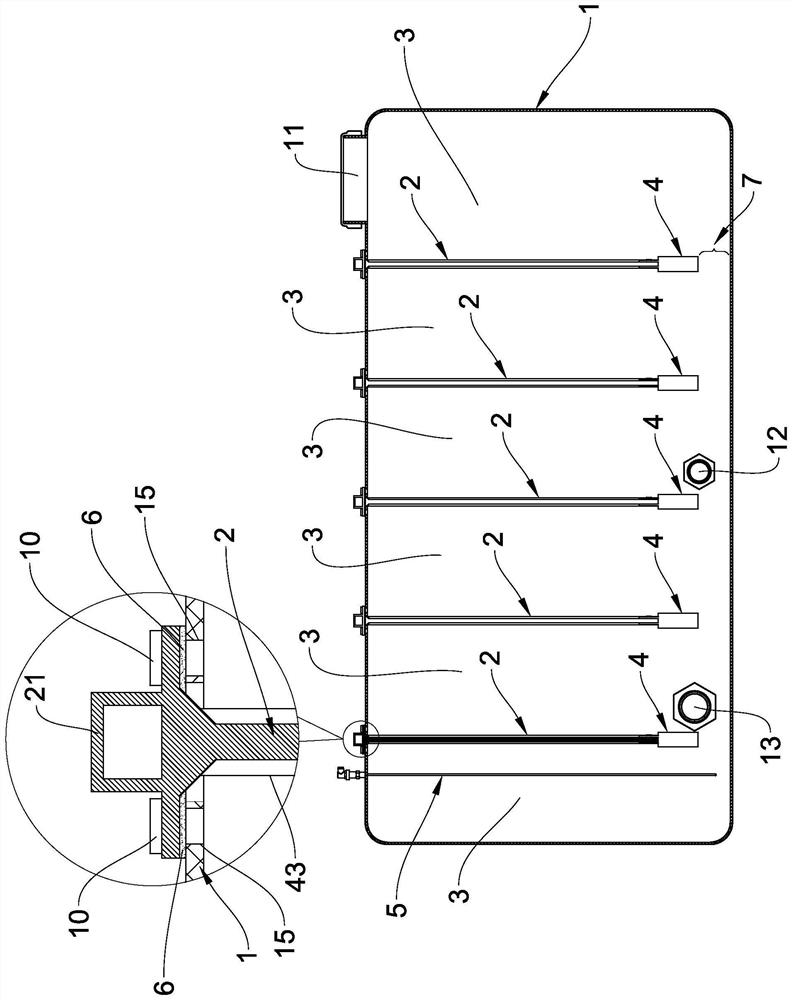

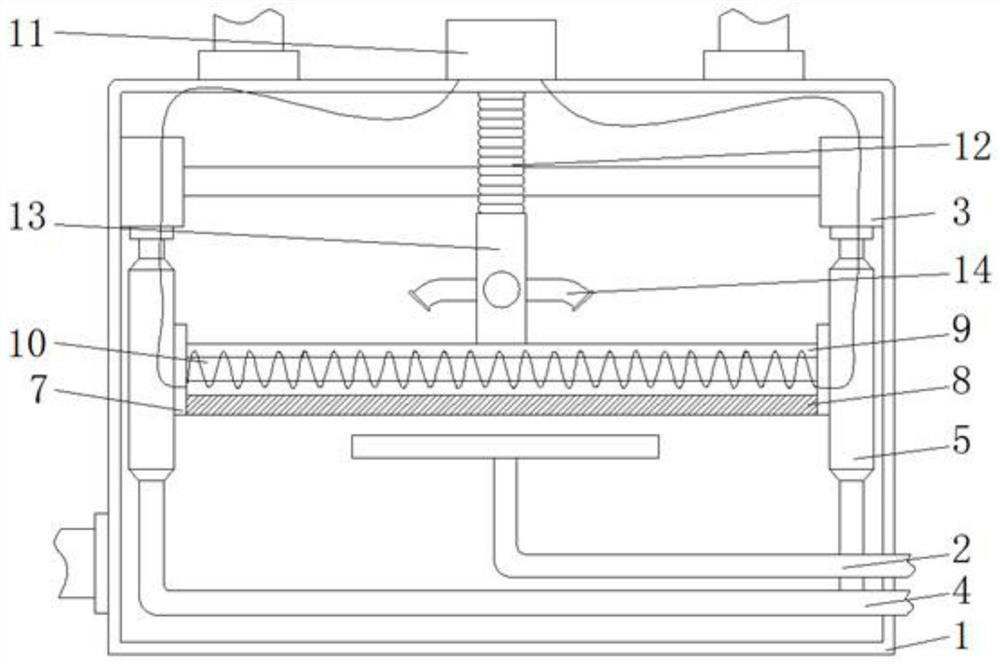

Vehicle-mounted water tank device with ultrasonic anti-condensation and self-cleaning functions

PendingCN112744895AWon't hurtAffect the service lifeVehicle arrangementsWater/sewage treatment with mechanical oscillationsMicroorganismUltrasonic cavitation

The present invention relates to a vehicle-mounted water tank device with ultrasonic anti-condensation and self-cleaning functions. The vehicle-mounted water tank device comprises a water tank body, a plurality of wave-proof plates are evenly arranged in the water tank body at intervals, an ultrasonic module is further arranged on the bottom edge of each wave-proof plate, and each ultrasonic module is composed of a sealed outer shell, an ultrasonic transducer and a sealed line pipe. An electronic temperature measuring probe element is further arranged on the water tank body. The ultrasonic module is used for conducting ultrasonic cavitation cleaning on the inner cavity of the water tank, microorganisms in water are killed, and water scale is completely eradicated; due to the design of the wave-proof plate, the wave potential of water in the water tank can be completely eradicated in the vehicle running process, and the situation that the wave potential affects the vehicle running safety is prevented; besides, by means of cooperation of the ultrasonic module and the electronic temperature measuring probe element, when the water temperature in the water tank is too low, the ultrasonic module can be started for cavitation, water molecules in the water generate intense mutual impact movement, and the purposes of increasing the water temperature and preventing water condensation are achieved.

Owner:彭志军

Casting method of low temperature-resisting hard sealing check valve casting

InactiveCN103286265ASolve air resistanceSolve the problem of air shrinkage defectsMolten metal supplying equipmentsFoundry mouldsCheck valveProduct defect

The invention provides a casting method of a low temperature-resisting hard sealing check valve casting. The casting method comprises the following steps of: 1, preparing the mould; 2, sand-discharging, core-making and modeling; 3, drawing, shaping; 4, applying a temperature-resistant coating, baking a casting mould; 5, core-matching and mould-assembling; 6, making a quantitative shifting type sprue cup and a conical plug, wherein the capacity of the quantitative shifting type sprue cup is slightly more than the pouring weight of molten iron; 7, placing the sprue cup; 8, melting the molten iron; 9, rapidly analyzing materials of the molten iron before pouring; 10, pouring the molten iron; 11, pouring a test block, analyzing a sample block; 12, insulating the casting mould; and 13, mould-disassembling and cleaning. According to the casting method, the product defect caused by an existing casting process can be effectively eliminated, the production quality of the low temperature-resisting hard sealing check valve casting is improved, and the casting cost is lowered.

Owner:浙江坤博精工科技股份有限公司

Dust-eliminating grinding machine

PendingCN106985074AEliminate smoke and dustImprove production environmentGrinding/polishing safety devicesStructural engineeringManufacturing engineering

The invention provides a dust-eliminating grinding machine and belongs to the technical field of machining. A grinding machine motor is fixedly connected with a machine seat. Two wind wheel shells are symmetrically arranged on a main shaft of the grinding machine motor in a sleeved manner. A coaxial adjusting rod is installed between the two wind wheel shells. After the gap between each wind wheel shell and the main shaft of the grinding machine motor is adjusted, the wind wheel shells are fixed to the machine seat with bolts. Wind wheels are installed in the wind wheel shells. The wind wheels are fixed to the main shaft of the grinding machine motor through screws. Second safety covers are installed on the outer sides of the wind wheels. The upper edge of an opening of each second safety cover is adjusted to form an angle of 15 degrees with the horizontal plane, and the second safety covers are fixed through screws. Abrasive disks are installed in the second safety covers, and the abrasive disks are fastened to the main shaft of the grinding machine motor. First safety covers are installed on the outer sides of the abrasive disks. The upper edge of the opening of each first safety cover is adjusted to be at the same angle with the second safety covers, and the first safety covers are fixed with screws. One end of a dust guide pipe is inserted into a mouth of an air outlet pipe of each wind wheel shell, and the other end of each dust guide pipe is inserted into a dust collecting water tank. An appropriate amount of water is added to the dust collecting water tank, and the dust collecting water tank is placed in a cavity of the machine seat.

