Patents

Literature

37results about How to "Guaranteed stereotypes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method of green bud tea

The invention discloses a processing method of green bud tea, comprising the following steps: paving tea leaves on a tea groove, wherein the paving thickness is 10-15cm; ventilating with an assistant blower, wherein the paving time is 10-14h; water-removing the tea leaves, wherein the cylinder temperature of the tea inlet end is 269-275 DEG C, the middle section temperature is 253-260 DEG C, the tea outlet end temperature is 219-225 DEG C, the leaves temperature is 102-108 DEG C, and; the water removing time is 1min25s-1min30s; directly putting the water removed tea leaves to a vibration groove, and putting the tea leaves into a wind selector, sending the selected tea leaves to a microwave water removing machine through a transporter, wherein the temperature of the water removing machine is 120 DEG C, the tea leaves temperature is 46-49 DEG C, the rotary speed is 1100r / min, and the water removing time is 50s; grading, carding, shaping, drying, infrared flavor enhancing. The method canincrease the shape, color and smell of green bud tea.

Owner:贵州湄潭兰馨茶业有限公司

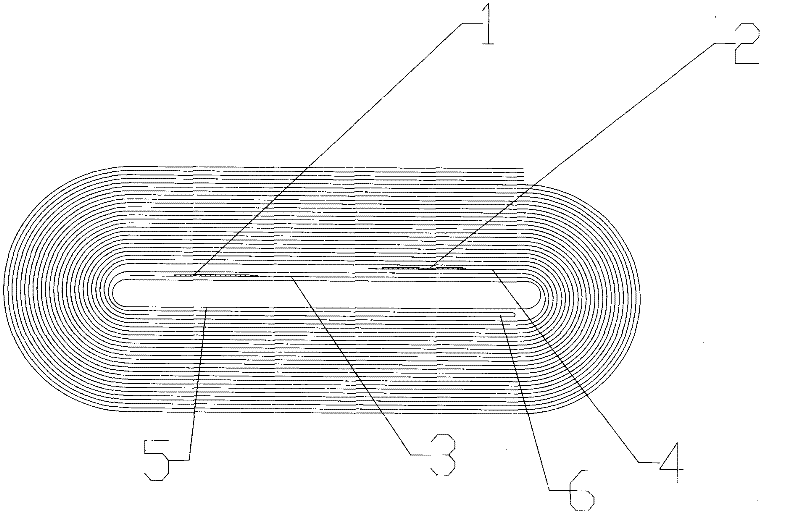

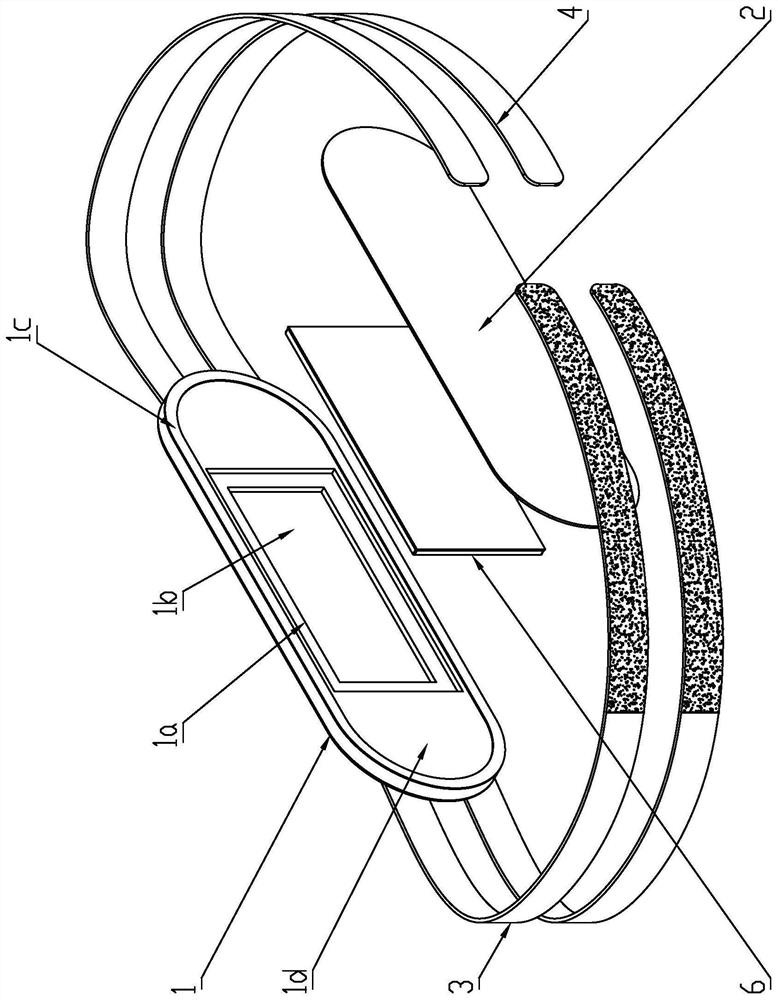

Winding structure for lithium ion battery and manufacturing process thereof

ActiveCN102332614AImprove permeabilityPerformance is not affectedFinal product manufactureSecondary cellsEngineeringLithium-ion battery

The invention relates to a flexibly packaged lithium ion secondary battery, and particularly relates to a winding structure for a lithium ion battery. A battery cell is formed by winding an anode piece, a cathode piece and an isolation film, wherein an aluminum pole lug is welded on an inner ring of the anode piece; a nickel pole lug is welded on an inner ring of the cathode piece; and a winding core is arranged on the inner ring of the isolation film, thereby solving the deformation and safety problems of the flexibly packaged lithium ion battery; and the winding core is made from polymers, can be dissolved in an electrolyte after having a swelling action with the electrolyte but cannot influence the property of the battery cell. The invention also provides a manufacturing process for the winding structure for the lithium ion battery.

Owner:DONGGUAN AMPEREX TECH

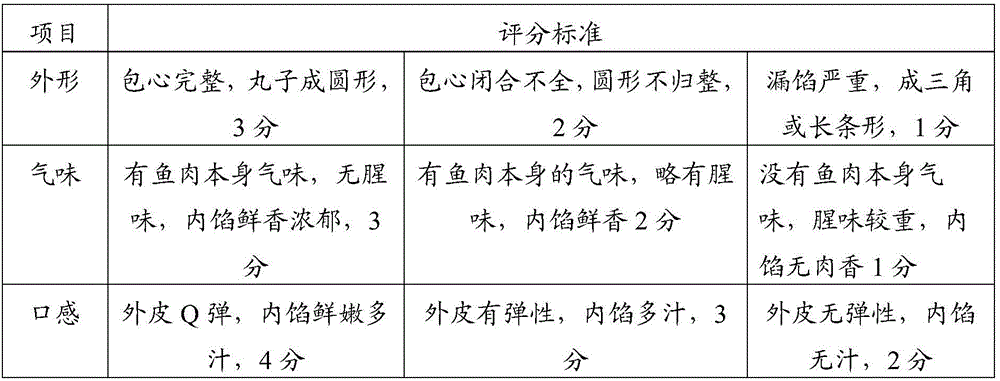

Juicy fish ball and making method thereof

The invention provides a juicy fish ball which is elastic in surface and fresh and juicy in stuffing. Minced fillet is used as the surface main raw material, the material temperature is required to be controlled to be 10 DEG C or below in the processing technology, and the freshness and elasticity of the raw material are kept to the maximum extent; the fish ball is cooked and shaped through a two-stage heating method, the temperature at the first stage is 75-85 DEG C, the temperature at the second stage is 85 DEG C or above, the gelatinization of minced fillet is ensured, and the shaping and cooking of the product are ensured. Pork and chicken meat are used as the stuffing main raw materials, pork jelly which is formed by decocting pigskin and cooling the liquid in advance is added, and the product is fresh and juicy.

Owner:通威(成都)水产食品有限公司

Stuffing of cooked wheaten food and preparation method thereof

The invention relates to stuffing of cooked wheaten food. The stuffing is prepared from the following raw materials: vegetable materials and oil materials. The vegetable materials in the raw materials comprise the following components in parts by weight: 4 pars of cabbage, 1 part of egg, 1 part of mushroom, 1.5 parts of silk noodles, 1 part of deep-fried dough sticks, 0.2 part of green Chinese onion, 0.2 part of ginger, 0.1 part of sesame oil, 0.05 part of smashed mushroom, 1.5 parts of grated carrots, 0.1 part of salt, and 0.1 part of gourmet powder. The weight part of the oil material is 0.5. The ratio of the soybean oil to refined lard to the dried onion in the raw materials is 10:1:5. The stuffing provided by the invention has the advantages of reasonable formula of the raw materials and abundant nutrition. The stuffing, which is prepared by frying multiple types of oil materials in a mixing mode, can be used for efficiently enhancing the taste of the stuffing, and meanwhile controlling the oil quantity of the stuffing, so that the stuffing is easy to adhere to the inner side of the pasta wrapper so as to enhance the adhesive degree of the pasta and the stuffing in the wrapping process of the cooked wheaten food.

