Patents

Literature

60results about How to "Elastic enough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

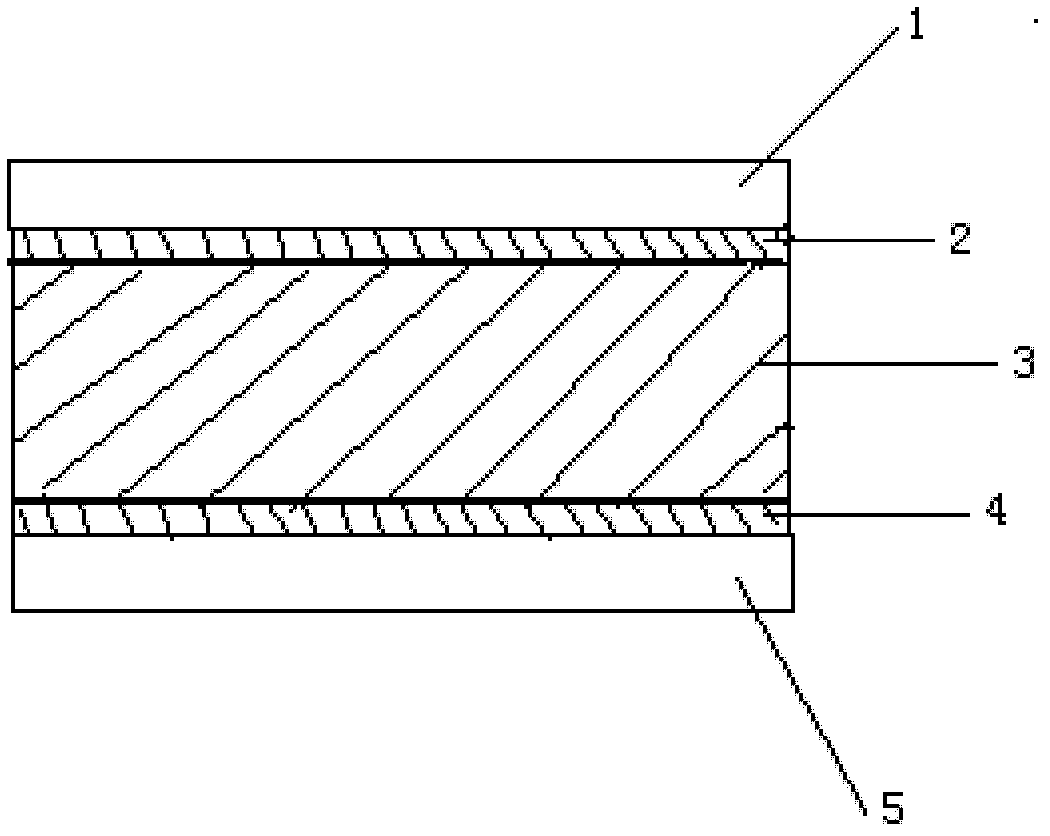

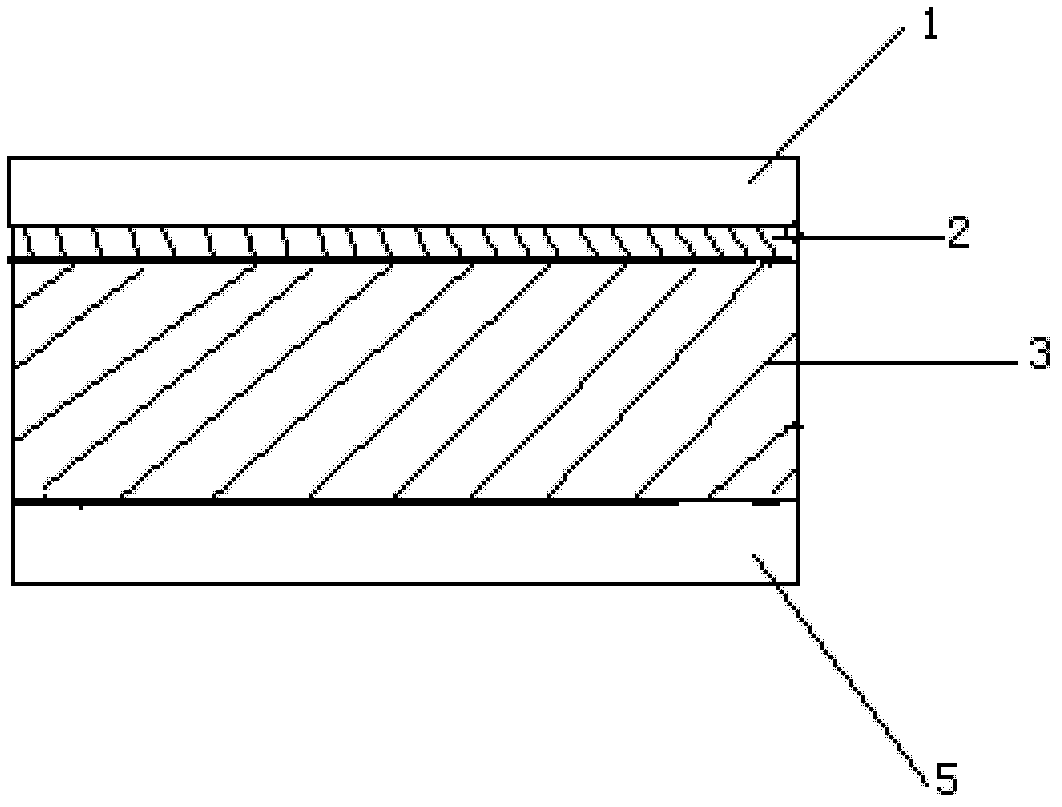

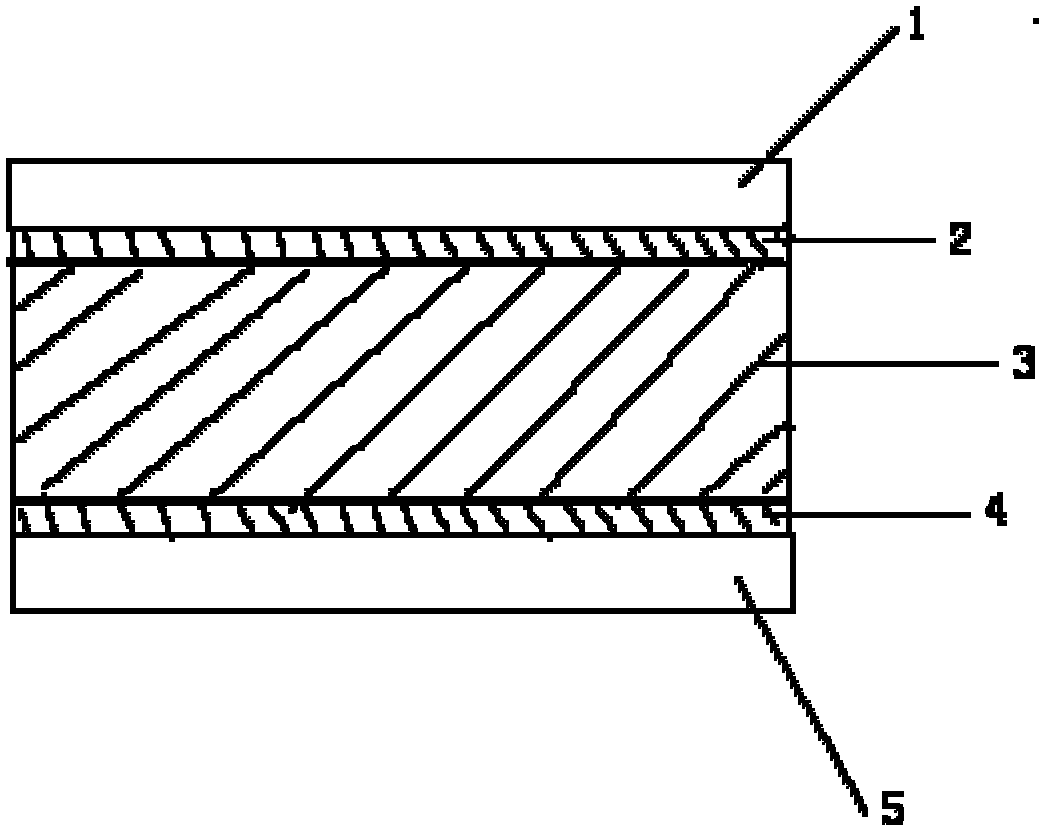

Universal health-care board and preparation method thereof

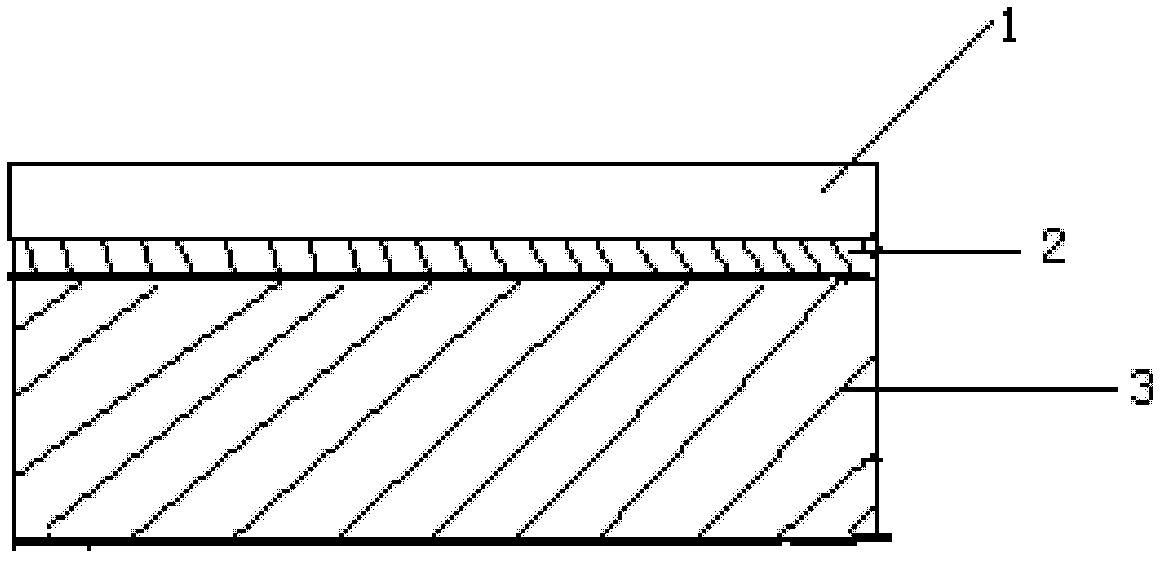

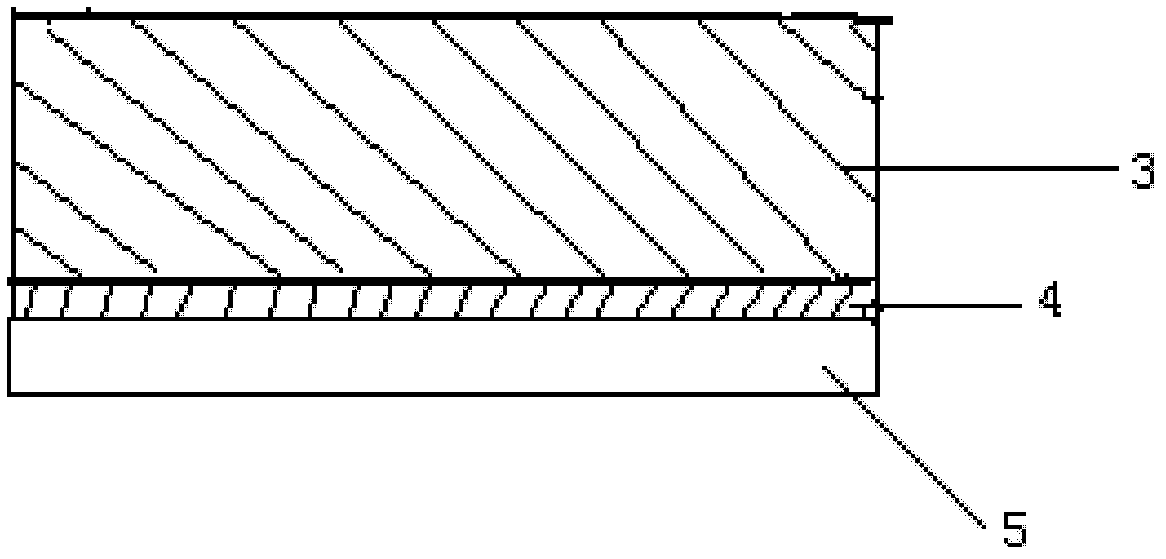

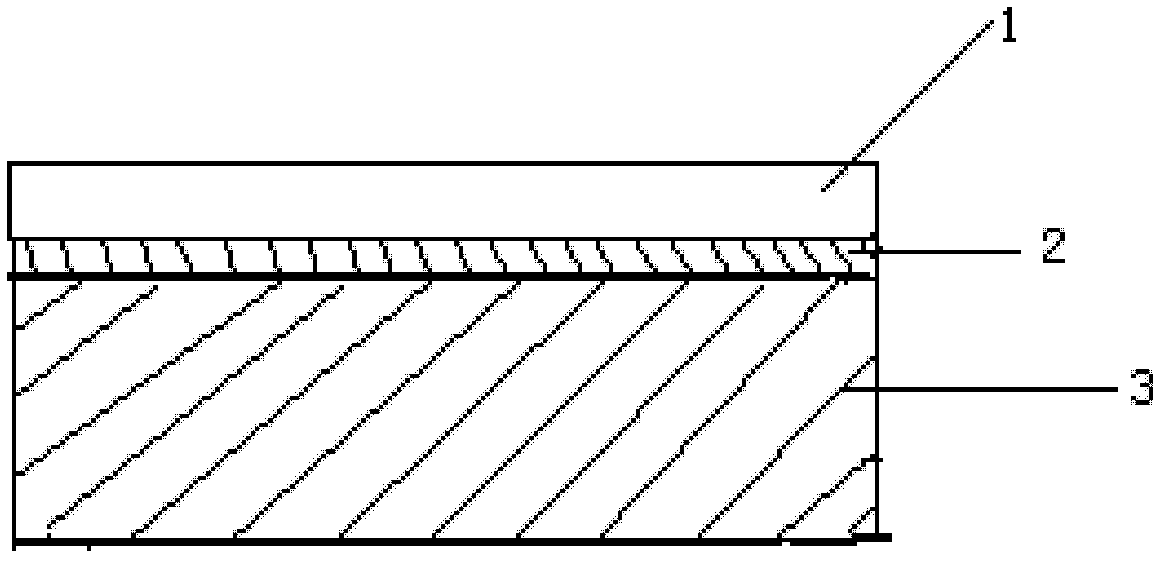

ActiveCN102514254AGood elastic recoveryGood strength and elasticityStuffed mattressesLamination ancillary operationsFiberSurface layer

Owner:JIANGSU REDBUD DYEING TECH CO LTD

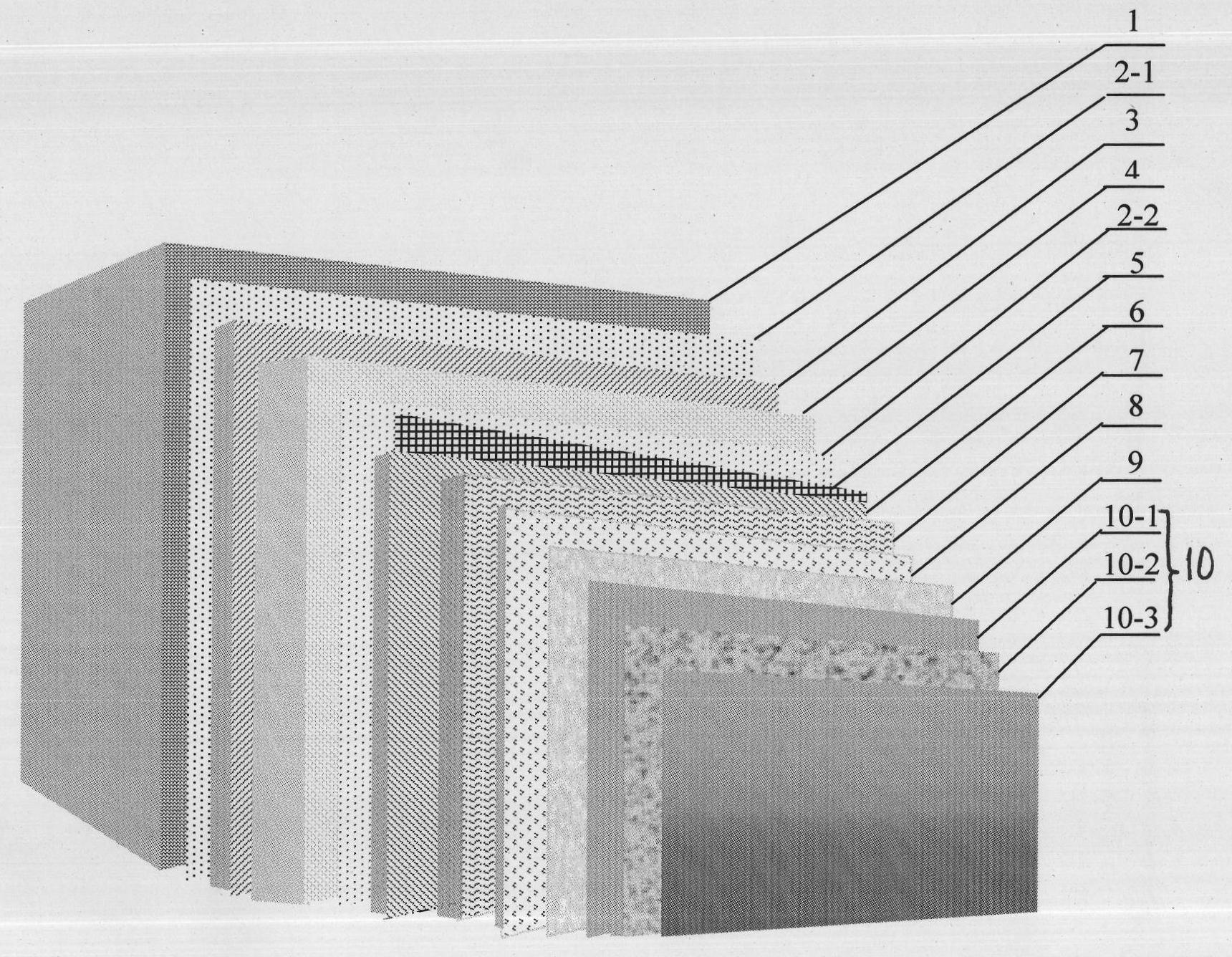

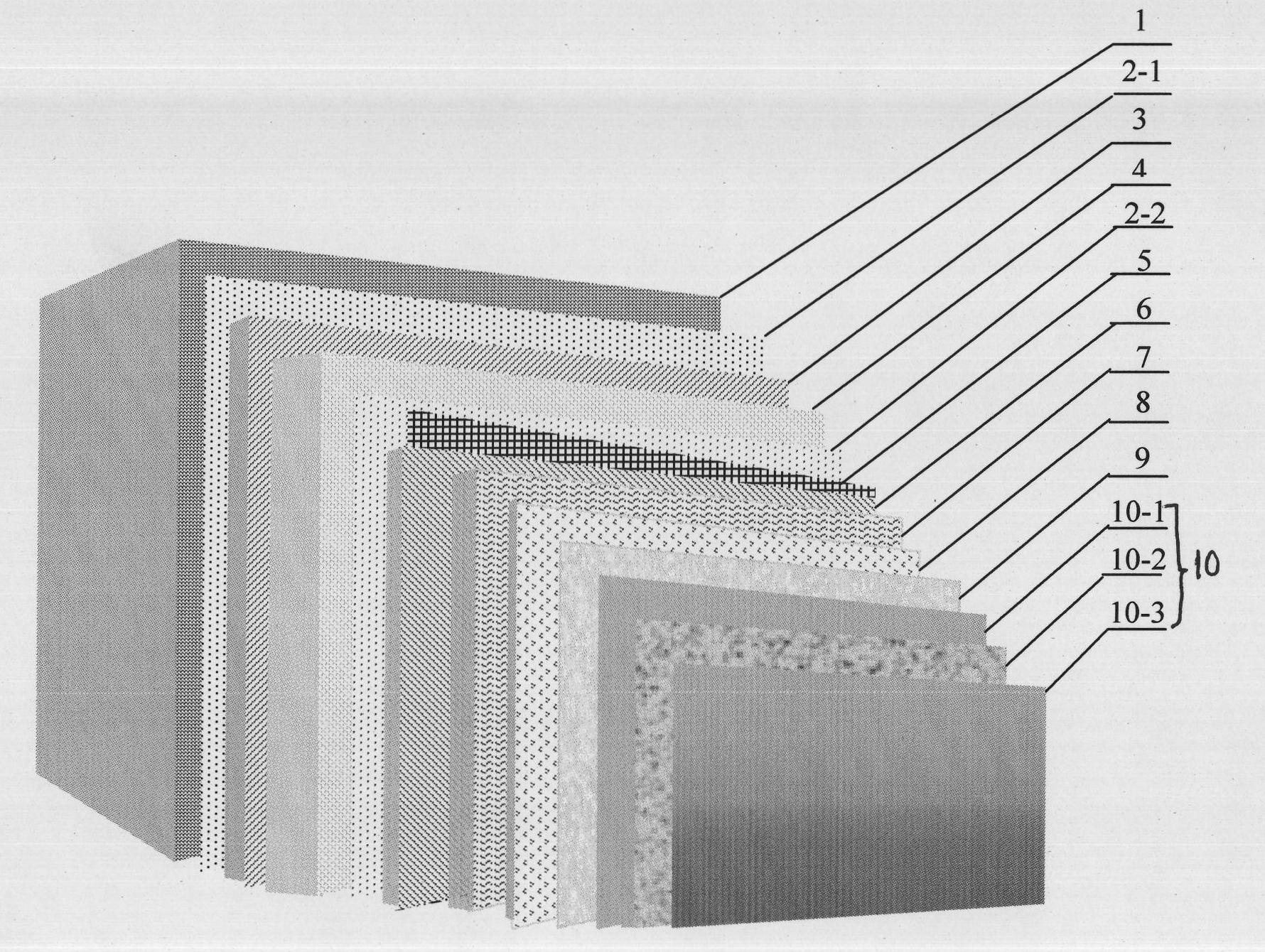

External thermal insulation system of water-based simulated natural granite paint finish

ActiveCN101798860AElastic enoughGood value for moneyCovering/liningsMulticolor effect coatingsWater basedFiberglass mesh

The invention relates to an external thermal insulation system of a water-based simulated natural granite paint finish. The specific structure is as follows: sequentially arranging a first interface binder layer (2-1), an adhesive mortar layer (3), a polystyrene board thermal insulation layer (4), a second interface binder layer (2-2), a polymer anti-crack mortar rendering layer (6) of a liner fiberglass mesh (5), a polymer flexible putty leveling layer (7), a smooth putty layer (8), a seal primer layer (9) and a finishing layer (10) which are arranged on the external surface of a basal layer wall body (1) from inside to outside, and the invention is characterized in that the finishing layer (10) consists of a flexible ground color layer (10-1), a water-based flexible colorful pattern layer (10-2) and a mat coat protection layer (10-3) sequentially arranged from inside to outside, and the various layers are integrated with the basal layer wall body (1) after drying and curing. With an appropriate price and simple process, the invention makes the building get the effect of granite building material and improves the external thermal insulation and the safety of the external wall.