Owner:SHENYANG AIRCRAFT CORP

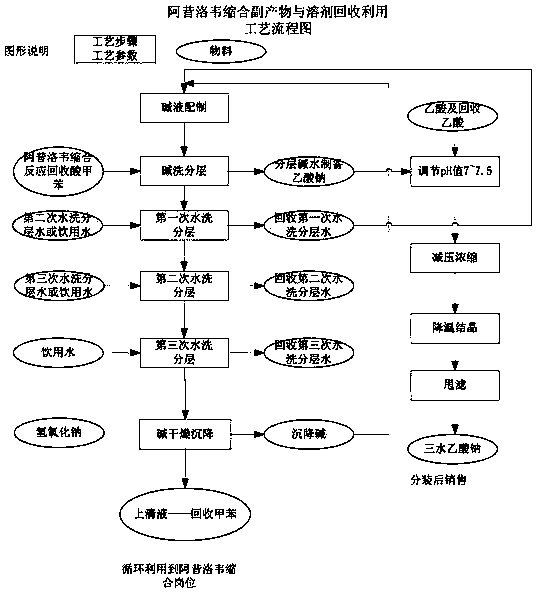

Method for recycling acyclovir condensation by-products and solvents

ActiveCN109970543AReduce consumptionReduce generationOrganic compound preparationPreparation from carboxylic acid anhydridesSodium acetateAcetic anhydride

The invention discloses a method for recycling acyclovir condensation reaction by-products and solvents, which comprises the following steps of: neutralizing and recycling acetic anhydride in a next batch of toluene by using sodium hydroxide for toluene drying, so that consumption of the sodium hydroxide for recycling and treating the toluene is reduced; thoroughly removing sodium acetate and impurities in the recycled toluene by adopting a mode of multiple water washing and layering, so that the quality of the finally recycled toluene is guaranteed, and the quality of the recycled toluene meets the requirement of process use; utilizing the water washing and layering water gradient recycling to improve the concentration of the sodium acetate in the water washing and layering water; using the gradient recycling water as the solvent for alkali washing and neutralizing the sodium hydroxide, so that the concentration of the sodium acetate after the alkali washing is maximized, preparationof the sodium acetate is facilitated, and it is beneficial to reduce the cost of preparing the sodium acetate; repeat recycling of a mother solution generated by the preparation of the sodium acetate,so that generation of waste water is reduced; and utilizing the water washing and layering water gradient recycling by acid toluene, so that the generation of the waste water with high salinity and high COD is eliminated.

Owner:HUBEI YITAI PHARMA

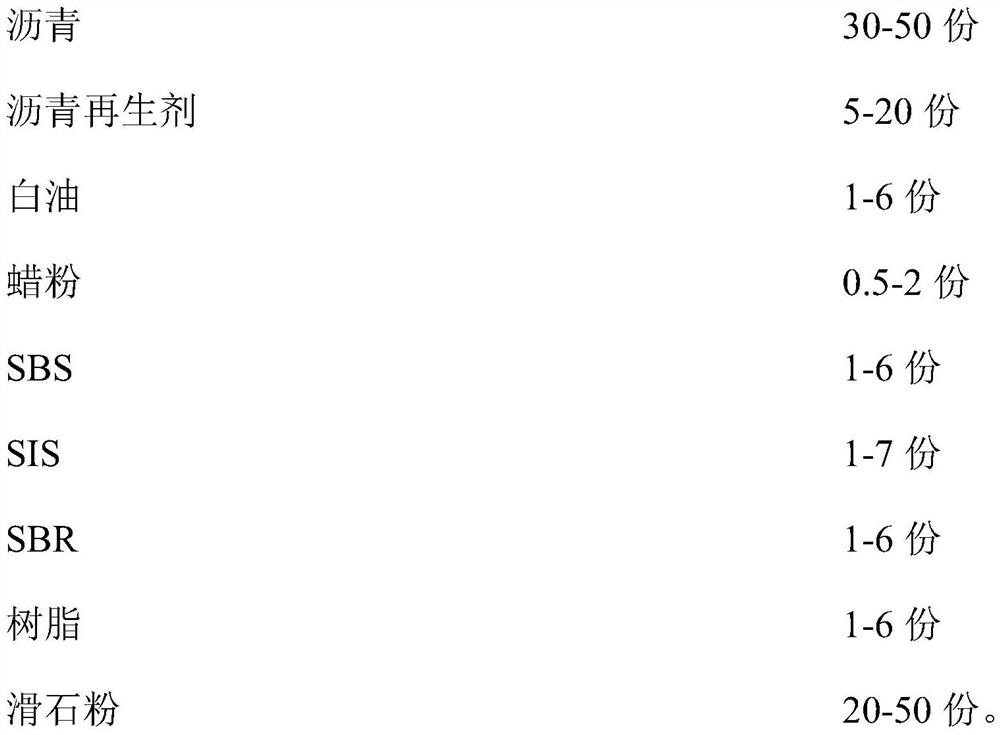

Modified asphalt and preparation method and application thereof

PendingCN113999537ATo achieve the effect of dissolutionShorten modification timeBuilding insulationsAsphaltPitch

The invention relates to modified asphalt and a preparation method and application thereof, and the modified asphalt is prepared from the following raw materials in parts by weight: 30-50 parts of asphalt, 5-20 parts of an asphalt regenerant, 1-6 parts of white oil, 0.5-2 parts of wax powder, 4-25 parts of a modifier and 20-50 parts of talcum powder. The preparation method comprises the following steps: mixing asphalt, an asphalt regenerant and white oil according to a formula ratio, and preserving heat to obtain premixed asphalt; shearing, grinding and mixing the modifier and the premixed asphalt according to the formula ratio to obtain a first shearing material; adding talcum powder into the first shearing material, stirring and mixing, preserving heat, and then shearing, grinding and mixing to obtain the modified asphalt. Through shearing, grinding and mixing in the preparation process, the modification time of asphalt is shortened, and the adverse effect of carbides generated in the high-temperature modification process on coiled material preparation is also avoided.

Owner:SHENZHEN ZHUOBAO TECH +1

Organic modified waterproof paint

InactiveCN105802481AImprove waterproof performanceImprove performancePolyurea/polyurethane coatingsChlorine dioxideSodium Bentonite

The invention discloses an organic modified waterproof paint which comprises the following raw materials in part by weight: 30 to 35 parts of isocyanate, 25 to 30 parts of polyether, 15 to 20 parts of modifier, 20 to 25 parts of sodium methyl silicate, 5 to 8 parts of ferrum dioxide, 11 to 15 parts of silicon dioxide, 6 to 9 parts of sodium carbonate, 40 to 45 parts of deionized water, 13 to 16 parts of perlite, 12 to 15 parts of nano mica, 3 to 6 parts of chlorine dioxide, 4 to 7 parts of bentonite, 7 to 9 parts of polyacrylamide and 3 to 5 parts of polydimethylsiloxane. A preparation method of the organic modified waterproof paint comprises the following steps of: S1, adding the isocyanate, the polyether and the deionized water into a stirrer, and stirring for 2 to 3 hours at a temperature of 40 to 45 DEG C at a stirring speed of 35 to 45rpm; S2, adding the modifier, the sodium methyl silicate, the ferrum dioxide, the silicon dioxide and the sodium carbonate, and then stirring for 5 to 6 hours at a stirring speed of 20 to 25rpm. The organic modified waterproof paint has excellent waterproofness, high tensile strength and excellent flexibility, is simple in construction, healthy and environmental-friendly, and takes a very important effect on concrete construction.

Owner:TIANJIN PENGTENG NEW BUILDING MATERIALS

Ammonia desulfurization method and ammonia desulfurization device

ActiveCN113856441AGeneration and eliminationLess investmentGas treatmentDispersed particle separationFlue gasProcess engineering

The invention relates to an ammonia desulfurization method, in which flue gas containing SO2 and SO3 is desulfurized by means of an ammonia desulfurization device, ammonia is used as a first desulfurizer, and a metal alkaline desulfurizer is used as a second desulfurizer. The invention also relates to the ammonia desulfurization device, and the ammonia desulfurization method can be implemented by using the ammonia desulfurization device. According to the invention, SO2 and SO3 in the flue gas can be synergistically removed, and improvement can be realized in the aspects of solving flue gas trailing and aerosol generation.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

