Switch, botton switch and rotation switch

A switch and button technology, which is applied in the direction of electric switches, electrical components, contact engagement, etc., can solve the problems of inability to obtain movement amount, reduce balance contacts, and contact performance degradation, etc., and achieve small size, proper spring function, and high-efficiency configuration Composition, the effect of reducing assembly man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

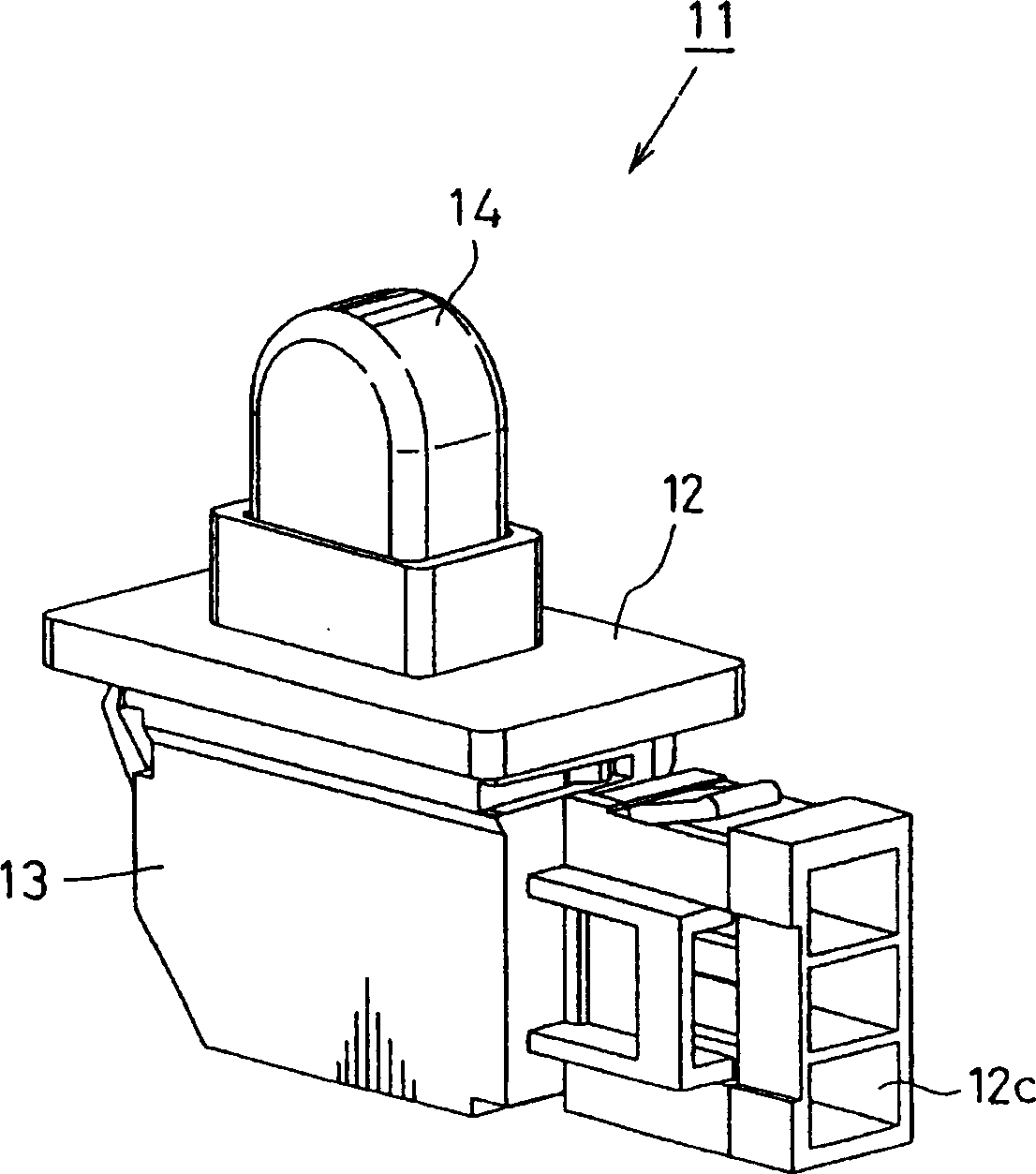