Owner:CHINA NAT OFFSHORE OIL CORP +2

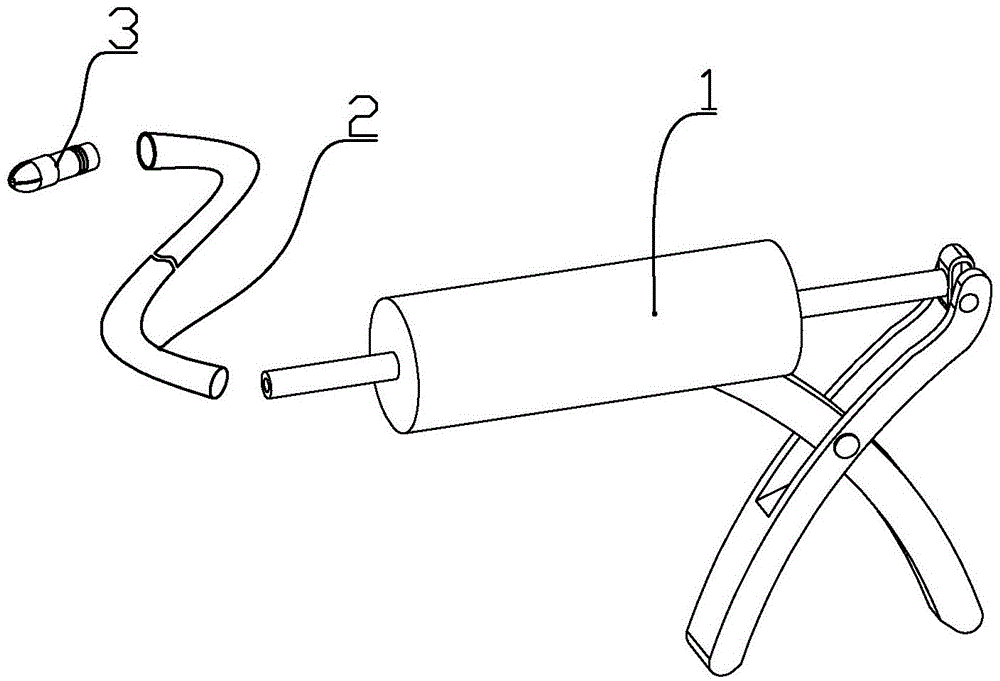

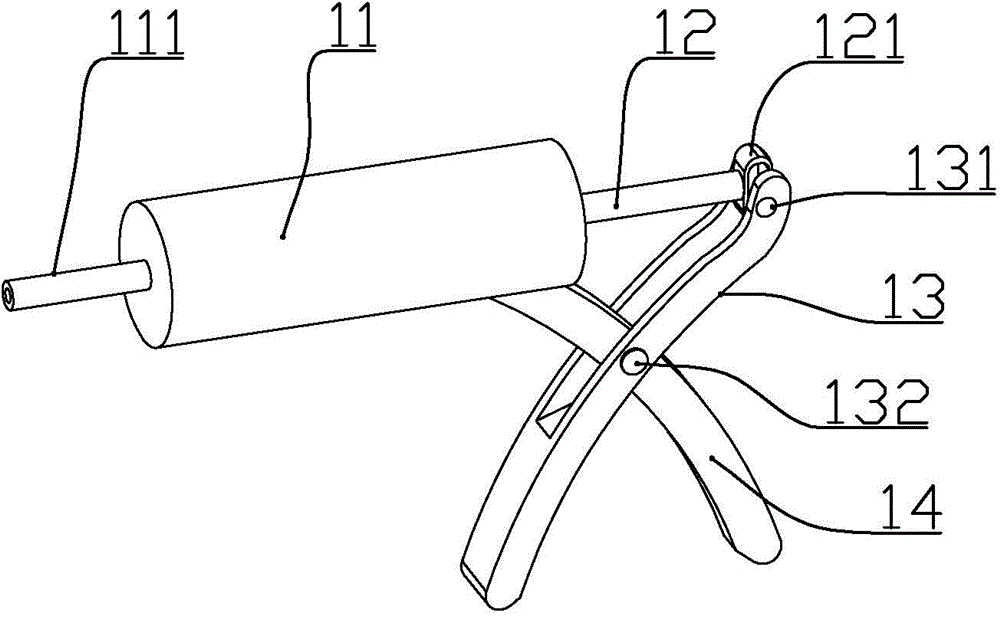

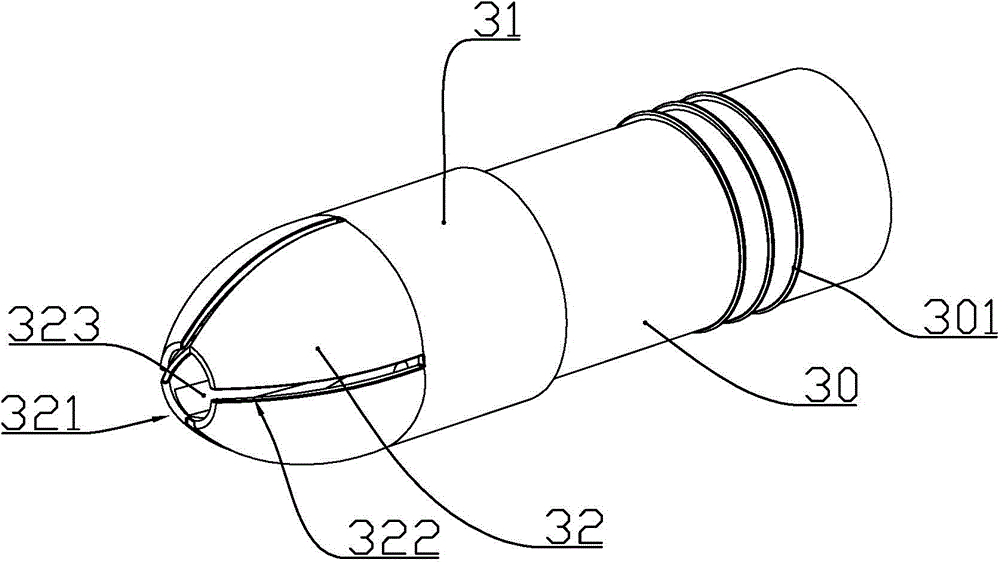

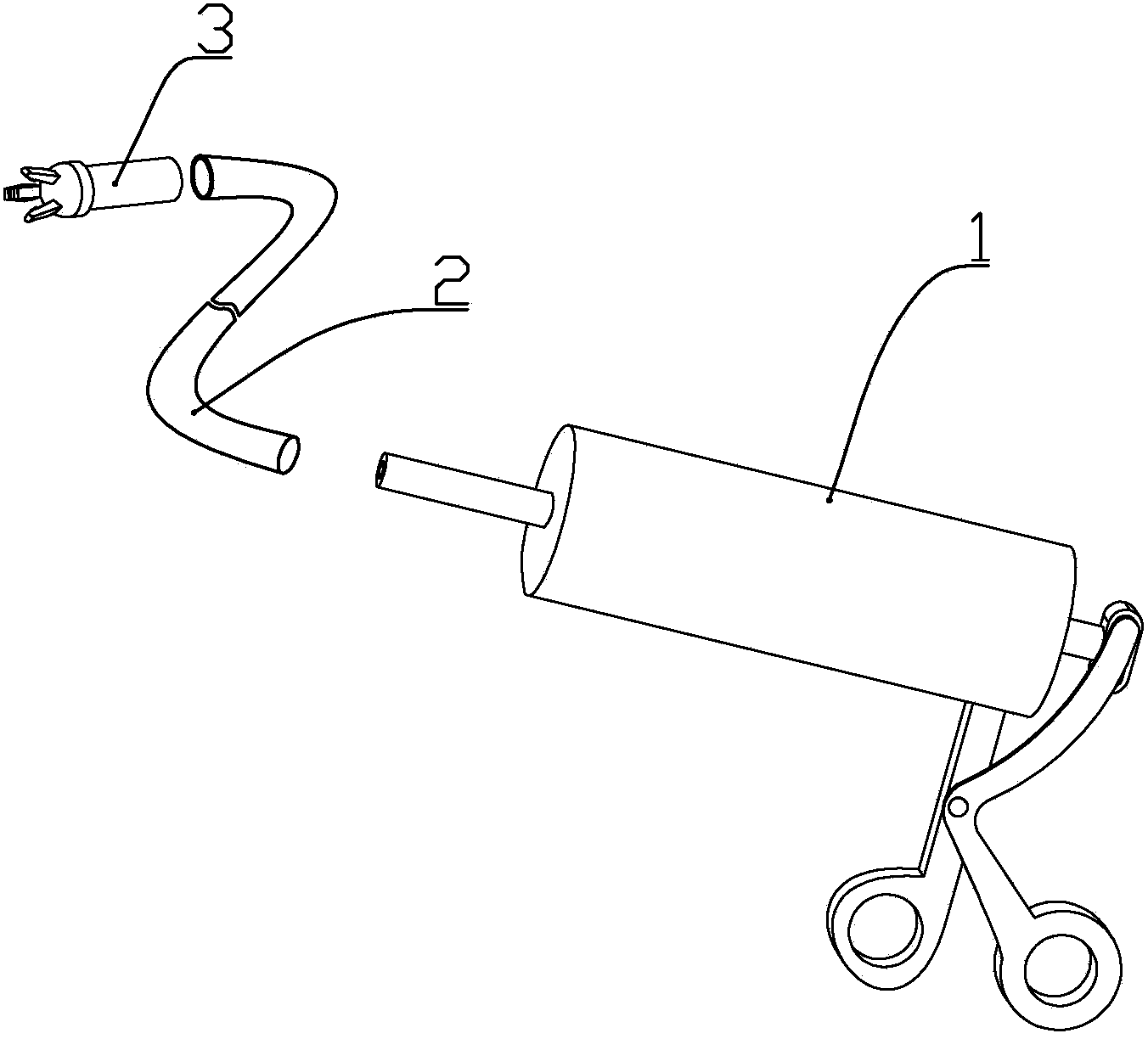

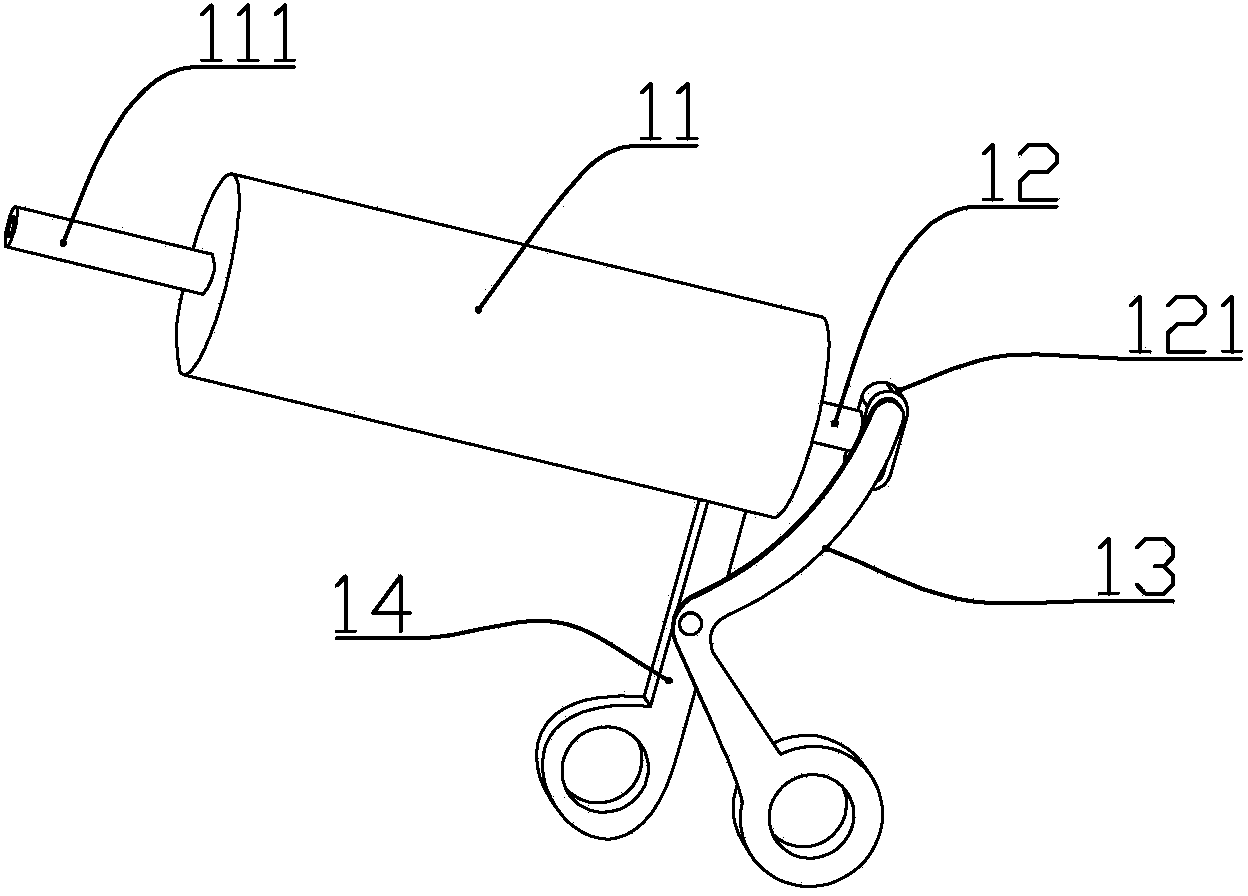

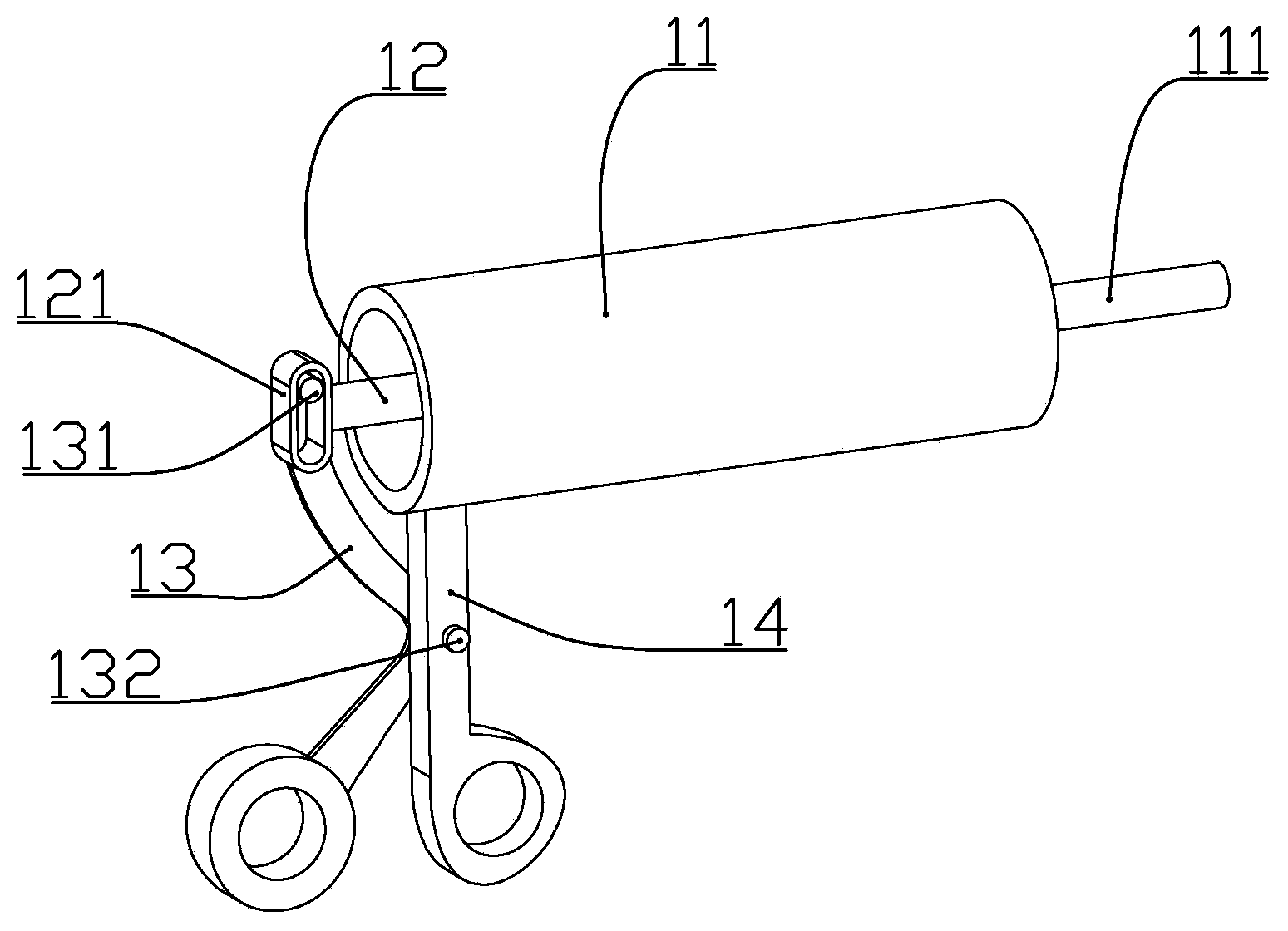

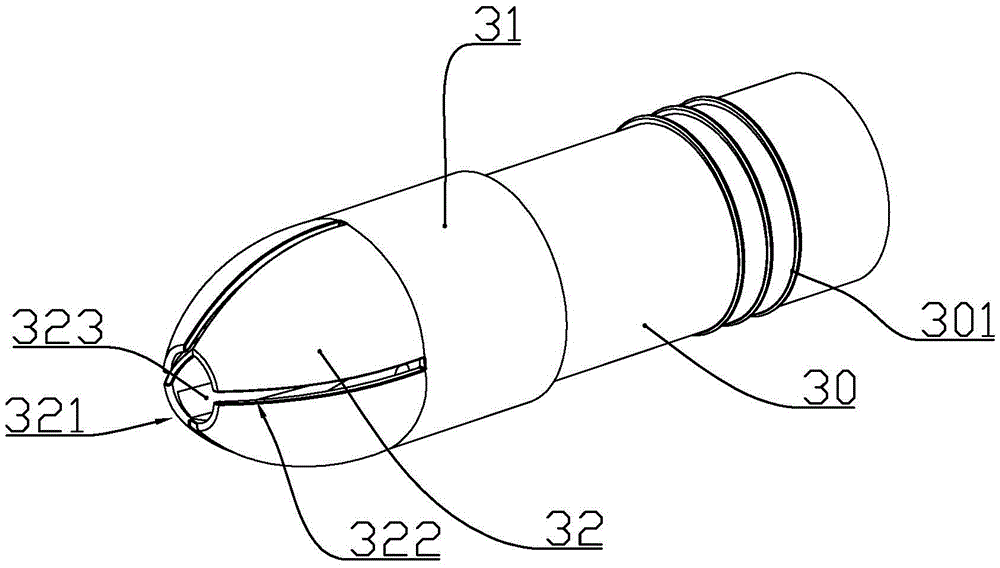

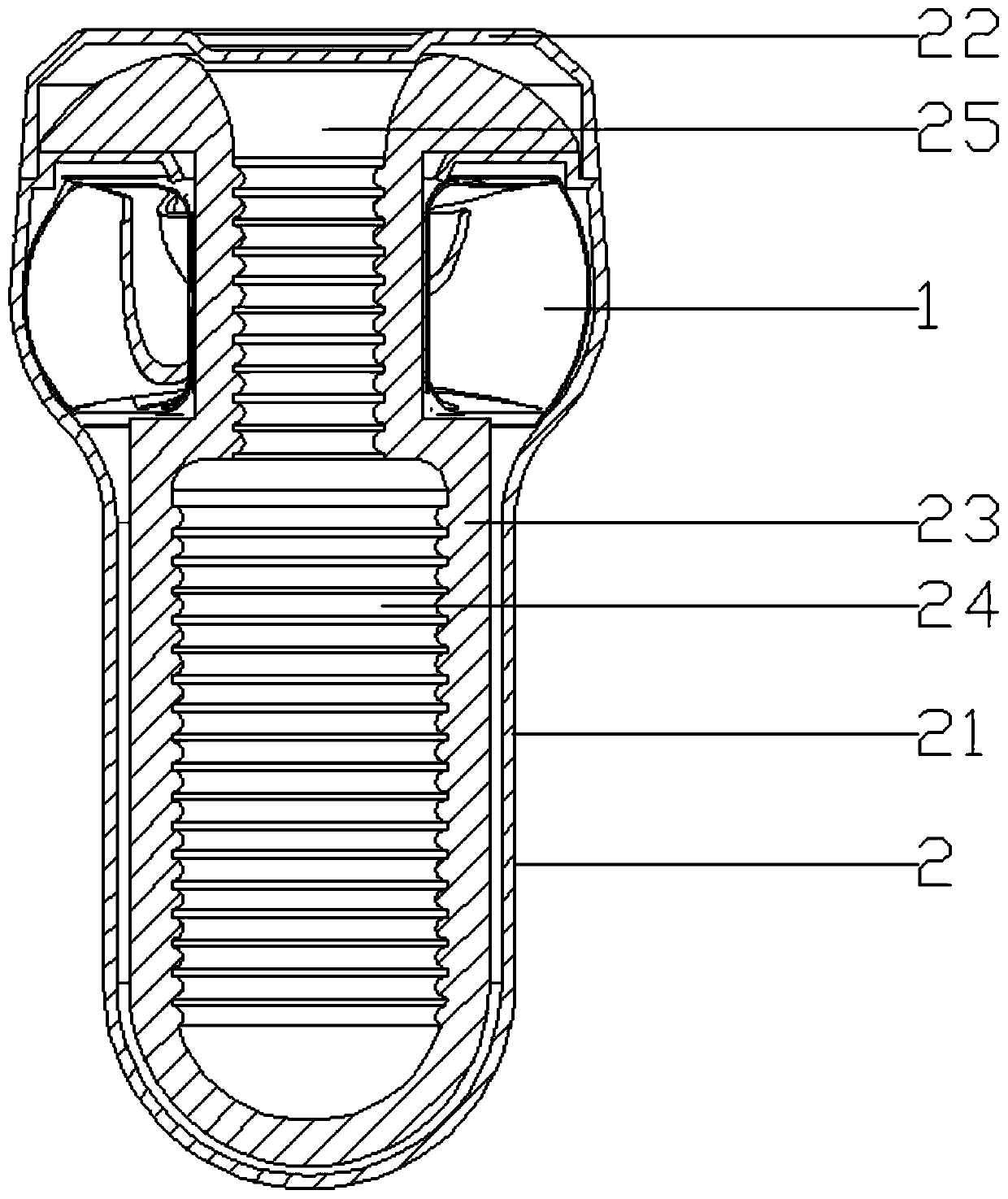

Tracheal foreign body forceps device and forceps body

The invention discloses a tracheal foreign body forceps device and forceps body. The forceps body is integrally molded by elastic rubber or plastic. The structure of the forceps body is formed by successively and integrally connecting a circular tubular tube joint b, a circular tubular supporting ring, a spherical rib connecting surface and four clamping slices, wherein the rib connecting surface concavely extends into the supporting ring; the four clamping slices are evenly and tightly connected at the periphery of the outer surface of the rib connecting surface; the end parts of the four clamping slices are surrounded to form a circular front opening; a side gap is formed between the adjacent two clamping slices; supporting ribs are formed on the inner side of each clamping slice; the bottoms of the supporting ribs are connected onto the outer surface of the rib connecting surface. The forceps body is integrally molded by the elastic rubber or plastic, so that the forceps body is convenient to machine, low in production cost and smooth in surface, and has no burr or sharp end part. Thus, the discomfortableness and the damage of the forceps body to tracheas are tiny.

Owner:HUAIAN ANJIE MEDICAL EQUIP LIMITED BY SHARE

Composite health care pad and manufacture method thereof

InactiveCN102514257AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite health care pad, which comprises a middle layer, wherein an upper surface layer and a lower surface layer are respectively arranged on the upper surface and the lower surface of the middle layer, a layer of blocking layer is respectively arranged between the middle layer and the upper surface layer and / or between the middle layer and the lower surface layer. The upper surface layer and the lower surface layer are non-woven layers containing 5%-50% low-melting-point fibers, and the middle layer is a non-woven layer containing the following components: fibrilia and 5%-50% of low-melting-point fibers. The blocking layers are non-woven layers containing 5%-100% of fibrilia, and the content of fibrilia in the composite health care pad ranges from 5% to 65%. The invention further discloses a manufacture method of the composite health care pad, which includes the following steps: respectively manufacturing the middle layer, the upper surface layer, the lower surface layer and the blocking layers, sequentially overlaying all the layers, and carrying out procedures including drying in a drying oven, cold rolling, cooling, cutting, inspection and packing. The composite health care pad and the manufacture method thereof solve the problems that the existing mattress can become damp and mildewed easily, can be damaged by worms, is apt to be layered, and is poor in ventilation and inconvenient to use caused by the fact that hard fibers in the middle of the mattress prick out.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

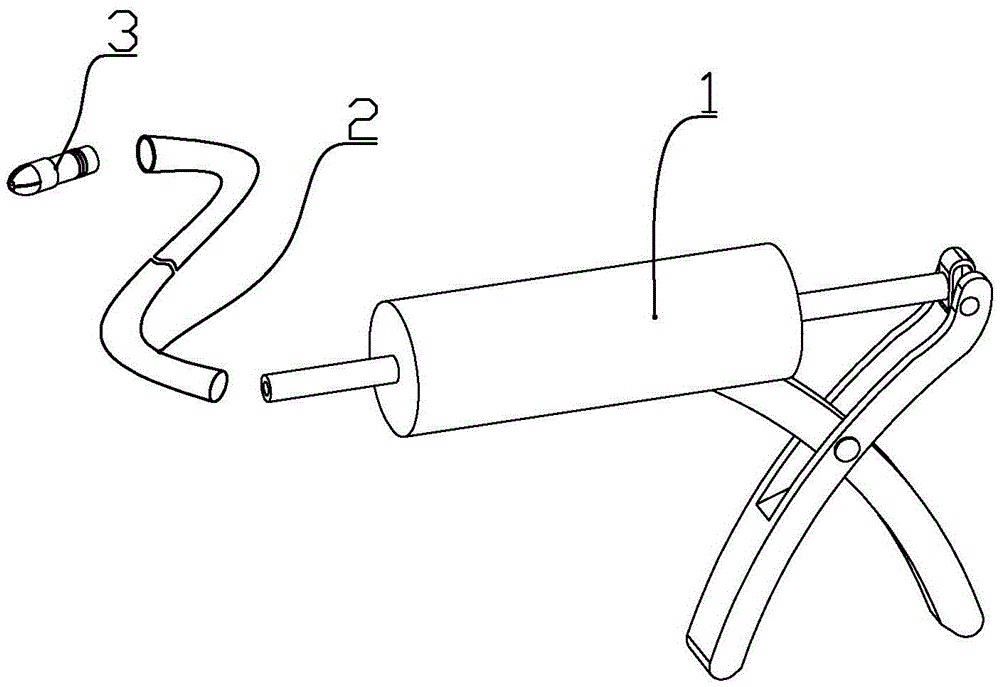

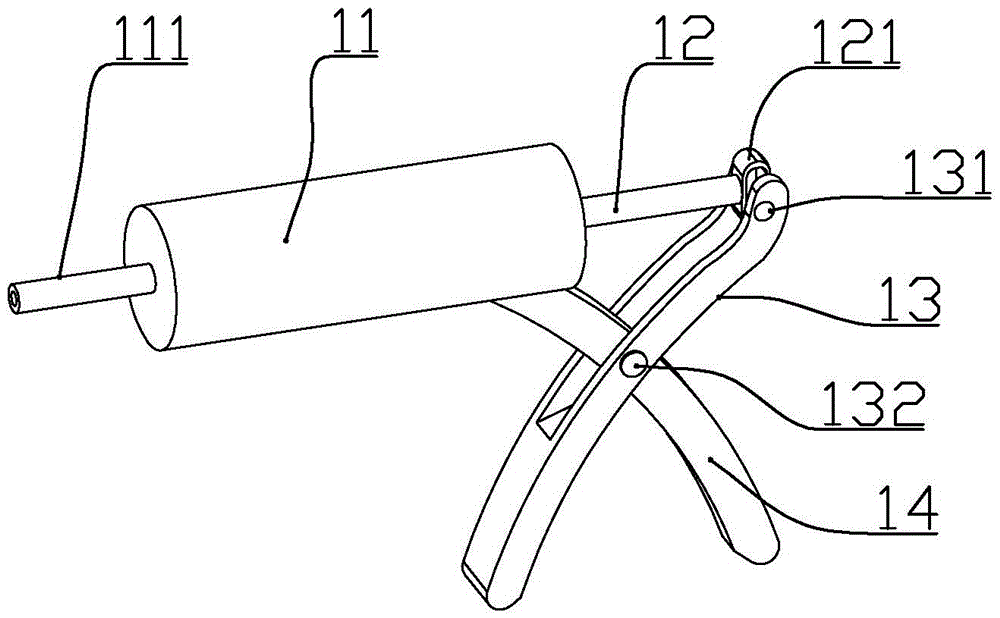

Trachea foreign body tweezers and tweezer body

The invention discloses trachea foreign body tweezers and a tweezer body. The tweezer body is integrally molded by use of elastic rubber or plastics; the tweezer body is structurally composed of a circularly tubular pipe joint b, a circularly tubular support ring, a spherical surface-shaped claw connecting surface and three claws, all of which are orderly and integrally connected together; the three claws are evenly connected to the external surface of the claw connecting surface and located in the same circle; a piston body is slidingly connected to the inner wall of the pipe joint b, and a connecting rod is connected between the piston body and the center of the claw connecting surface; through holes are evenly formed in the claw connecting surface and distributed in a circumferential array with the connecting rod as the center. The tweezer body is integrally molded by use of the elastic rubber or plastics, and thus is convenient to manufacture and low in manufacturing cost. The piston body is driven by negative pressure to move toward a piston barrel so that the claw connecting surface can be recessed, and then the three claws are driven by the claw connecting surface to realize a clamping action so as to clamp a foreign body.

Owner:邱兆友

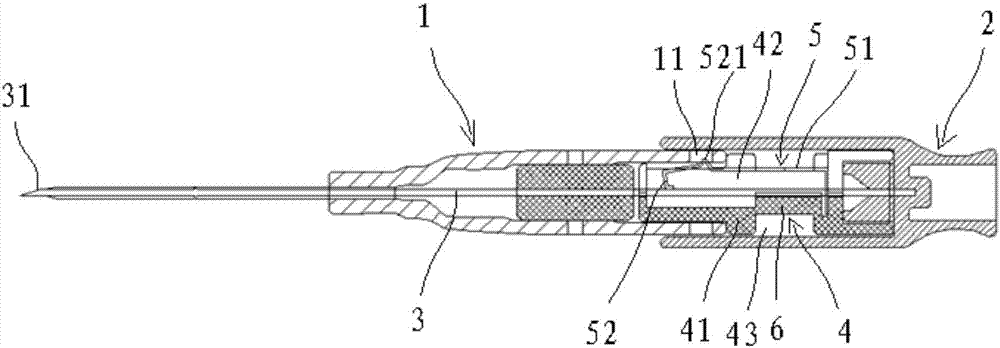

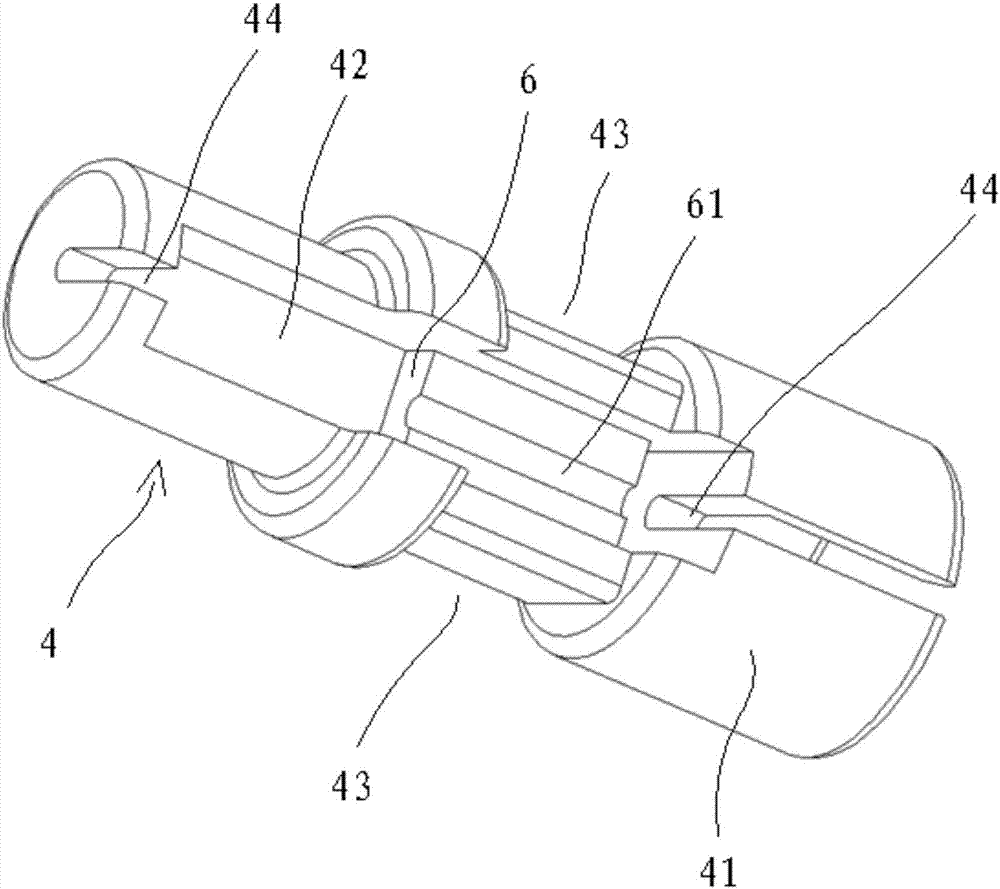

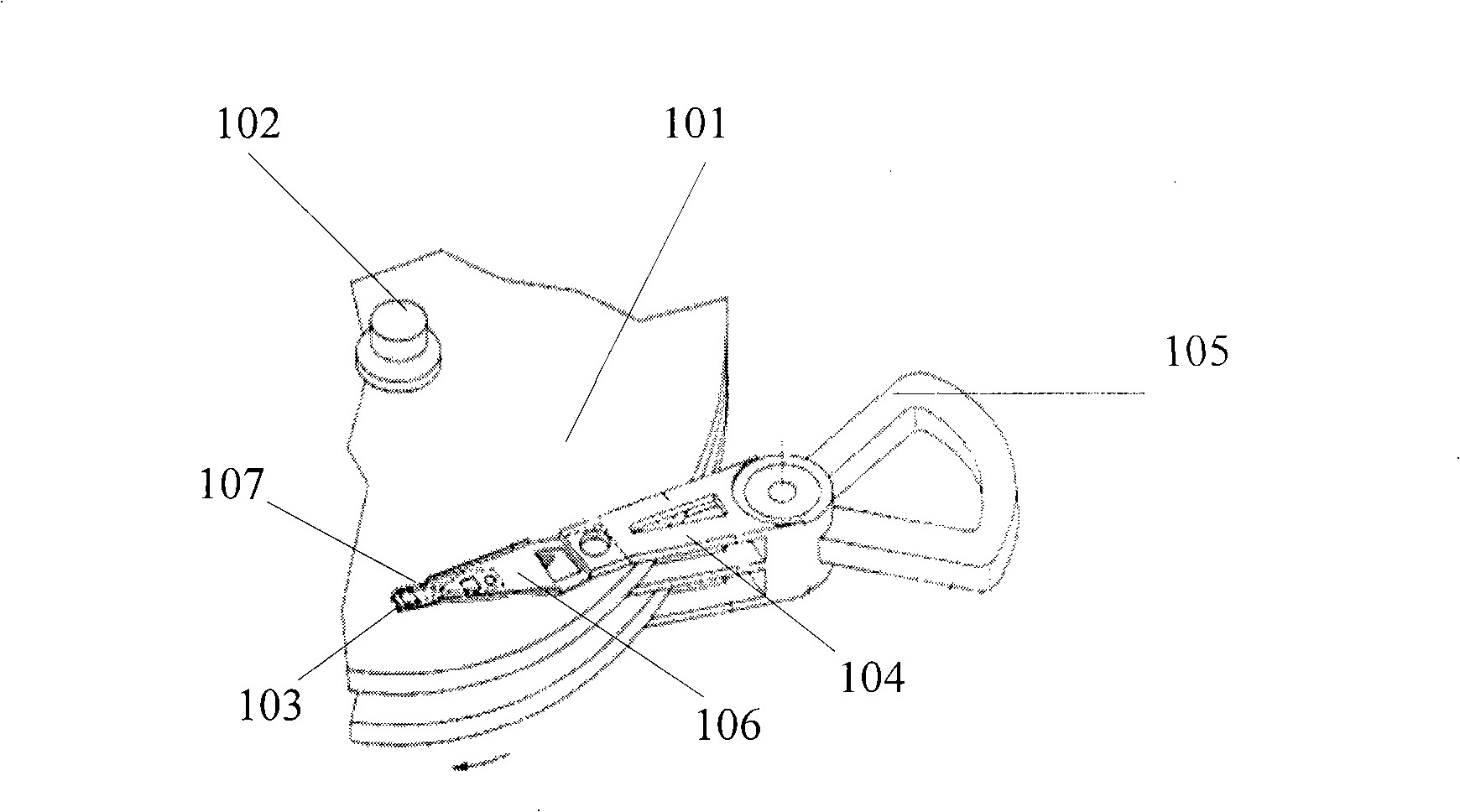

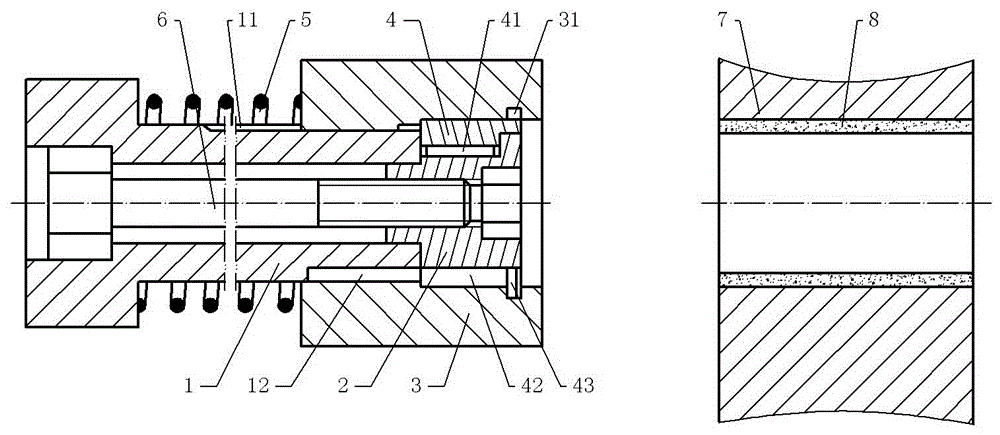

Puncture-preventing indwelling needle

PendingCN107050567AGuarantee normal implementationAvoid deformationCatheterInfusion needlesProtection mechanismCatheter

The invention provides a puncture-preventing indwelling needle. The puncture-preventing indwelling needle comprises a catheter base, a needle file, a needle tube and a protection mechanism, wherein the needle file sleeves the catheter base in a sliding manner; the needle tube is mounted to the needle file, and the needle point can penetrate through the catheter base; the protection mechanism is arranged between the catheter base and needle file, and is composed of a protection base and a protection plate mounted on the protection base, the protection base is provided with a protection base body allowing the needle tube to pass through, and an accommodating cavity for accommodating part of the needle tube is formed in the protection base body; the protection plate is provided with a protection plate body, a baffle plate accommodated in the accommodating cavity is formed at one end of the protection plate body, the baffle plate has the first state of pushing against the needle tube and a second state of sheltering the needle point, a support structure is arranged in the accommodating cavity, the support structure applies a supporting force to the needle tube, and the direction of the supporting force is opposite to that of the resisting force applied by the baffle plate. For the puncture-preventing indwelling needle, the support structure applies the supporting force to the needle tube, the direction of the supporting force is opposite to that of the resisting force applied by the baffle plate, so that the needle tube has small possibility of deformation under the pushing and pressing of the baffle plate.