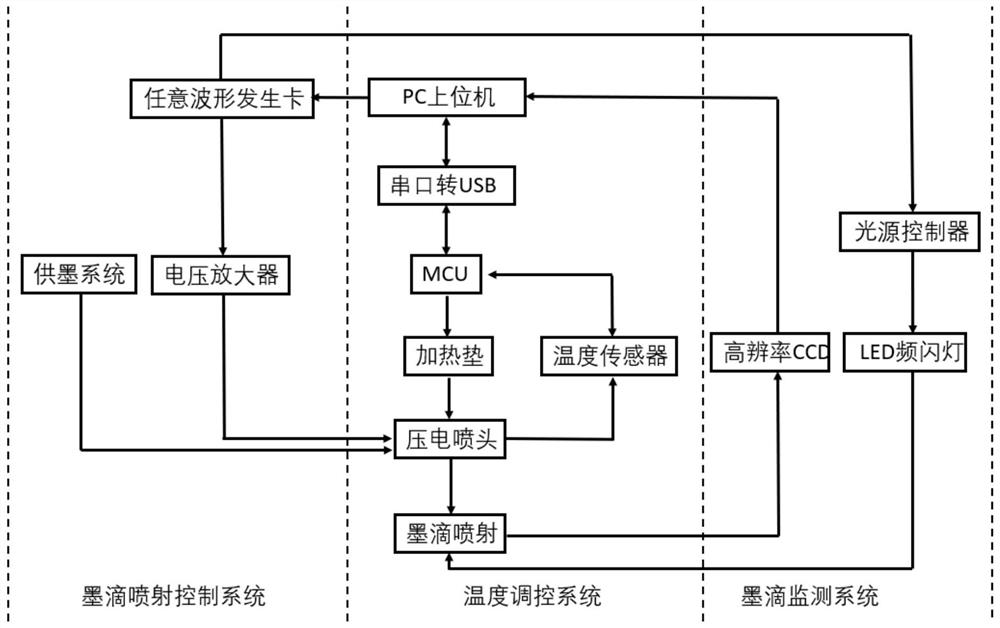

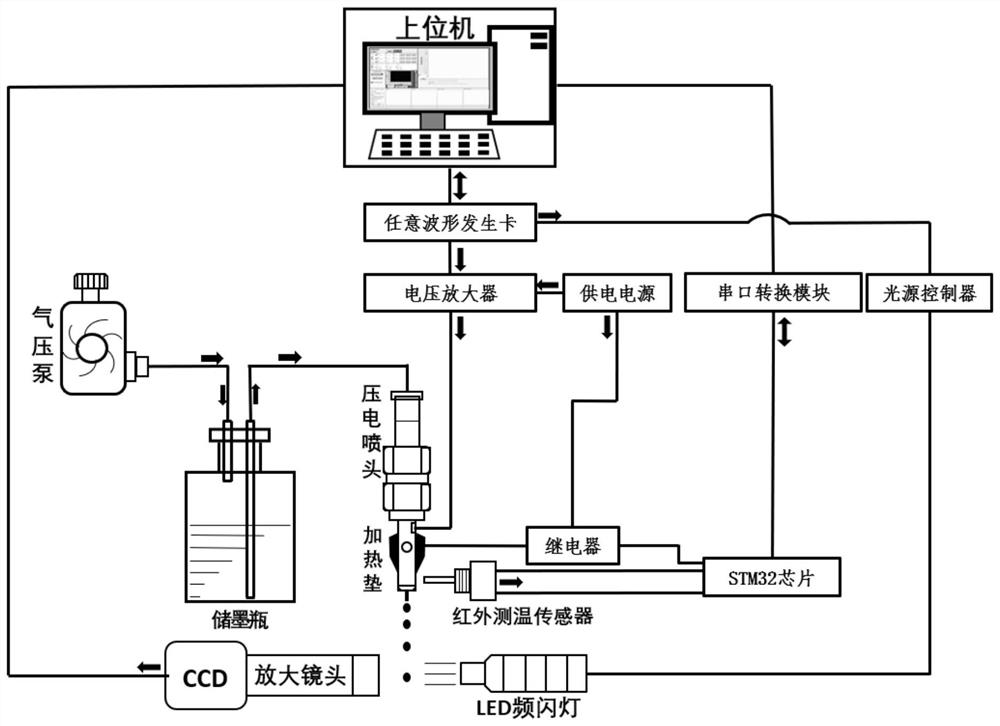

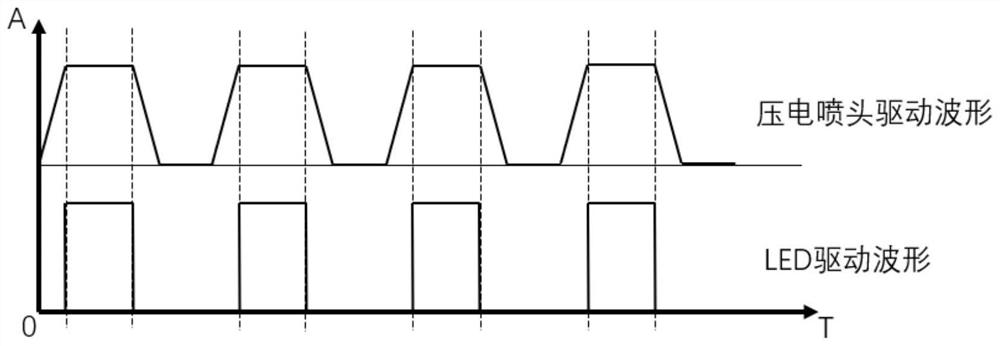

Ink piezoelectric control system and ink piezoelectric control optimization method capable of improving printing precision

ActiveCN113211979AGeneration and eliminationEliminate temperature setting errorsPrintingControl systemMonitoring system

The invention discloses an ink piezoelectric control system and ink piezoelectric control optimization method capable of improving printing precision. The system controls a piezoelectric driving module through an upper computer to drive a nozzle to jet ink droplets; meanwhile, an ink droplet monitoring system continuously collects a plurality of images in the falling process of the ink droplets, carries out image comparison and analysis, judges whether satellite droplets are generated or not, and transmits a data result to the upper computer; and the upper computer analyzes the data result, controls a temperature regulation and control system to automatically regulate the temperature of the piezoelectric nozzle, and feeds back a real-time temperature value to the upper computer, so as to eliminate generation of the satellite droplets. The system is not limited by printing ink types, is wide in application range and high in automation degree, can automatically eliminate the satellite droplets generated by ink temperature setting errors, nozzle wear, nozzle surface aging and the like without human interference, and provides guarantee for ultrahigh-precision graphical ink-jet printing which is high in quality and free of a stray satellite point.

Owner:SOUTH CHINA UNIV OF TECH

Switch, botton switch and rotation switch

InactiveCN1290131CReduce in quantityReduce assembly man-hoursContact engagementsEngineeringPush switch

The present invention is provided with a contact switching mechanism having a movable contact member that is bent into a U shape, allowed to press and contact a fixed contact member side, and supported so as to freely tilt and move thereon. In this mechanism, a switching operation is carried out between contacts by reversing the movable contact member in a see-saw manner, with a tilt-movement fulcrum portion of the movable contact member being always in contact with the contact portion of the common fixed contact member. The movable contact member is allowed to have a spring function conformed to elastically shift in response to a switching operation in addition to a contact function that is inherent to the movable contact member so that it is possible to provide a switch having high reliability, such as a push-button switch and a rotary-lever switch, which can cut costs by reducing the number of parts, and ensure a superior contacting property.