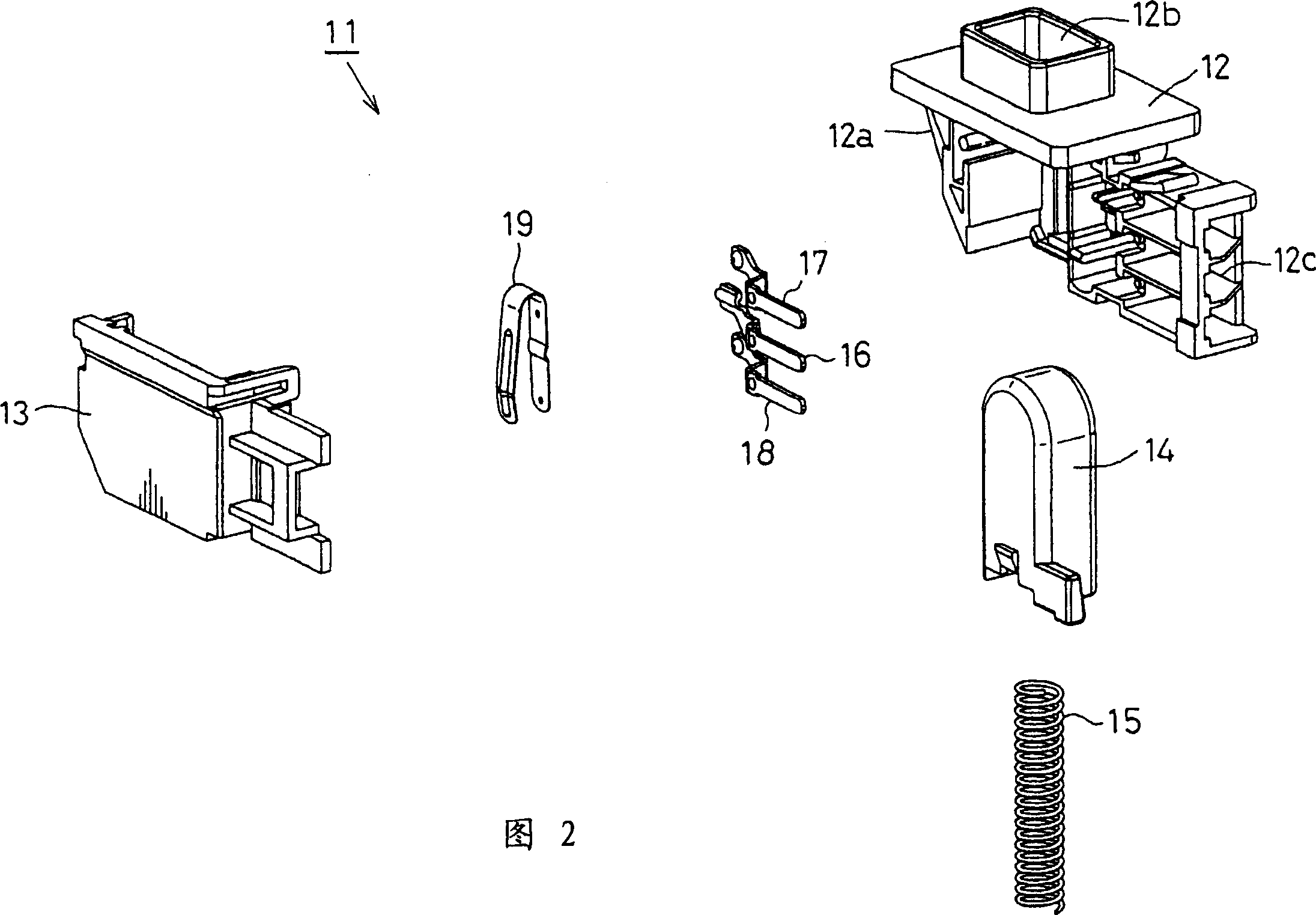

[0084] The attached picture shows a push button switch for refrigerator door opening and closing, in figure 1 As shown in FIG. 2 , the push button switch 11 is composed of a housing 12 , a cover 13 , a button 14 , a return spring 15 , three fixed terminals 16 to 18 and a movable piece 19 .

[0085] The housing 12 has an attachment cavity in which the above-mentioned components are assembled, and the cavity is closed by a cover 13 which will be described later.

