External thermal insulation system of water-based simulated natural granite paint finish

A granite coating and external thermal insulation technology, applied in the field of external thermal insulation systems, can solve the problems of limited load-bearing capacity, complex structure, temperature rise, etc., and achieve the effects of low organic volatile matter content, simple construction process, and improved stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further specifically described below in conjunction with the accompanying drawings and embodiments, but is not limited thereto.

[0021] All raw materials used in the examples are industrial products and can be purchased through commercial channels. The tools and equipment used to practice the invention are those commonly used in the paint and construction industries.

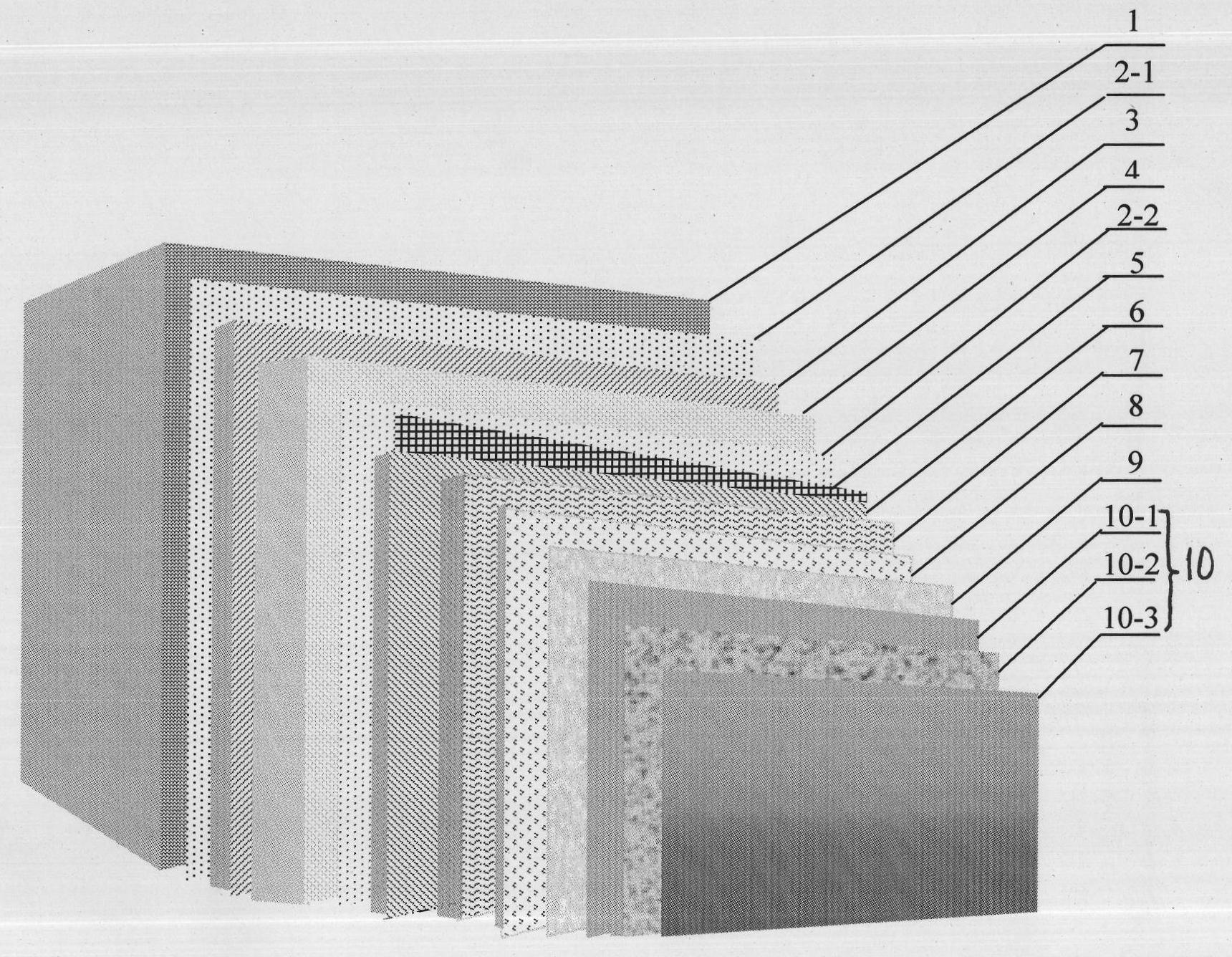

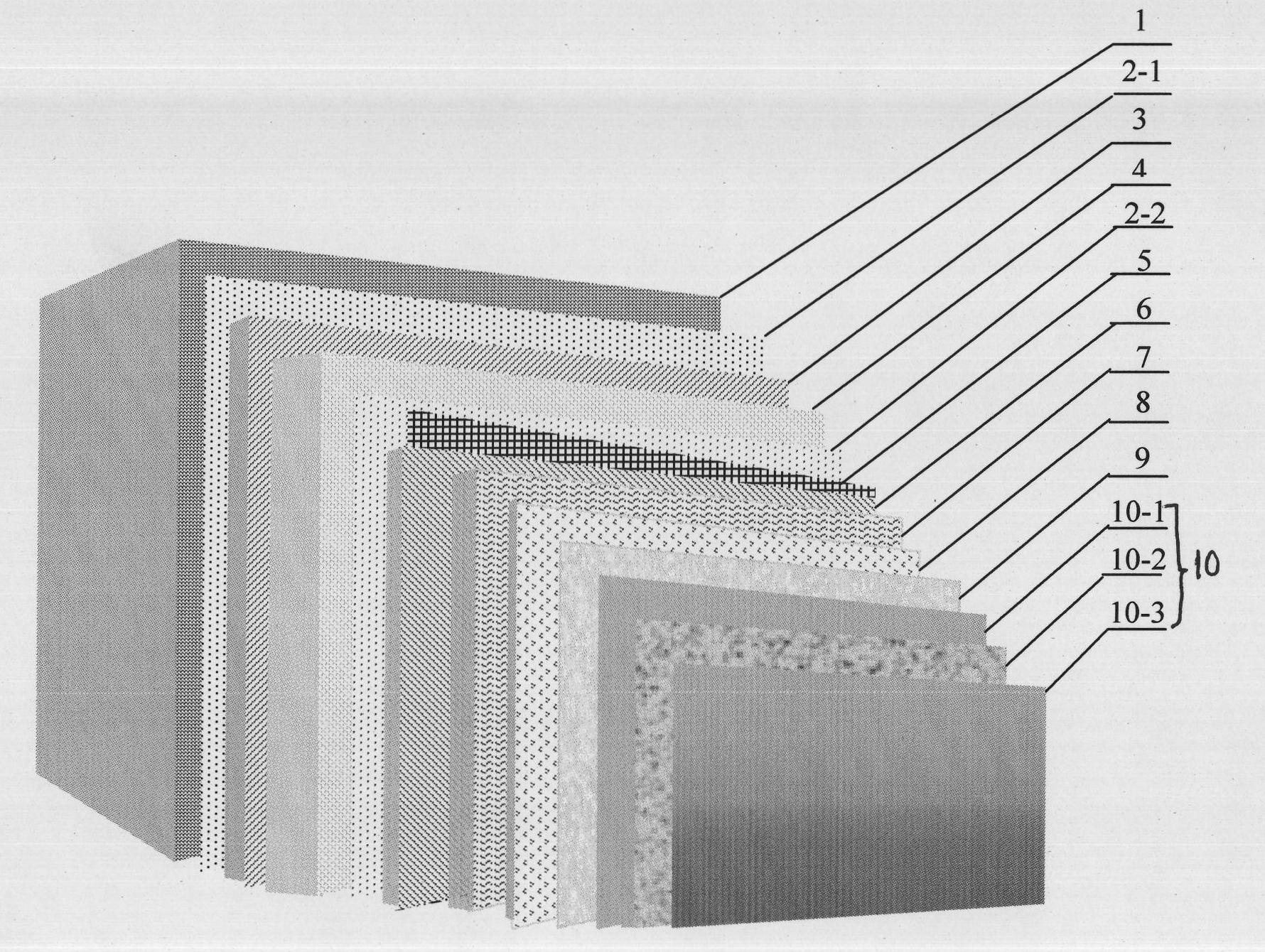

[0022] Such as figure 1 As shown, an external thermal insulation system with a water-based imitation natural granite paint finish, its specific structure is: on the outer surface of the base wall 1, the first interface adhesive layer 2-1, bonding mortar Layer 3, polystyrene board insulation layer 4, second interface adhesive layer 2-2, polymer anti-cracking mortar plastering layer lined with glass fiber mesh cloth 5, polymer flexible putty leveling layer 7, smooth surface Putty layer 8, sealing primer layer 9 and finish layer 10 are characterized in that finish layer 10 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com