Owner:DRAGON HEART MEDICAL DEVICES

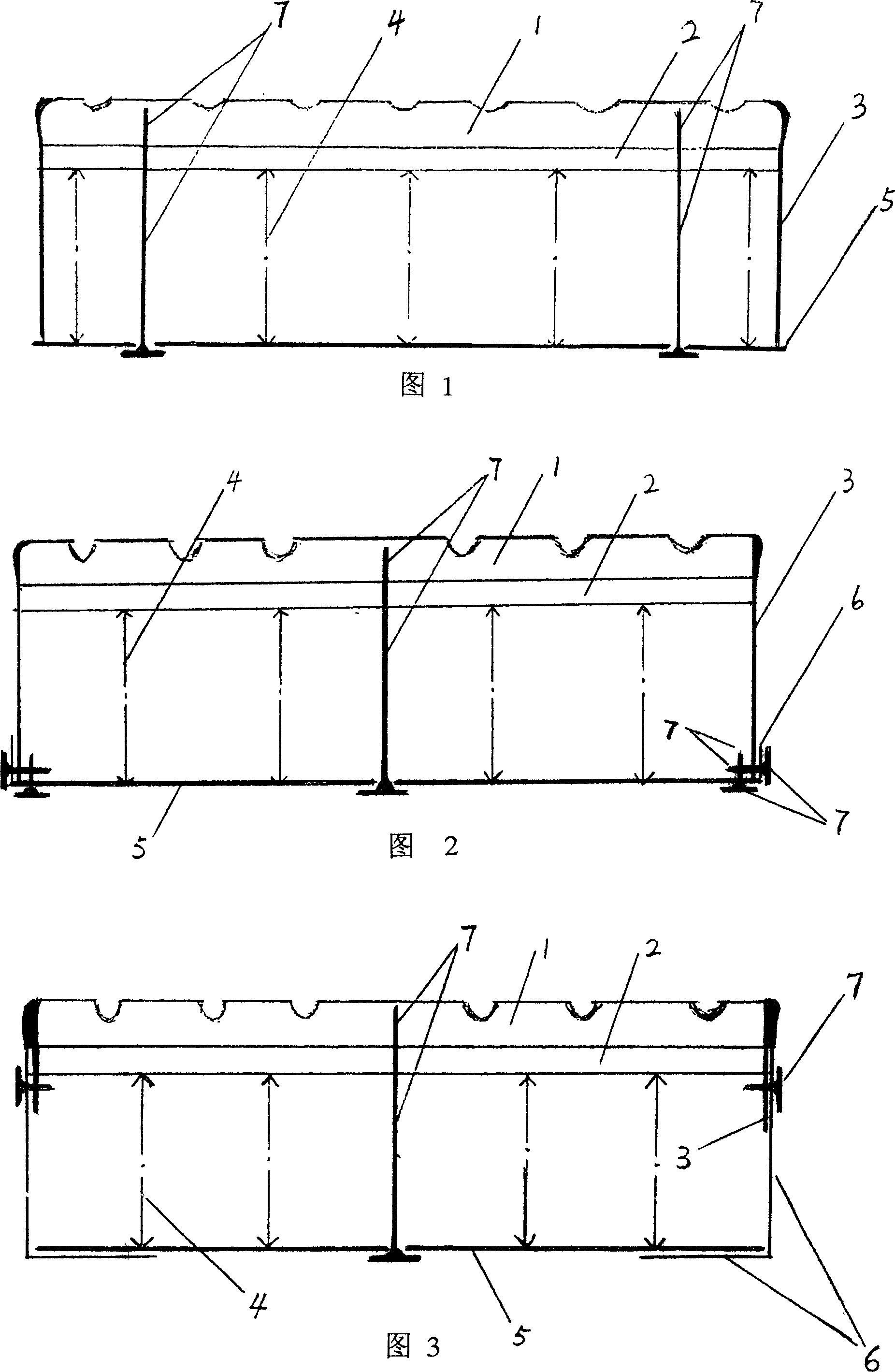

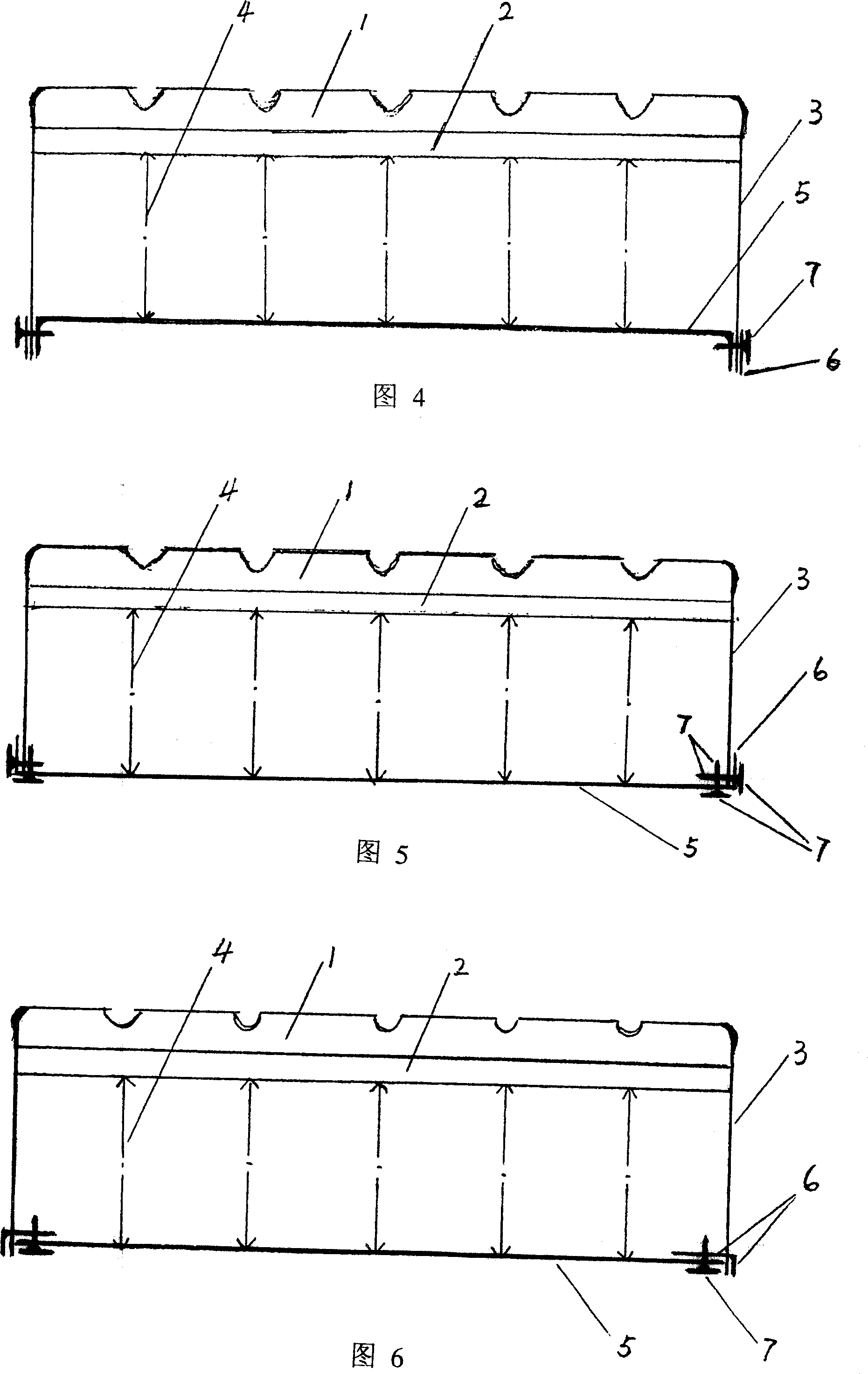

Elastic structure link rod connected type tyre

InactiveCN101007489AIncrease the inflatable structureEasy to assembleNon-inflatable tyresWheelsTreadSupport materials

Flexible structure connecting-bar-linking tire. The tire is equipped on the rim and consists of tread tire shoulder layer, tire base layer, tire side layer and rim structure, the two sides of tire base layer is connected with tire side layer, its features are: flexible structure is many flexible support materials and installed between the inner surface of tire base layer and the top surface of rim, it composes the flexible supporting device of tread tire shoulder layer and tire base layer; at the same time, the tread tire shoulder layer, tire base layer and tire base layer are connected with the rim through the connecting-bar and frame protecting component. The invention is different from Flexible structure of traditional tire; while the connecting mean between tire and rim is different: connecting the tire and new rim through connect components such as connecting-bar and frame protecting component firmly; the resiliency of tire is generated by new flexible structure. The tread of the tire moves radically with the relaxation of flexible structure, and has sufficient flexibility; so the tire repairing rate and tire changing rate are reduced, the safety and quality of running is improved.