Owner:TIANJIN YUETAN STUDENT NOURISHING MEAL DISTRIBUTION

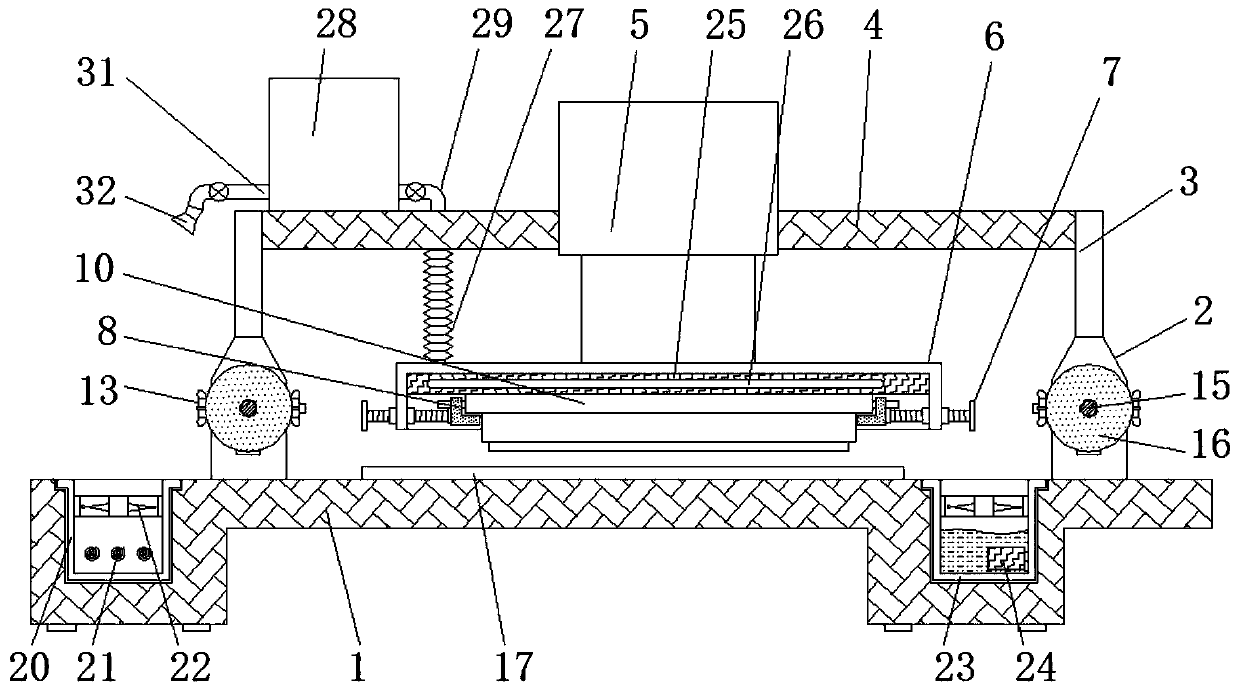

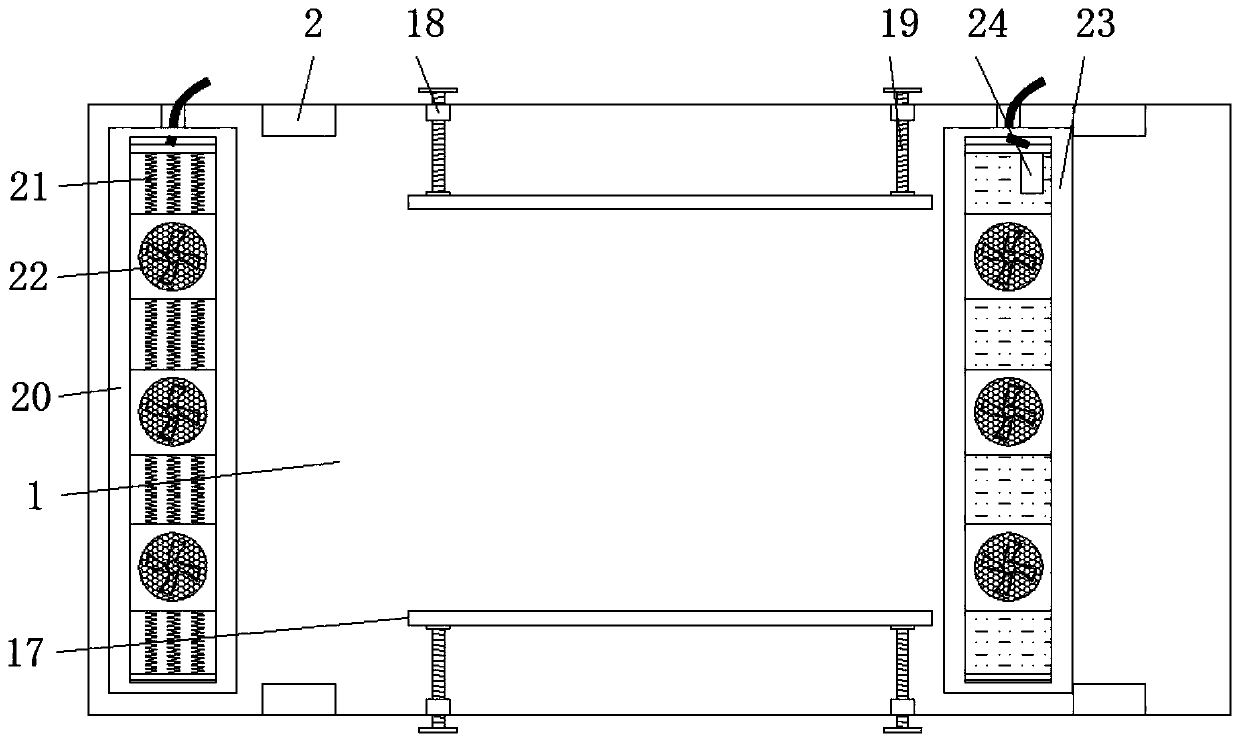

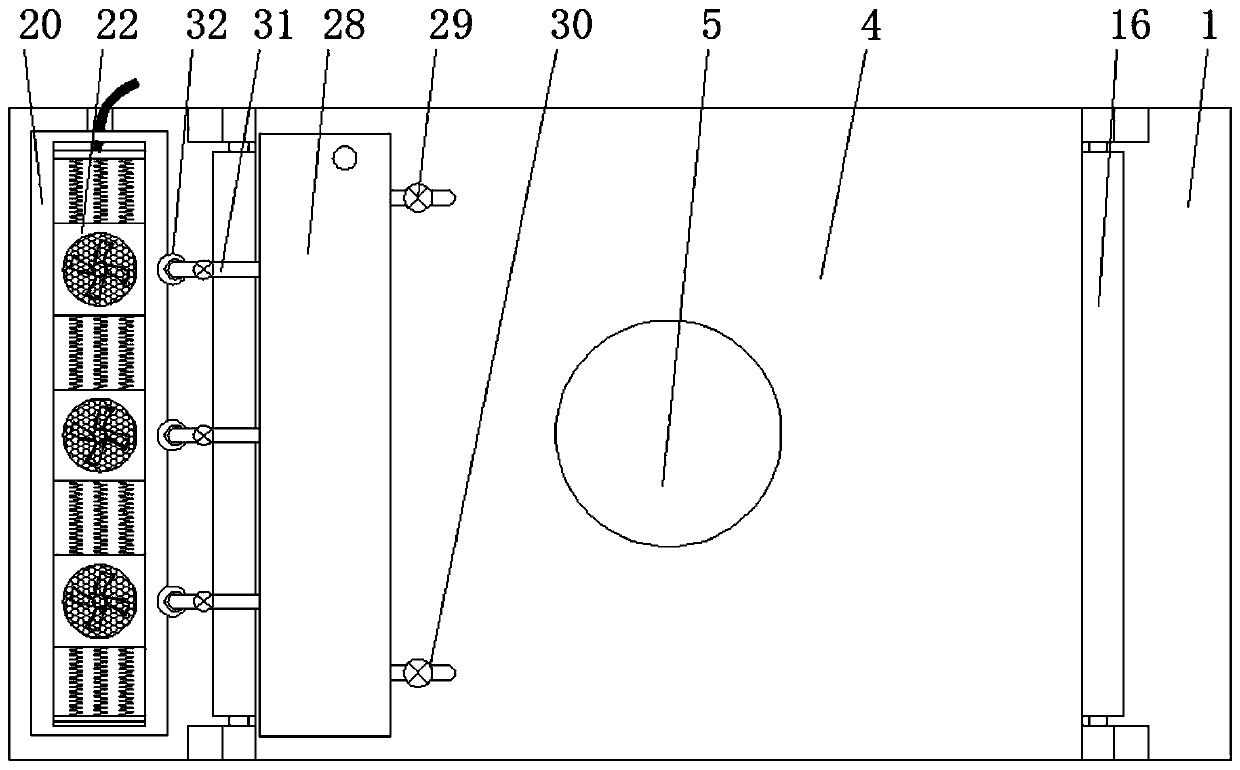

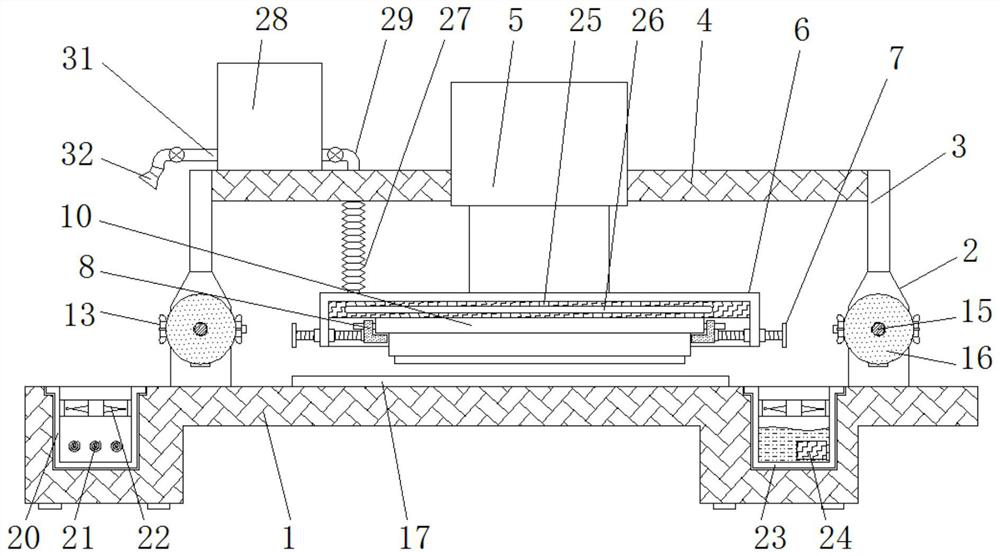

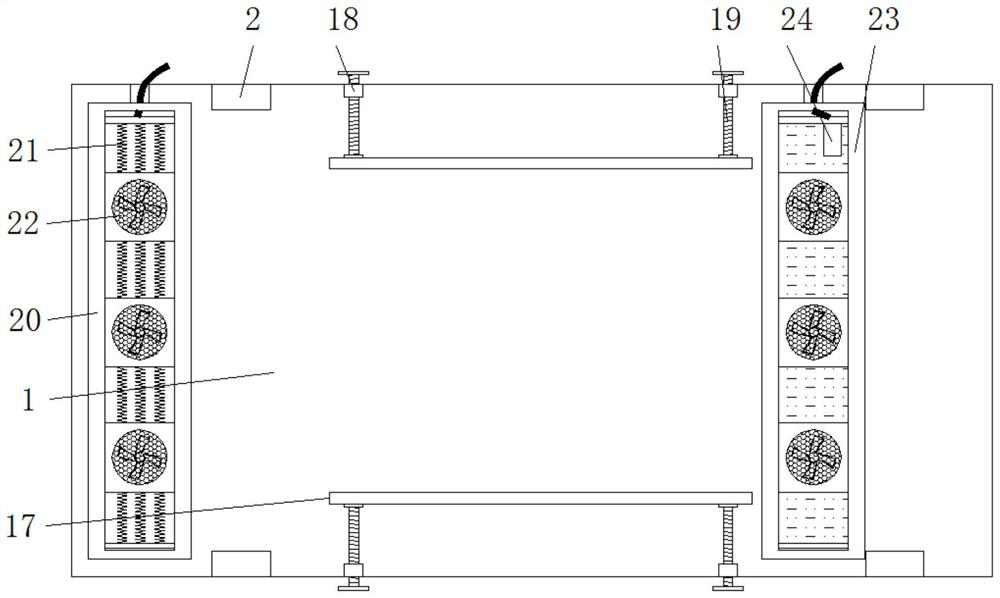

Cloth bag pattern printing device convenient to replace template

ActiveCN110884248AEasy to replaceTimely and effective dryingRotary pressesPrinting press partsTextile printerEngineering

The invention discloses a cloth bag pattern printing device convenient to replace a template. The device comprises a supporting table frame, a printing template, a drying box and a pressure tank; a support plate is fixedly mounted at the top end of the supporting table frame, a support frame plate is mounted at the top end of a support column, the bottom end of a hydraulic telescopic system is connected with a fixing frame, and a lifting groove is formed in the support plate; a fixing bolt is connected to the outer side of a fixing block, and a supporting rod is connected to the inner side ofthe fixing block; and the drying box is arranged inside the left side of the supporting table frame, a fan box is arranged above heating wires, a cooling box is mounted inside the right side of the supporting table frame, and a connecting pipe is connected to the top end of a cooling pipe. According to the cloth bag pattern printing device convenient to replace the template, the printing templatecan be conveniently replaced, the cloth can be timely and effectively dried, the flatness of the cloth is conveniently guaranteed, the cloth stability is conveniently guaranteed, and the printing quality is conveniently guaranteed.