Owner:ORMON CORP

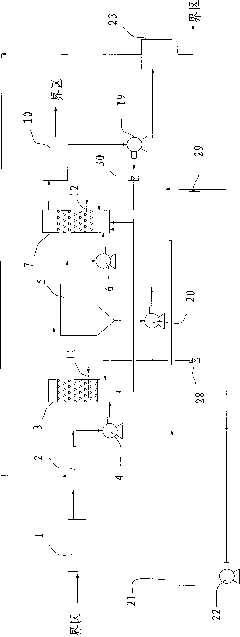

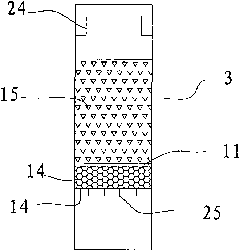

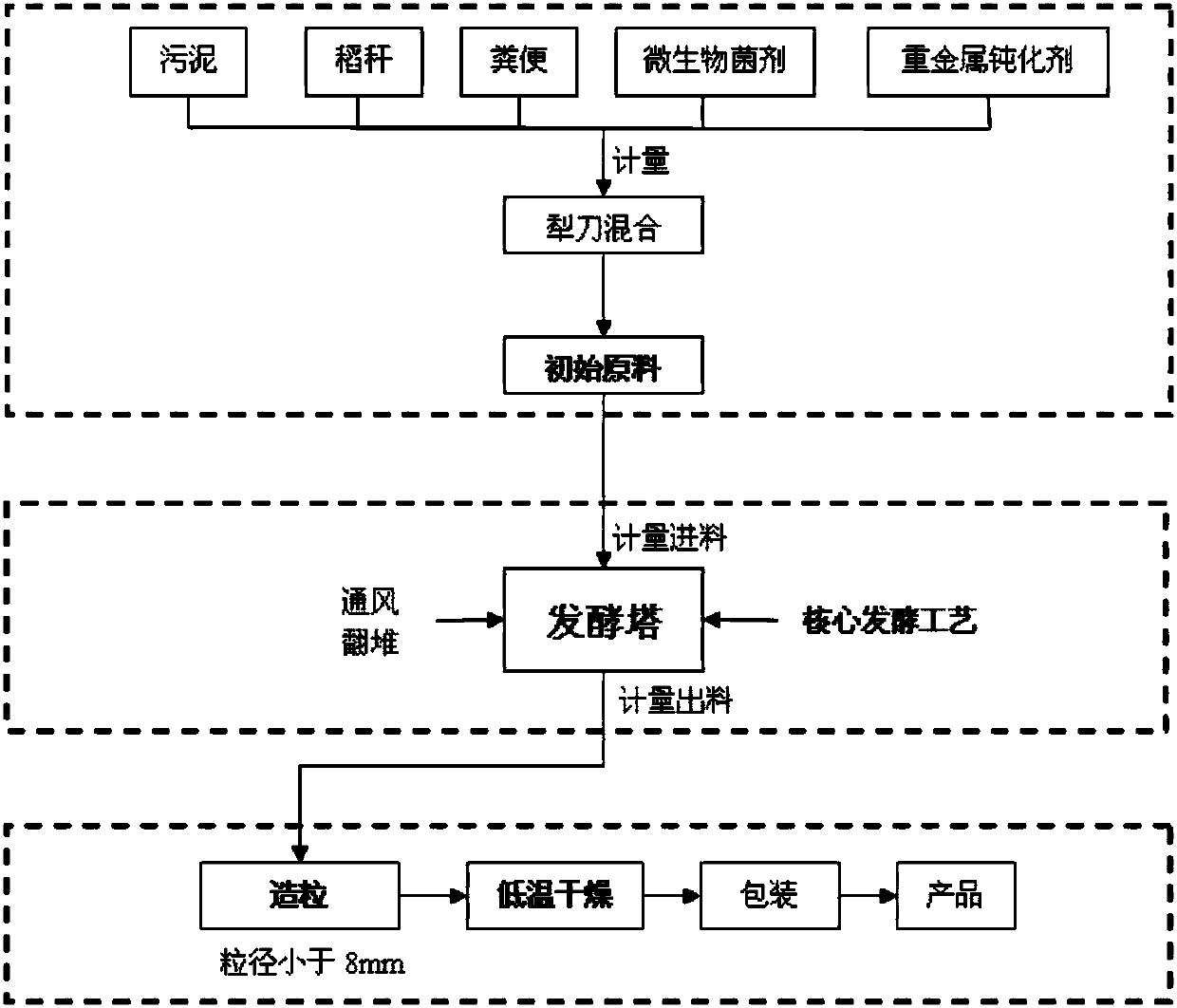

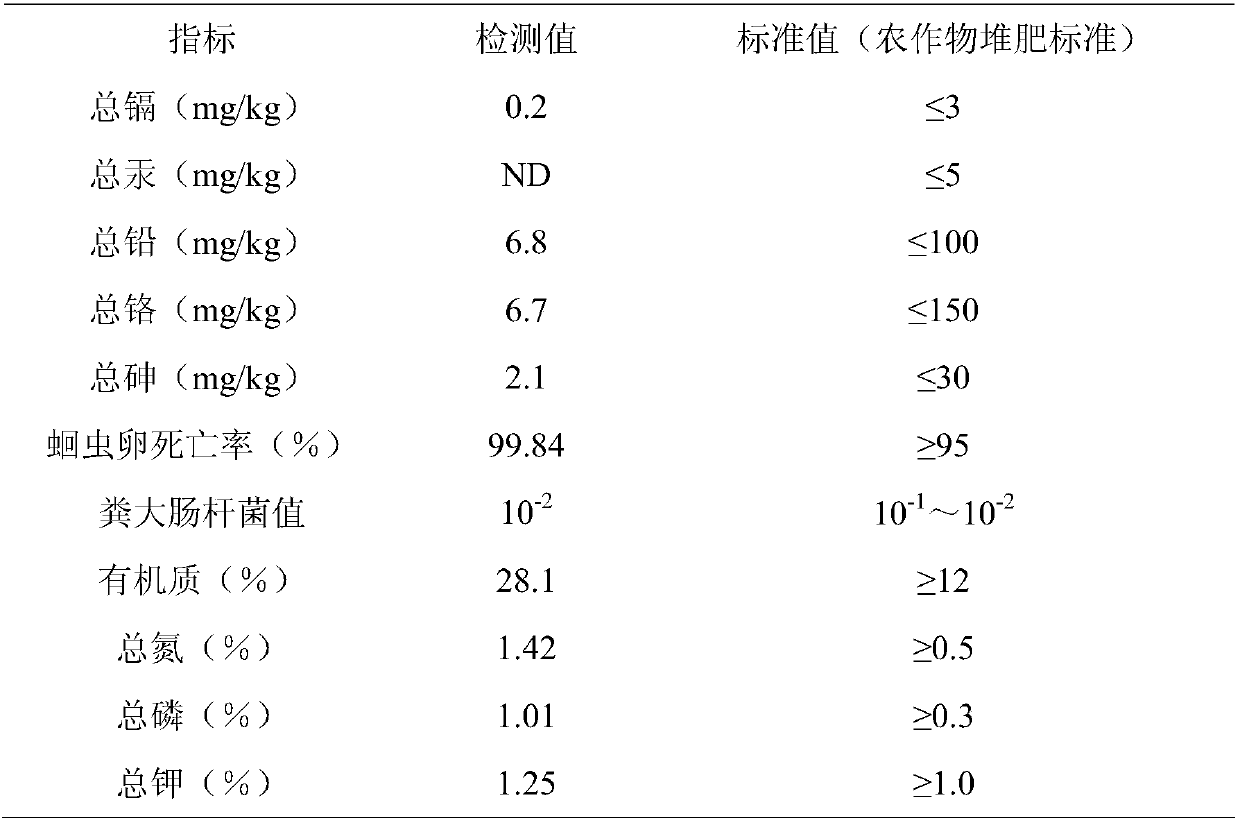

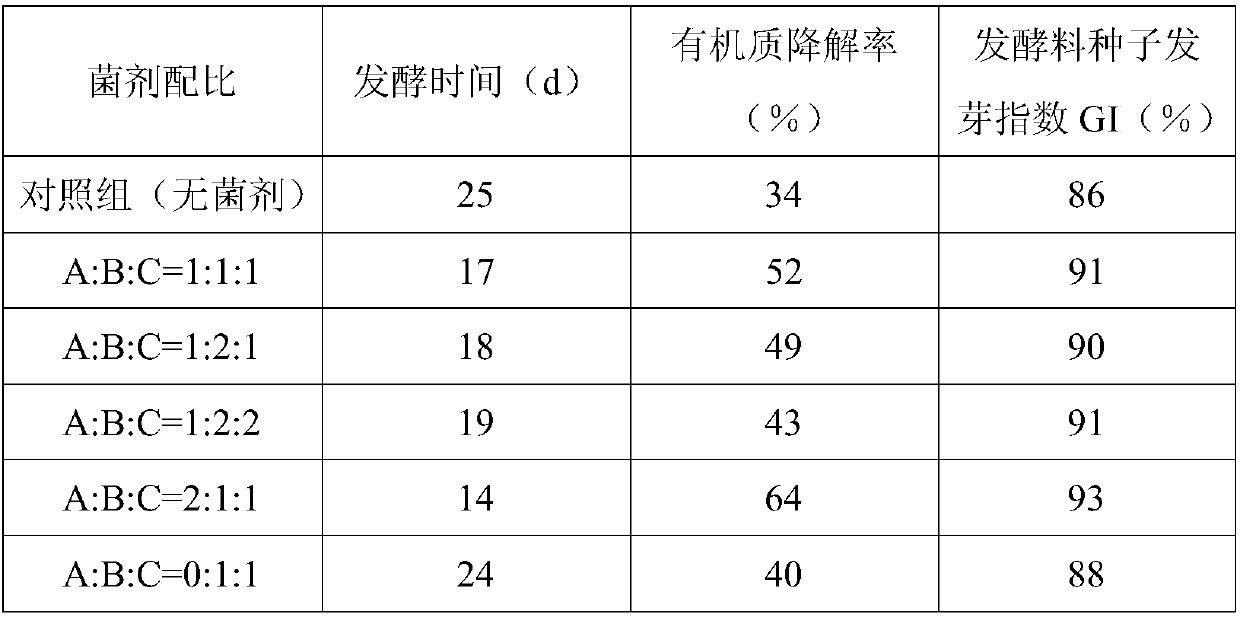

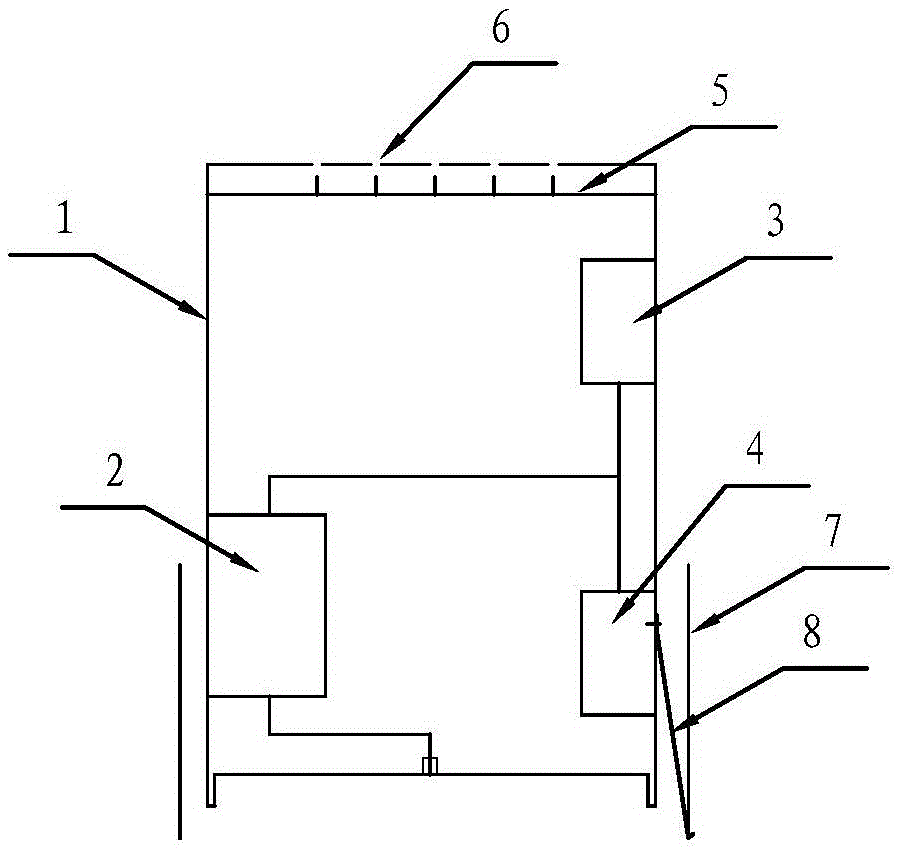

A method for rapidly preparing soil conditioner by using municipal sludge

ActiveCN106495945BLow running costAchieve stabilizationExcrement fertilisersSewage/sludge fertilisersAutomatic controlPoultry manure