Owner:阚国梁

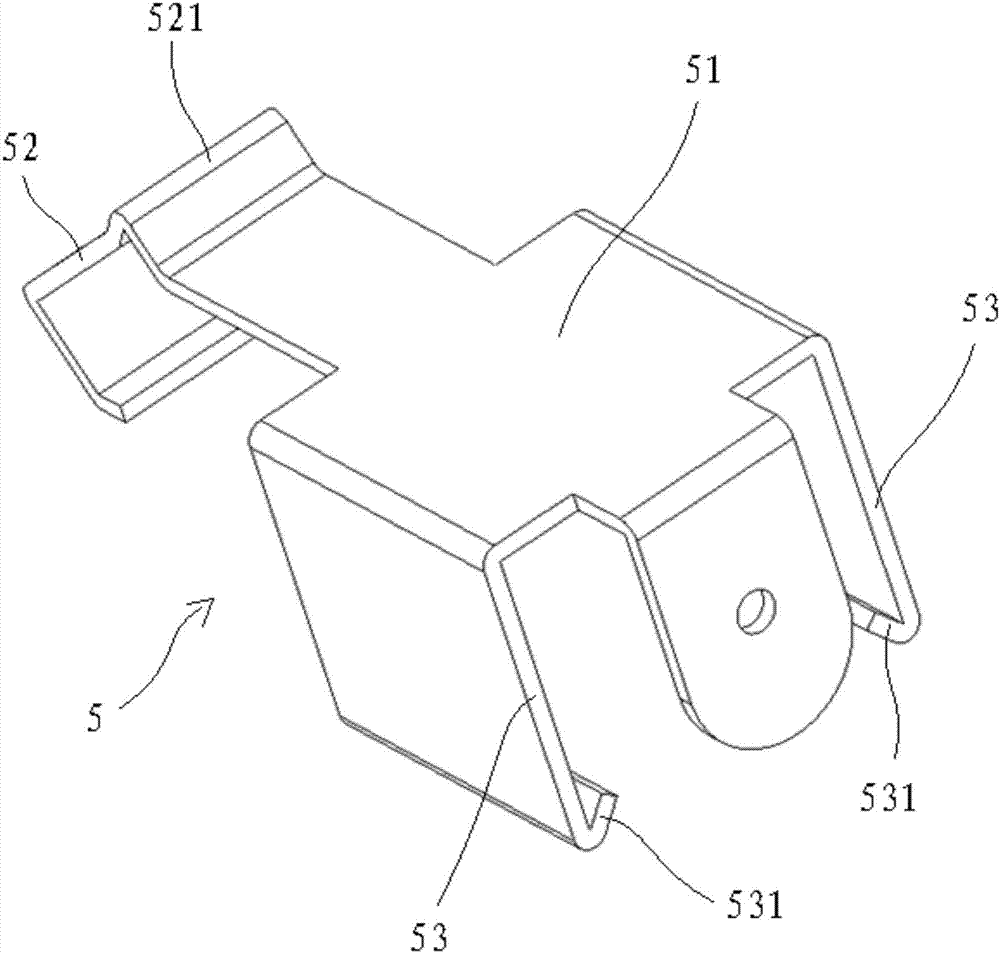

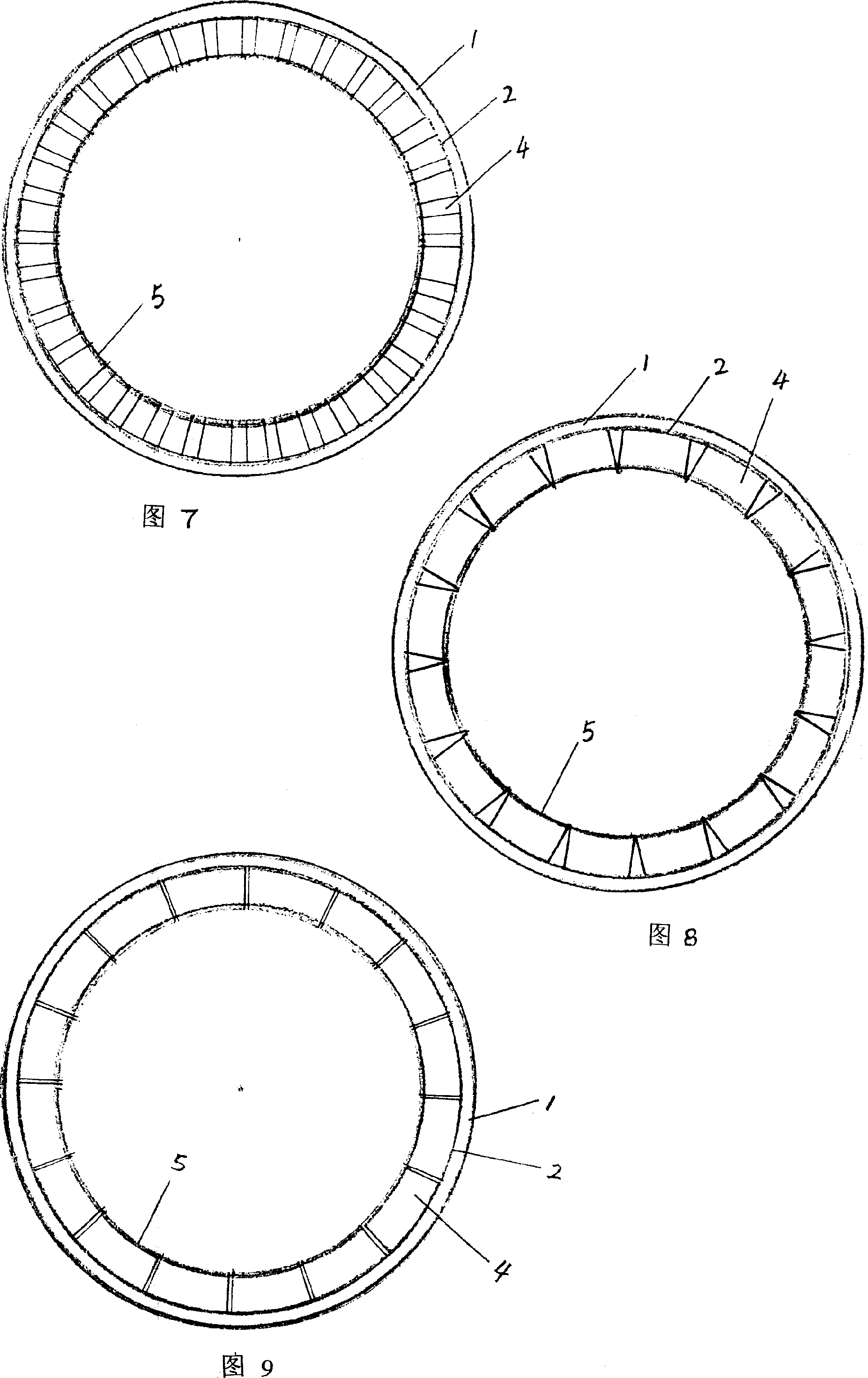

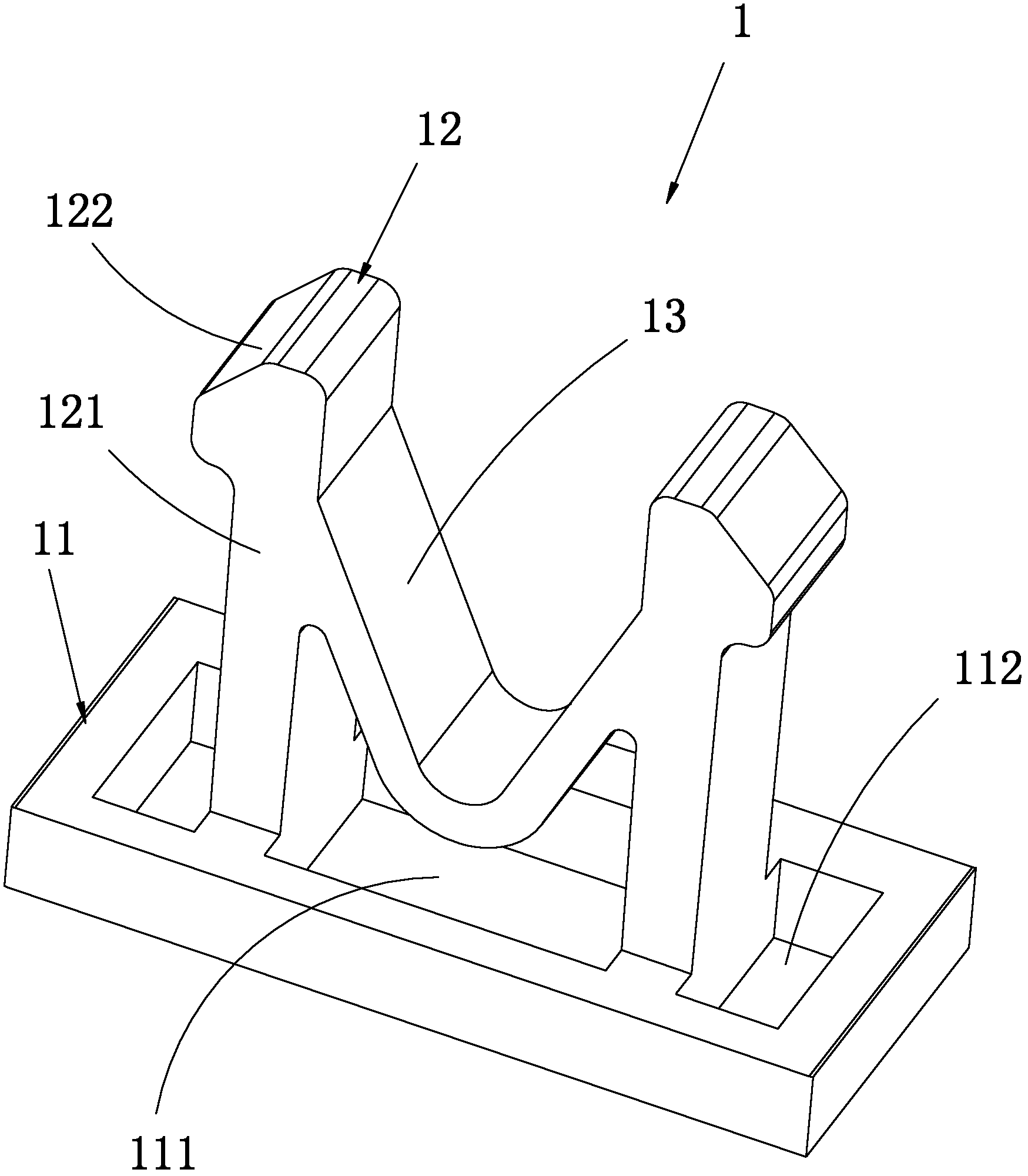

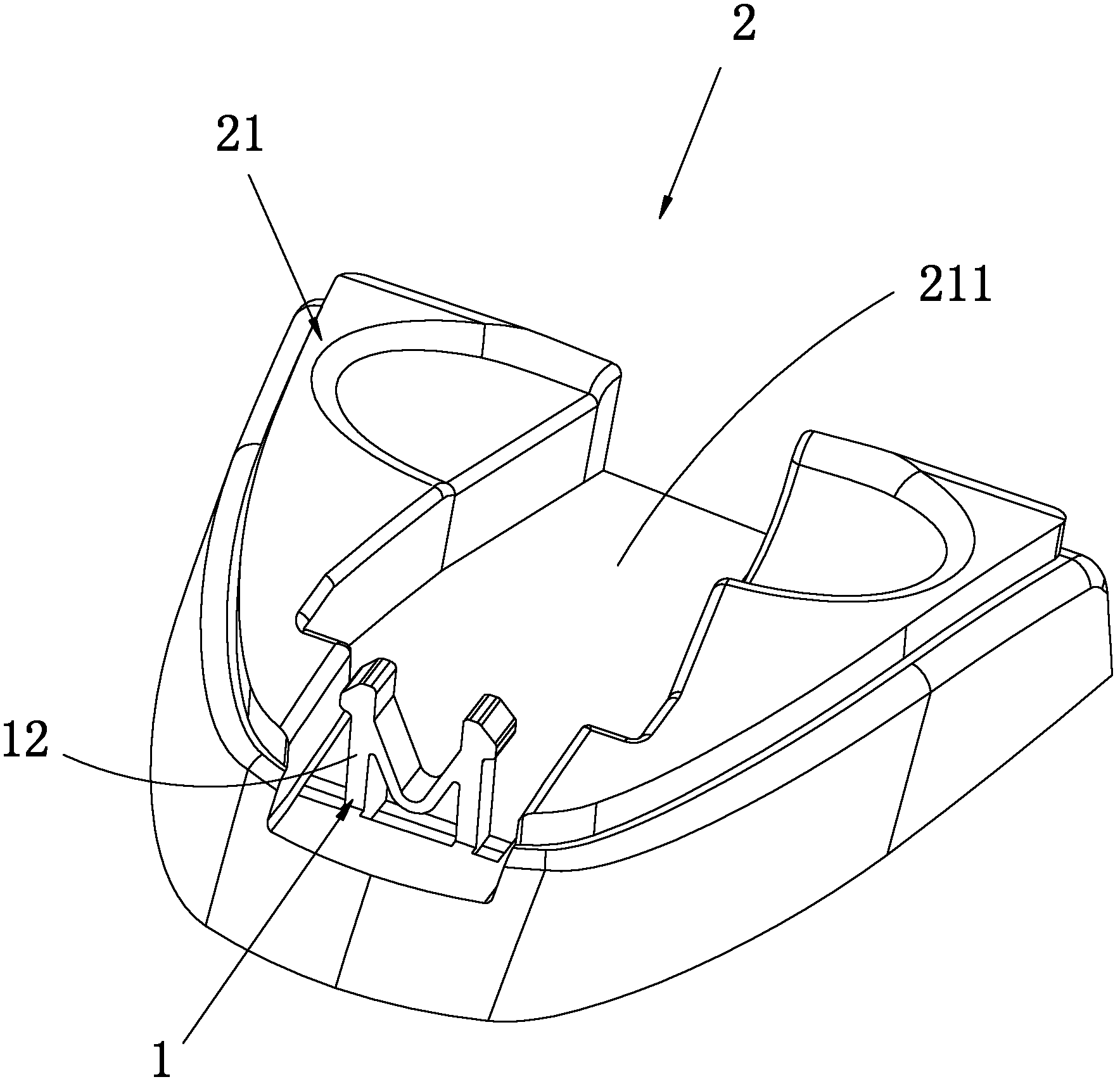

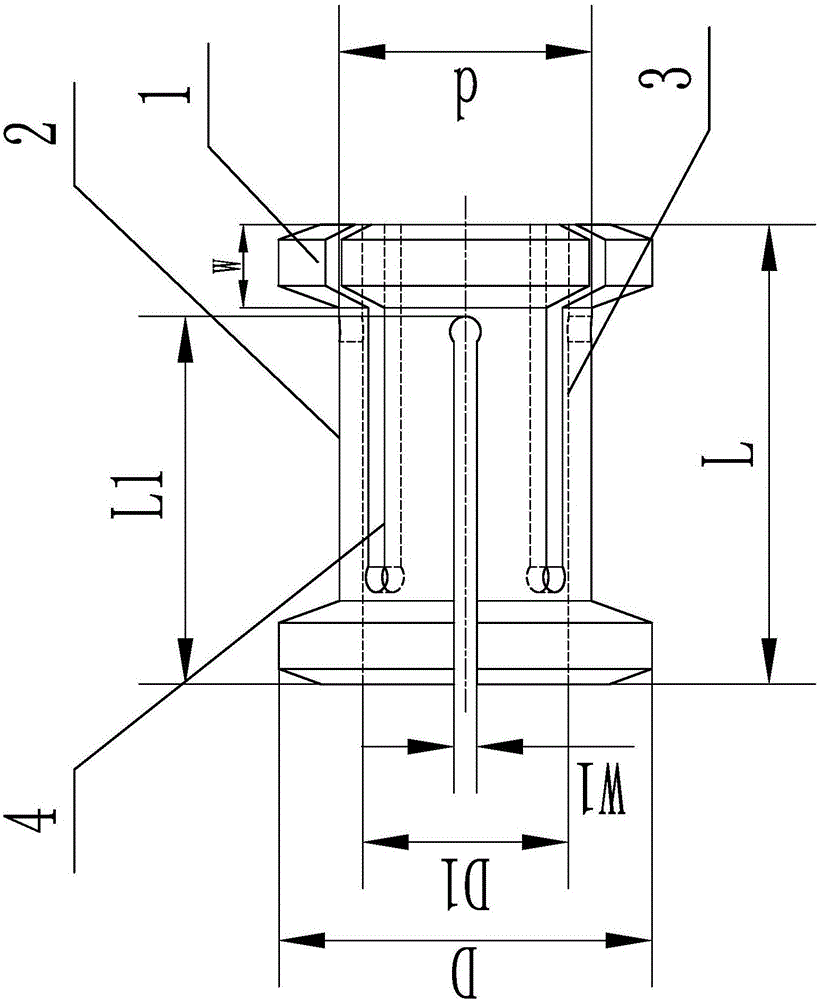

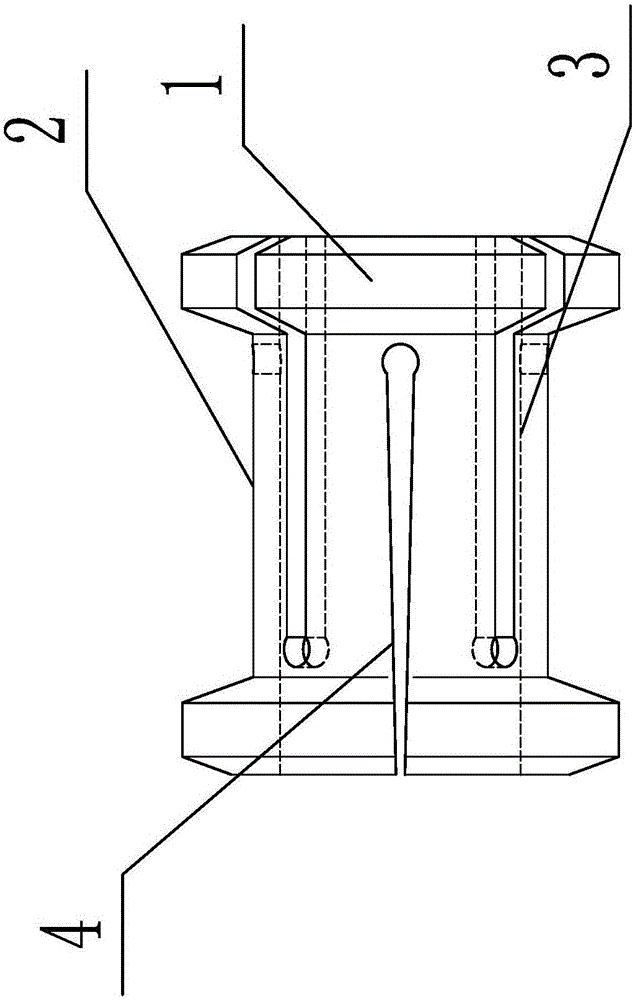

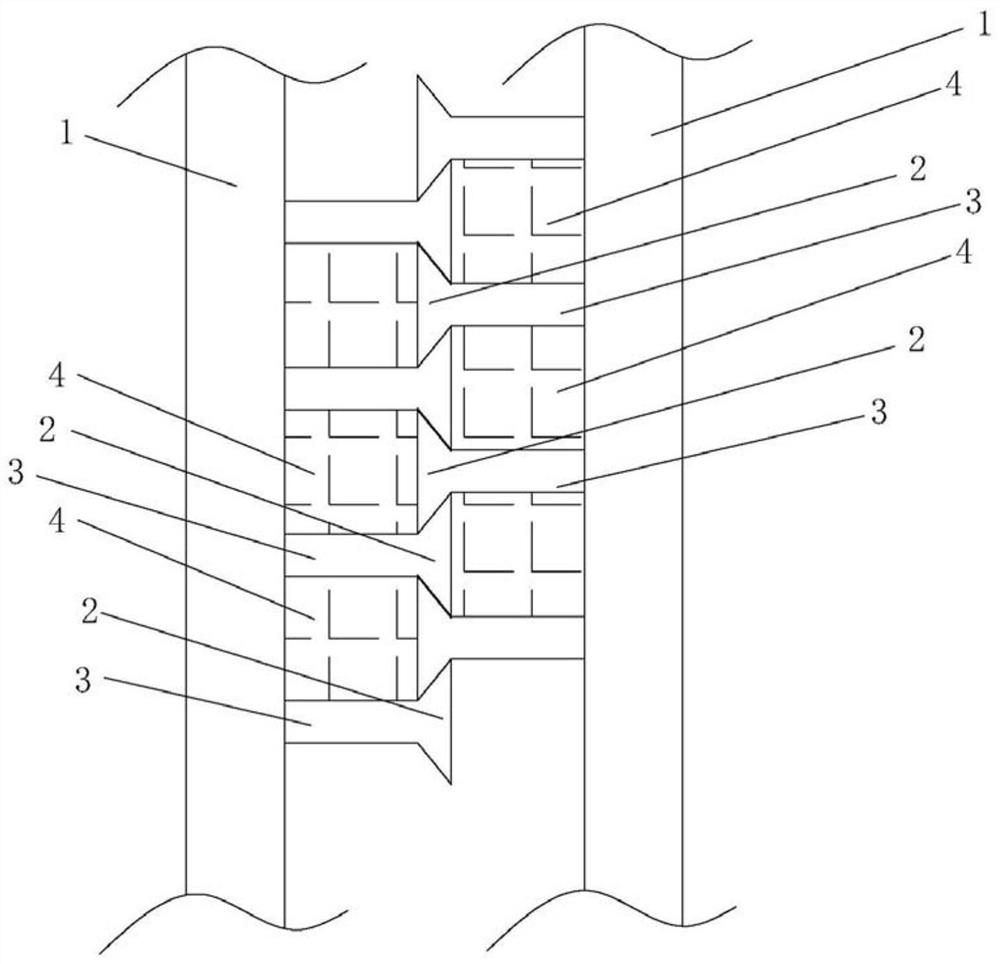

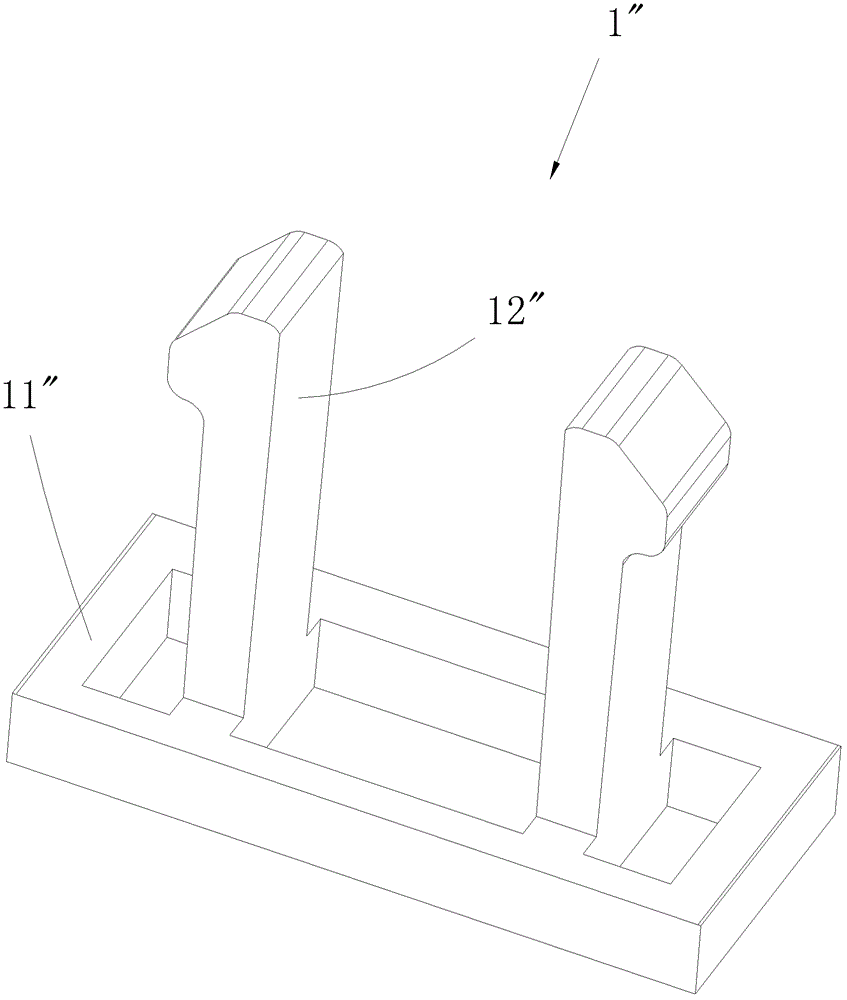

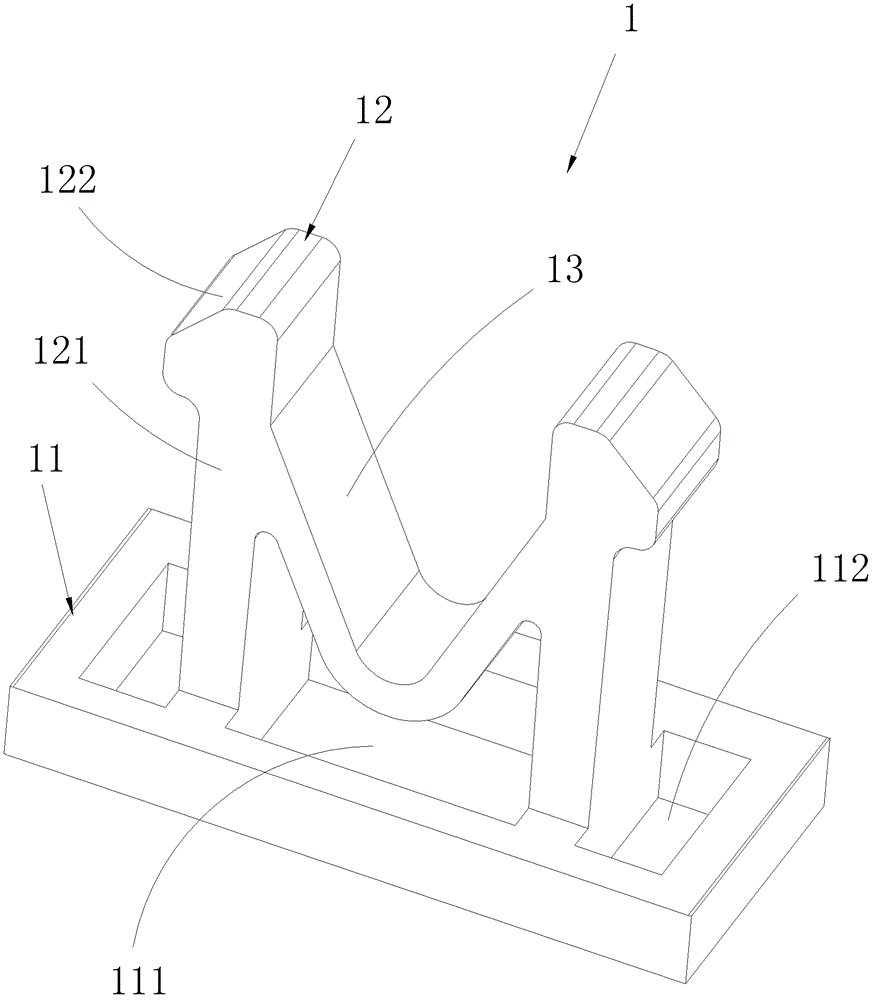

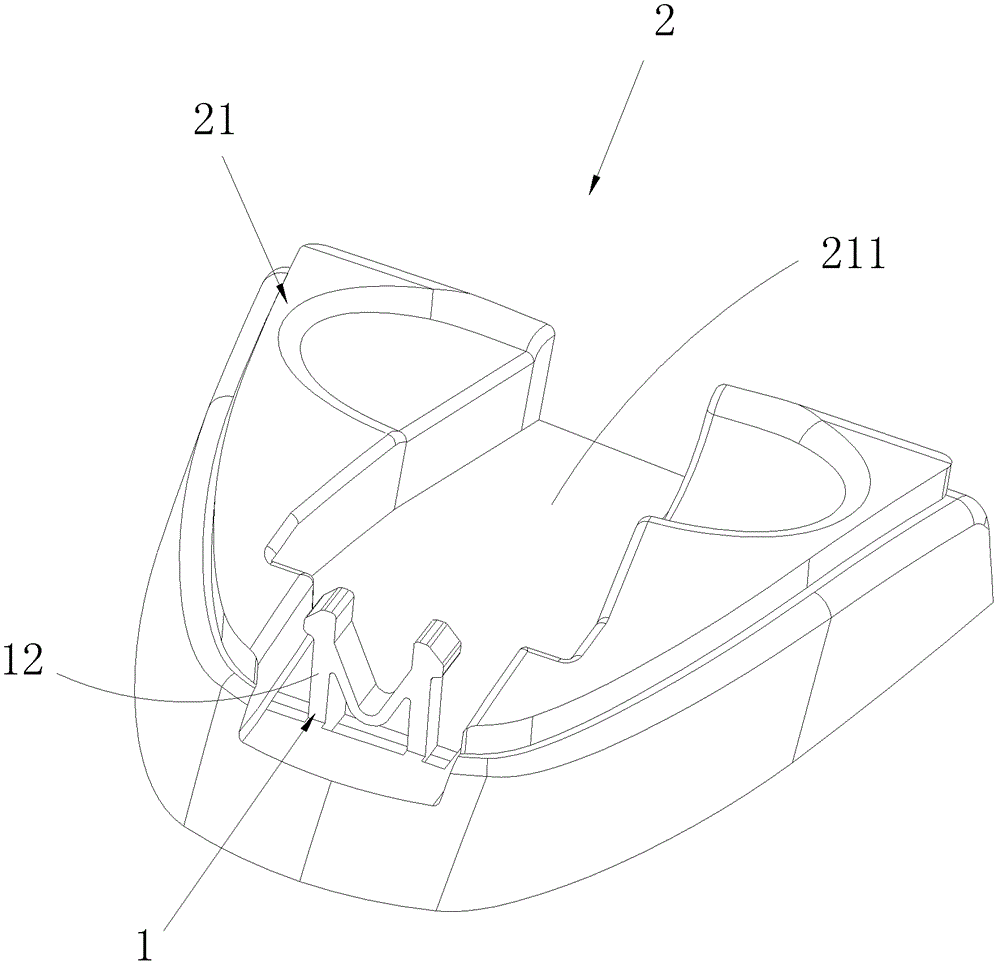

Fastener, pedestal and fastening assembly

InactiveCN102434549AElastic enoughIncrease elasticityFriction grip releasable fasteningsBuckle FastenerEngineering

The invention discloses a fastener, a pedestal comprising the fastener and a fastening assembly comprising the pedestal, relating to the technical field of connecting members. The fastener comprises a base and a plurality of fastening columns which are arranged on the base and connected with external equipment in a fastening way, and the fastener also comprises elastic structure members arranged among the fastening columns. Compared with the prior art, the elastic structure members are arranged among the fastening columns of the fastener, so that enough elasticity among the fastening columns can be ensured, and using reliability is achieved; in addition, the fastening columns are unnecessarily designed to be too thickened, so that problem of difficulty in processing is solved, and favorable elasticity of the fastener can be ensured in the long-term and repeated using process.

Owner:SHENZHEN NETCOM ELECTRONICS CO LTD

Natural fiber health-care board and preparation method thereof

ActiveCN102514256AGuaranteed performanceGuaranteed breathabilityLaminationLamination apparatusPolymer scienceSurface layer

The invention discloses a natural fiber health-care board which consists of a middle layer and a surface layer arranged on the upper surface or the lower surface of the middle layer. The surface layer is a non-woven layer comprising 5 percent to 50 percent of low melting point fibers. The middle layer is a non-woven layer which comprises the following components: bastose and 5 percent to 50 percent of low melting point fibers. In the natural fiber health-care board, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the natural fiber health-care board, which comprises the following steps of: respectively preparing the middle layer and the upper or lower surface layer; then sequentially paving the layers; and preparing the natural fiber health-care board by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption of the natural fiber health-care board and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer and has poor air permeability is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