Owner:浙江同盟工艺品有限公司

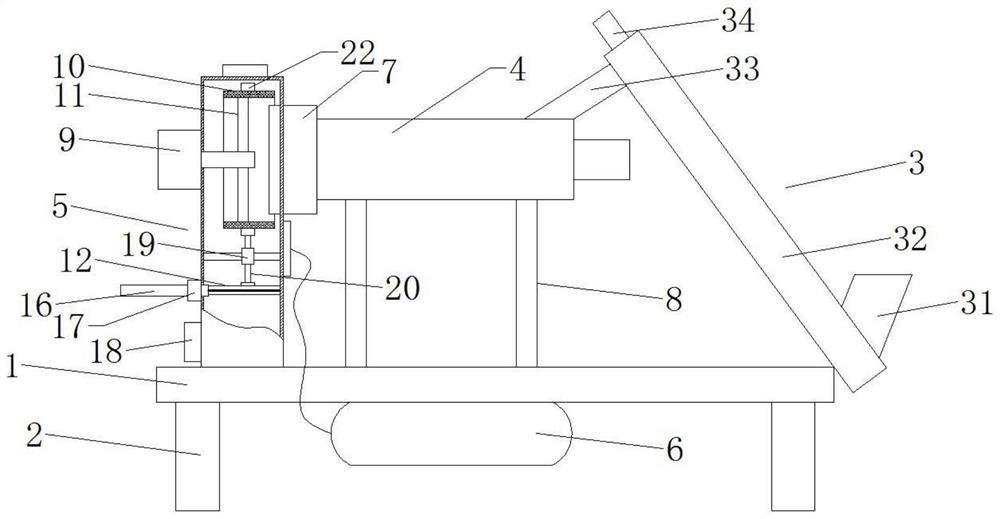

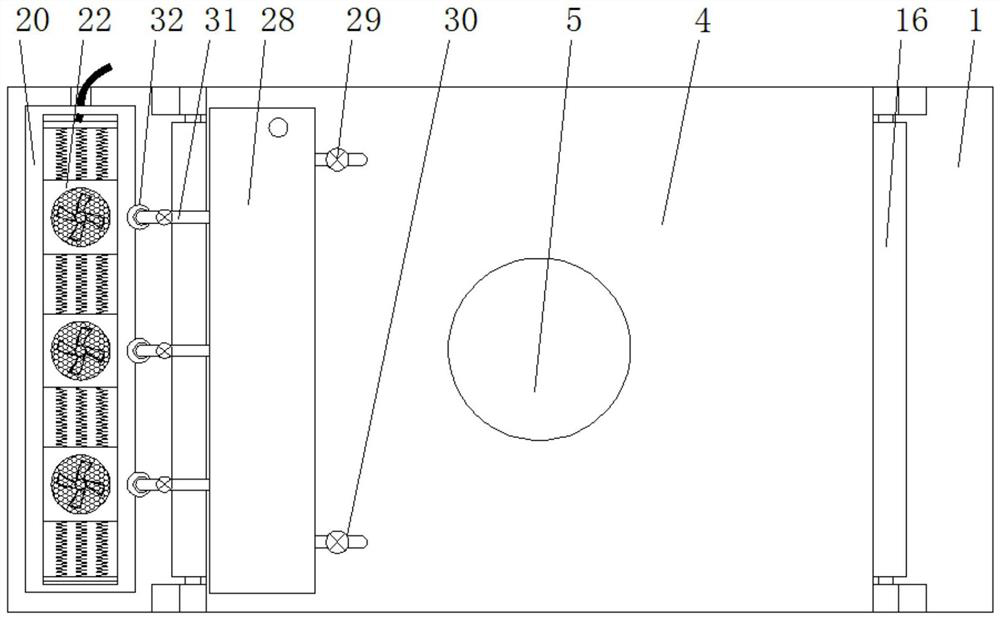

Elastic speed reducing and cooling food processing extrusion forming machine

InactiveCN111713723AReduce the temperatureIncrease cooling timeDomestic cooling apparatusLighting and heating apparatusEngineeringMechanical engineering

The invention relates to the field of food processing, and particularly discloses an elastic speed reducing and cooling food processing extrusion forming machine. The forming machine comprises a base,supporting legs, a feeding mechanism, an extrusion cylinder and a cooling box; a horizontal material receiving net cylinder is arranged in the cooling box horizontally opposite to an extrusion device; an elastic speed reducing mechanism located under the material receiving net cylinder is arranged in the cooling box; the elastic speed reducing mechanism comprises a fixed frame fixed on the innerwall of the cooling box; and two symmetrical speed reducing nets are arranged in the fixed frame, and the speed reducing nets are made of elastic materials. Food received by the speed reducing nets enables the middles of the speed reducing nets to deviate downwards, and the gap between the two speed reducing nets is enlarged. Food discharged through the extrusion device enters the cooling box, thefood falling from the material receiving net cylinder falls on the speed reducing nets of the elastic speed reducing mechanisms below, and the food collected on the two speed reducing nets made of elastic materials can open a certain gap between the two speed reducing nets by means of the action of the food, so that the food falls down.

Owner:常敏

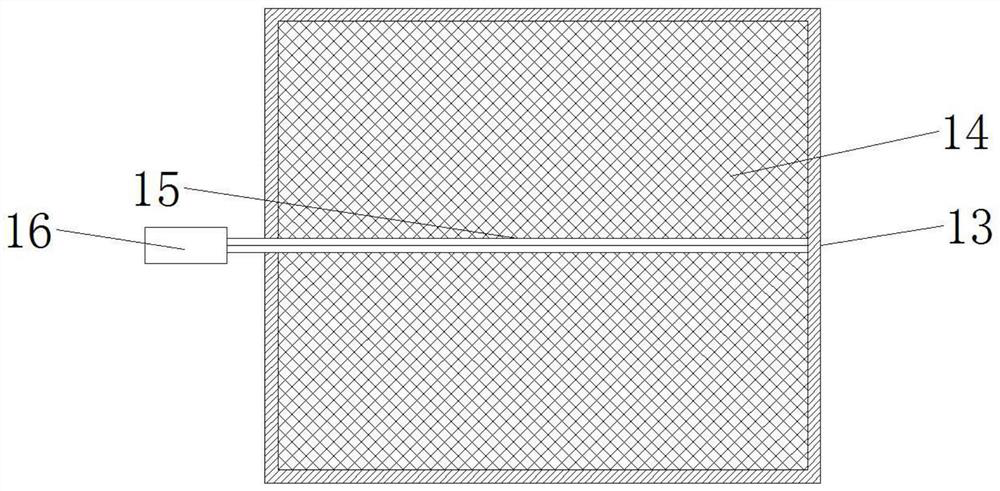

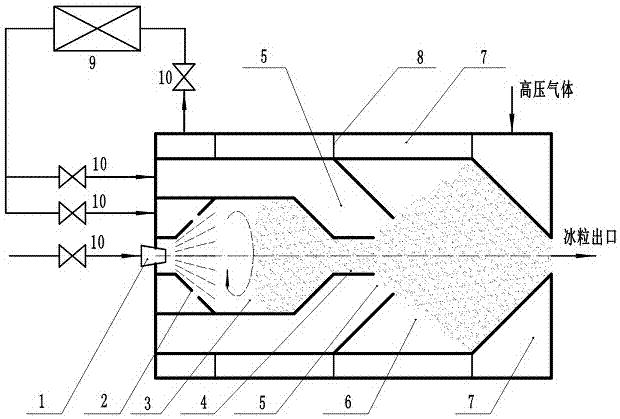

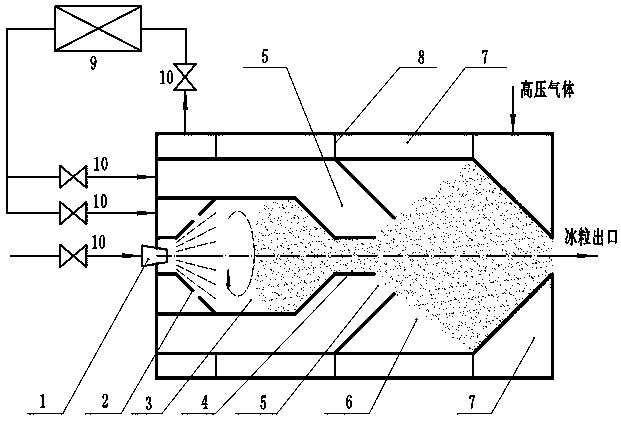

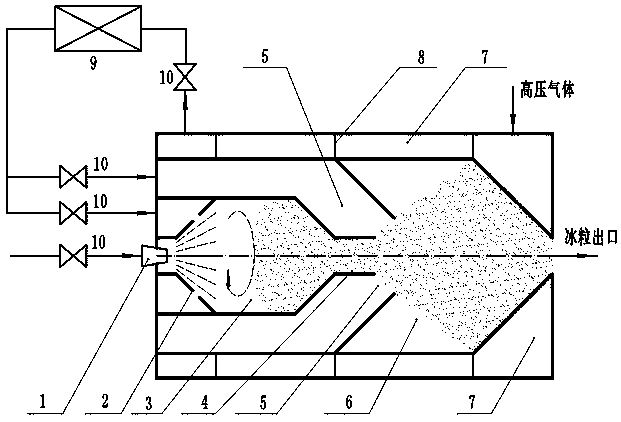

Continuous ice particle making device

InactiveCN107166831AStrong swirl mixing abilityIncrease contact areaLighting and heating apparatusIce productionIce storageAirflow

The invention provides a continuous ice particle making device. The continuous ice particle making device comprises an atomizing nozzle, a swirl nozzle, an ice making compartment, a hollow pipe, a hollow circulation nozzle, a mixing chamber, a precooling chamber and the like. Water is atomized to generate water droplets through the atomizing nozzle, low-temperature swirl gas is sprayed through the swirl nozzle, the atomized water droplets are frozen to generate ice particles, and the low-temperature gas passes through the hollow circulation nozzle so as to continuously make ice particles. Under the action of swirl, injection, entrainment and mixing of the swirl nozzle and the hollow circulation nozzle, the ice particles are quickly generated, the particle size is uniform, and the intensity is high; the precooling chamber is precooled to be cool, and the cooling capacity is recycled, so that heat loss of the low-temperature gas is reduced and eliminated, and energy is saved. The system has the advantages of simple structure, small size, light weight and low manufacturing cost and can be used for continuously making the ice particles, and for example, the ice particles can be injected in application occasions such as surface cleaning, derusting, ice storage, food processing and the like.