The invention discloses a method for quickly preparing a soil conditioner with municipal sludge. The method includes uniformly mixing raw materials including domestic sludge, rice straw, livestock and poultry manure, heavy metal passivator and microorganism bacterium agent to obtain mixed material; subjecting the mixed material to high-temperatureaerobic fermentation with a multi-layer vertical mixing and turning fermentation tower to obtain fermented material; subjecting the fermented material to granulation prior to low-temperature drying to obtain the soil conditioner. With the method, stabilized, harmless, reducing and resourceful treatment of sludge is realized, sludge can be prepared into the soil conditioner capable of heightening soil quality and improving plant growth, preparation cost is low, the device is small in floor area, full-automatic control in process can be realized, and industrial production is facilitated.

Owner:HUNAN HENGKAI ENVIRONMENT TECH INVESTMENT CO LTD

A method for reducing the production of malodorous gas in farms

ActiveCN106268287BReduce generationInhibited DiffusionSpecific water treatment objectivesDispersed particle separationAnimal sciencePig breeding

The invention discloses a novel method for reducing generation of malodorous gases in a breeding farm. The method has the advantages of being simple in production, low in using cost, significant in effect and the like and is beneficial for solving the present existing pig breeding environment pollution problem. The method has the advantages that the synergistic effect of compound Chinese herbs and probiotic fermentation and the strong adsorption effect of an adsorbent are fully utilized, more than 10 kinds of malodorous gases such as NH3, H2S and CH4 in the breeding farm can be effectively removed, and the deodorant effect is good; by adopting the mode of combining a solid deodorant with a liquid deodorant, not only can the control area be increased through the liquid deodorant, but also major control can be conducted on a serious contaminated region through the solid deodorant, and both effectiveness and convenience are achieved; the deodorants are high in infiltration capacity, and therefore the defect that traditional deodorants cannot make full contact with livestock and poultry manure due to the fact that the traditional deodorants are poor in permeability is overcome; the safety is higher, the effect can be continuously achieved for a long time, the maintaining capability is good, and no bad influence is caused to microbial activities in the breeding farm.

Owner:裕龙农牧科技股份有限公司

Ecological anion purifier collecting pollutants by non-fan filter through coulomb force

InactiveCN105576508AAvoid increased concentration of positive ionsSolve the waste of electricityElectrical apparatusDeodrantsChemistryDust particles

The invention relates to an ecological anion purifier collecting pollutants by a non-fan filter through coulomb force. The ecological anion purifier comprises a case, a circuit control board, an anion generation unit, a positive high pressure generator, an anion releaser, a releaser cover and a pollutant adsorber. The ecological anion purifier has an attractive appearance and can be put flexibly; ecological anions produced by the ecological anion purifier can reach a far distance so as to combine with pollutants like dust particles, viruses, allergens and so on in the air, so that the pollutants carry the negative electricity to be adsorbed by the pollutant adsorber; and the anions can change the electric potential polarity of the virus cell so as to achieve the purpose of sterilizing. As the ecological anion purifier has dual disinfecting technologies of anion disinfection and electrocatalyst catalytic decomposition, third-level pollutants, physical pollutants (suspending particles), chemical pollutants (ozone, methanol, benzene compounds, carbon monoxide, nitrides and so on) and microbiological pollutants (bacteria and virus) in the air can be thoroughly eliminated. Due to a forest phytoncid ionized slowly releasing system, a forest air effect is created.