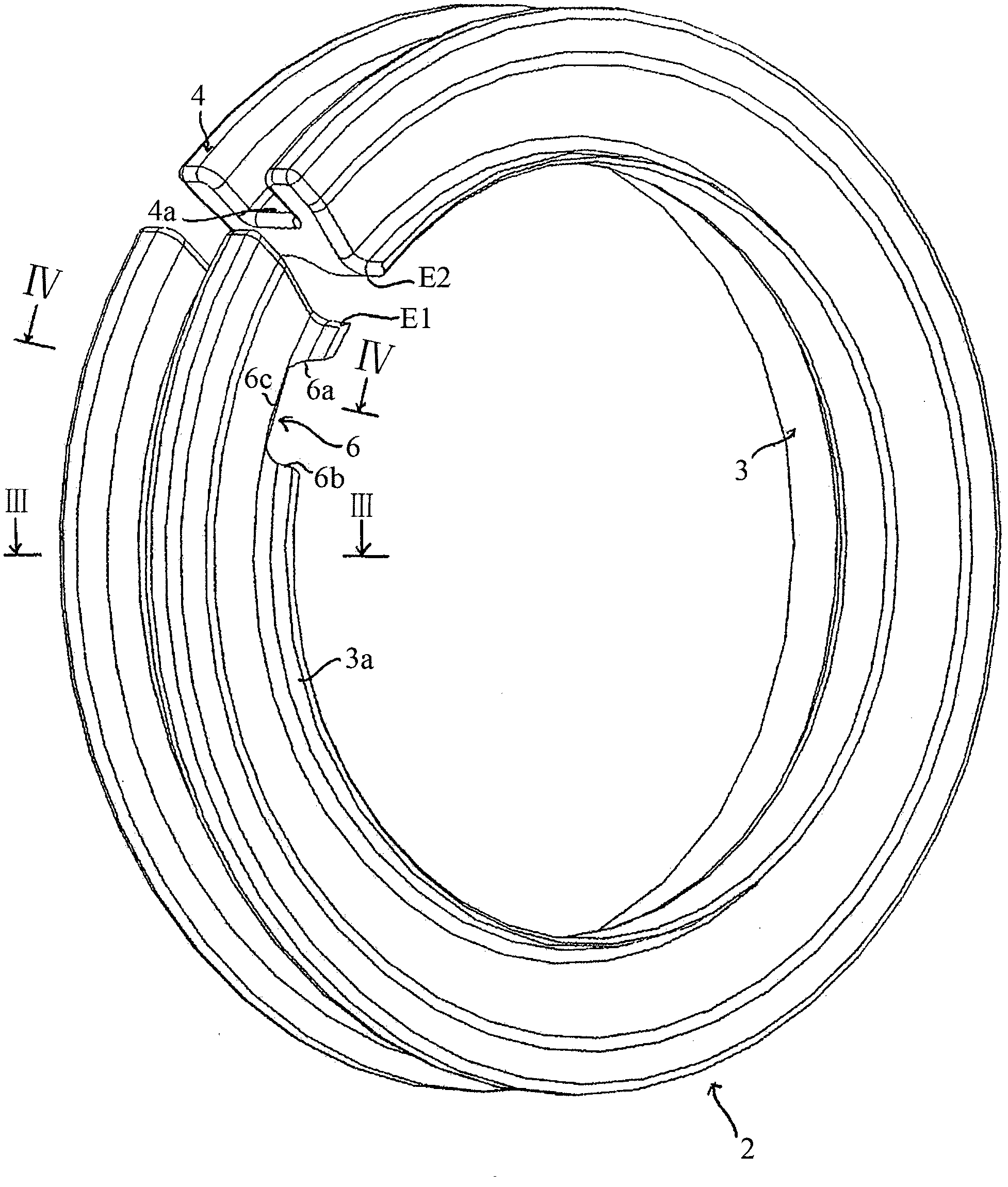

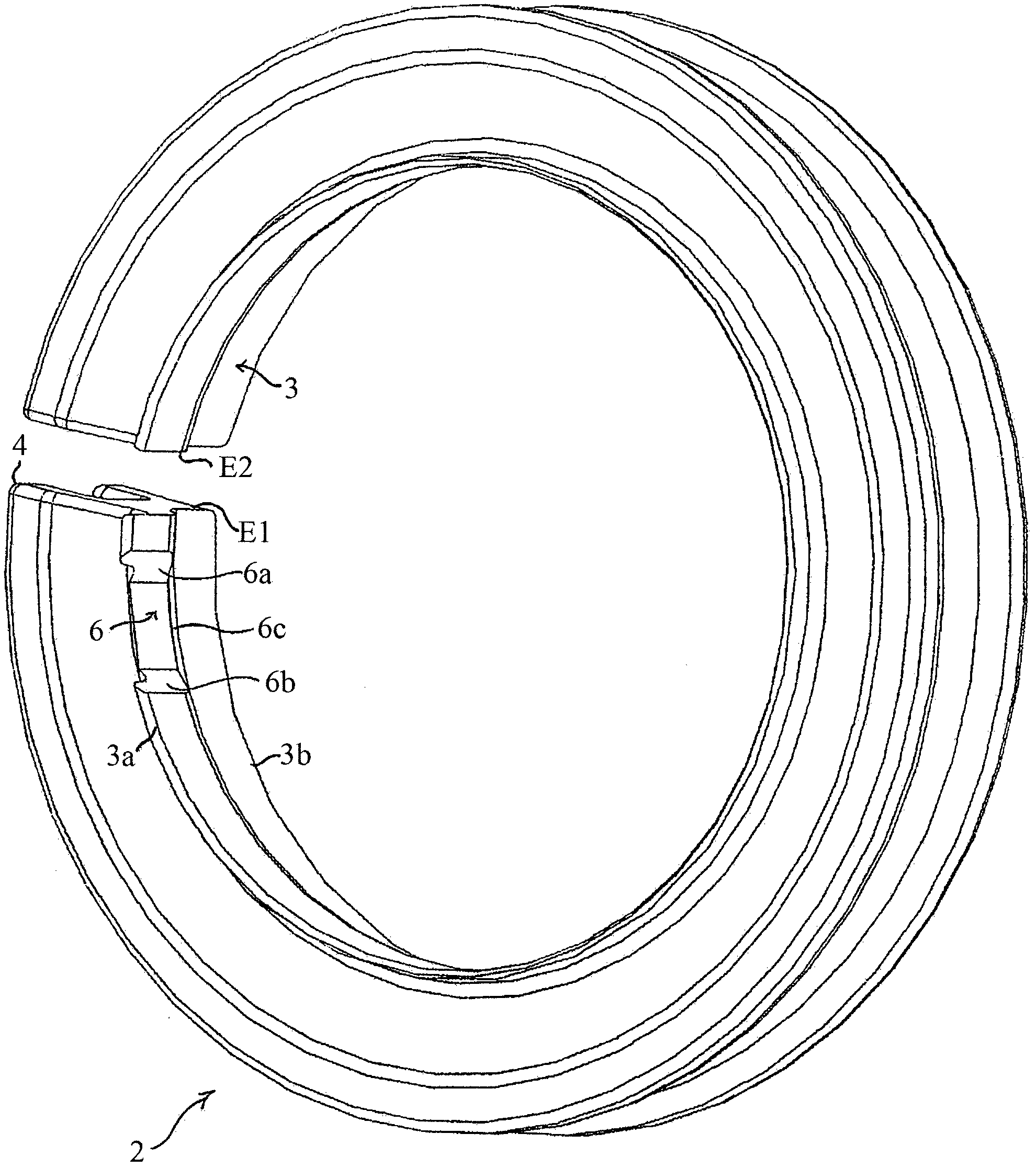

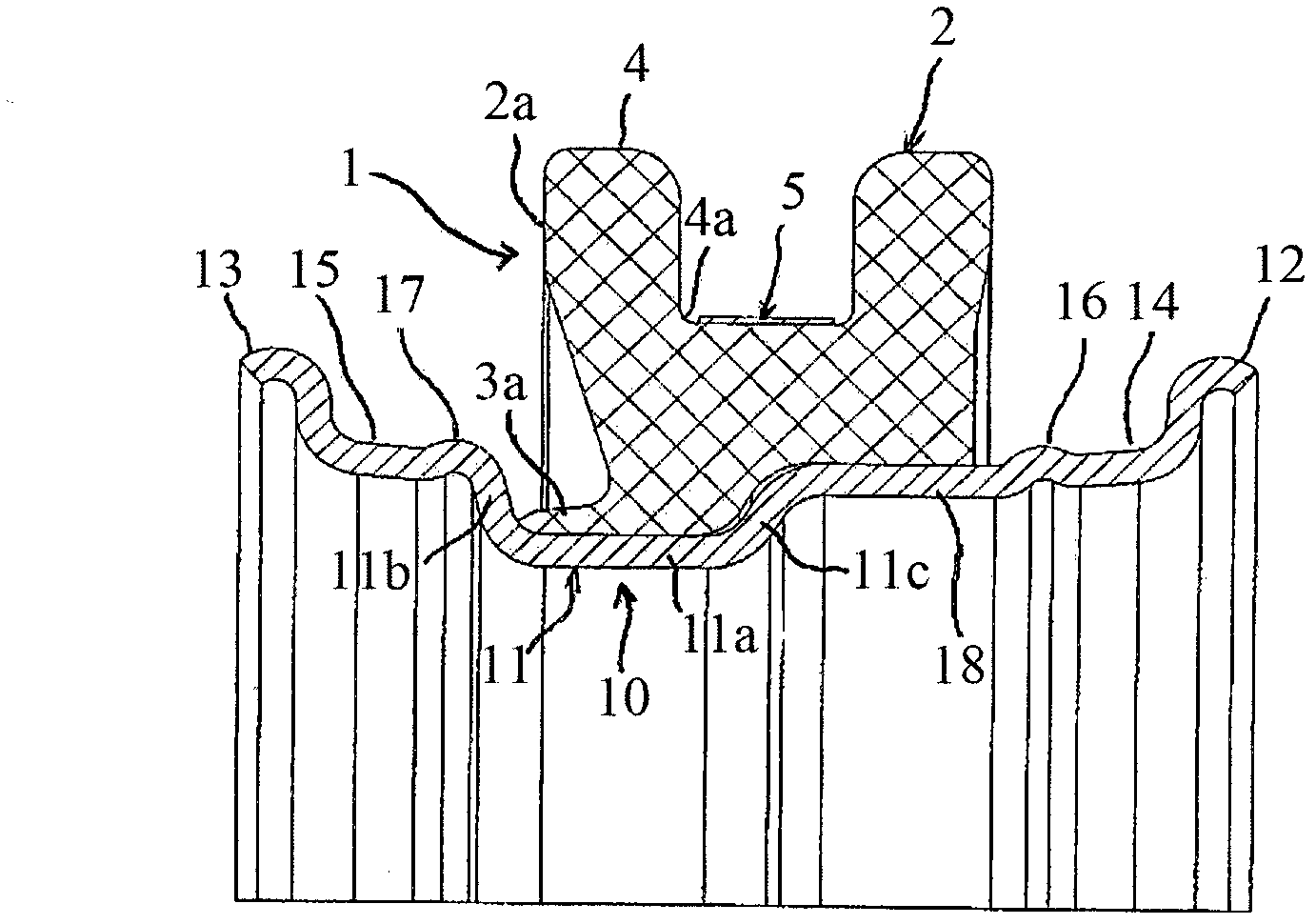

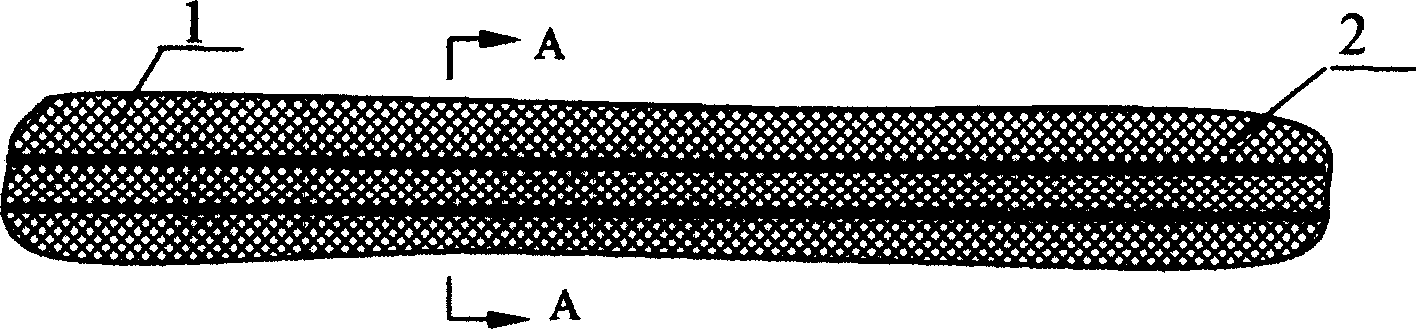

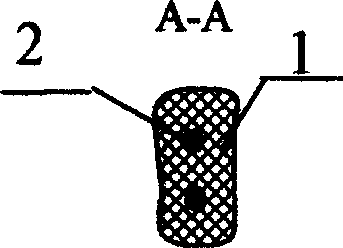

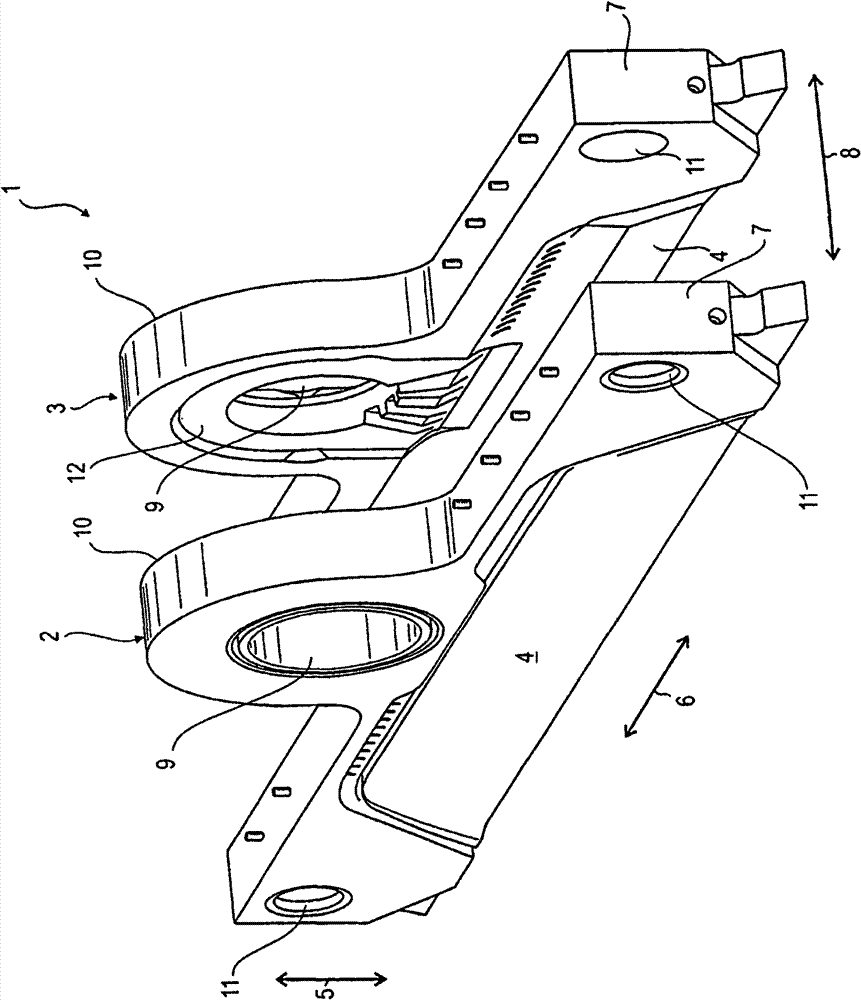

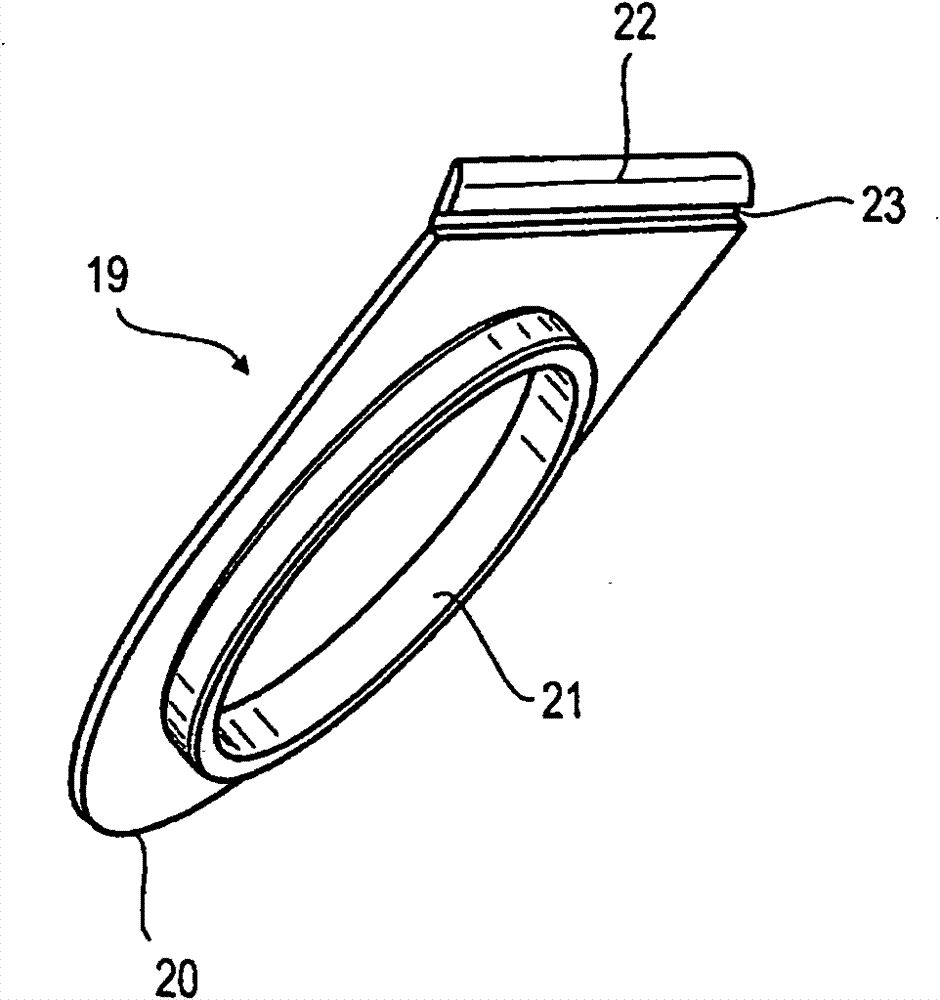

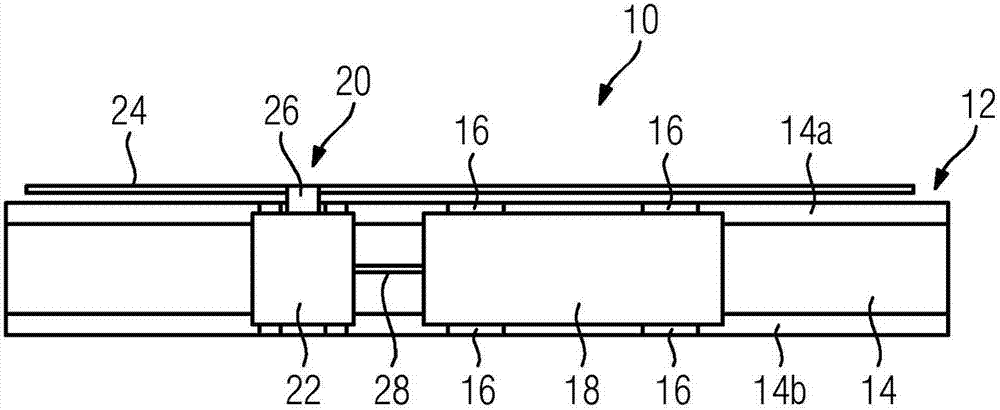

Flat-running device for an automobile, mounted assembly including same and related mounting/removal method

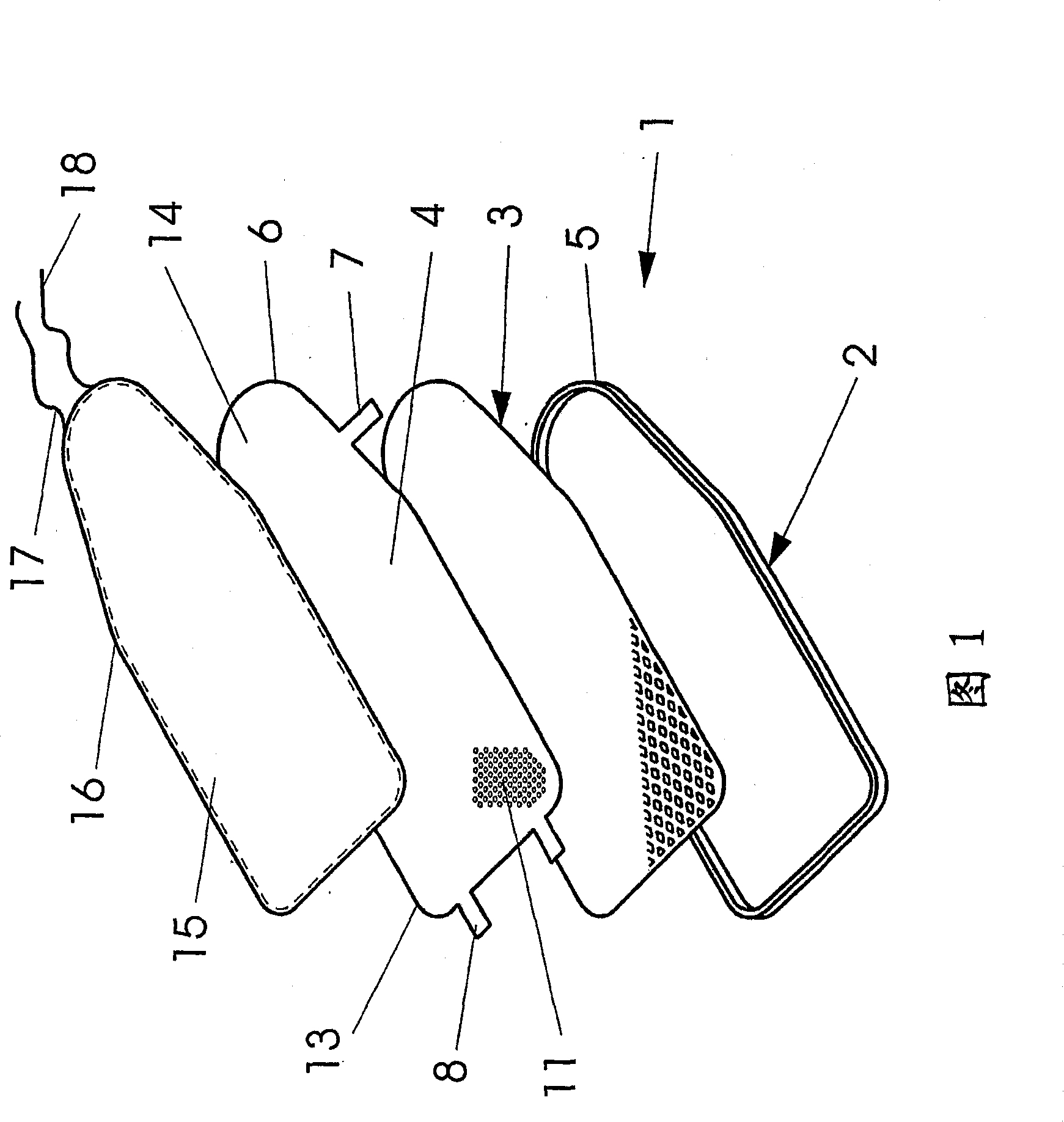

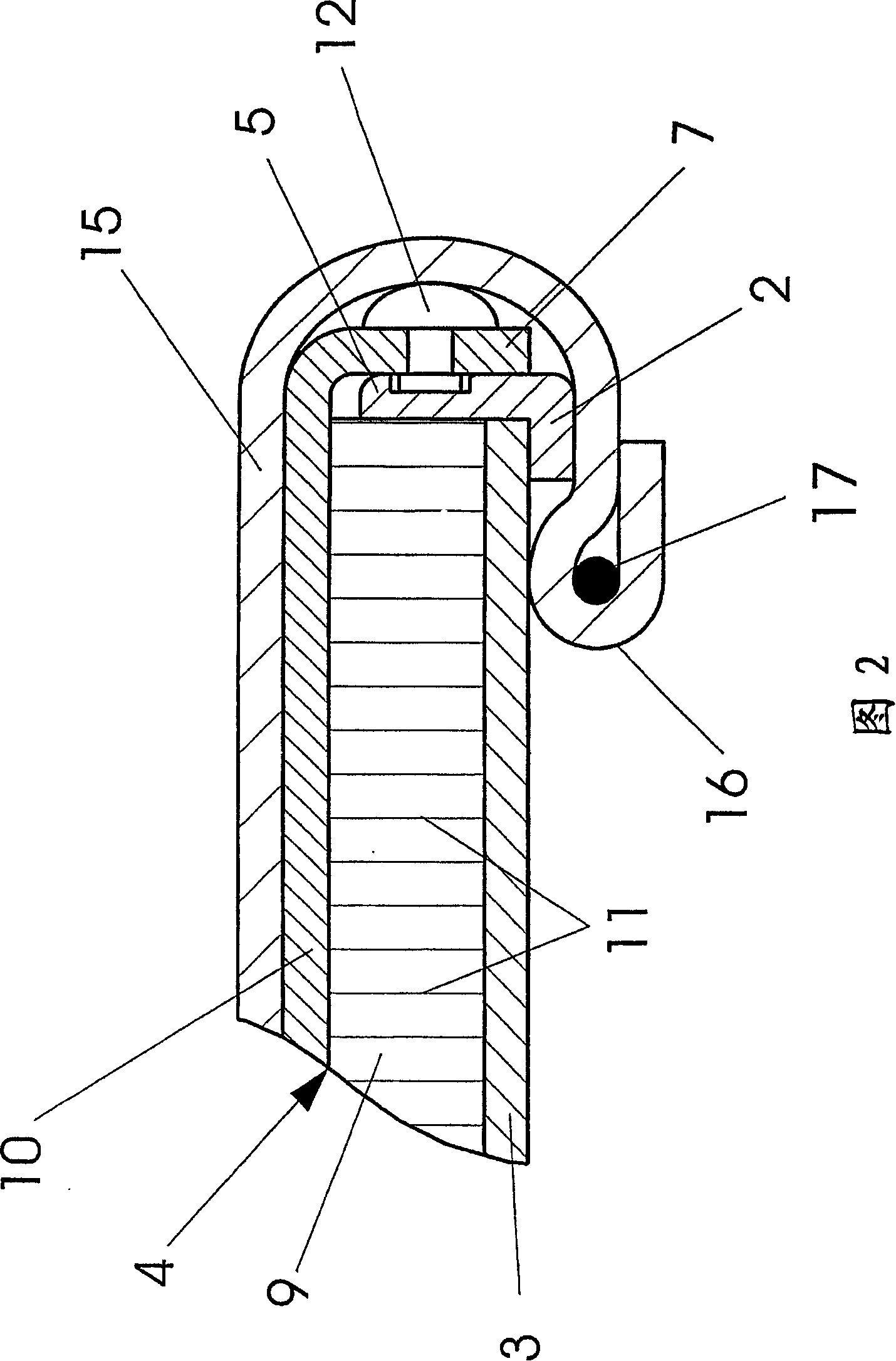

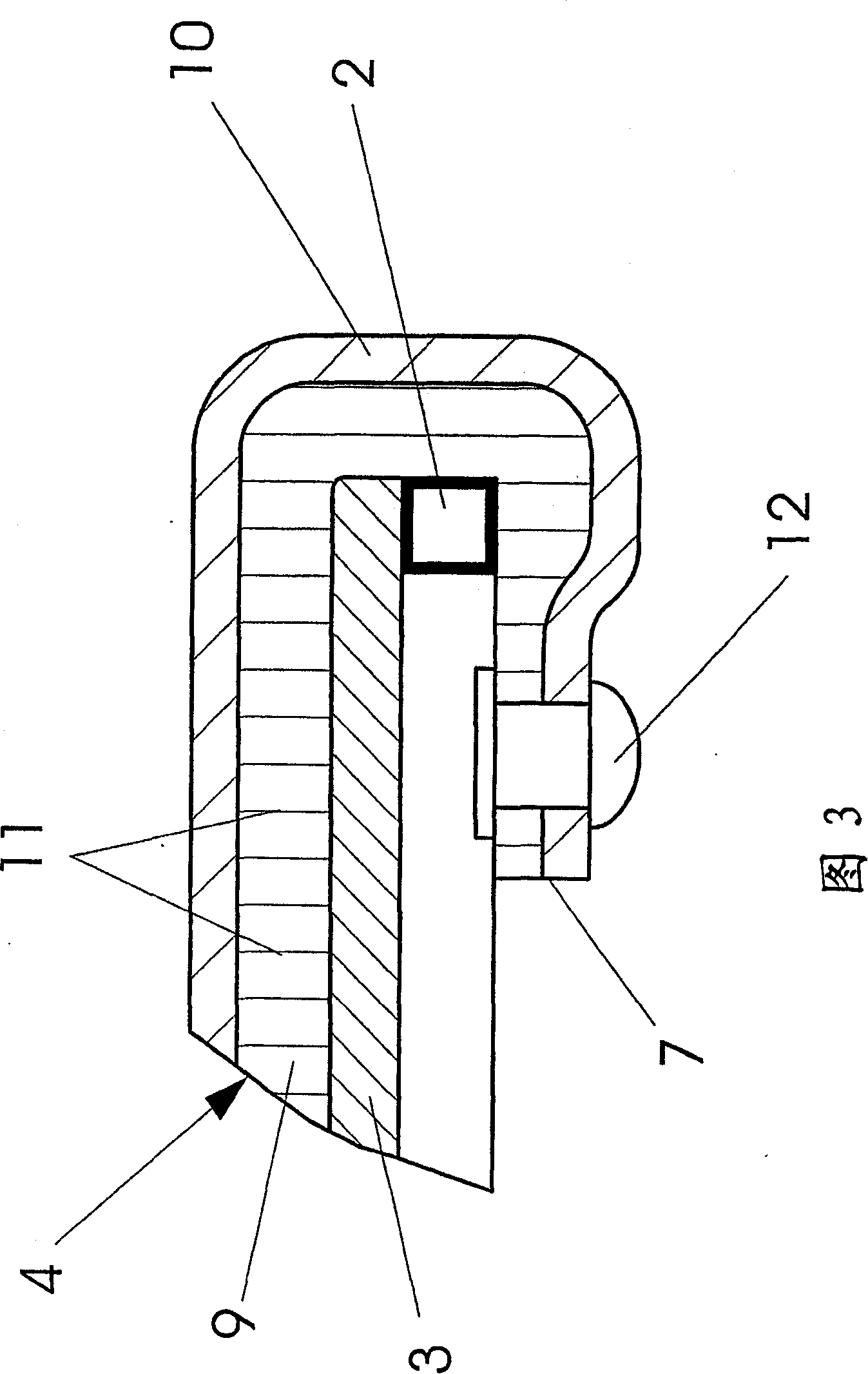

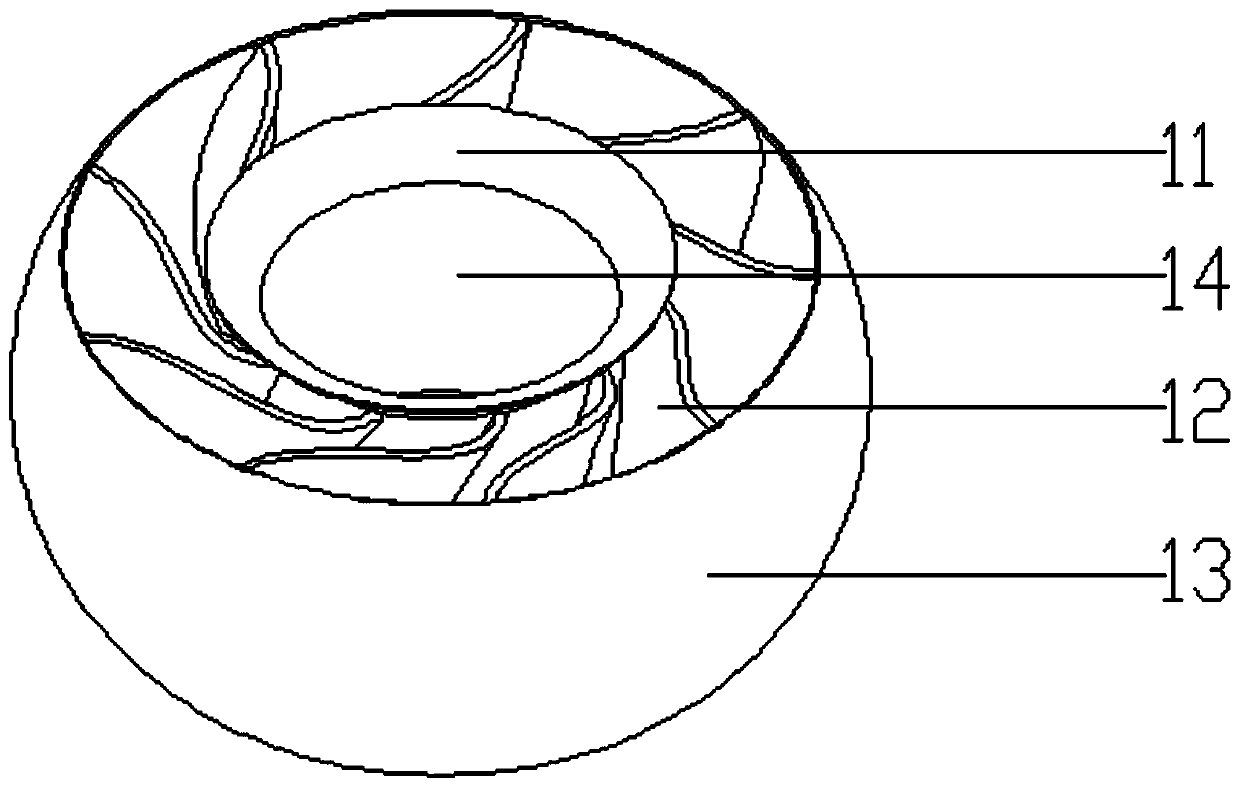

The present invention relates to a flat-running device intended for being fitted on an assembly mounted on a tubeless one-piece rim for an automobile, said mounted assembly including said device, and to a method for mounting and / or removing said mounted assembly. The device according to the invention (1) includes a ring (2) with a radially internal mounting surface for the device, intended to closely match the hollow section of the rim (11), the ring having an open structure with two ends held closely facing one another by a means (5) for clamping the ring. According to the invention, at least one transverse notch (6), the two edges and the bottom of which are located under one of the ends of the ring, is formed in at least one of said side portions (3a), forming a circumferential lip which projects axially from the corresponding side wall of the ring, which includes said recess and is suitable for wedging the ring in the hollow section of the rim, such as to enable, via said notch, transverse insertion of a tool (7) such as a lever between the rim and said mounting surface in order to facilitate the operations of mounting and / or removing the device on the rim.

Owner:HUTCHINSON SA

Natural fiber composite health-care cushion and preparation method thereof

ActiveCN102514274AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLayered productsSurface layerNatural fiber

The invention discloses a natural fiber composite health-care cushion which comprises a middle layer. A surface layer is arranged on the upper surface or the lower surface of the middle layer. A block layer is arranged between the middle layer and the surface layer. The surface layer is a non-woven layer comprising 5 percent to 50 percent of low melting point fibers. The middle layer is a non-woven layer which comprises the following components: bastose and 5 percent to 50 percent of low melting point fibers. The block layer is a non-woven layer comprising 5 percent to 100 percent of low melting point fibers. In the natural fiber composite health-care cushion, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the natural fiber composite health-care cushion, which comprises the following steps of: respectively preparing the middle layer, the upper or lower surface layer and the block layer; then sequentially paving the layers; and preparing the natural fiber composite health-care cushion by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption ofthe natural fiber composite health-care cushion and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer, has poor air permeability and is discomfortable to use due to protruded hard fibers in the middle of the mattress is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

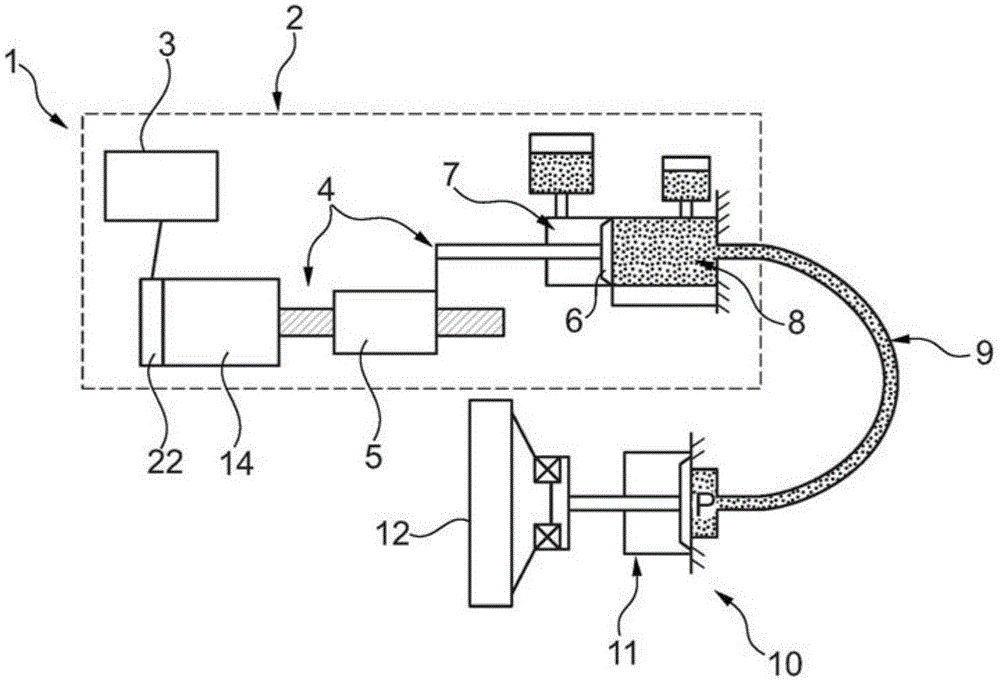

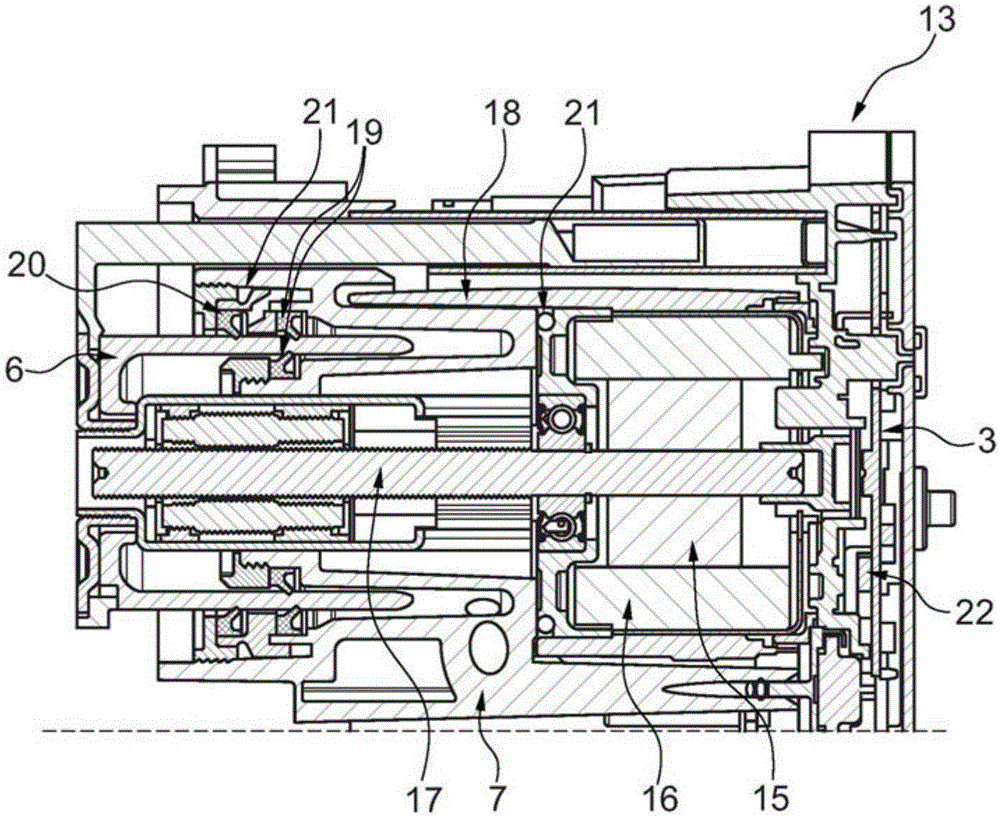

A method for local heating of a viscous elastic component of a hydrostatic actuator of a vehicle and a hydrostatic clutch actuator

ActiveCN105370750AIncrease temperatureEnough temperatureFluid actuated clutchesCouplingsElastic componentHydraulic fluid

The invention relates to a method for local heating of a viscous elastic component of a hydrostatic actuator of a vehicle, in particular a hydrostatic clutch actuator, in which the hydrostatic actuator (13) comprises a cylinder (7), in which a piston (6) is mounted axially movable , by an electric motor (14) is moved via a transmission (5), whereby a hydraulic fluid (8) in a hydraulic path of the hydrostatic actuator (13) is moved opposite to the area with viscous elastic components (19, 20, 21) is sealed. is the case of a method in which the operation of the hydrostatic actuator over a wide temperature range, at least one viscous elastic component (19, 20, 21) at low outdoor temperatures, and when the ignition of the vehicle is controlled by a current supply of an electrical circuit (22).

Owner:SCHAEFFLER TECH AG & CO KG

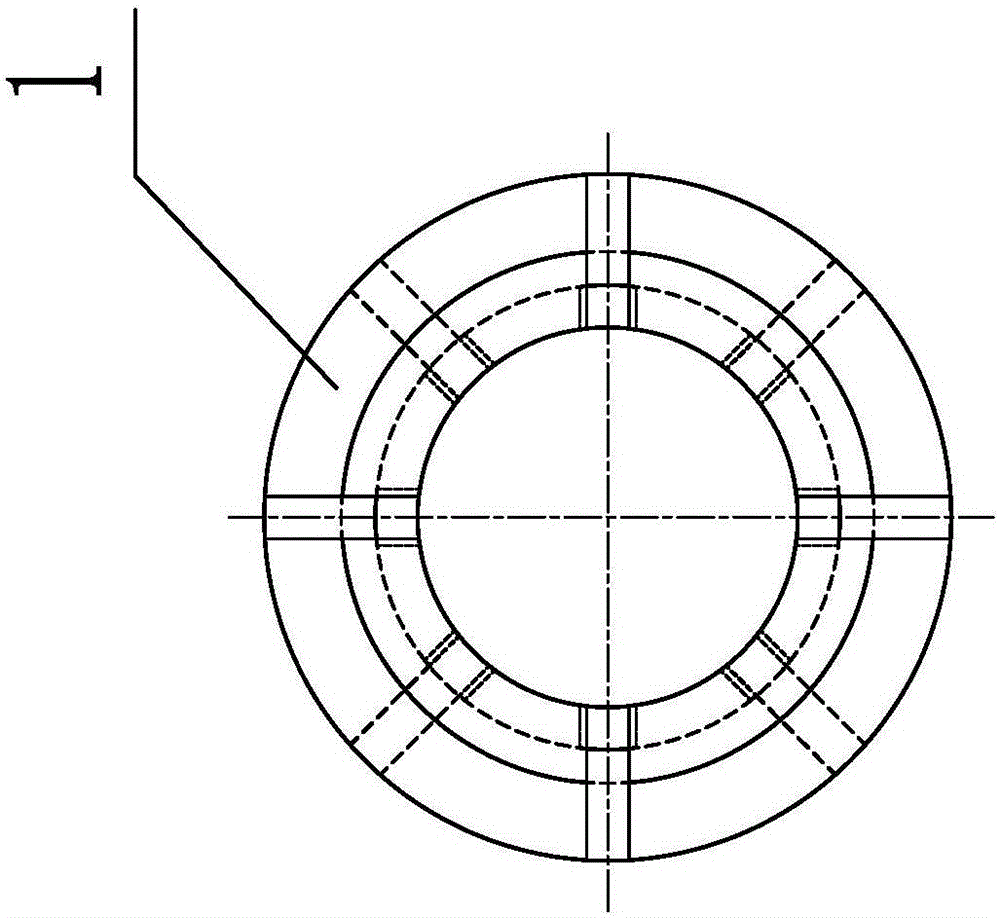

Method for machining elastic nuclear power jackets

ActiveCN106271420AIncrease elasticityImprove manufacturing precisionNuclear engineeringNuclear power

The invention discloses a method for machining elastic nuclear power jackets, and relates to a method for machining elastic nuclear power jackets. The method includes steps of firstly, preparing materials; secondly, carrying out rough lathing; thirdly, carrying out heat treatment; fourthly, grinding inner holes; fifthly, grinding outer circular surfaces; sixthly, scribing open slots; seventhly, linearly cutting the various open slots; eighthly, fixedly clamping clips; ninthly, carrying out tempering heat treatment; tenthly, carrying out rounding, to be more specific, detaching the clips 5 at two ends of each elastic jacket by the aid of bench workers and rounding various edges to completely machine the elastic jackets. The method has the advantages that problems of poor elasticity of elastic jackets in the prior art, insufficient shrinkage of inner holes in two ends of each elastic jacket and influence on work effects can be solved by the aid of the method; the method is applied to the field of components of nuclear power welding machines.