Owner:QINGDAO UNIV

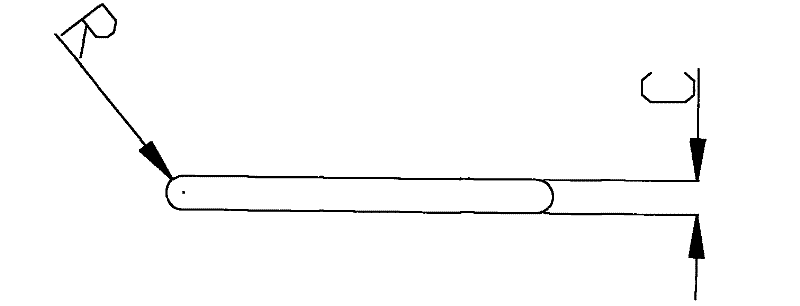

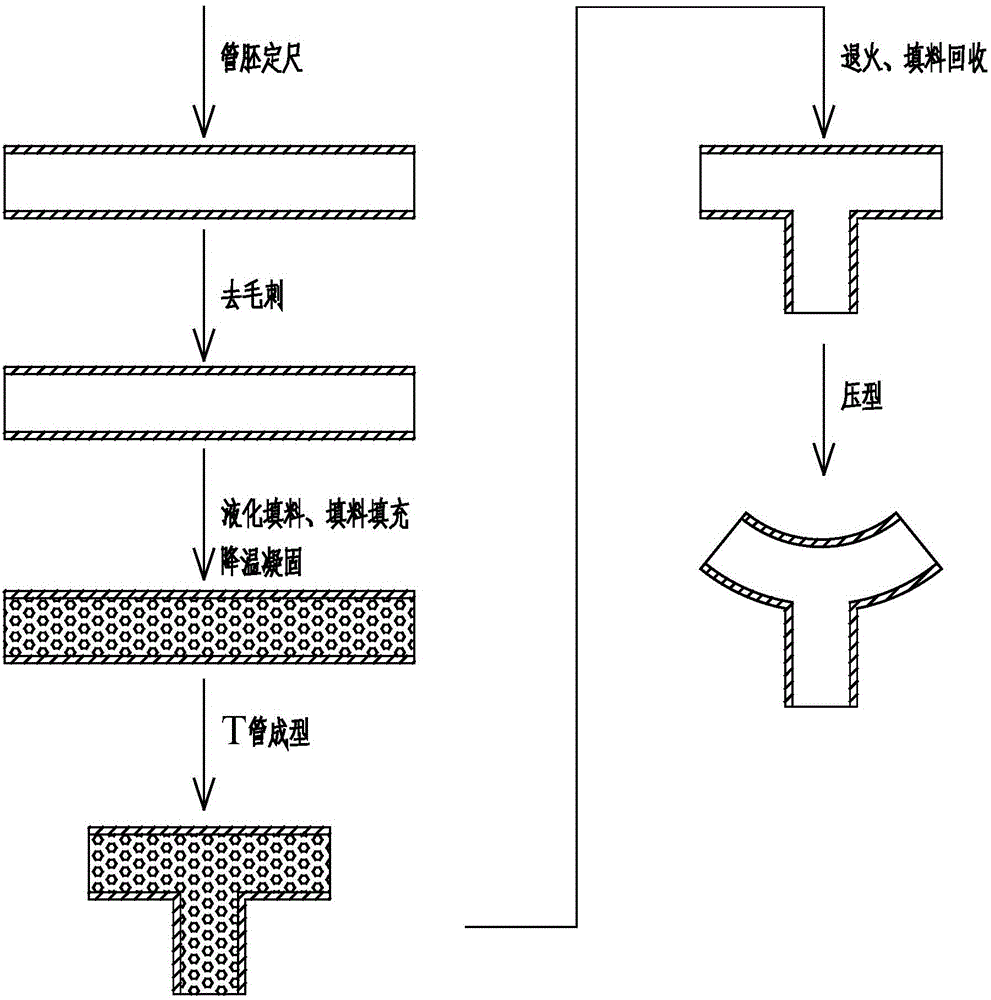

Extrusion processing process for special-shaped T-pipe

An extrusion processing process for a special-shaped T-pipe comprises the following steps: pipe blank sizing, deburring, filler liquefying, filler packing, cooling for solidification, T-pipe forming, annealing, filler recovering, and profiling. The special-shaped T-pipe uses a liquid-state molten inorganic nonmetal material as fillers, the liquid-state fillers flow into a pipe blank fully and the pipe blank is filled up with the liquid-state fillers, the amount of the fillers in the pipe blank is guaranteed to be sufficient, and enough fillers are guaranteed to be used for supporting and sizing in extrusion forming. After cooling for solidification, the fillers become liquid state fillers to be fixed in the pipe blank, the pipe blank needs not to be sealed, the process step is simplified, and the working efficiency is improved.

Owner:左铁军 +1

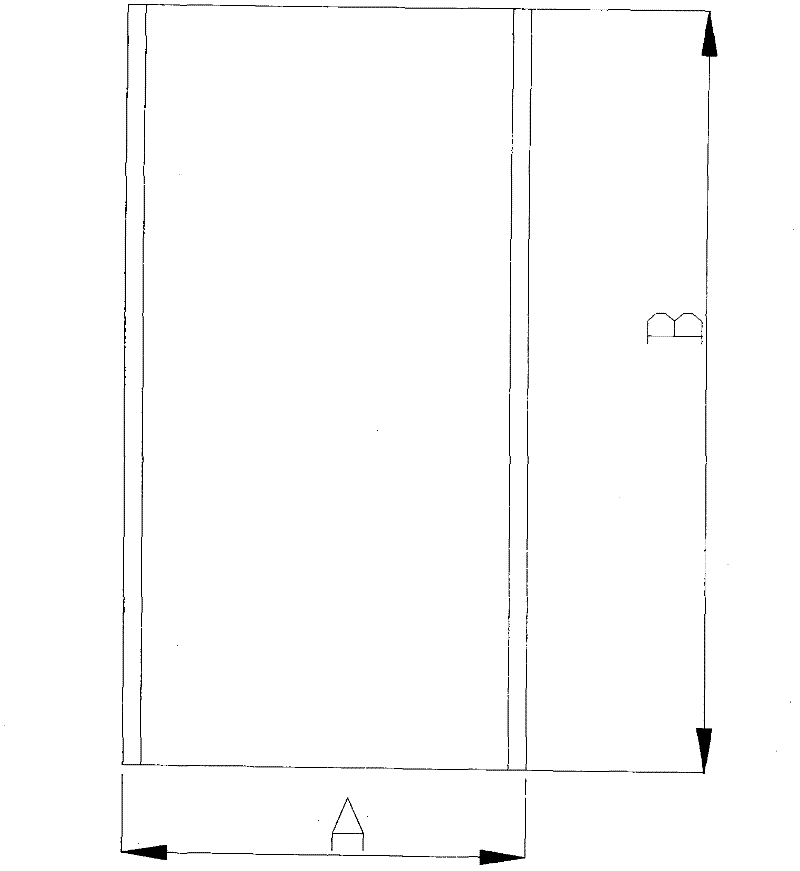

Floor production method

InactiveCN107650482AGuaranteed stereotypesAvoid curlLaminationLamination apparatusMetallurgyMethods of production

A board production method includes: mixing materials, performing melt extrusion, coating an extruded blank, cooling and cutting. The coating is characterized by including the steps of firstly, performing first-stage heating and compacting on the extruded blank, and coating the surface on one side of the extruded blank with a first layer of film in the process of the first-stage heating and compacting; secondly, performing at least one second-stage heating and compacting on the extruded blank after the first compacting; thirdly, performing third-stage heating and compacting on the heated extruded blank, and coating the surface of the first layer of film with a second layer of film in the process of the third-stage heating and compacting. The method has the advantages that the second-stage heating and compacting is performed on the blank coated with the first layer of film, the fitting degree of the first layer of film and the blank is increased, a plasticizing effect on the first layerof film is achieved at the same time, then the second layer of film is coated, and the fitting degree of the second layer of film and the blank can be also increased.

