Oxide shell treatment device for reverse extrusion machine

A technology of reverse extrusion and processing device, applied in the field of mechanical processing, can solve the problems of damage to the extrusion cylinder, hindering the shrinkage of the cleaning ring, and large friction between the cleaning ring and the extrusion cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

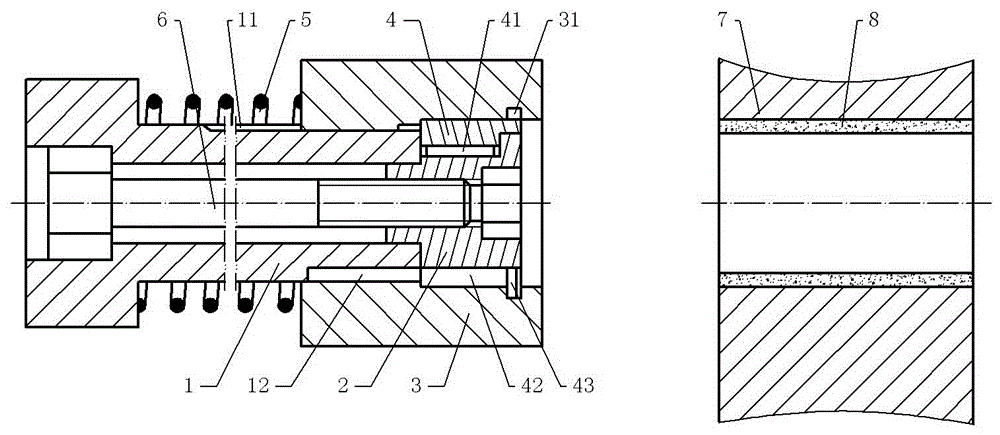

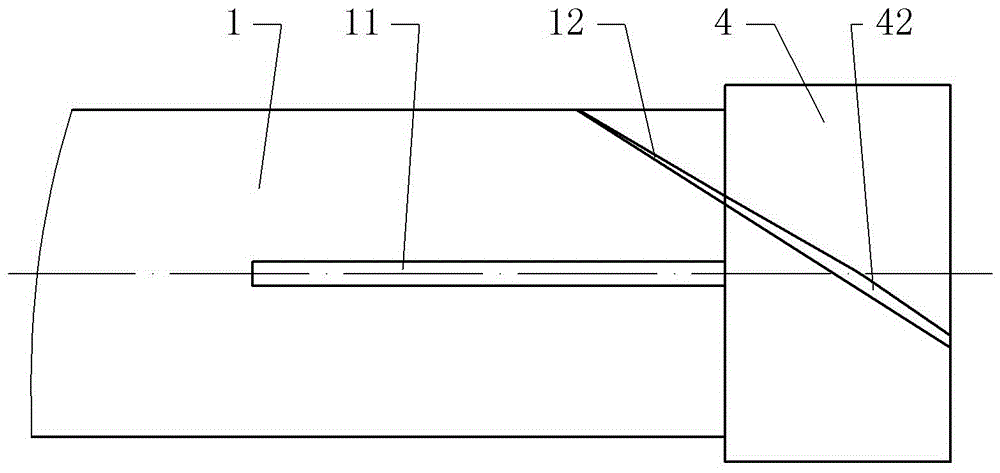

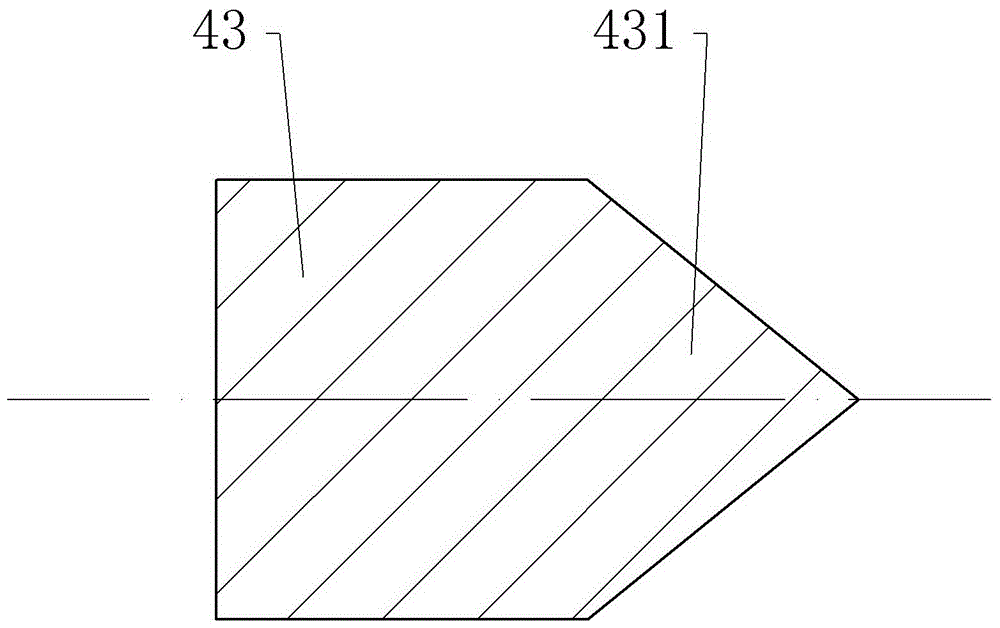

[0020] The reference signs in the drawings of the description include: cleaning shaft 1, anti-rotation groove 11, guide groove 12, pressure ring 2, fixed sleeve 3, annular groove 31, cleaning ring 4, positioning key 41, gap 42, scraper Block 43, convex rib 431, return spring 5, screw rod 6, extruding cylinder 7, oxidation shell 8.

[0021] The embodiment is basically as figure 1 , figure 2 Shown:

[0022] The oxidation shell processing device of the reverse extrusion machine in this embodiment includes a cleaning ring 4, a positioning key 41, a pressure ring 2, a screw rod 6, a cleaning shaft 1 and a fixed sleeve 3, wherein one end of the screw rod 6 is installed on the On the cleaning shaft 1, to prevent the screw rod 6 from loosening due to rotation, the pressure ring 2 is installed on the other end of the screw rod 6 through the threaded hole in the center, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com