Owner:HARBIN TURBINE +1

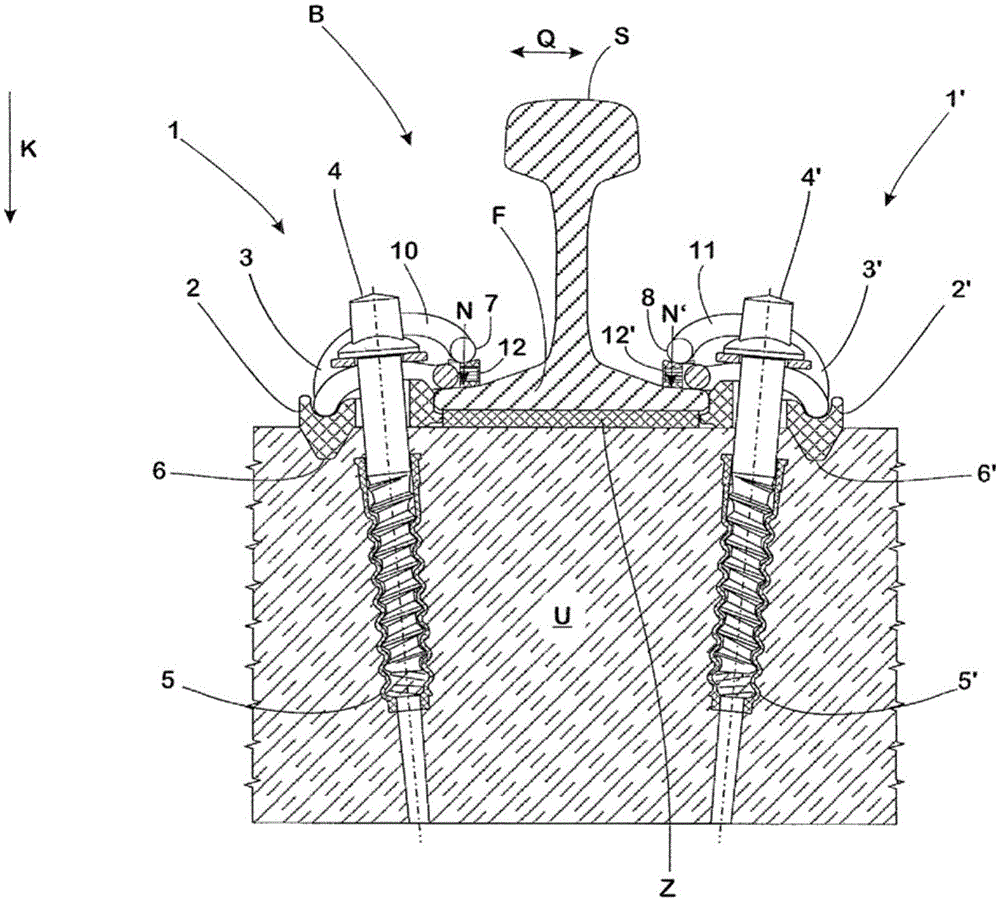

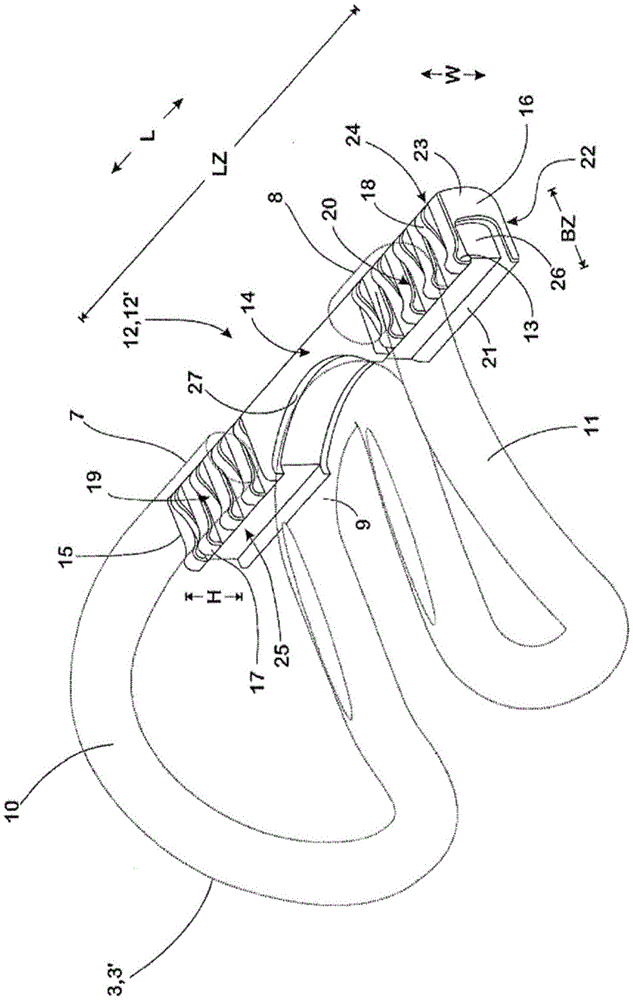

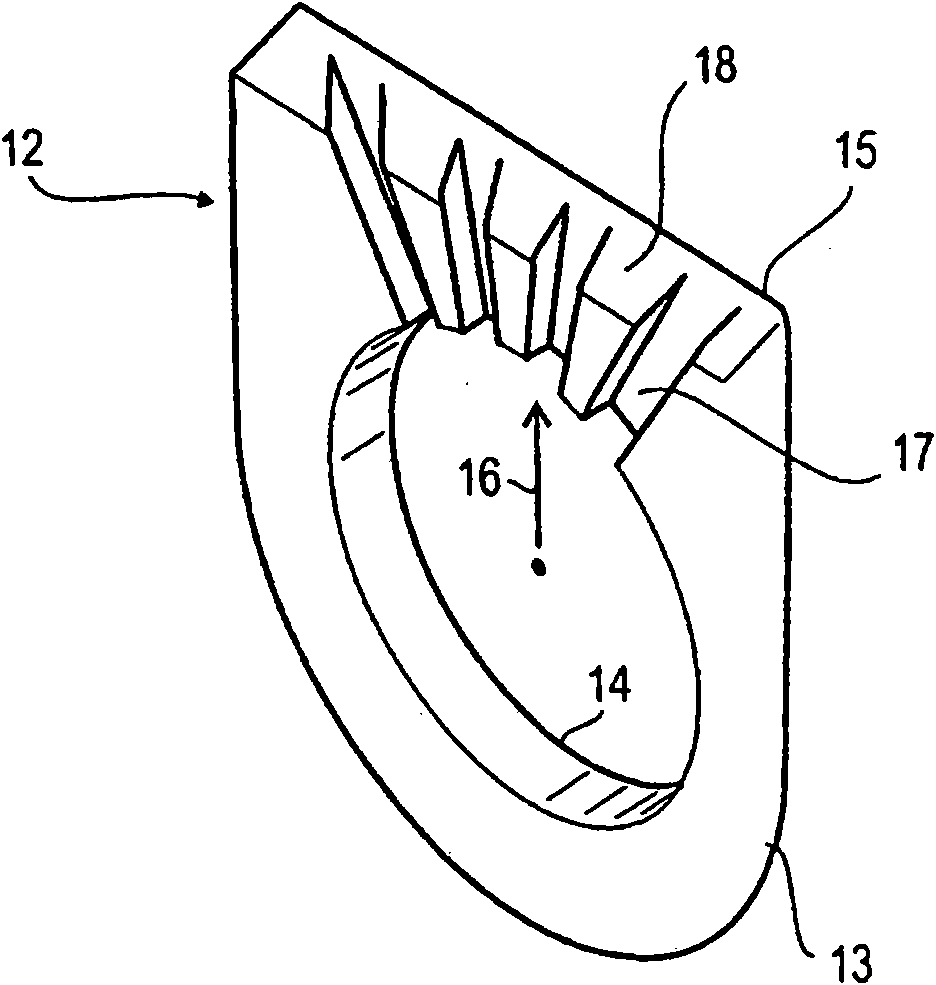

Resilient intermediate piece for clamping rail base

InactiveCN105658871AImprove scalabilityReduce rigidityRail fastenersIntermittent motionSupport surface

The invention relates to a system and to an intermediate element for a system (1, 1') for fixing a rail (S) for a rail vehicle to a base (U). The intermediate element (12, 12') is provided to be arranged between an end section (7, 8) of a spring element (3, 3') and the rail (S), such that the spring element (4, 4') transmits a holding-down force (N, N') to the rail (S) via the intermediate element (12, 12'). The intermediate element (12, 12') has a supporting surface (14), on which the end section (7, 8) of the spring element (3, 3') lies during use, and a standing surface (22), with which the intermediate element (12, 12') is seated on the rail (S) during use. According to the invention, the intermediate element (12, 12') is designed to be resiliently compliant in an active direction (W) directed from the supporting surface (14) toward the standing surface (22). As a result of the installation of an intermediate element (12, 12') according to the invention in a rail fixing system, the risk of shortening the service life of the spring element (3, 3') which is used to hold down the rail in the system, as a result of periodic movements that occur, is minimized.

Owner:VOSSLOH WERKE GMBH

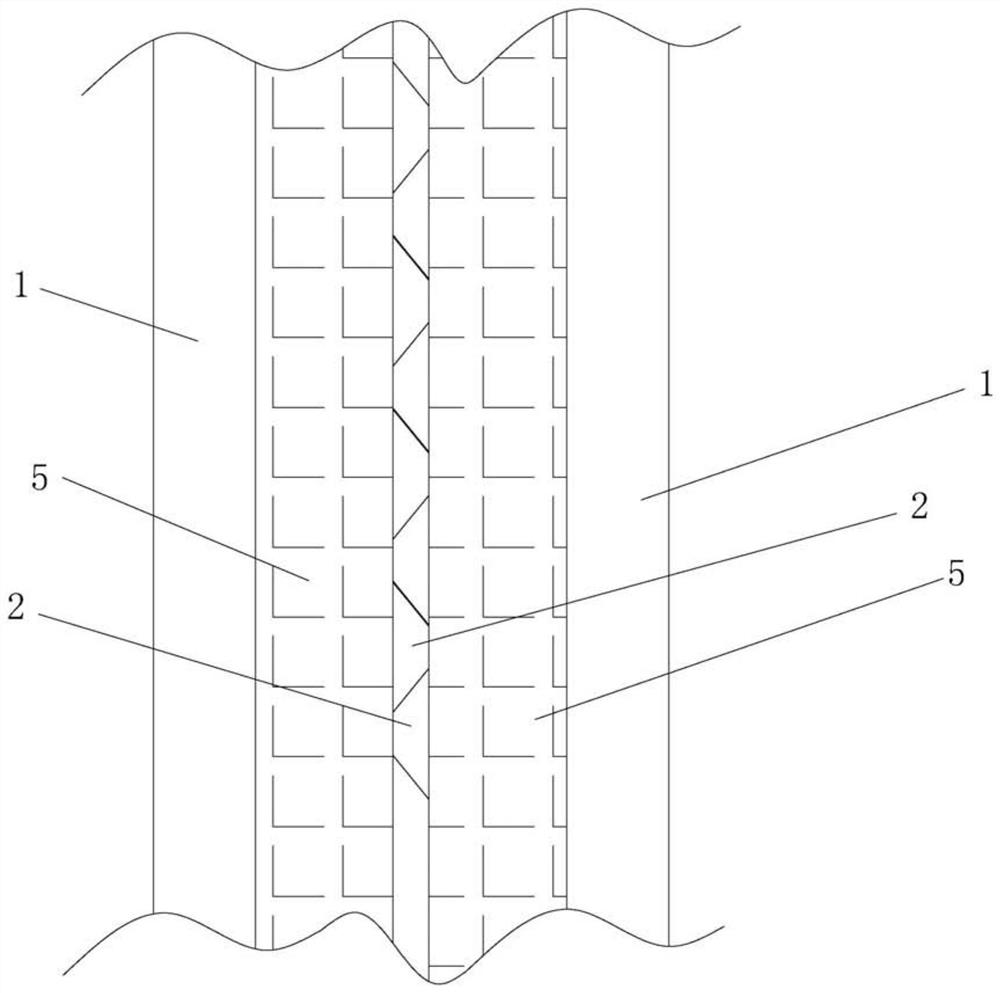

Longitudinal reinforced polymer profile

InactiveCN1718422AElastic enoughElastomer and other materials, so that the profile structure has sufficient strength and sufficientFiberPolymer