Owner:QINGDAO SANYI PLASTIC MACHINERY

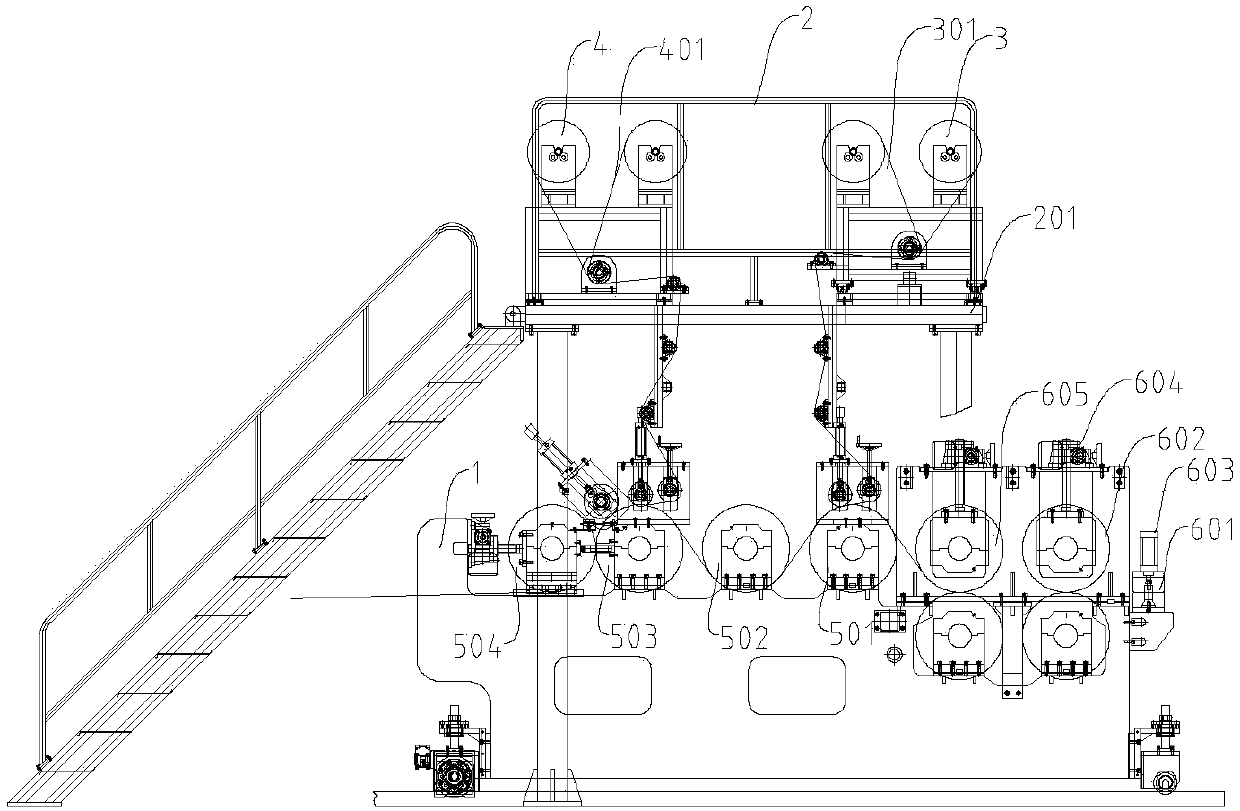

Accurate braiding device of straw braiding machine

InactiveCN109249494AImprove surface qualityAvoid deformationCane mechanical workingEngineeringLimit setting

Owner:湖南广播电视大学

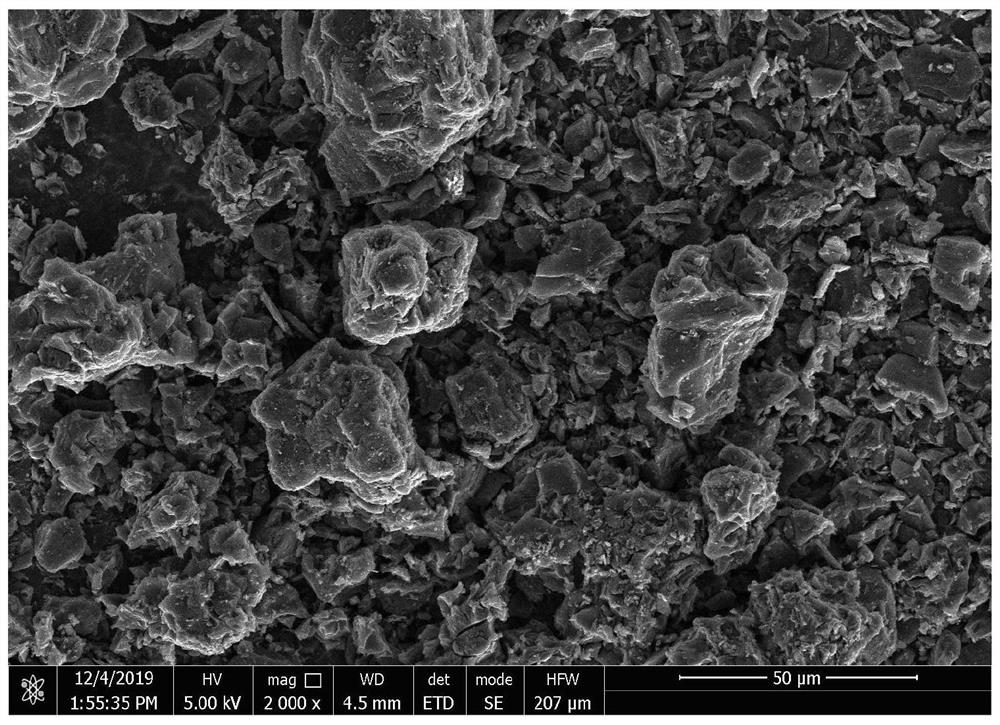

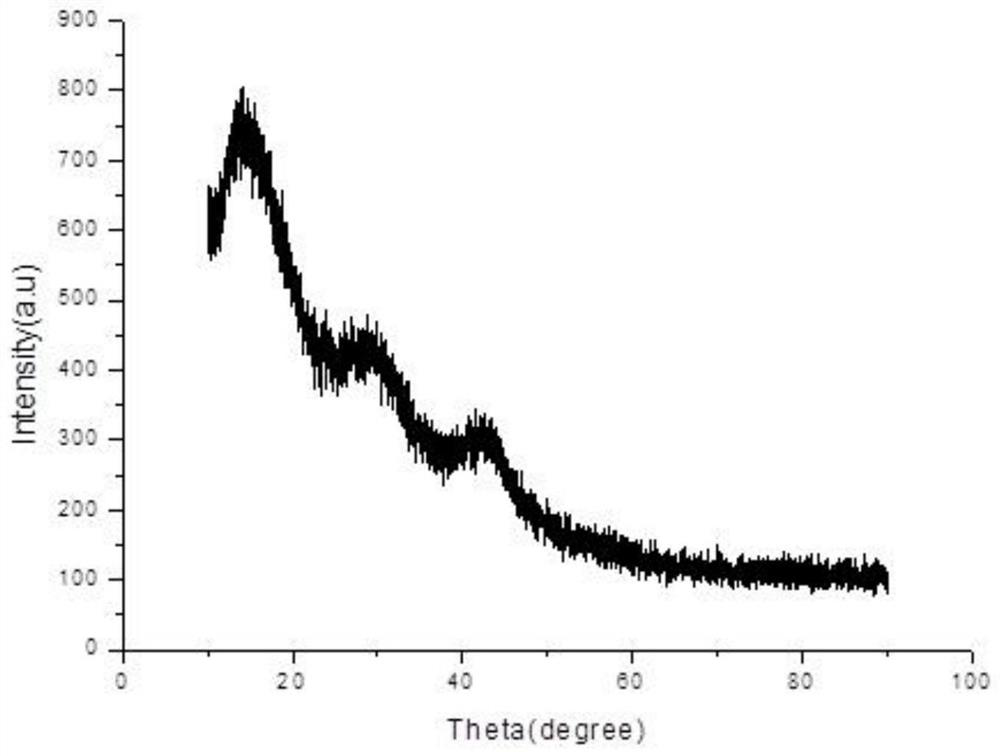

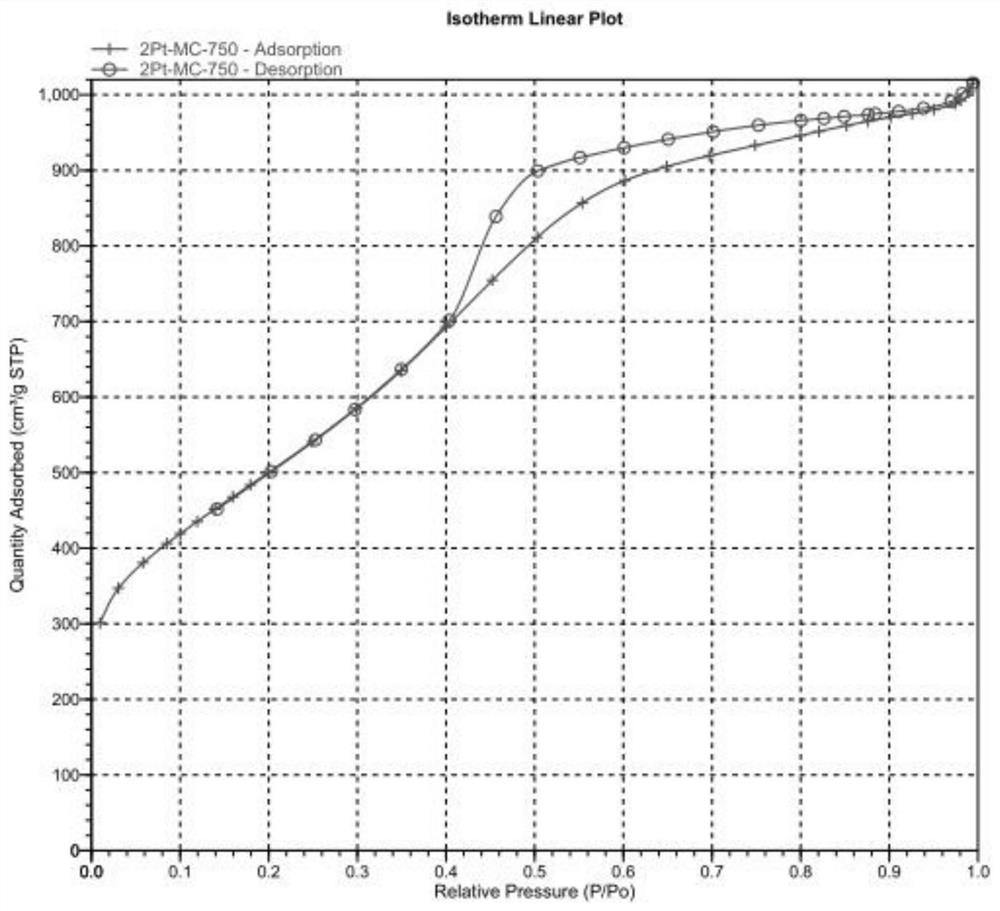

Nitrogen-doped mesoporous carbon supported platinum catalyst as well as preparation method and application thereof

InactiveCN113509948AGuaranteed reducibilityLarge specific surface areaPhysical/chemical process catalystsOrganic compound preparationNitro compoundPtru catalyst

The invention belongs to the technical field of catalysts, and particularly relates to a nitrogen-doped mesoporous carbon supported platinum catalyst as well as a preparation method and application thereof. The preparation method of the nitrogen-doped mesoporous carbon loaded platinum catalyst provided by the invention comprises the following steps of: mixing a magnesium source solution with a nitrogen source, and sequentially carrying out evaporation and foaming treatment to obtain a foaming body; sequentially crushing and calcining the foaming body to obtain a calcined material; sequentially acid-pickling, washing and drying the calcined material to obtain a nitrogen-doped porous carbon material; and sequentially carrying out Pt loading and reduction treatment on the nitrogen-doped porous carbon material to obtain the nitrogen-doped mesoporous carbon loaded platinum catalyst. Experimental data show that the nitrogen-doped mesoporous carbon supported platinum catalyst provided by the invention has a mesoporous structure, and when the used in a nitro compound hydrogenation reaction, the nitrogen-doped mesoporous carbon supported platinum catalyst is high in catalytic activity, high in chemical selectivity as high as 99.9%, high in catalytic selectivity and good in catalytic effect.