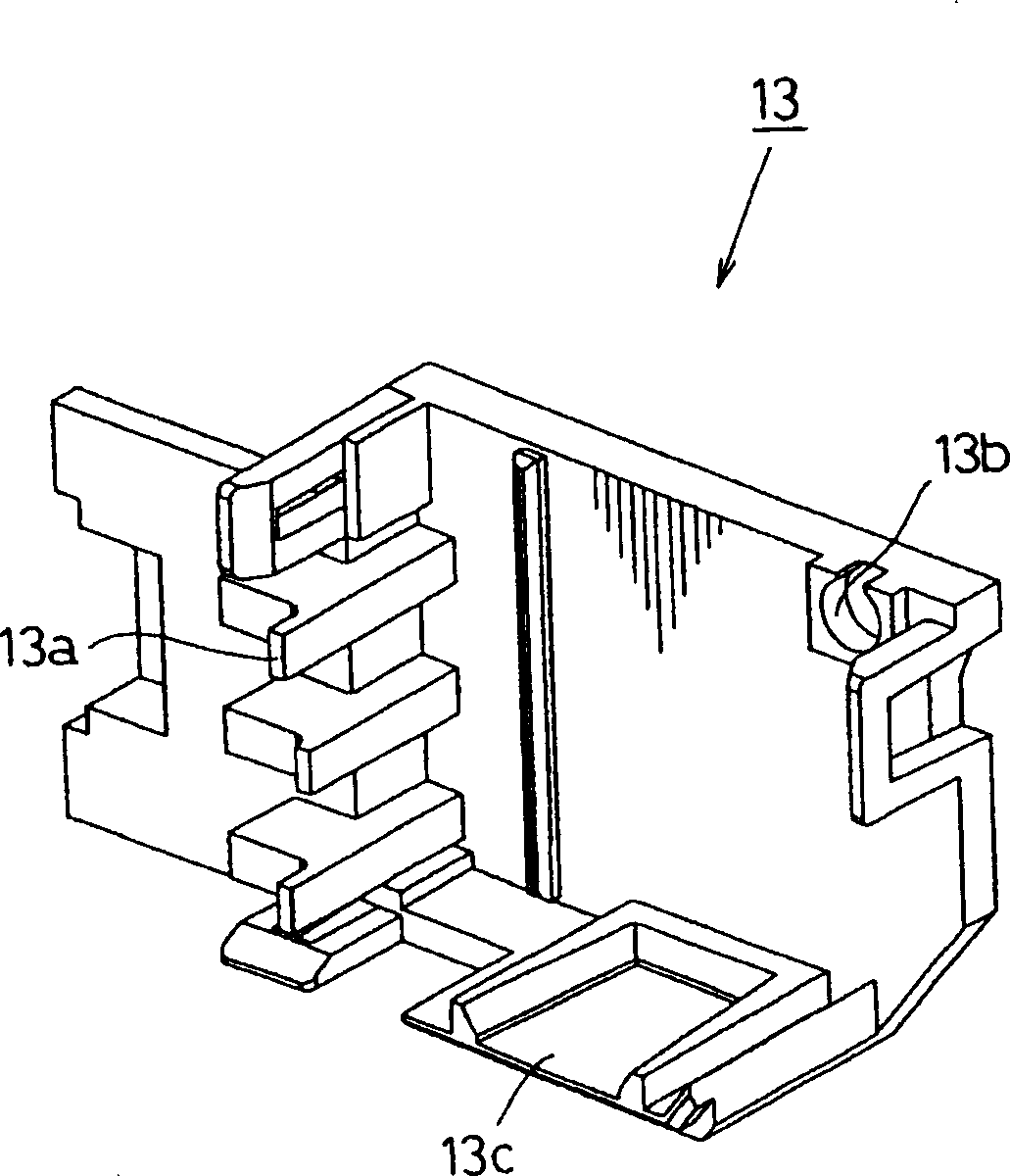

[0086] image 3 The cover 13 is shown, and the cover 13 is installed from a side opening 12a (refer to FIG. 2 ) of the casing 12, and the inner surface of the cover 13 has fixed terminals 16 to 18 and movable terminals respectively divided and supported to be described later. Partition member 13a of sheet 19.

[0087] On the upper side of the cover 13, there is a shaft support portion 13b that realizes the common use of rotary switches of different specifications. This type of cover 13 can be used for push-button swi...

no. 2 Embodiment

[0111] Hereinafter, instead of the push-button switch 11, a case where a rotary switch is similarly used as a refrigerator door switch will be described.

[0112] Figure 14 with Figure 15 Among them, the rotary switch 141 is formed by integrally assembling the housing 142, the cover 143, the rotary joystick 144, the return spring 145, the three fixed terminals 146-148, and the movable piece 149.

[0113] The housing 142 has a hollow portion for fitting the components described above, and the hollow portion is closed by a cover 143 which will be described later.

[0114] The cover 143 and image 3 The illustrated cover 13 is the same as the push button switch 11, and is integrally attached from one side opening 142a of the housing 142. As shown in FIG.

[0115] Figure 16 Represents the rotating joystick 144, the rotating joystick 144 has a fan shape, along its inclined upper surface, a joystick pressing piece 144a is extended obliquely upward, and a supporting shaft 144b...

no. 3 Embodiment

[0150] Figure 27 And Fig. 28 represents another kind of button switch 271 that is used for refrigerator door switch, and the feature of this button switch 271 is to be provided with the housing 272 that can be used in common for multiple button switches, is housing 272, cover 273, button 274, back-moving spring 275, 3 fixed terminals 276~278, movable piece 279 carry out integral assembly and constitute.

[0151] Figure 29 The housing 272 is shown, and the housing 272 has a hollow part for assembling the components described above, and a push button 274, a return spring 275, three fixed terminals 276 to 278, As for the movable piece 279, the one side opening 272a is closed by a cover 273 which will be described later.

[0152] On the upper surface of the housing 272, there is a cylindrical portion 272b penetrating in the vertical direction. Here, the push button 274 is slidably inserted in the vertical direction. At a position adjacent to the inner side of the button 274, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com