Owner:济南三达信科技有限公司

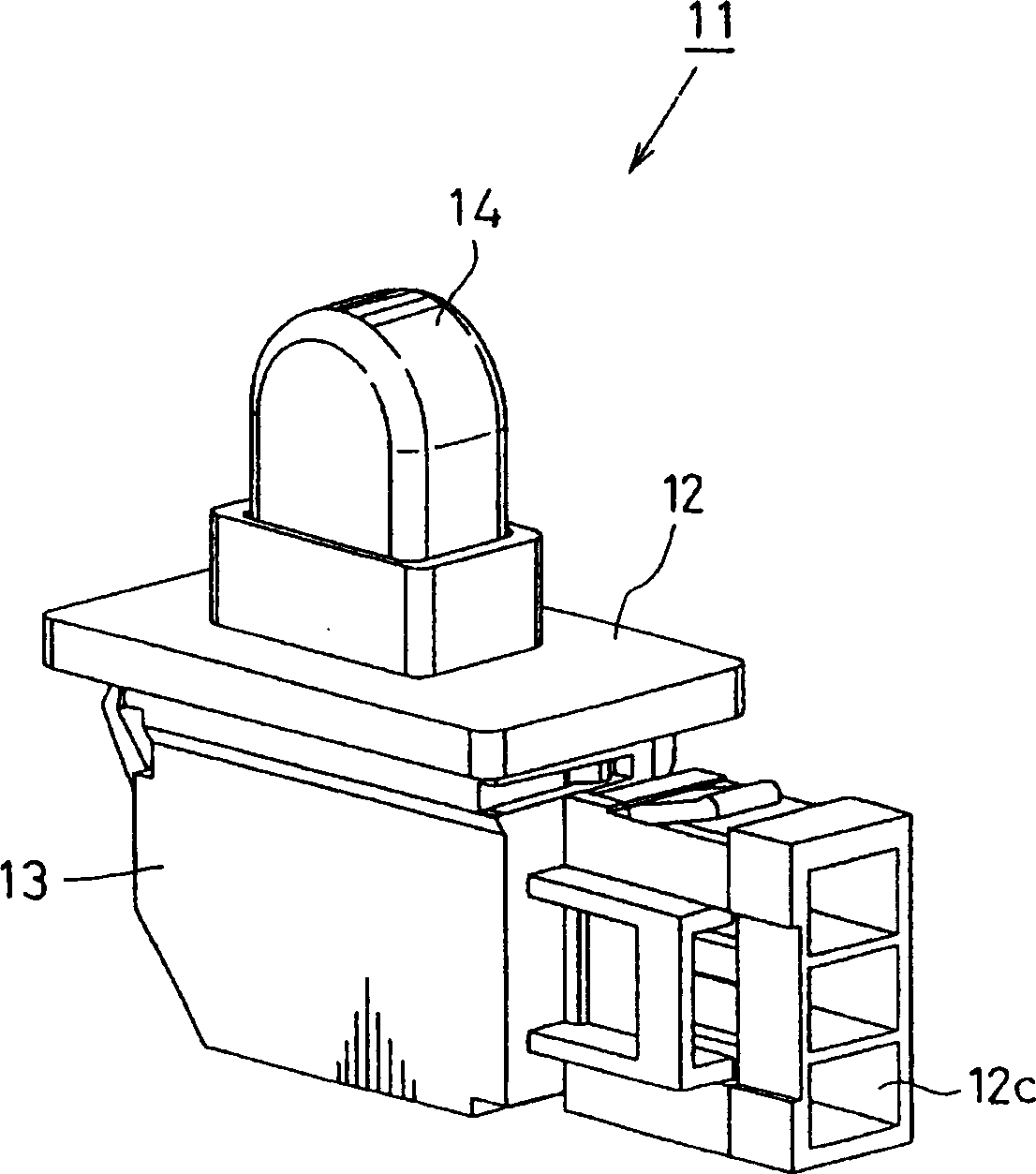

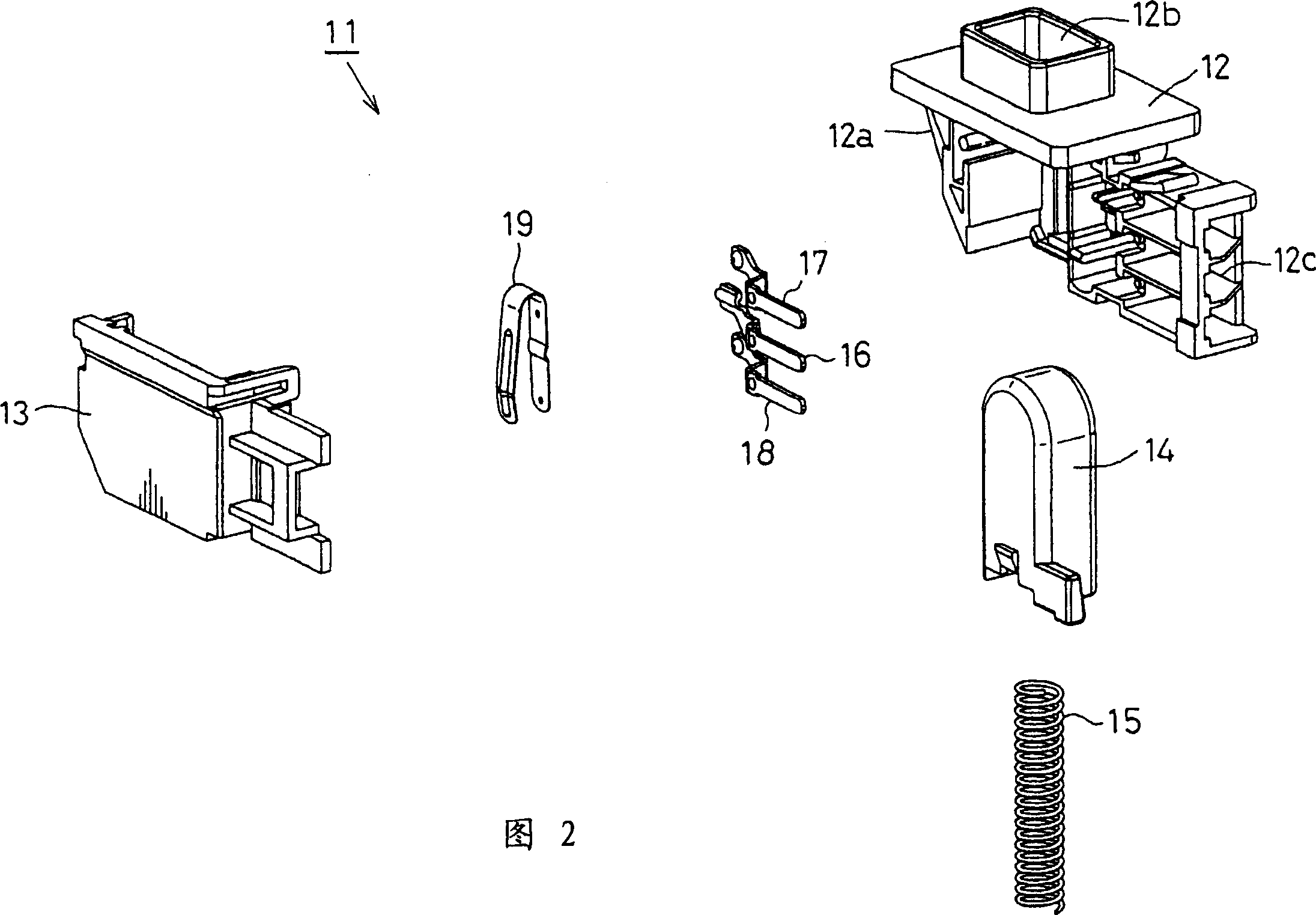

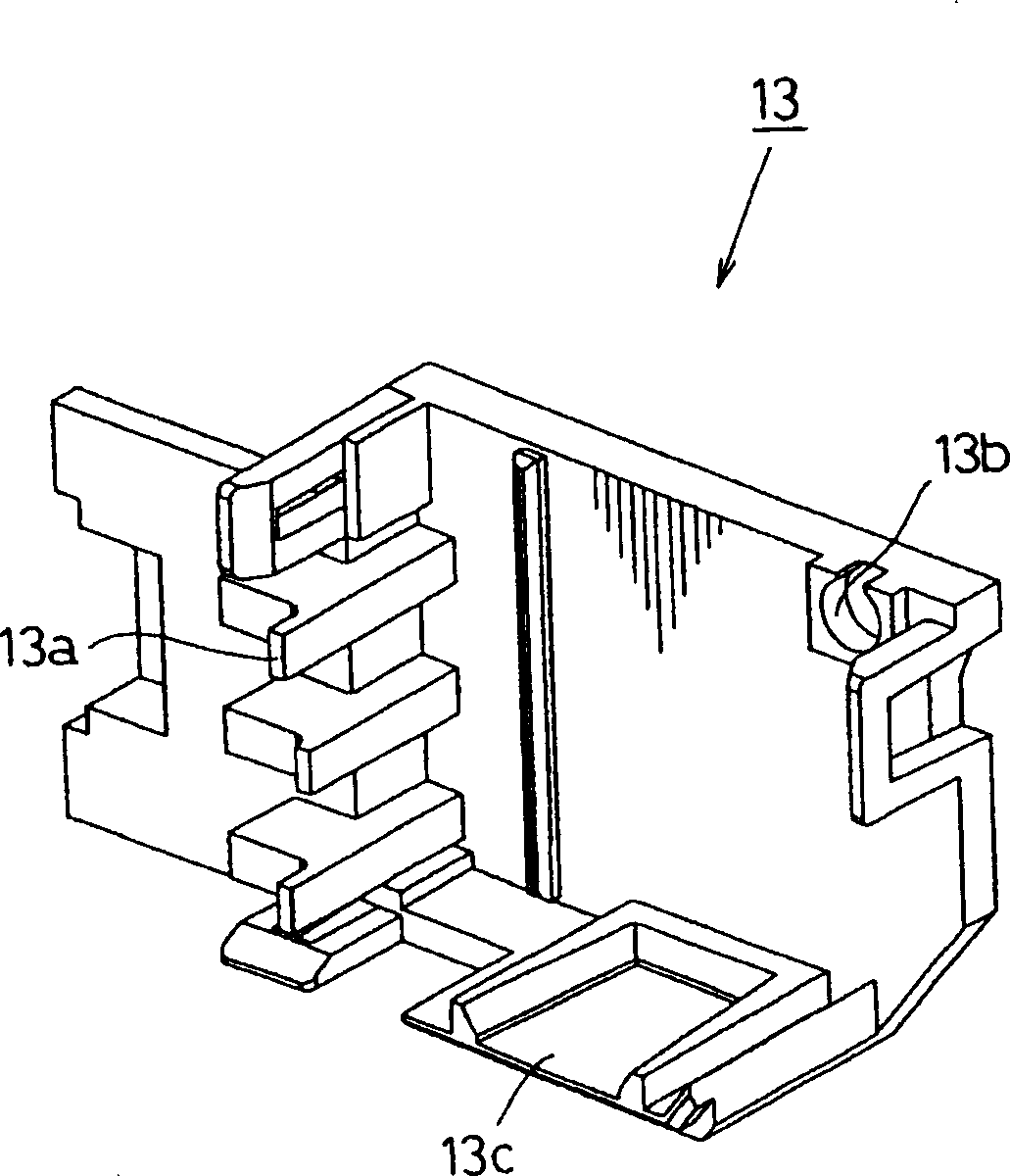

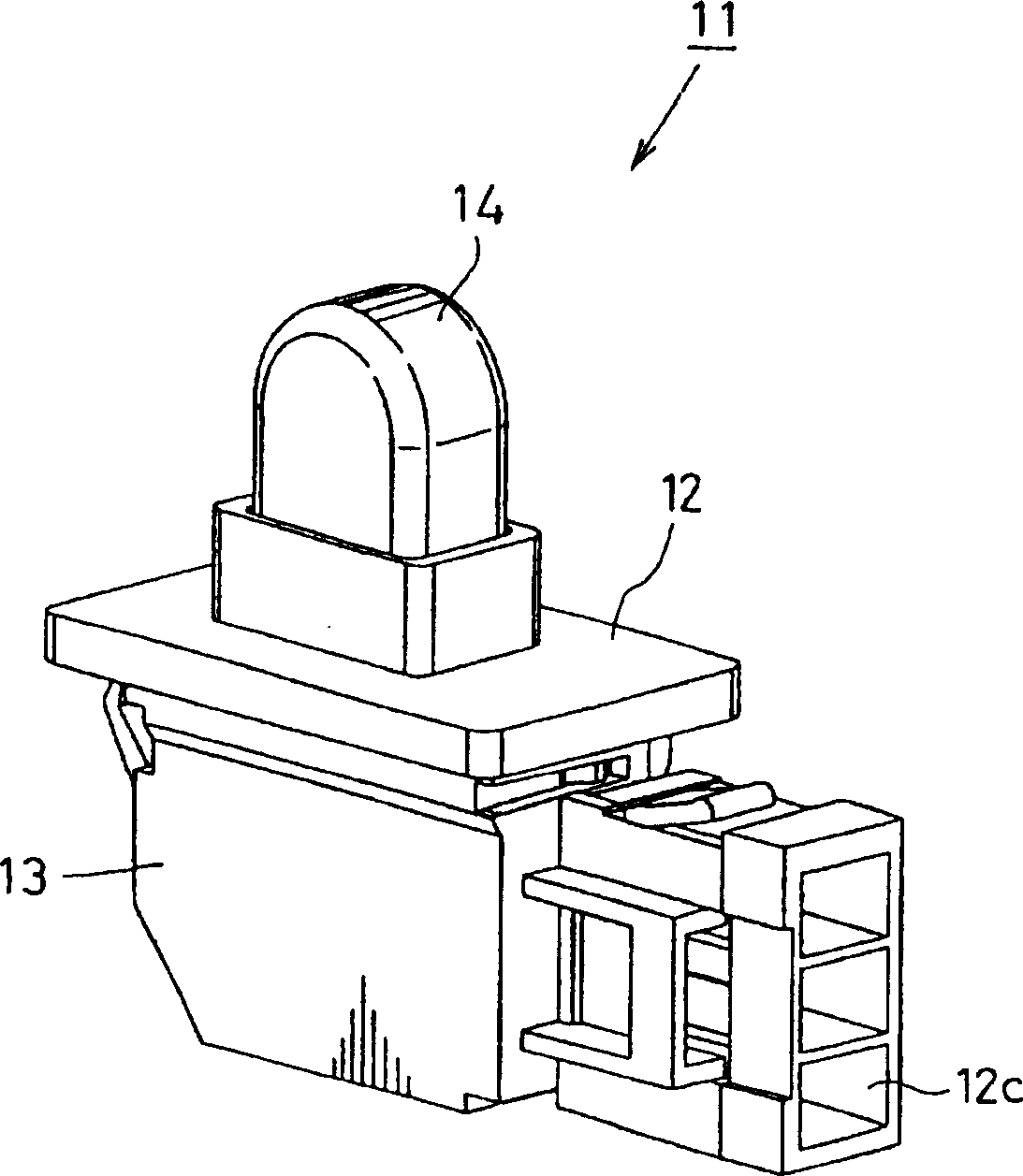

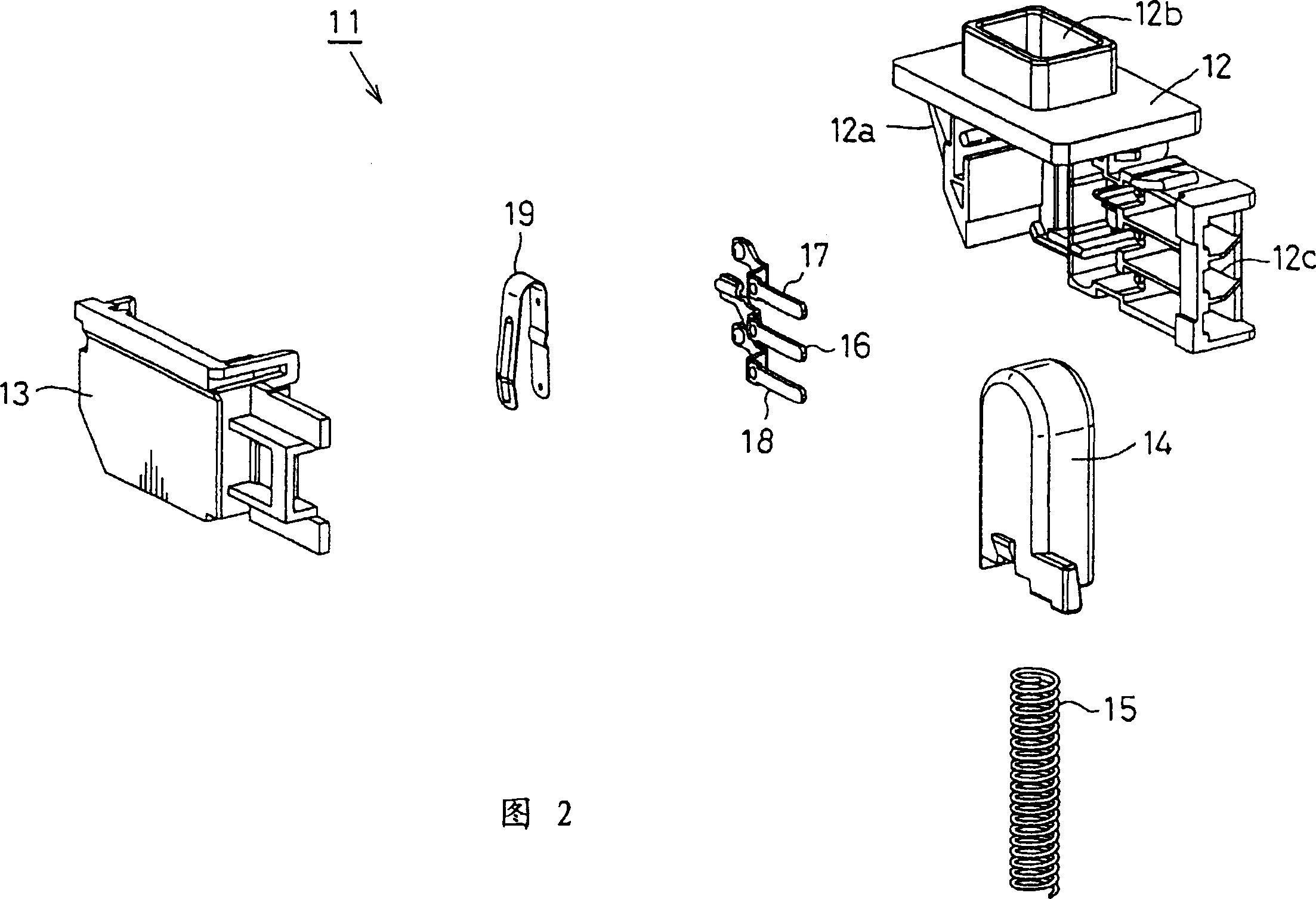

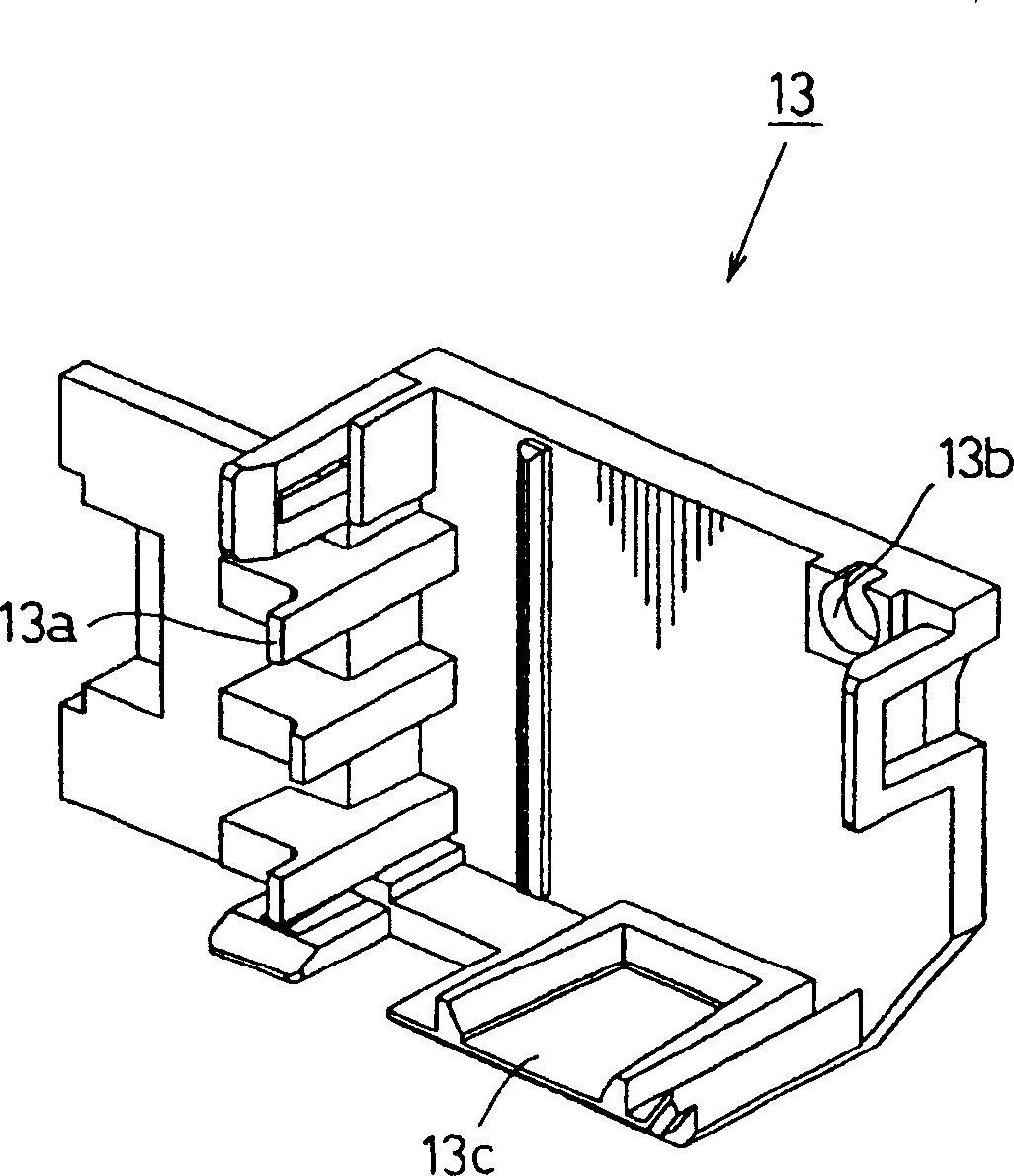

Switch, botton switch and rotation switch

InactiveCN1409337AReduce in quantityReduce assembly man-hoursContact engagementsEngineeringPush switch

The present invention is provided with a contact switching mechanism having a movable contact member that is bent into a U shape, allowed to press and contact a fixed contact member side, and supported so as to freely tilt and move thereon. In this mechanism, a switching operation is carried out between contacts by reversing the movable contact member in a see-saw manner, with a tilt-movement fulcrum portion of the movable contact member being always in contact with the contact portion of the common fixed contact member. The movable contact member is allowed to have a spring function conformed to elastically shift in response to a switching operation in addition to a contact function that is inherent to the movable contact member so that it is possible to provide a switch having high reliability, such as a push-button switch and a rotary-lever switch, which can cut costs by reducing the number of parts, and ensure a superior contacting property.

Owner:ORMON CORP

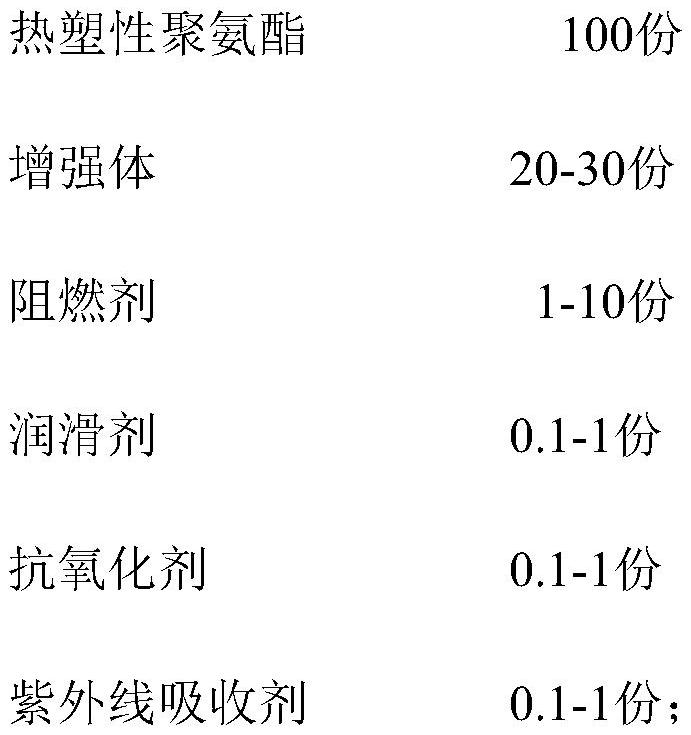

Polyurethane elastomer sealing process of waterproof zipper tape

ActiveCN112778749AImprove embedding stabilityImprove waterproof performanceSlide fastenersBio-packagingPolyurethane elastomerPolymer science

The invention relates to the technical field of zipper tapes, and particularly relates to a polyurethane elastomer sealing process of a waterproof zipper tape. Each zipper tooth comprises a tooth root and a tooth head, the tooth heads are meshed with one another, empty grooves between the tooth roots are filled with first resin bodies, and second resin bodies are compounded on the upper surfaces and the lower surfaces of the tooth roots and the first resin bodies. According to steps of the injection molding sealing process, a polyurethane elastomer serves as injection molding resin to conduct injection molding on the zipper tape. Through the injection molding process, the non-meshing parts of the zipper teeth, namely, the empty grooves between the tooth roots, are filled with the resin bodies so as to achieve the water seepage prevention effect, meanwhile, in order to improve the embedding stability of the resin bodies and further improve the waterproofness, the resin bodies are integrally filled into the upper surfaces and the lower surfaces of the tooth roots through the injection molding process, and the complete and continuous polyurethane elastomer completely covering the tooth roots is formed, so that the tooth roots can fix the position of the polyurethane elastomer as a positioning column, the polyurethane elastomer is not prone to dislocation or falling off, the structural stability is improved, and the waterproof performance is also improved.

Owner:东莞市瑞翔新型材料科技有限公司

Fastener, pedestal and fastening assembly

InactiveCN102434549BElastic enoughIncrease elasticityFriction grip releasable fasteningsBuckle FastenerFastener

Owner:SHENZHEN NETCOM ELECTRONICS CO LTD

Forceps body structure of tracheal foreign body forceps device

The invention discloses a forceps body structure of a tracheal foreign body forceps device. The forceps body is integrally molded from elastic rubber or plastic and structurally formed by sequentially and integrally connecting a round-tubular pipe joint b, a round-tubular support ring, a spherical rib connecting surface and four clamping pieces, wherein the rib connecting surface is recessed towards inside of the support ring, the four clamping pieces are uniformly and adjacently connected to the periphery of the outer surface of the rib connecting surface, and a round front opening is defined by ends of the four clamping pieces; a side seam is reserved between every two adjacent clamping pieces; a support rib is formed on the inner side of each clamping piece, and the bottom of the support rib is connected onto the outer surface of the rib connecting surface. The forceps body is integrally molded from the elastic rubber or plastic, is convenient to process and low in production cost, has smooth surface without burrs or sharp ends and produces little discomfort and damage to the trachea.

Owner:王超峰

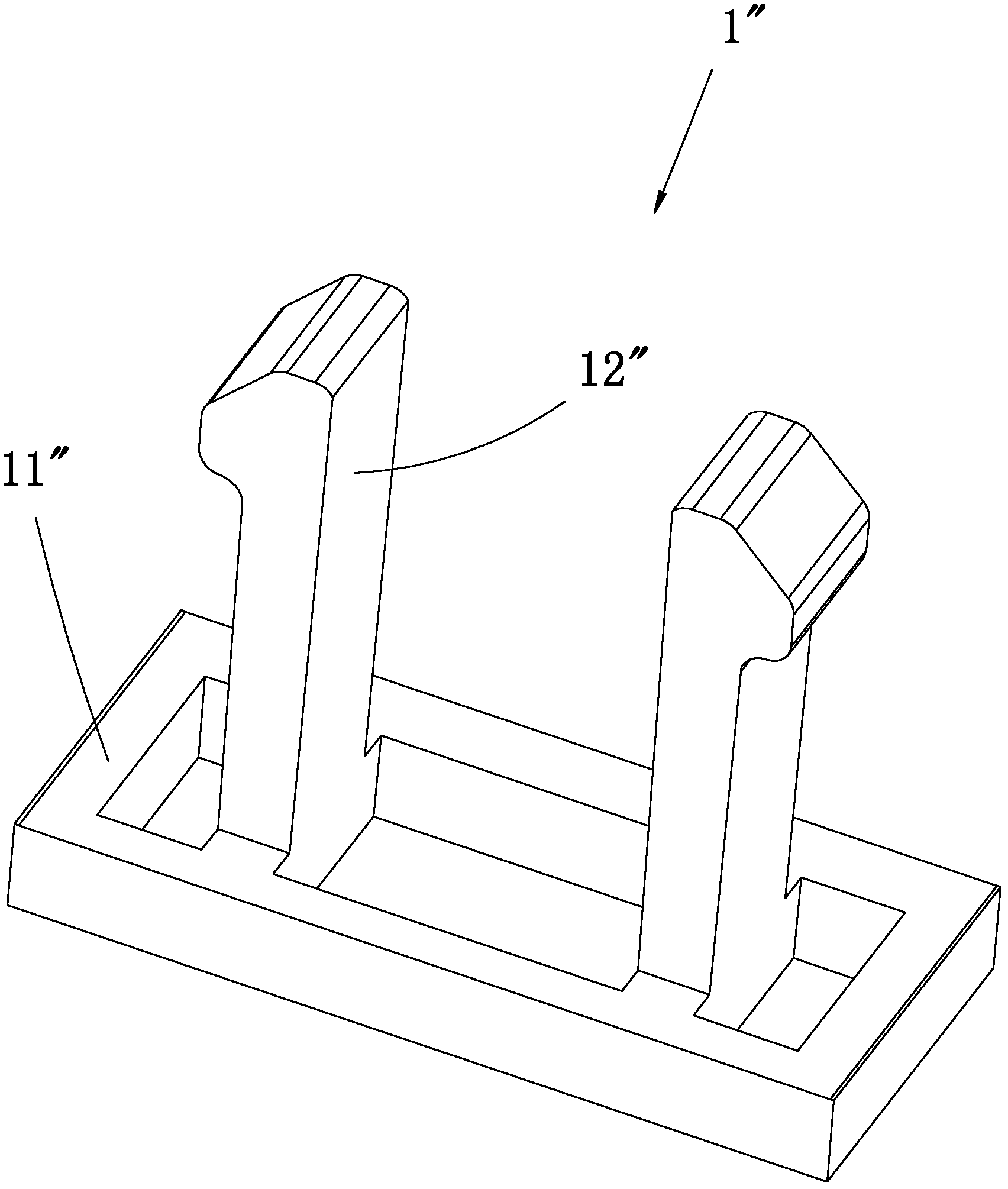

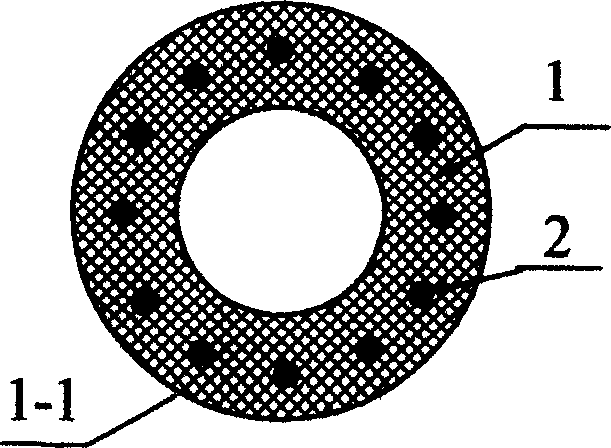

Filter panel laminates and diaphragm filter panel

ActiveCN101784320BAvoid inadvertent tearingEfficient allocationFiltration separationInlet channelSludge

A filter panel contains a sludge inlet, a distributor ring which is arranged at the sludge inlet and has at least one inlet channel, and a support ring assigned to the distributor ring. A protective lip is mounted on the support ring and rests on the distributor ring in its closed position and partly covers the inlet channel.

Owner:JVK FILTRATION SYST

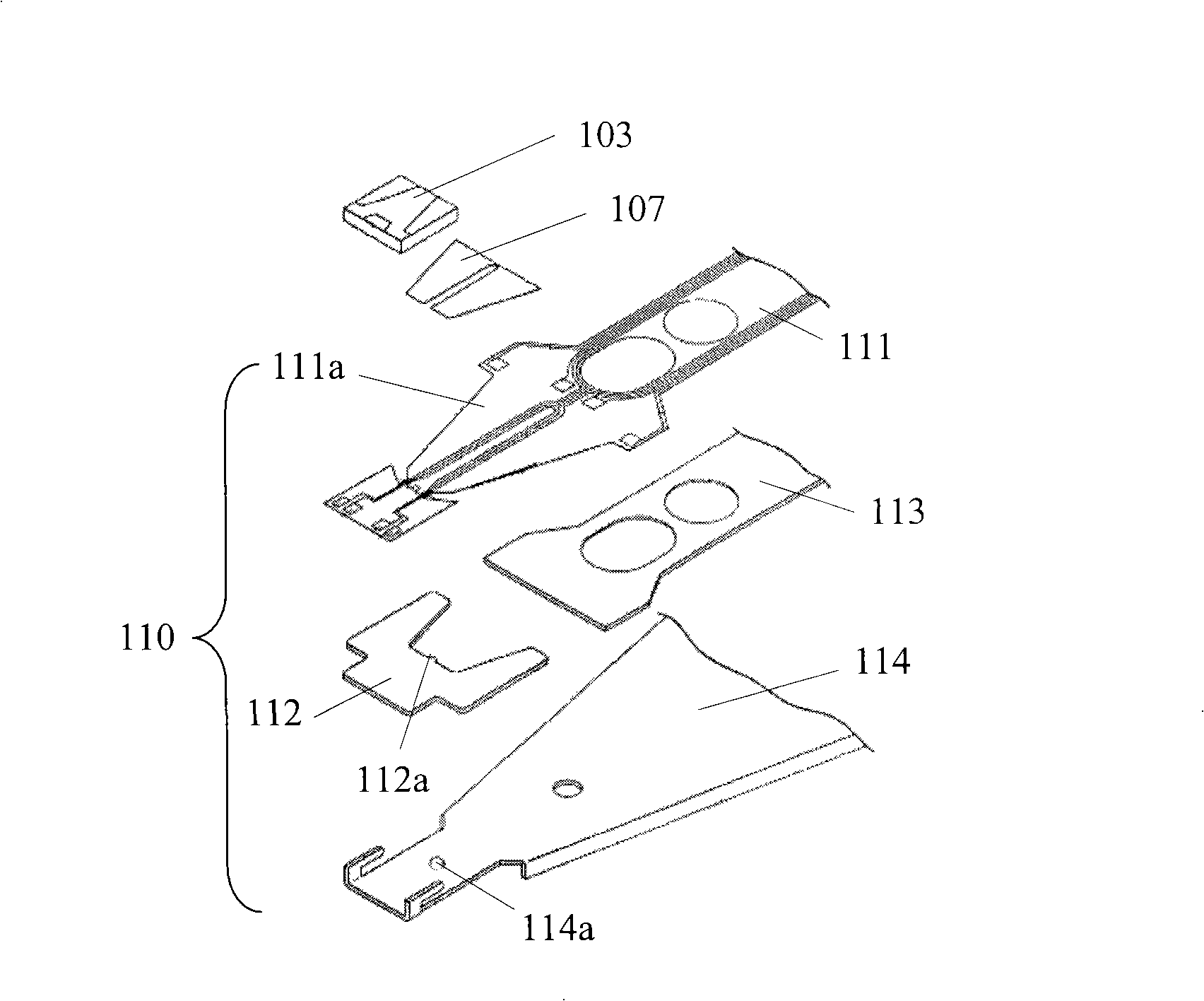

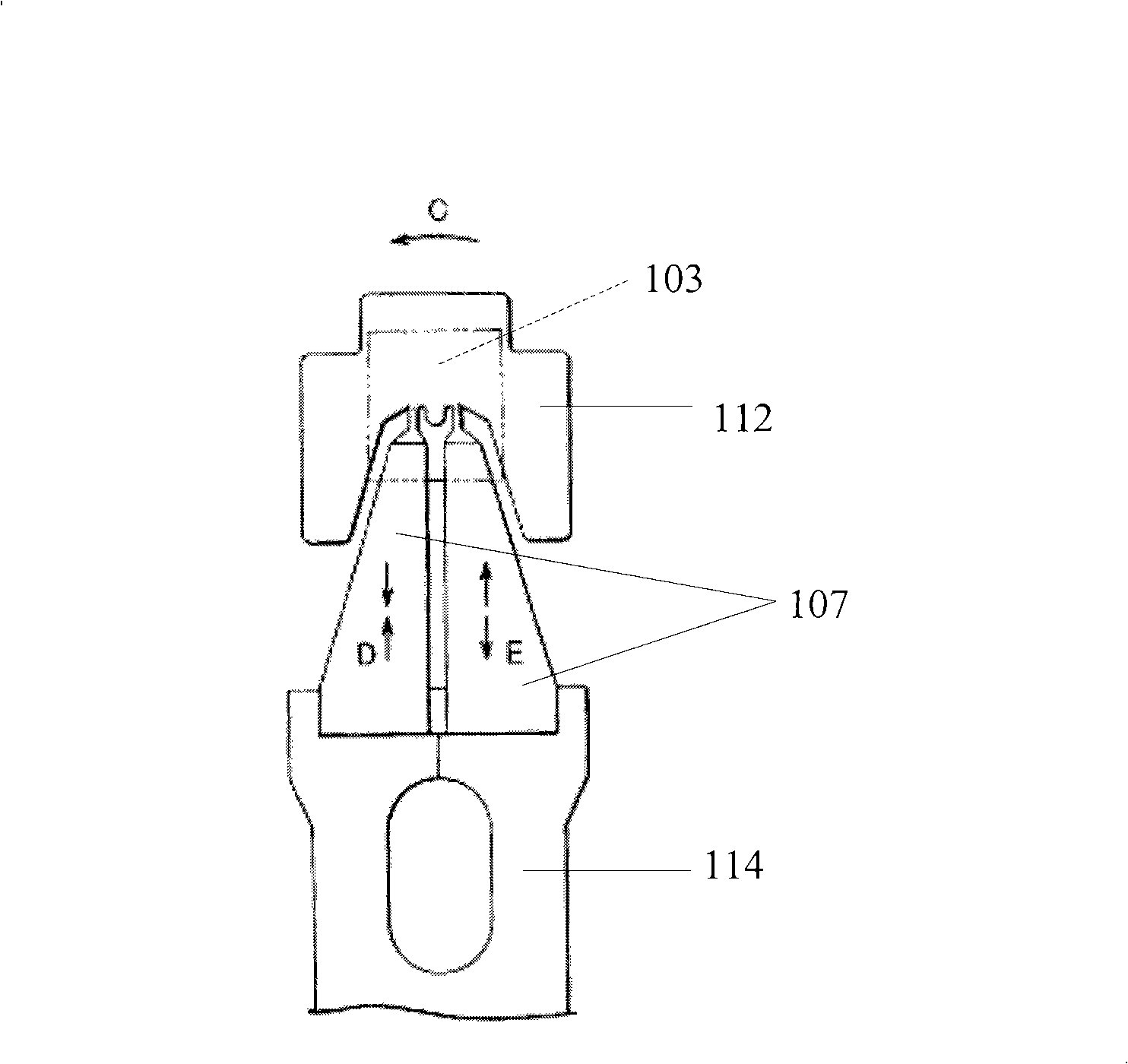

Cantilever member, magnetic head folding piece combination and manufacturing method and disk driving unit

ActiveCN101315773AImprove shock resistanceImprove dynamic performanceRecord information storageMounting of arm assembliesStatic performanceCantilever

The invention discloses a cantilever piece of a magnetic head folded piece combination, which comprises a flexible member provided with a tongue region and an external trigger board, wherein, the external trigger board is provided with a pair of rigid arms and a pair of elastic arms; the pair of elastic arms lead the flexible member to have favorable flexibility and is helpful to a magnetic head to have enough displacement; the pair of rigid arms provide enough rigidity to the flexible member, thus not only preventing the magnetic head folded piece combination provided with the external trigger board from generating cantilever piece deformation and emboss separation successfully, but also contributing to the improvement of the shakeproof performance of a magnetic head folded piece group. Moreover, the structure of the cantilever piece provides good static property to the magnetic head; therefore, the dynamic property of the magnetic head folded piece combination is enhanced. The invention also discloses the magnetic head folded piece combination provided with the cantilever piece and a manufacturing method thereof as well as a disk driving unit provided with the magnetic head folded piece combination.

Owner:SAE MAGNETICS (HK) LTD

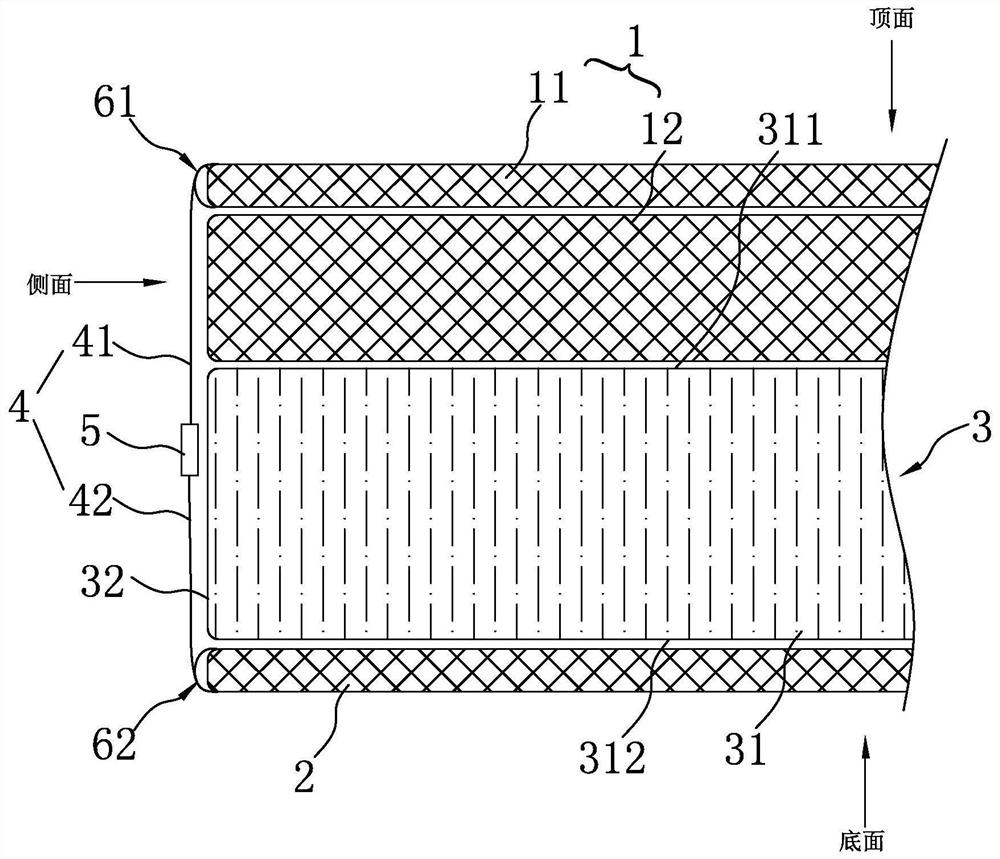

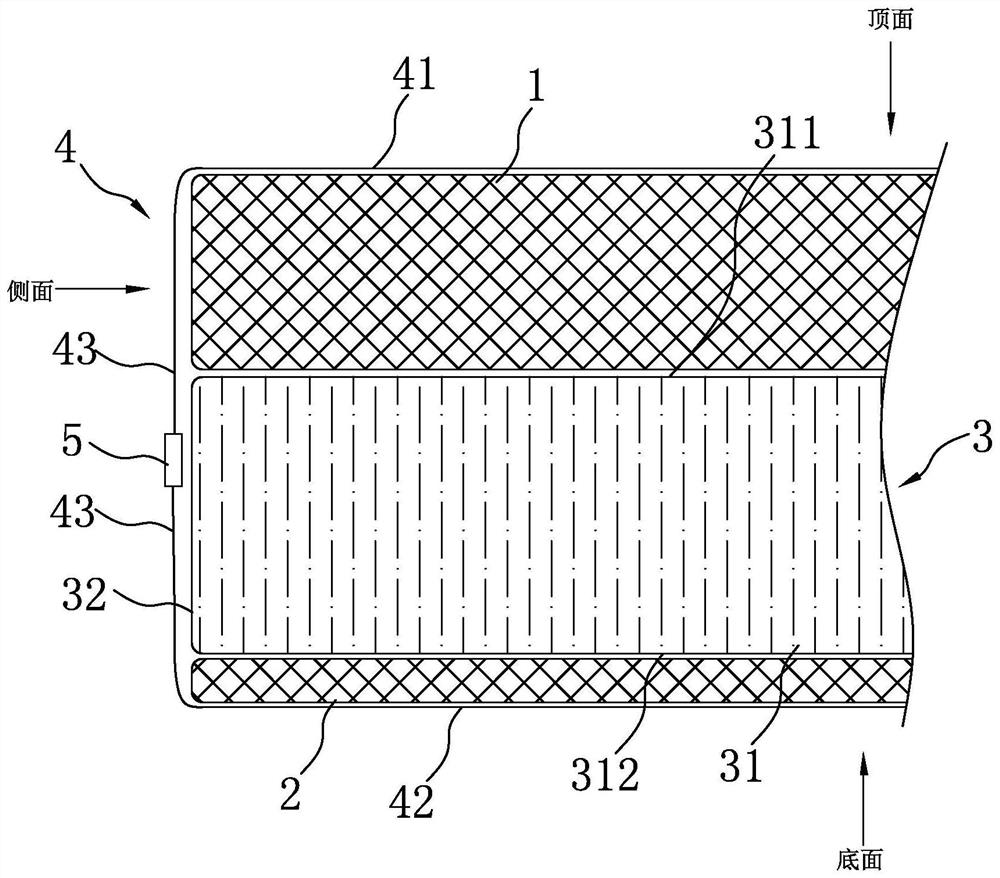

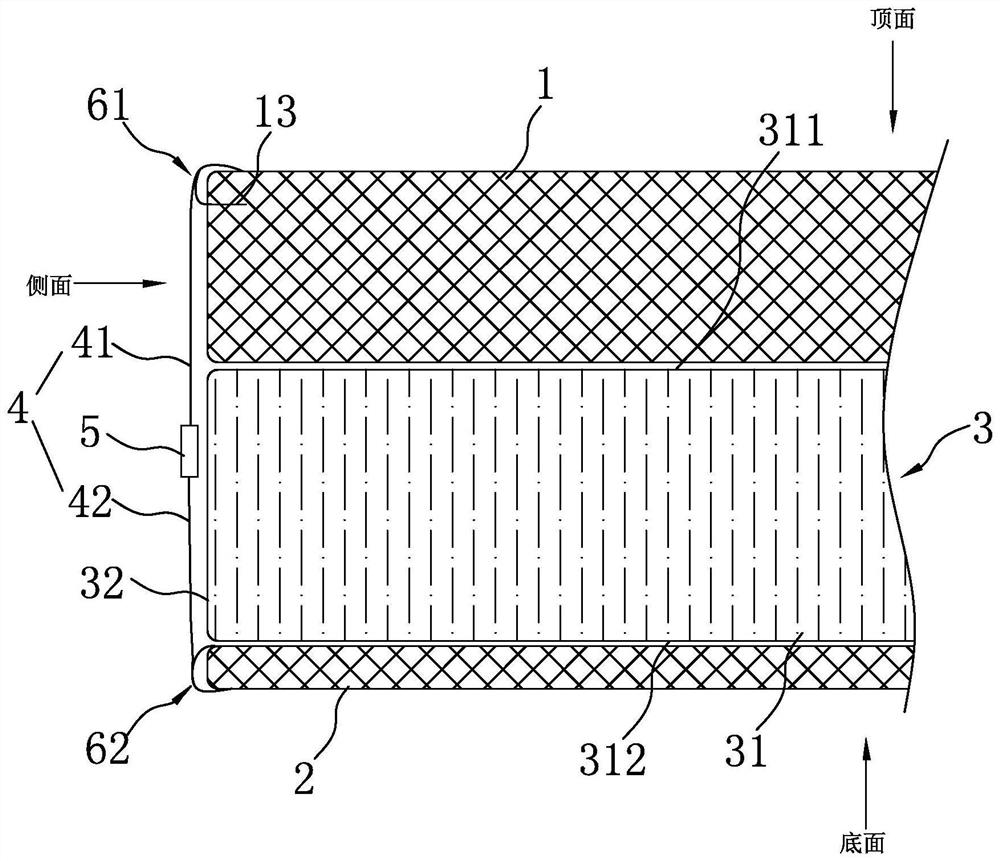

Mattress

The invention relates to the field of daily necessities and particularly relates to a mattress. The mattress comprises a first 3D fabric layer, an inflatable elastic cushion layer, a second 3D fabric layer and a side wrapping layer wrapping a side face of the mattress, wherein the first 3D fabric layer, the inflatable elastic cushion layer and the second 3D fabric layer are arranged in a stacked mode, the side wrapping layer wraps a side face of the mattress, and the inflatable elastic cushion layer is clamped between the first 3D fabric layer and the second 3D fabric layer and is of an extractable structure; the side coating layer comprises an upper side coating layer connected with the first 3D fabric layer and a lower side coating layer connected with the second 3D fabric layer, the upper side coating layer is connected with the lower side coating layer through a connecting unit, the connecting unit is arranged on the side face of the mattress, thickness of the first 3D fabric layer is 5-8 cm, thickness of the second 3D fabric layer is 0.8-1cm, and the upper side coating layer and the first 3D fabric layer as well as the lower side coating layer and the second 3D fabric layer are respectively provided with an edge covering structure. The mattress is used for solving a problem that the comfort, air permeability and logistics cost of the mattress cannot be considered at the same time.