Owner:SHANGHAI UNIV

Making method of bunge pricklyash leaf tea

InactiveCN107319070AGuaranteed stereotypesGive full play to nutritional valueTea substituesWater contentEngineering

The invention proposes a method for making prickly ash leaf tea, and the specific steps are: (1) manual picking and spreading; (2) fixing; (3) kneading; (4) baking and shaping; (5) selection. The initial baking and drying are used in the baking and setting, and four times of baking are carried out in the first baking. The first baking is controlled at a temperature of 125-130°C; then the temperature is gradually reduced to 85% of the previous temperature, and then baked Roast three times to get semi-finished pepper leaf tea with a water content of 10‑12%. The present invention learns from the existing production method of green leaves, and adopts four times of successive cooling and roasting during the initial baking according to the characteristics of the pepper leaves, which not only maintains the unique scent of the pepper leaves, but also ensures the shaping, and finally realizes the taste of pepper leaf tea. Production, make full use of the resources of pepper leaves, and give full play to the nutritional value of pepper leaves.

Owner:竹溪县兴龙农业专业合作社

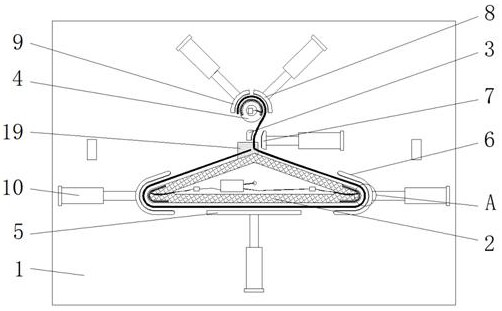

Method for rapidly manufacturing recombinant bamboo

InactiveCN104875269ACool evenlyUniform and further rapid coolingWood working apparatusFlat articlesEngineeringEnergy consumption

The invention belongs to the field of fire doors, and particularly relates to a method for rapidly manufacturing recombinant bamboo, wherein the method is uniform in heating process, quick in speed and low in energy consumption. The method comprises steps of firstly, selecting bamboo wood, secondly, uniformly paving the bamboo wood and applying glue on the bamboo wood to form a bamboo plate to be pre-pressed, thirdly, pushing the pre-pressed bamboo plate into a high frequency hot press, fourthly, pre-pressing the bamboo plate to be pre-pressed, and fifthly, starting the high frequency hot press to manufacture a bamboo plate through high frequency hot pressing for 6 to 45 minutes. The high frequency hot press comprises a lower support board used for supporting a bamboo plate to be pre-pressed, an upper pressing plate used for pressing on the bamboo plate to be pre-pressed and a side pressing plate applying pressure on a side of the bamboo plate to be pre-pressed. The high frequency voltage is characterized in that the high frequency electric field can penetrate a base plate, so that the inner and the outer of the base plate can be synchronously and uniformly heated, the method is quick in speed and low in energy consumption, so the method is particularly suitable for hot-press gluing a bamboo plate with a large section.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

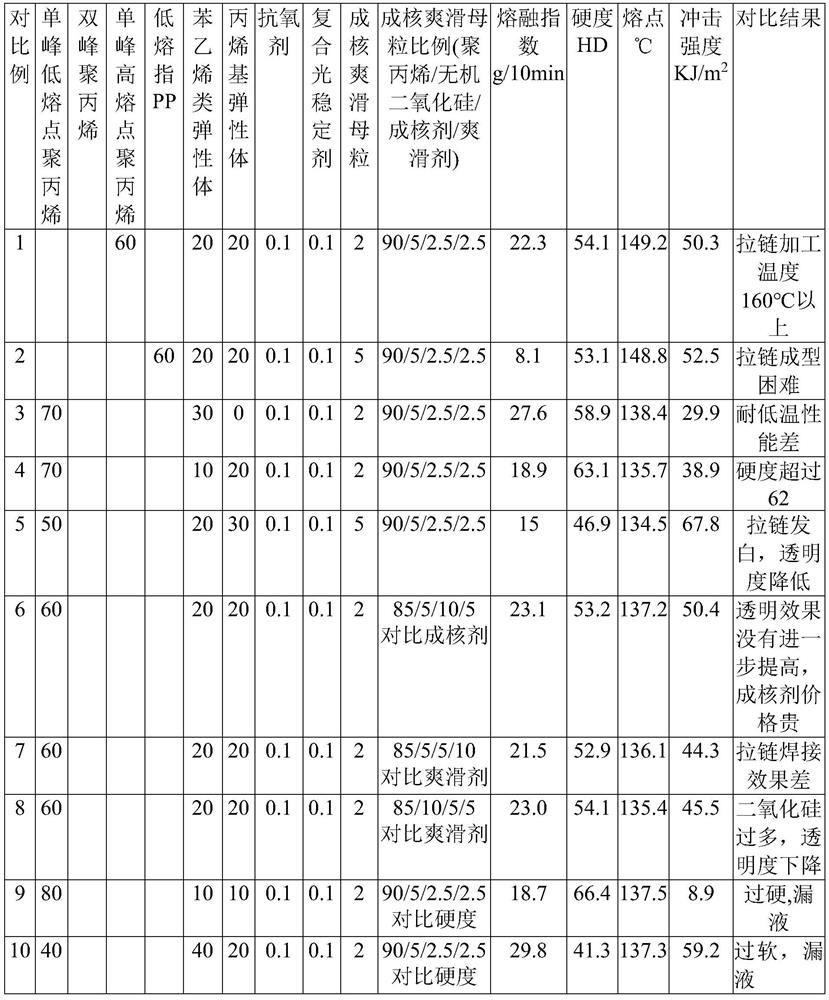

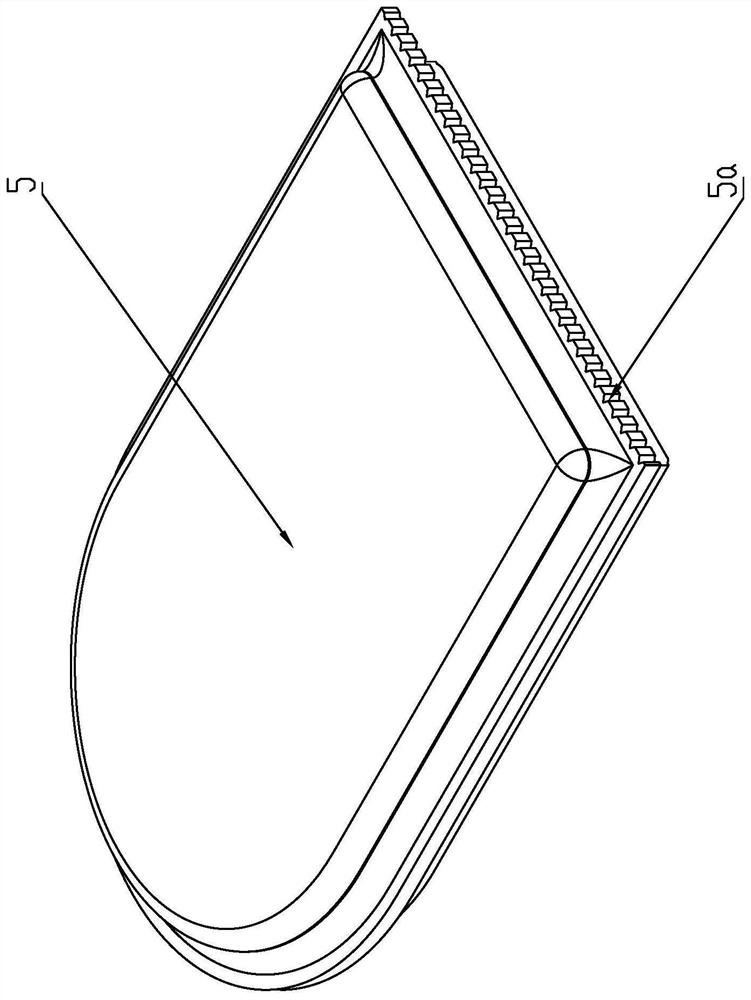

Polypropylene zipper for liquid packaging and preparation method thereof

The invention discloses a polypropylene zipper for liquid packaging and a preparation method thereof. The polypropylene zipper is obtained by putting a polypropylene zipper material into a feeding cylinder of a high-speed zipper extruder, melting at high temperature, extruding through a mouth mold, and cooling and shaping. The polypropylene zipper material is prepared from the following components in parts by weight: 50 to 70 parts of polypropylene I, 30 to 50 parts of toughening elastomer, 2 to 10 parts of nucleating smooth master batch, 0.05 to 0.1 part of antioxidant and 0 to 0.1 part of composite light stabilizer, wherein the total amount of the polypropylene I and the toughening elastomer is 100 parts; and the nucleating smooth master batch comprises polypropylene II, inorganic silicon dioxide, a nucleating agent and a slipping agent. The waterproof effect of the PP zipper is achieved, the performance that PP is prone to embrittlement, not resistant to low-temperature freezing and resistant to high-temperature steaming and boiling is improved, and about 50% of production energy consumption of the zipper is reduced.