Owner:叶向阳

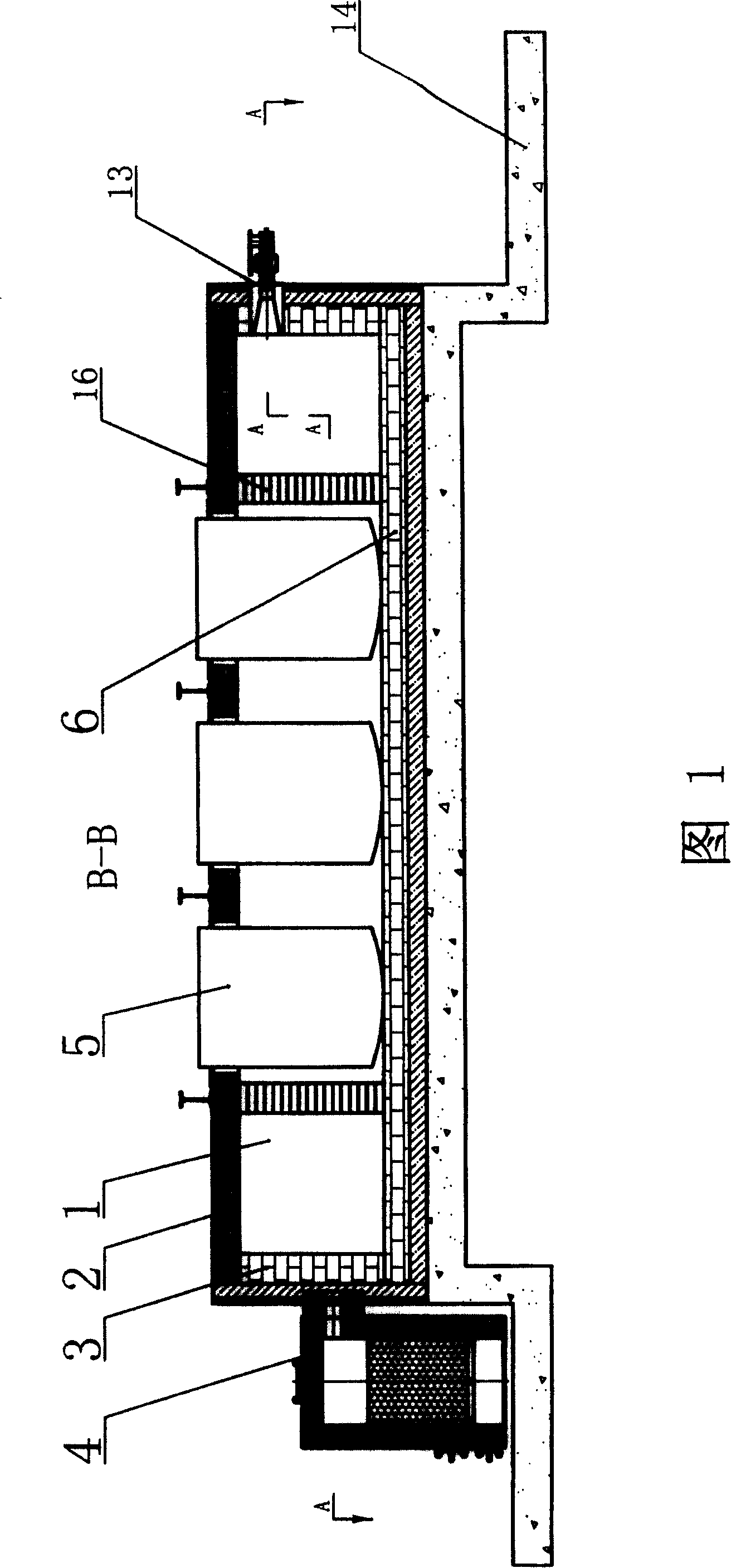

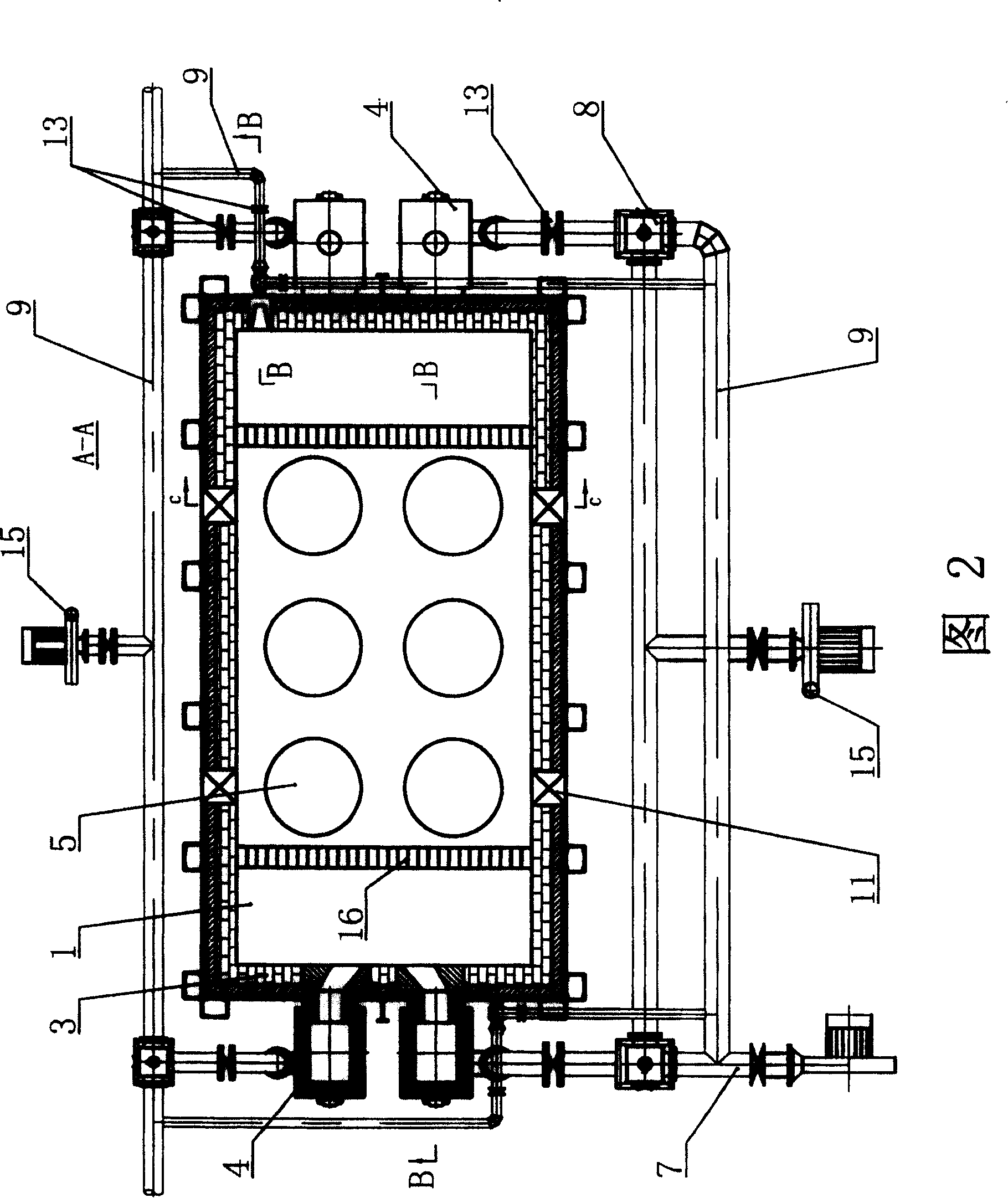

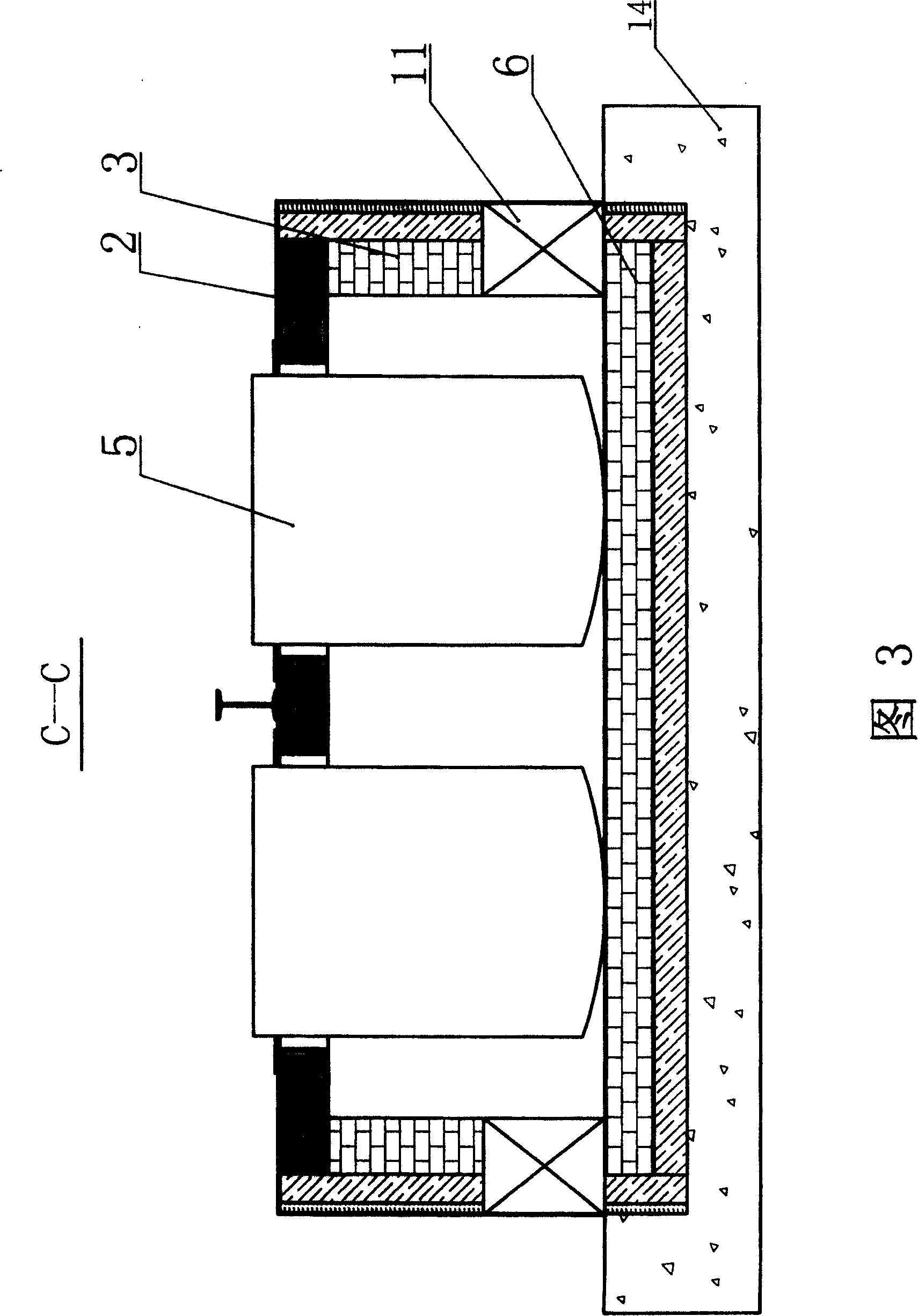

High performance. Energy saving, environmental protective heat storage type refinery furnace for metal magnesium

This invention relates to an energy-saving and environmentally friendly regenerative furnace for refining magnesium. The furnace comprised a furnace body, a furnace top, two furnace walls, nozzles, a refining kettle, a funace hearth and a wind blowing system. The nozzles are symmetrically arranged along the width direction on the bottom of the two furnace walls at both ends. Two reversing valves are installed on the two furnace walls at both ends, and connect the nozzles and the wind blowing system through pipelines and a reversing control system. The furnace has such advantages as low energy consumption, uniform temperature in the furnace, and special combustion mode, good environmental protection, long service life, and high combustion efficiency, low thermal loss of the flue gas, high productivity, low cost and high safety.