Owner:QUANZHOU XINHENG OUTDOOR EQUIP

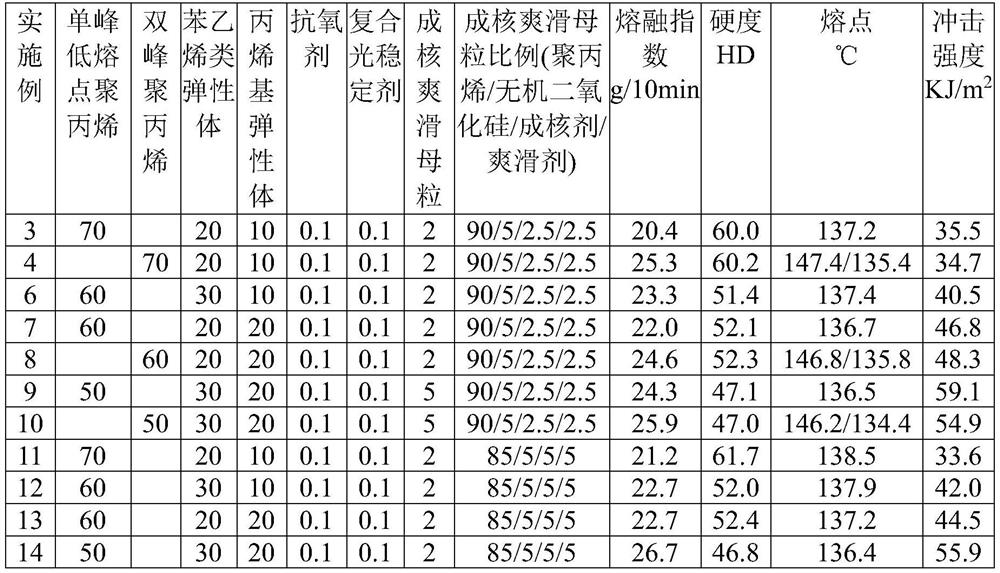

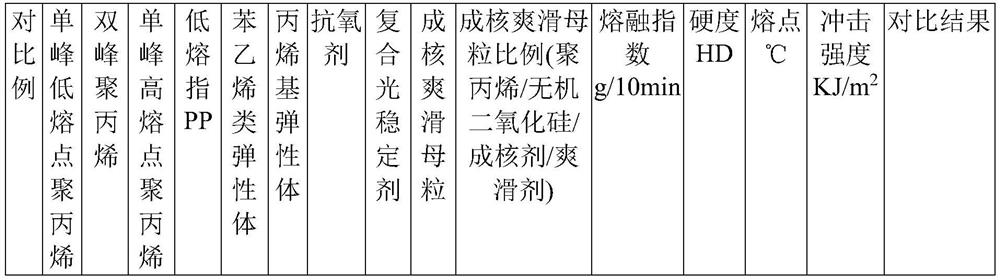

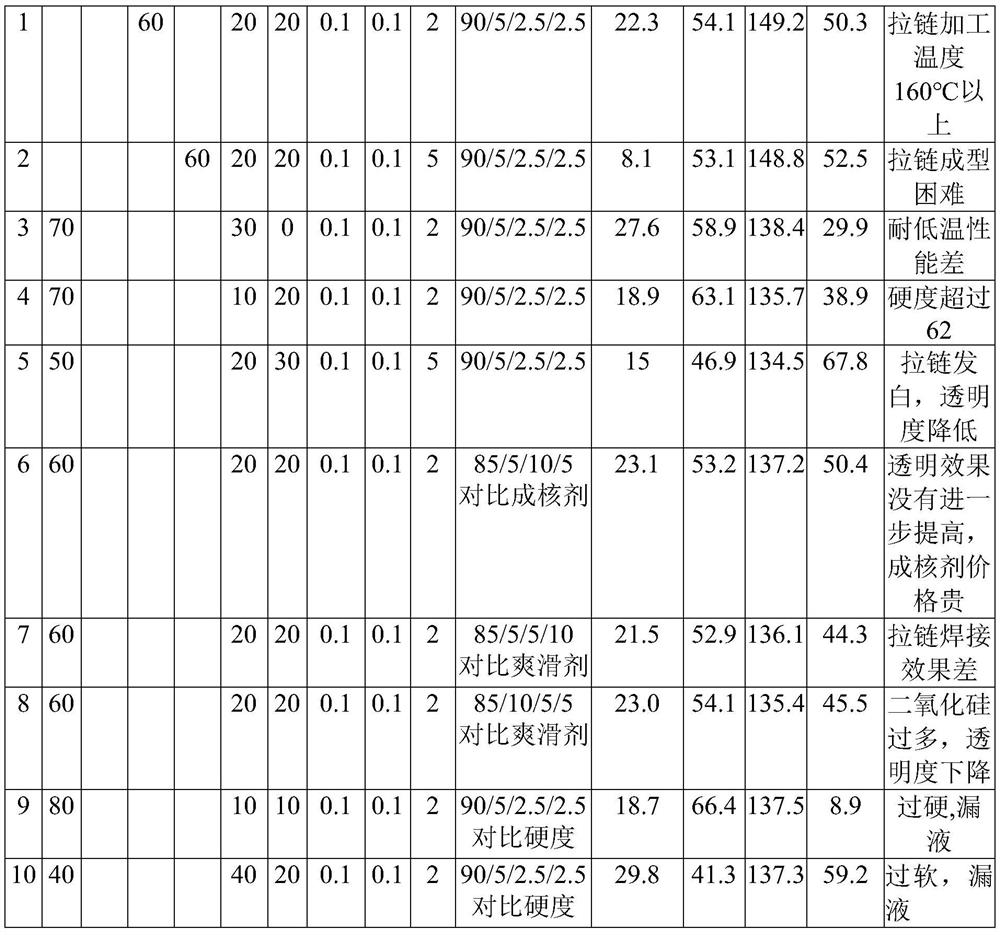

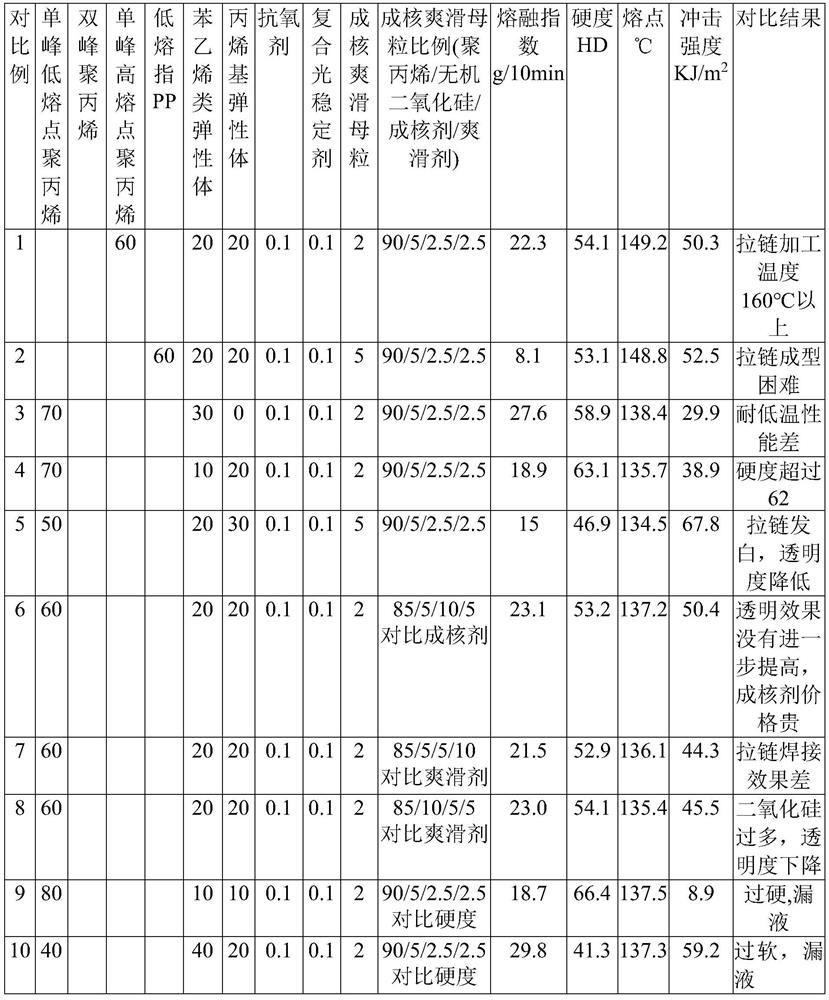

Modified polypropylene zipper material for liquid packaging and preparation method thereof

The invention discloses a modified polypropylene zipper material for liquid packaging and a preparation method thereof. The formula comprises the following components in parts by weight: 50-70 parts of polypropylene I, 30-50 parts of a toughening elastomer, 2-10 parts of nucleating smooth master batch, 0.05-0.1 part of an antioxidant and 0-0.1 part of a composite light stabilizer, wherein the total amount of the polypropylene I and the toughening elastomer is 100 parts by weight; the nucleating smooth master batch is prepared from polypropylene II, inorganic silicon dioxide, a nucleating agent and a slipping agent, and the mass ratio of the polypropylene II to the inorganic silicon dioxide to the nucleating agent to the slipping agent is (85-90): 5: (2.5-5): (2.5-5). According to the modified polypropylene zipper material, the waterproof effect of a PP zipper is achieved, the performance that PP is prone to embrittlement, not resistant to low-temperature freezing and resistant to high-temperature steaming and boiling is improved, and the production energy consumption of the zipper is reduced by about 50%.

Owner:RENOLIT HENGXUN PACKAGING TECH BEIJING CO LTD

Switch, botton switch and rotation switch

InactiveCN1290131CReduce in quantityReduce assembly man-hoursContact engagementsEngineeringPush switch

The present invention is provided with a contact switching mechanism having a movable contact member that is bent into a U shape, allowed to press and contact a fixed contact member side, and supported so as to freely tilt and move thereon. In this mechanism, a switching operation is carried out between contacts by reversing the movable contact member in a see-saw manner, with a tilt-movement fulcrum portion of the movable contact member being always in contact with the contact portion of the common fixed contact member. The movable contact member is allowed to have a spring function conformed to elastically shift in response to a switching operation in addition to a contact function that is inherent to the movable contact member so that it is possible to provide a switch having high reliability, such as a push-button switch and a rotary-lever switch, which can cut costs by reducing the number of parts, and ensure a superior contacting property.

Owner:ORMON CORP

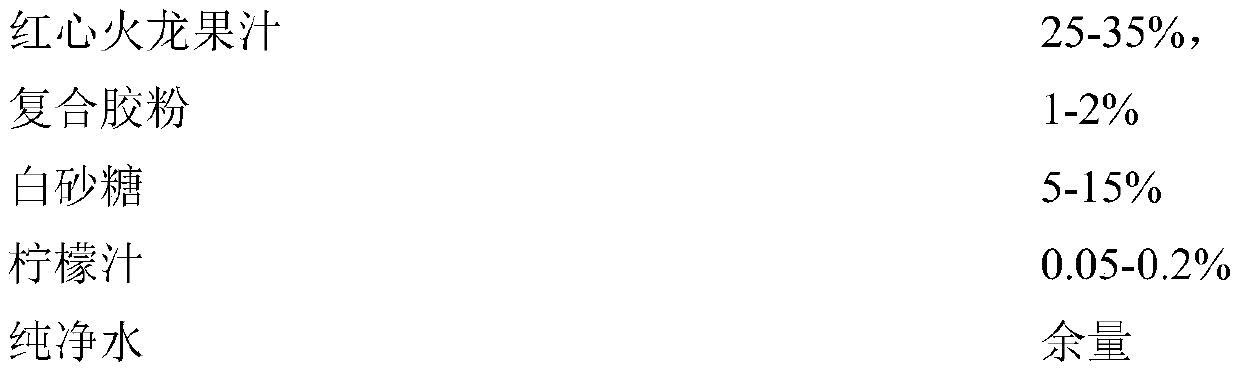

Red pitaya jelly and preparation method thereof

The invention relates to red pitaya jelly and a preparation method thereof. The jelly is characterized by being prepared from the following components by weight, wherein the composite gelatin powder is a mixture of carrageenan and sodium alginate in a weight ratio of 7:3. The preparation method of the red pitaya jelly comprises the following steps: cleaning red pitaya, draining water, freezing thewhole fruit at subzero 18- 20 DEG C for 24 hours or longer, taking out the red pitaya after the red pitaya is frozen in a hard state, placing the red pitaya in a stainless steel tank, and performingheating in water bath at 65-70 DEG C for unfreezing; performing filtering to remove peel and residues to obtain red pitaya juice.

Owner:ZHEJIANG WANLI UNIV

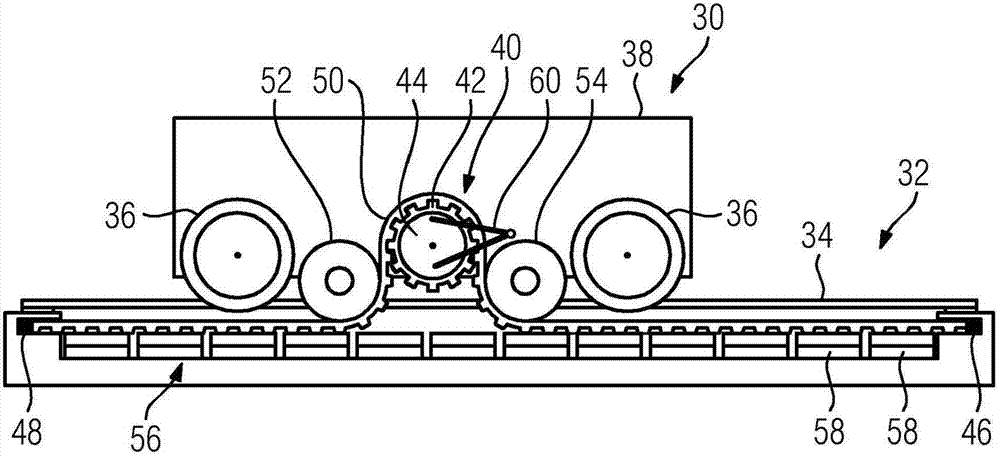

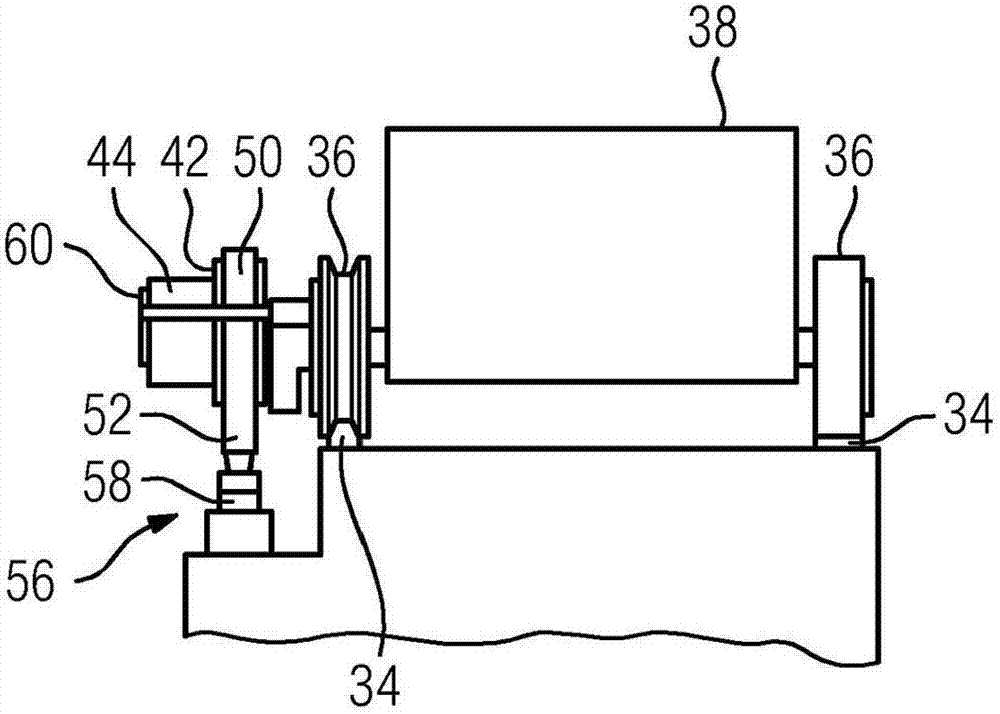

Vibration absorber

ActiveCN102878239AElastic enoughOffset lateral forceNon-rotating vibration suppressionLoad-engaging elementsLinear motorDynamic Vibration Absorber

The invention relates to a vibration absorber (10:30)used for reducing a vibratile structure (70) and especially the vibration of a crane. The vibration absorber comprises a sensor device (84) used for detecting the vibration motion of the structure (70); a linear motor (12:32)capable of being arranged on the vibratile structure (70)and comprising a linear guiding device (14:34) and a linear electric motor car(18:38) capable of moving back and forth on a wheel (16:36) along the linear guiding device (14:34) and enabling a damping block (86) to move; a measurement system used for detecting the actual speed and actual position of the linear electric motor car(18:38); and an adjusting device (88)of which the measurement parameter input end is connected with the sensor device and adjustment parameter output end is connected with the linear motor (12:32).

Owner:SIEMENS AG

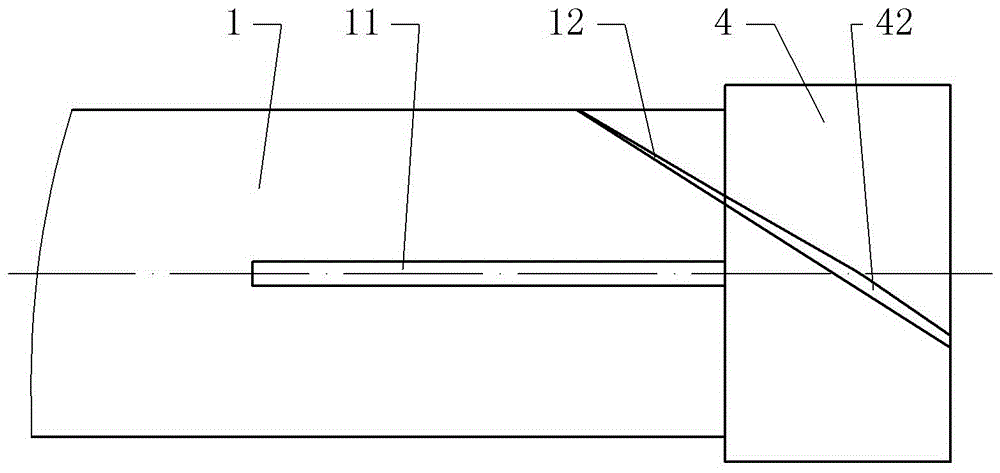

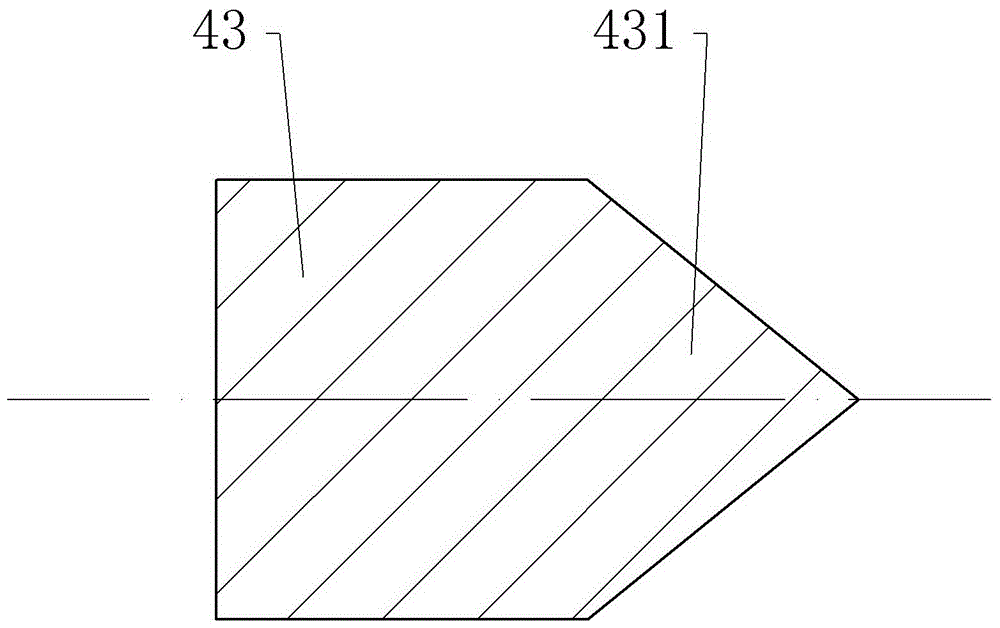

Oxide shell treatment device for reverse extrusion machine

The invention discloses an oxide shell treatment device for a reverse extrusion machine, and relates to the field of machining. The oxide shell treatment device comprises a cleaning shaft and a cleaning ring, wherein a screw rod is arranged on the end part of the cleaning shaft, one end of the screw rod is fixed to the tail part of the cleaning shaft through an anti-rotation mechanism, and the screw rod and the cleaning shaft are coaxial; a press ring is arranged at the other end of the screw rod, the cleaning ring is arranged on the outer wall of the press ring, a location key axially extending is arranged between the press ring and the cleaning ring, and an annular projected step is arranged at the front end of the press ring; a gap is formed in the cleaning ring; and a fixed sleeve is arranged outside the cleaning shaft, the cleaning shaft is slidably connected in the fixed sleeve, a guide groove penetrating through the gap in the cleaning ring and forming smooth transition is formed in the periphery of the cleaning shaft, a notch penetrating through the gap is formed in the annular step, a scraping block is arranged at the inner side of the fixed sleeve, and one end of the scraping block is embedded into the guide groove. The device timely cleans up oxide shells accumulated in the gap, so that the cleaning ring normally shrinks and deforms in an extrusion barrel.

Owner:江苏麦格美节能科技有限公司

Polypropylene zipper for liquid packaging and preparation method thereof

The invention discloses a polypropylene zipper for liquid packaging and a preparation method thereof. The polypropylene zipper is obtained by putting a polypropylene zipper material into a feeding cylinder of a high-speed zipper extruder, melting at high temperature, extruding through a mouth mold, and cooling and shaping. The polypropylene zipper material is prepared from the following components in parts by weight: 50 to 70 parts of polypropylene I, 30 to 50 parts of toughening elastomer, 2 to 10 parts of nucleating smooth master batch, 0.05 to 0.1 part of antioxidant and 0 to 0.1 part of composite light stabilizer, wherein the total amount of the polypropylene I and the toughening elastomer is 100 parts; and the nucleating smooth master batch comprises polypropylene II, inorganic silicon dioxide, a nucleating agent and a slipping agent. The waterproof effect of the PP zipper is achieved, the performance that PP is prone to embrittlement, not resistant to low-temperature freezing and resistant to high-temperature steaming and boiling is improved, and about 50% of production energy consumption of the zipper is reduced.

Owner:RENOLIT HENGXUN PACKAGING TECH BEIJING CO LTD

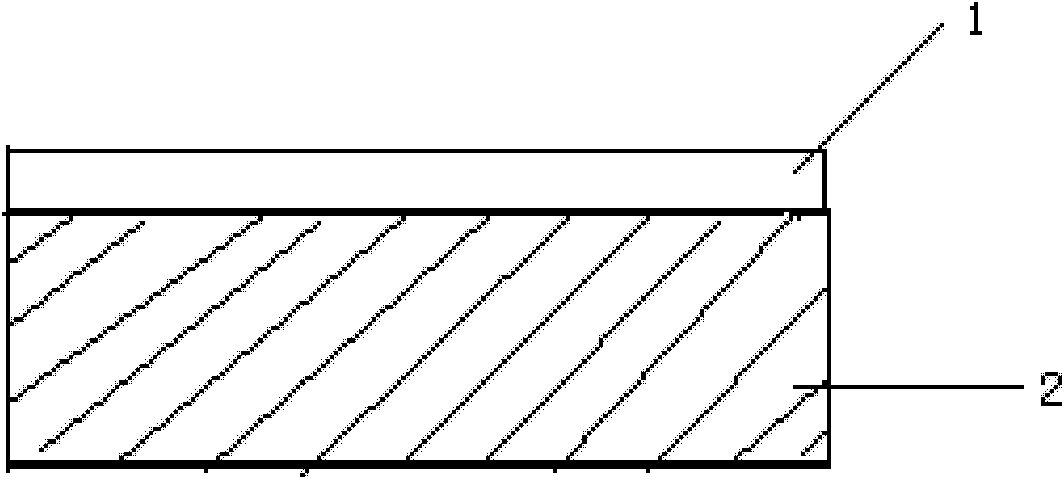

Ironing board covering comprised of a top layer and of a padding

Owner:CARL FREUDENBERG KG

Part for massager and massager

PendingCN111437172AImprove comfortEasy to fixGenitals massageObstetrical instrumentsPhysical medicine and rehabilitationPhysical therapy

The invention discloses a part for a massager and the massager with the part. The part is installed inside the massager. The part is characterized in that the part is a ring-shaped body, a center holeof the ring-shaped body is used for sleeving a massage inner core of the massager, and the part has evenly distributed elasticity in the radial direction. The massager includes an outer shell, a cover body, and the massage inner core. The massage inner core is an elastic silicone part and is internally provided with a massage channel, and the massage inner core is arranged inside the shell. The massager is characterized by further including the part for the massager, and the part sleeves outside the massage inner core through the central hole and is located in the range of the massage channel, and the outer part of the part is fixed to the inner side of the shell. The moderate tightness of the massage channel, strong support, timely rebound and convenient fixation can be realized.

Owner:杨海峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com