Owner:RENOLIT HENGXUN PACKAGING TECH BEIJING CO LTD

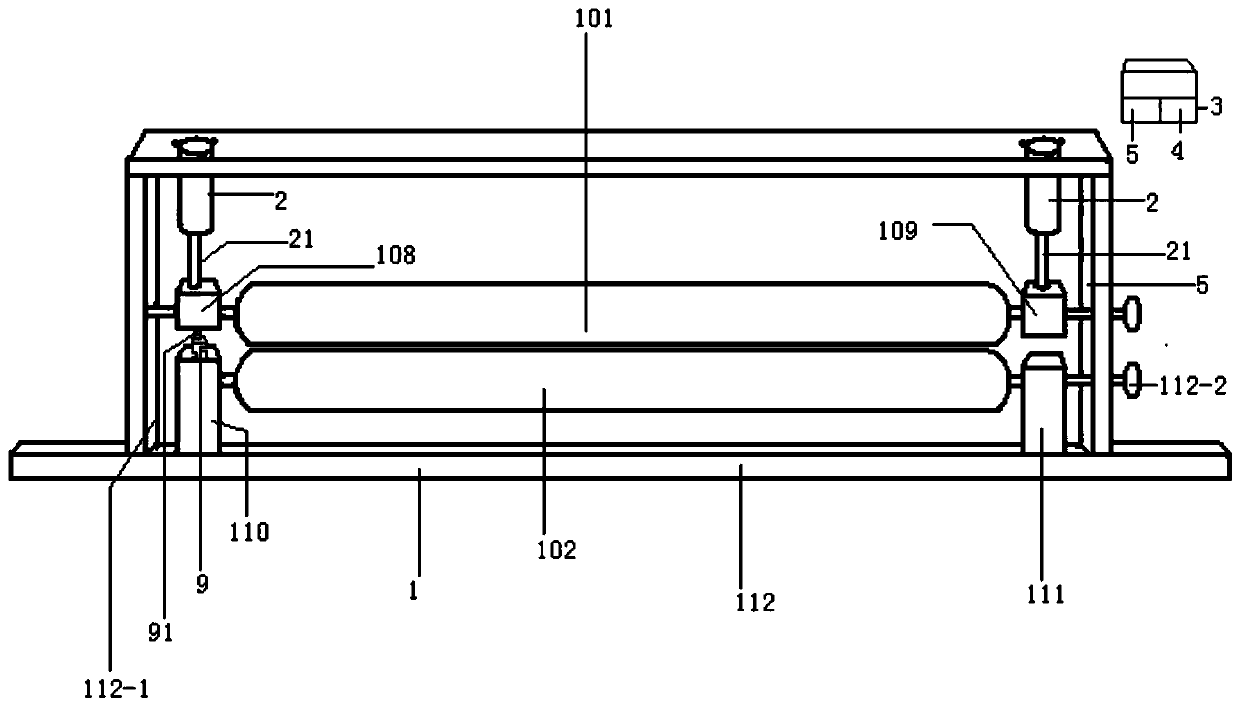

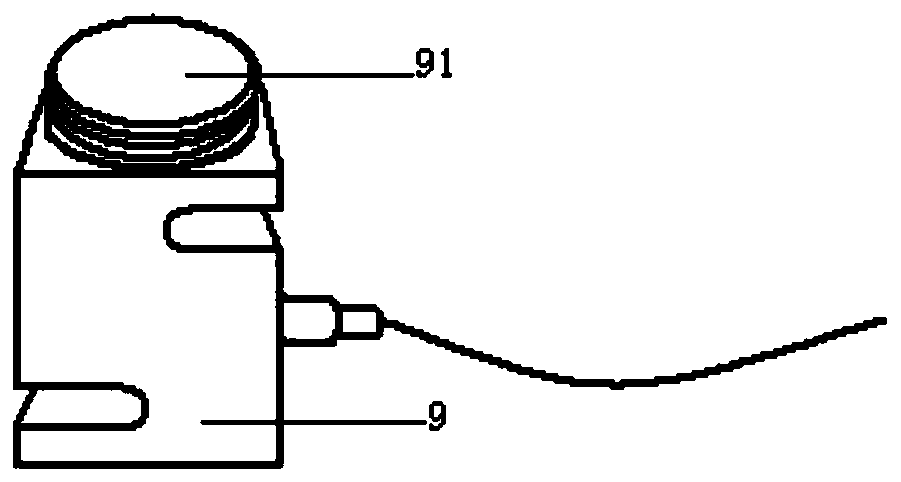

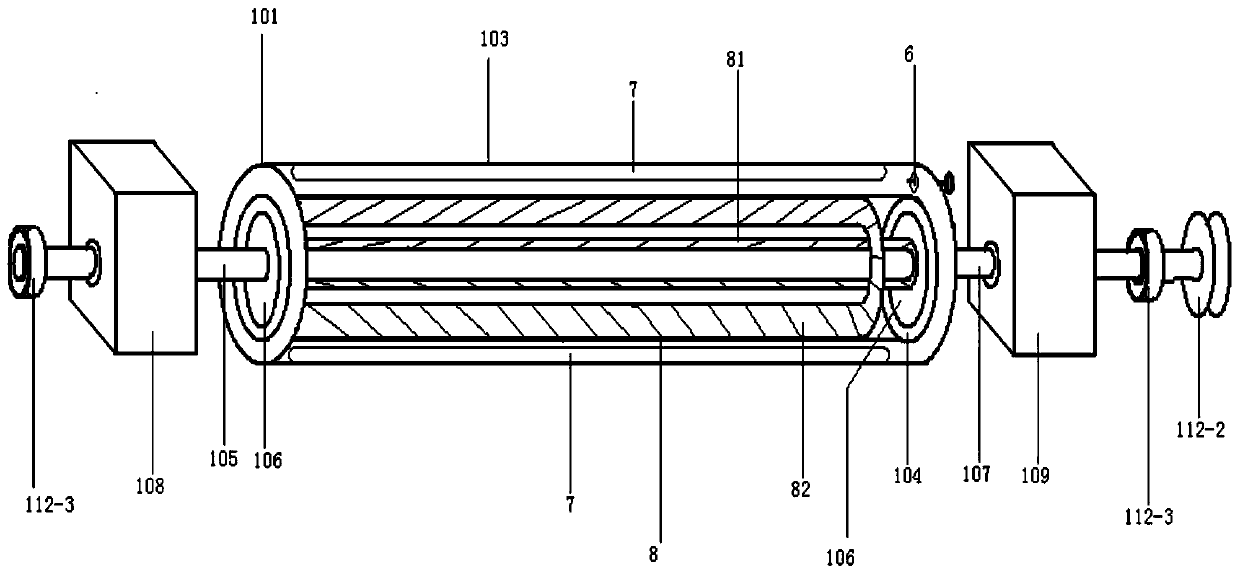

Soft calendering roller equipment for improving smoothness of paper and soft calendering method

ActiveCN110924217AReal-time adjustment of different gap valuesAdjust pressure in real timeCalendersEngineeringElectromagnetic valve

The invention discloses soft calendering roller equipment for improving the smoothness of paper and a soft calendering method. The soft calendering roller equipment comprises a soft calender roll device body, a hydraulic oil pump, hydraulic oil cylinders, an electromagnetic valve, a hydraulic oil pipe, a switching power supply, temperature control switches, electric heating pipes, a self-inductionpower generation heating mechanism, a pressure monitoring switch and a data processing module. The plurality of electric heating pipes are respectively arranged in an upper soft calendering roller outer layer and a lower soft calendering roller outer layer; the temperature control switches are respectively arranged in holes of the upper soft calendering roller and the lower soft calendering roller; shaft rods and bearings are arranged in the upper soft calendering roller and the lower soft calendering roller; a plurality of electromagnetic coils are respectively arranged on the inner layers of the upper soft calendering roller and the lower soft calendering roller; two permanent magnets respectively sleeve outside the shaft rods, the hydraulic oil cylinders are installed below the left side and the right side of the upper portion of the rack, the hydraulic oil cylinders are connected with the upper ends of bearing seats on the left side and the right side, the switching power supply and the data processing module are installed on a circuit board, and the pressure monitoring switch is installed below the bearing seat at the upper left end. The soft calendering method of the soft calendaring roller equipment is divided into four steps. According to the invention, the purposes of flattening, calendaring and shaping of finished paper are ensured.