Owner:北京胜亚恒源热能技术开发有限公司

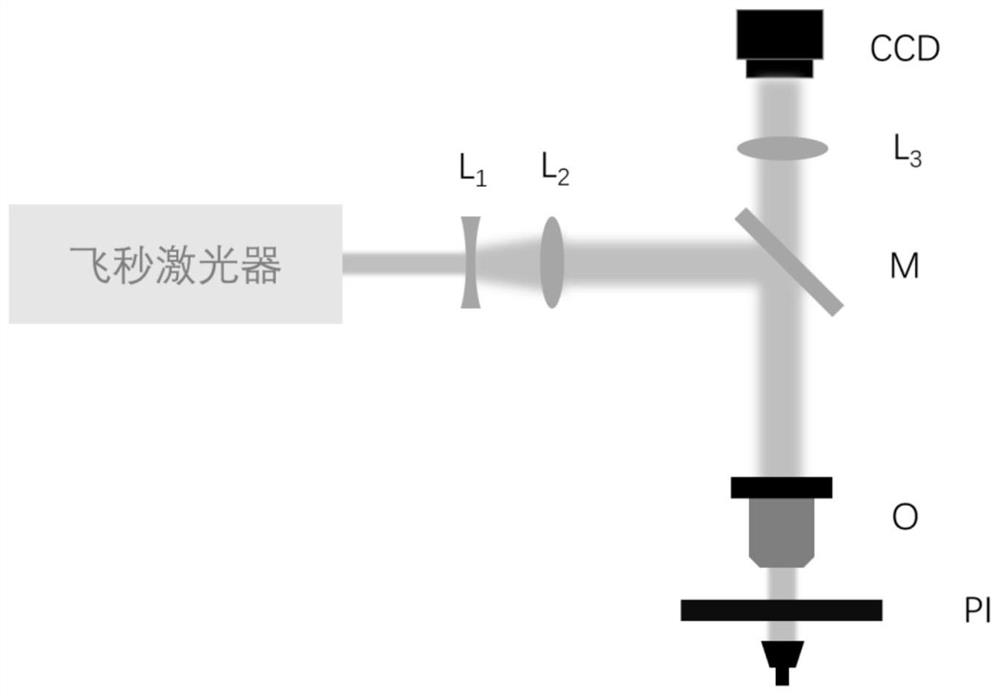

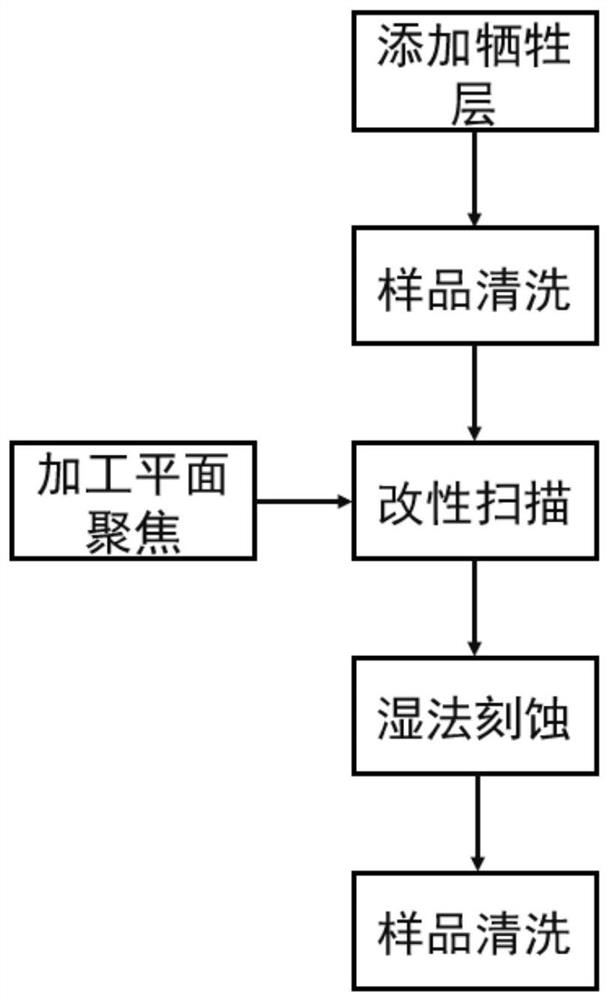

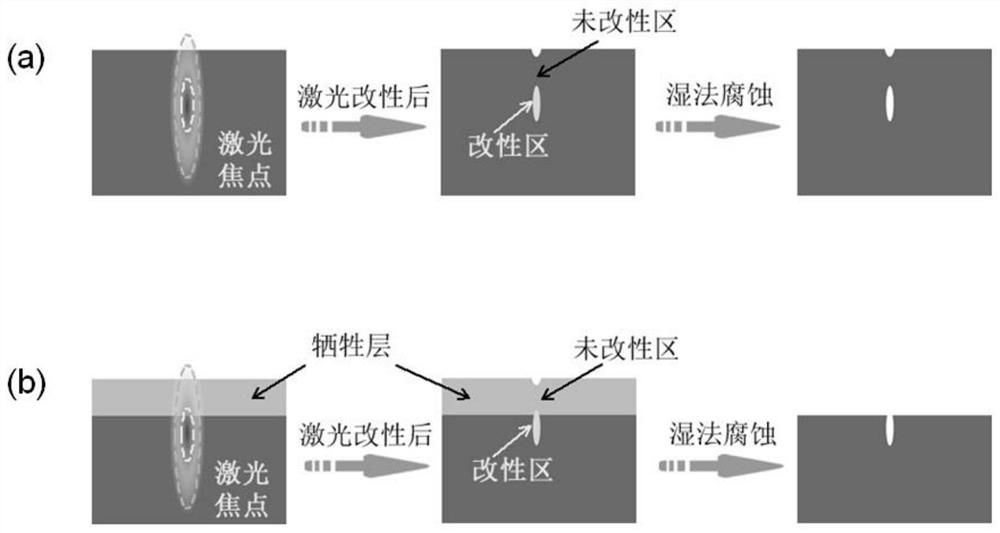

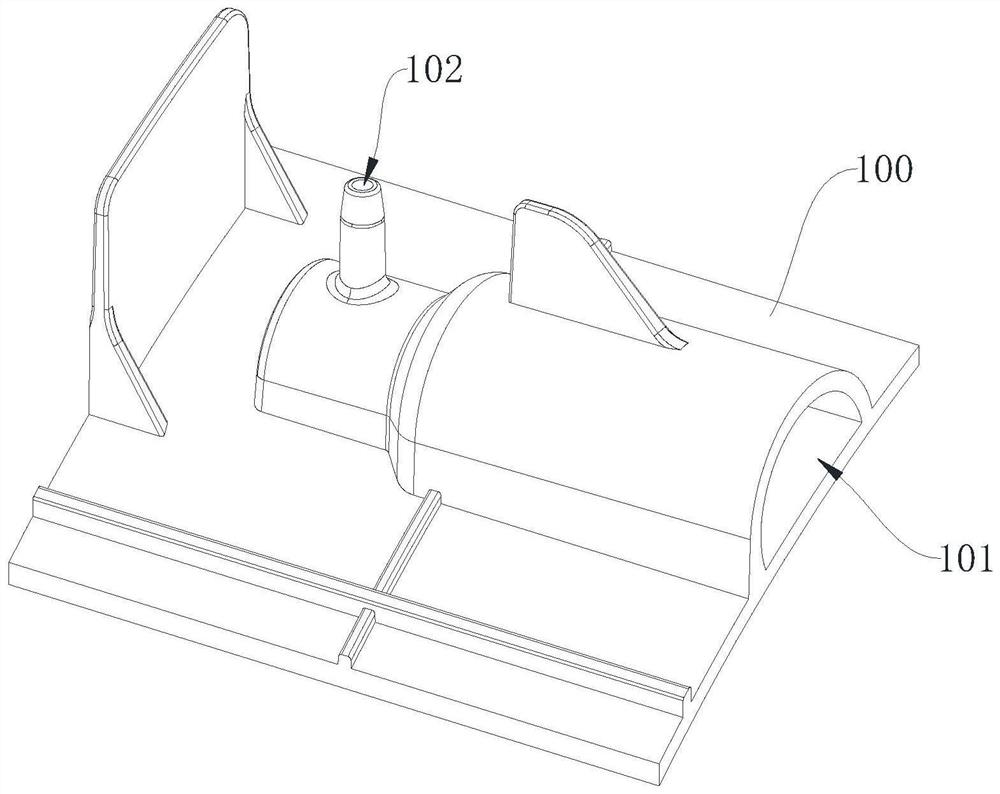

A processing method for high aspect ratio structures of hard and brittle materials and its application in the preparation of optical micro-nano structures

ActiveCN112548355BHigh precisionImprove smoothnessLaser beam welding apparatusEtchingNano structuring

