Enameled wire paint breaking alarming method and mechanism of enameling machine

An enameled wire and enameled machine technology, which is applied in alarms, conductor/cable insulation, instruments, etc., can solve the problems of unsatisfactory surface removal of aluminum wires, inability to repeat multiple coats of paint, and performance degradation of enameled wires, etc., to improve work efficiency and effect, reduction of power consumption, and effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

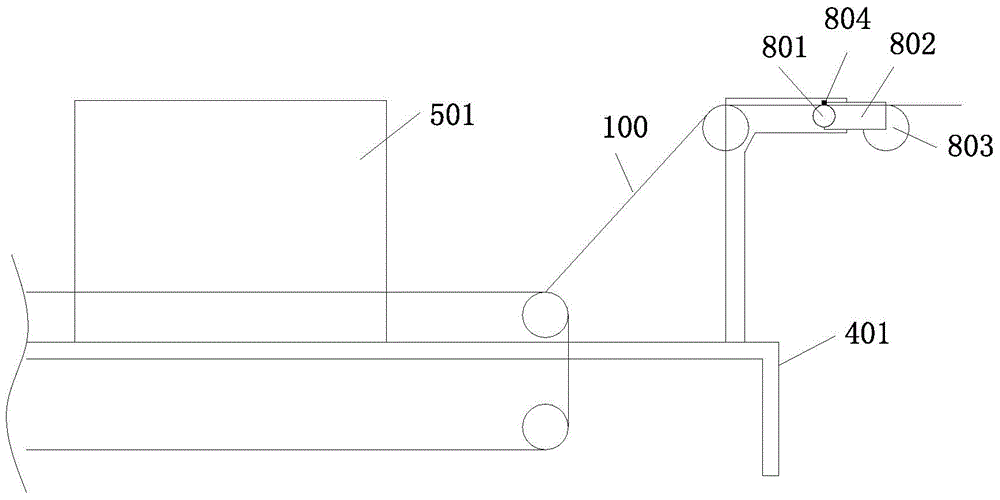

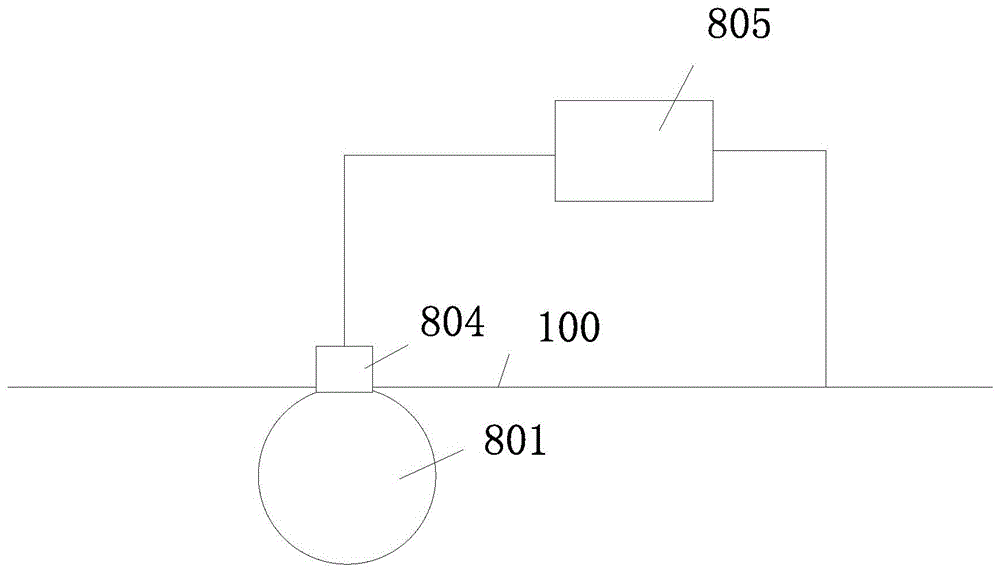

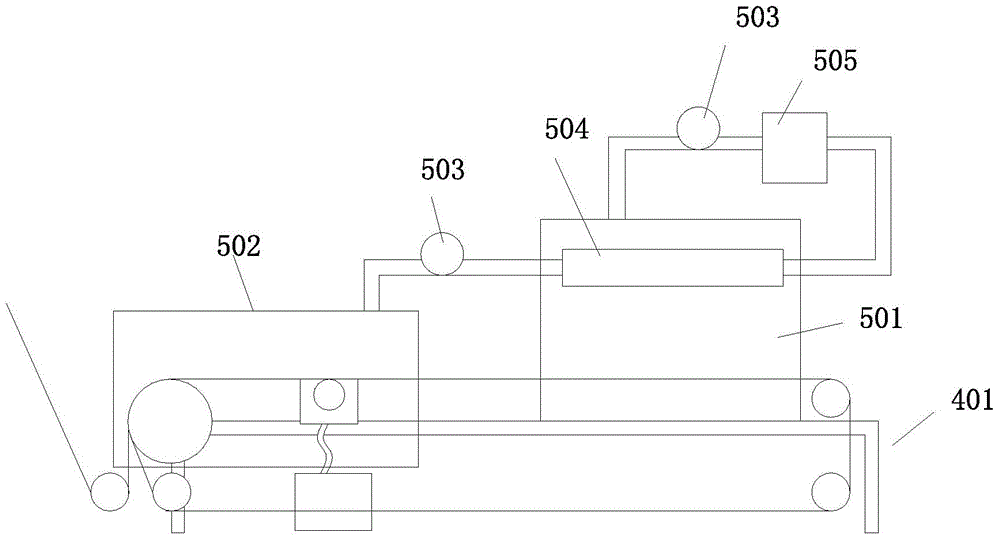

[0024] Embodiment: The enameled wire breakage alarm method of the enamelled machine, this method connects one end of the alarm to the exposed end point of the enameled wire, and the other end is connected to the conductive fixed shaft through the wire, and the enameled wire comes out of the oven and passes past the fixed shaft. When the bare section of the enameled wire with broken paint passes through the fixed shaft, the fixed shaft, the enameled wire and the alarm with its own power supply form a loop, and the alarm will send out alarm information such as sound and light to prompt the workers to remedy or adjust; The gas generated by the painting mechanism is collected through an outer cover and then passed into the heat exchange tube installed in the oven body for heating. After heating, it is transported to the catalytic combustion chamber to be heated again into hot gas, and then passed into the oven body to treat the enameled wire. Heat and tumble dry.

[0025] The mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com