Owner:JILIN UNIV

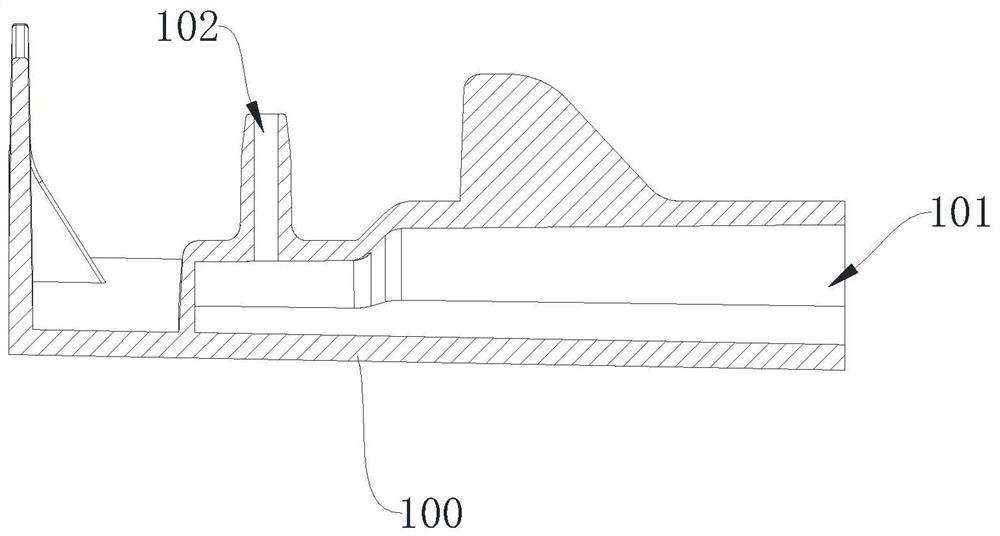

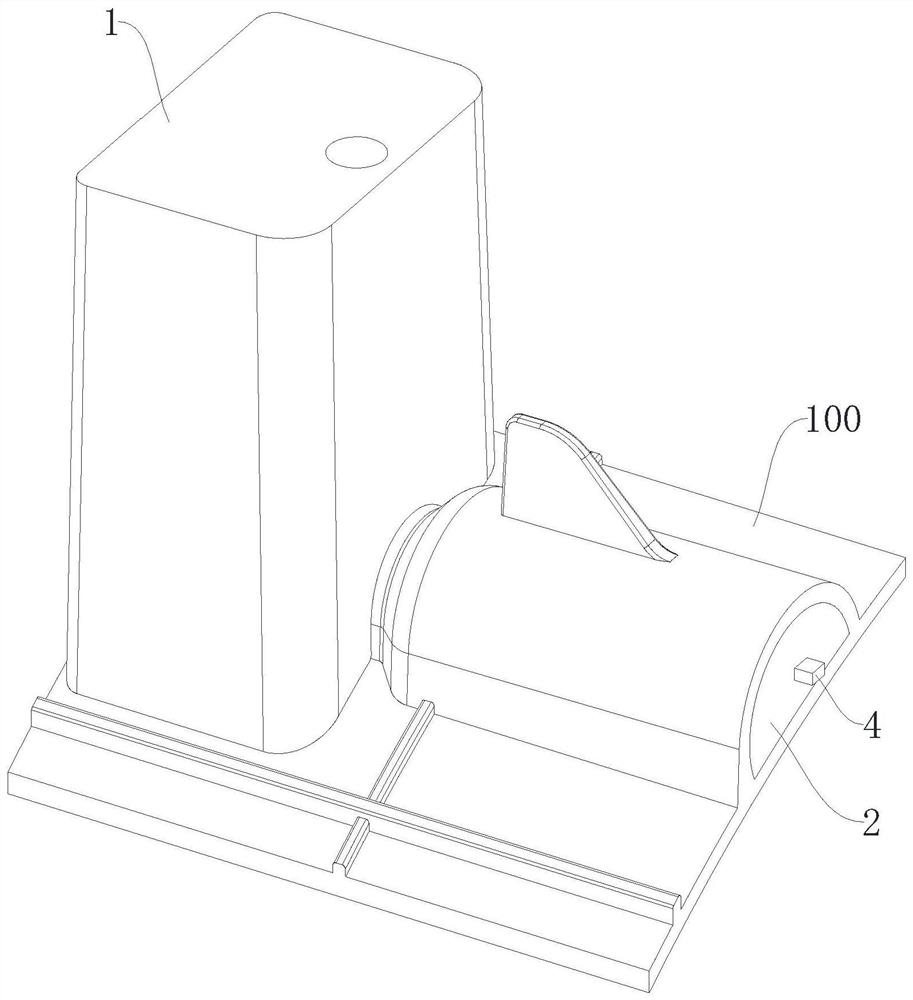

Flash-free slender hole forming mechanism of injection mold

The invention discloses a flash-free slender hole forming mechanism of an injection mold, which comprises a template for forming the outer contour of a shell plastic part, a side sliding block for forming an inner cavity on the shell plastic part, and a movable ejector core assembly for forming a slender hole on the shell plastic part, wherein the movable ejector core assembly comprises a movable core and an elastic piece, the movable core is arranged on the template in a sliding mode in the longitudinal direction, the lower end of the movable core penetrates through the template and is used for forming the slender hole, the elastic piece is arranged between the movable core and the template, and the elastic piece forces the movable core to move downwards to enable the movable core to move downwards; and when the injection mold is in a mold closing state, the elastic piece forces the lower end of the movable core to always abut against the upper end face of a side sliding block. The flash-free slender hole forming mechanism has the advantages of a simple structure, convenience in control and high forming quality.

Owner:宁海县第一注塑模具有限公司

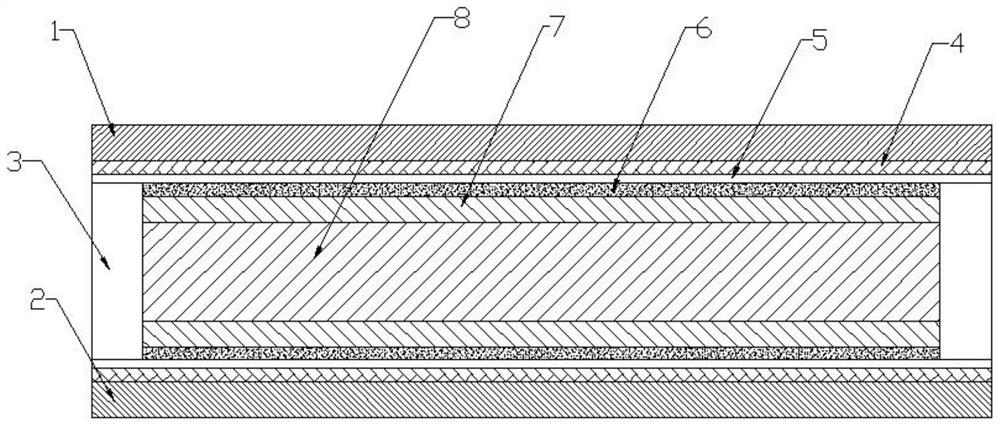

Water-based graphene electrothermal film and preparation method thereof

PendingCN112738930AImprove compatibilityAvoid reunionOhmic-resistance waterproof/air-tight sealsPolyurea/polyurethane coatingsElectrically conductiveElectric heating

The invention belongs to the technical field of electric heating, and particularly relates to a water-based graphene electrothermal film which comprises a first insulating protective layer, a graphene heating layer and a second insulating protective layer. The first insulating protective layer and the second insulating protective layer are attached to the top and the bottom of the graphene heating layer respectively, the graphene heating layer comprises a base material layer, a graphene conducting layer, an insulating layer, a heat preservation layer, a waterproof layer and an electrode, the outer wall of the base material layer is coated with the graphene conducting layer, and the outer wall of the graphene conducting layer is coated with the insulating layer; the outer wall of the insulating layer and the outer wall of the electrode are both coated with the heat preservation layer, the outer wall of the heat preservation layer is coated with the waterproof layer, and the left side and the right side of the graphene conducting layer are connected with the electrode. According to the invention, the main body of the solvent is water, so that the use of an organic solvent is reduced to the maximum extent. From the perspective of environmental protection, the water-based graphene electrothermal film only uses water as a diluent, is harmless to human health, does not contain harmful cancerogenic substances in preparation, and is non-toxic and odorless.

Owner:上海雅高新能源科技有限公司

Settling tank for oil field sewage

ActiveCN111154509BLow viscosityEasy to separateDewatering/demulsification with chemical meansFatty/oily/floating substances removal devicesDemulsifierSludge

The invention relates to the technical field of oilfield sewage treatment, and discloses a settling tank for oilfield sewage, which includes a tank body, a liquid inlet pipe, an oil collection tank, and a liquid infusion pipe. The sludge area is located at the bottom of the tank body, the sewage area is located above the sludge area, and the emulsification area is located above the sewage area. The settling tank for oil field sewage, through the density difference between the floating plate, sliding plate and the sewage area and the oily area, the floating plate is always floating in the middle of the sewage area and the oily area, thus driving the drug delivery pipe to be located in the emulsified layer , the sprayed demulsifier directly contacts the emulsification area, realizing the rapid demulsification of the emulsification area generated during the separation process of crude oil. On the one hand, a large amount of demulsifier is saved, so that the demulsifier directly acts on the emulsification area, and on the other hand, the elimination of emulsification is accelerated The formation of the zone reduces the loss of oil temperature during the separation process of crude oil, reduces the viscosity of crude oil, and thus speeds up the separation between crude oil and sewage.

Owner:肇州县海崴井下作业有限公司

Preparation method of free-of-immersion and quick-to-cook wild rice

PendingCN111820374AImprove featuresReduce cooking timeSeed preservation by freezing/coolingBiotechnologyStarch gelatinization

The invention discloses a preparation method of free-of-immersion and quick-to-cook wild rice. The wild rice is subjected to screening and impurity-removing treatments, properties of the wild rice areimproved by carrying out treatments with pressurizing and heating equipment to promote starch gelatinization and partial protein denaturation, so as to shorten cooking time of the wild rice, therebyobtaining ice crack-shaped wild rice without peculiar smell. The ice crack-shaped wild rice has strong aroma and good mouthfeel, nutrient substances are retained to the maximum extent, and the loss ofnutrient substances is reduced. After cooling and preserving treatment, heating treatment and drying treatment are carried out quickly to make the wild rice form the ice crack shape, thus facilitating later cooking, shortening cooking time and further improving the mouthfeel. The semi-finished wild rice is formed by using the preparation method of the invention, the semi-finished wild rice is notready to eat and not prone to producing harmful bacteria, and the low-temperature refrigeration treatment is carried out, thus eliminating some of the original harmful bacteria in the wild rice and prolonging the storage time of the wild rice.

Owner:乐世买(上海)实业发展有限公司

A kind of deodorizing purification concentrated liquid and its preparation method and application

ActiveCN111249173BCatch quicklyPromote decompositionAntibacterial agentsBiocideBiotechnologyArginine

The present invention provides a deodorizing purification concentrate and a preparation method and application thereof. The deodorant purification concentrate includes: lysine, arginine, glycine, taurine, trehalose, bacteriostatic sugar compound, monoalkyl glycerol, bactericide, solubilizer and water. The components of the deodorizing purification concentrate of the invention cooperate with each other, and have synergistic effect, which can quickly capture odor molecules in the environment, decompose or neutralize odor-producing organic substances, reduce the source of odor gas generation and eliminate it in time The odorous gas produced can also inhibit a variety of common bacteria or fungi, with short action time and strong inhibitory effect, and can be sprayed directly or diluted on the pet's body or hair, which is safe and reliable with low irritation.

Owner:XIAOPEI NETWORK TECH (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com