Owner:LONGYOU COUNTY JINLONG PAPER

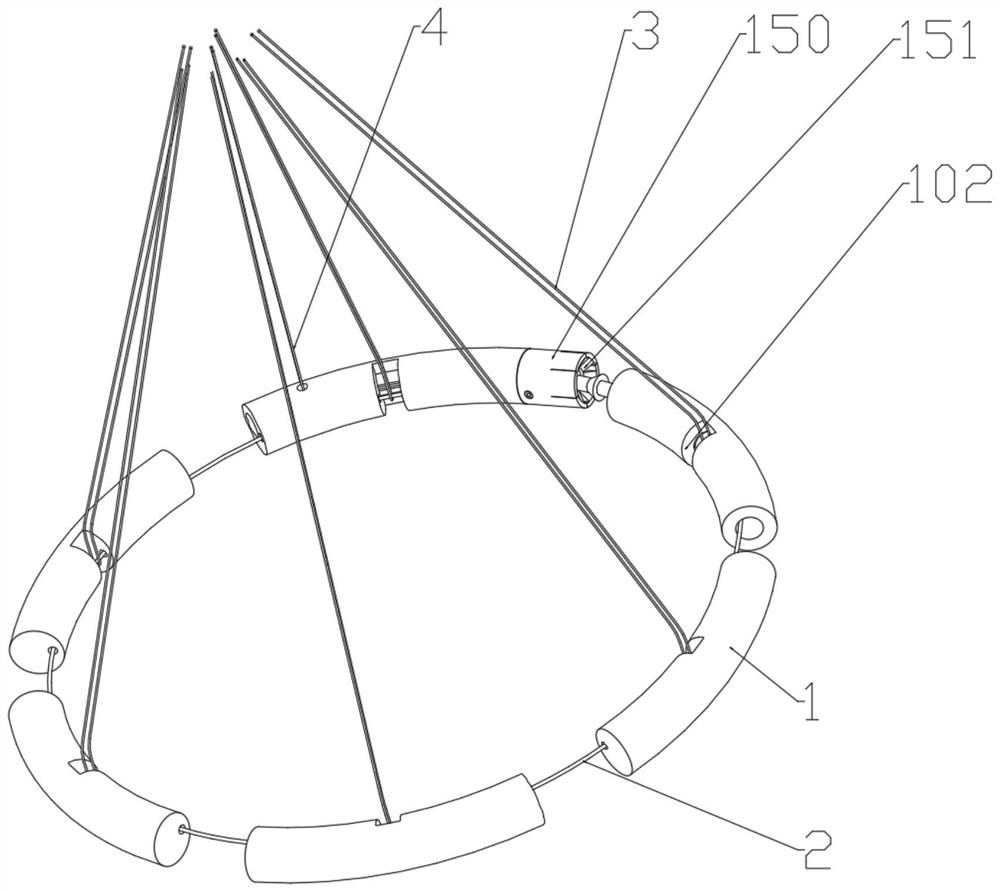

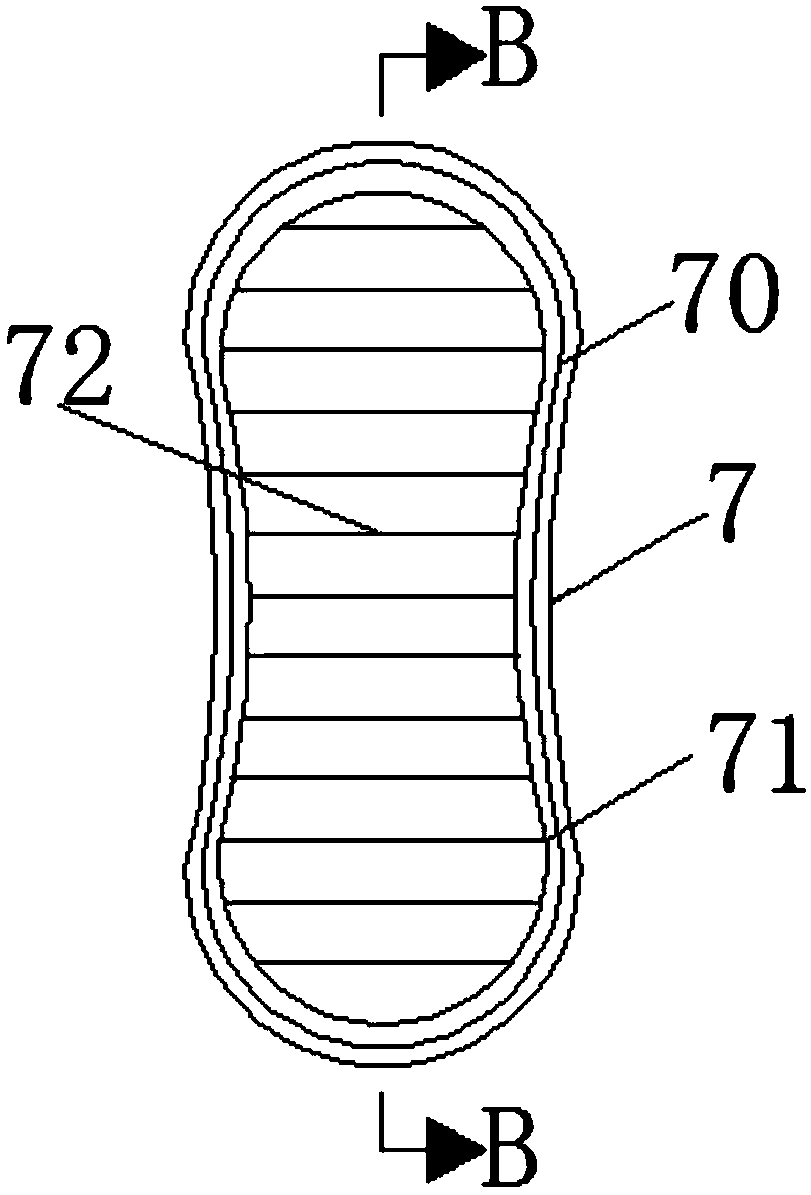

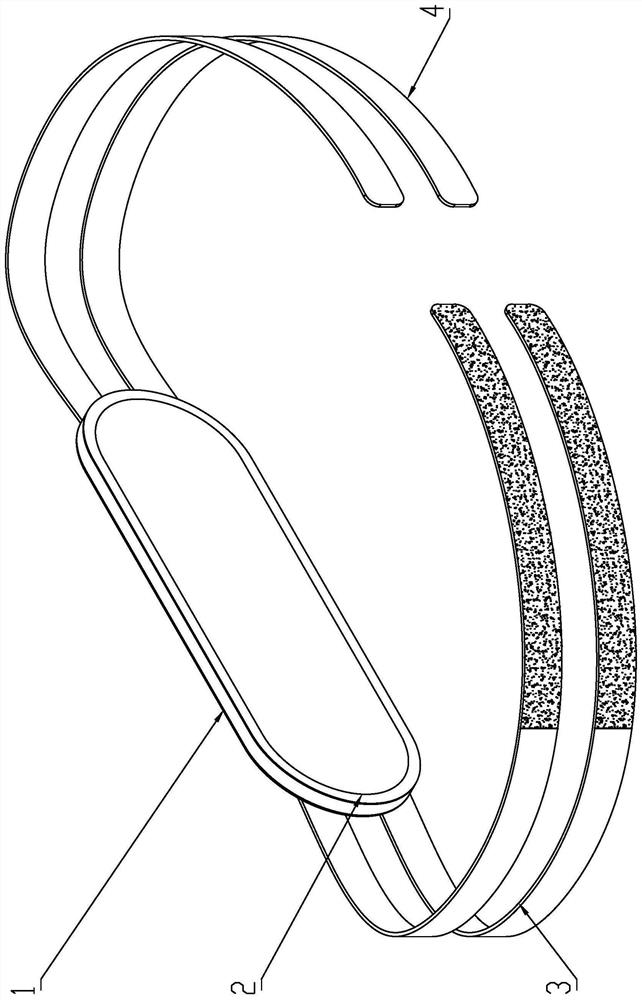

Mitral valve forming ring with coating base material

ActiveCN114452038AGuaranteed stereotypesGuaranteed tightnessAnnuloplasty ringsEngineeringMitral valve leaflet

The invention discloses a mitral valve forming ring with a coating base material, which comprises a forming ring body and the coating base material, the forming ring body comprises a plurality of contraction joints with a soft structure, and the plurality of contraction joints can be connected end to end to form an annular structure; the wrapping base material comprises a nickel-titanium alloy net wrapping the surface of each contraction joint, and each nickel-titanium alloy net comprises a wrapping section wrapping the surface of the corresponding contraction joint and an extending section which is connected to the wrapping section and extends outwards in the direction away from the center of the annular structure. The nickel-titanium alloy net is arranged on each contraction joint, and each nickel-titanium alloy net comprises a wrapping section wrapping the surface of the corresponding contraction joint and an extending section which is connected to the wrapping section and extends outwards in the direction opposite to the center of the annular structure of the forming ring, so that shaping during release of the forming ring and compactness of attachment of the forming ring and the autologous valve leaflet are guaranteed, and recycling is facilitated.

Owner:SHANGHAI HEALING MEDICAL DEVICES CO LTD

A continuous ice production device

InactiveCN107166831BGuaranteed stereotypesStrong swirl mixing abilityLighting and heating apparatusIce productionSurface cleaningIce storage

The invention provides a continuous ice particle making device. The continuous ice particle making device comprises an atomizing nozzle, a swirl nozzle, an ice making compartment, a hollow pipe, a hollow circulation nozzle, a mixing chamber, a precooling chamber and the like. Water is atomized to generate water droplets through the atomizing nozzle, low-temperature swirl gas is sprayed through the swirl nozzle, the atomized water droplets are frozen to generate ice particles, and the low-temperature gas passes through the hollow circulation nozzle so as to continuously make ice particles. Under the action of swirl, injection, entrainment and mixing of the swirl nozzle and the hollow circulation nozzle, the ice particles are quickly generated, the particle size is uniform, and the intensity is high; the precooling chamber is precooled to be cool, and the cooling capacity is recycled, so that heat loss of the low-temperature gas is reduced and eliminated, and energy is saved. The system has the advantages of simple structure, small size, light weight and low manufacturing cost and can be used for continuously making the ice particles, and for example, the ice particles can be injected in application occasions such as surface cleaning, derusting, ice storage, food processing and the like.

Owner:QINGDAO UNIV

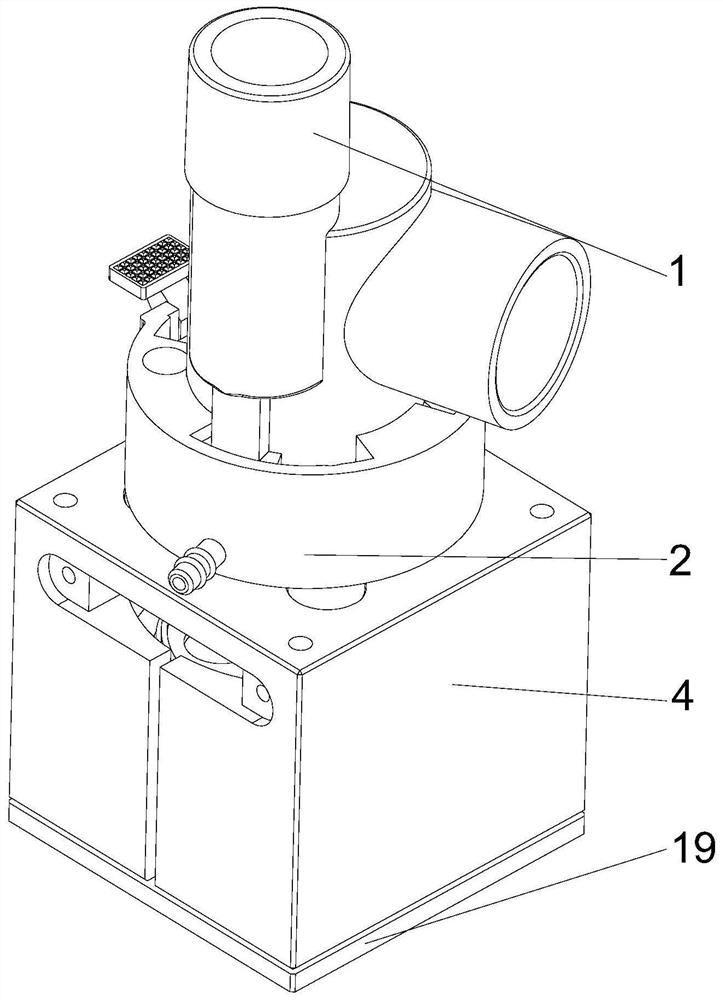

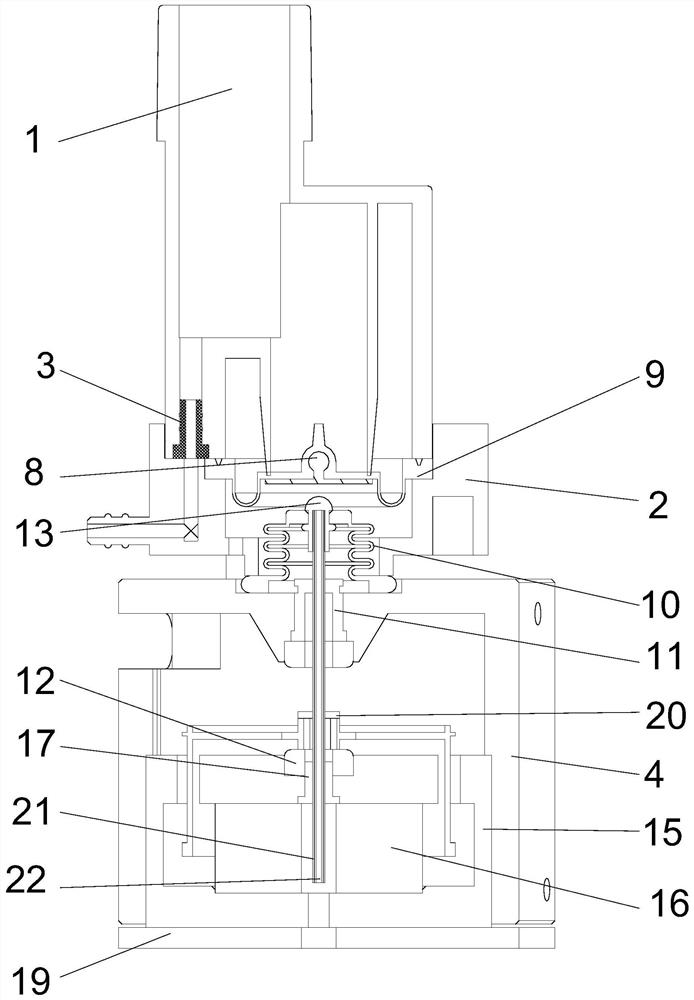

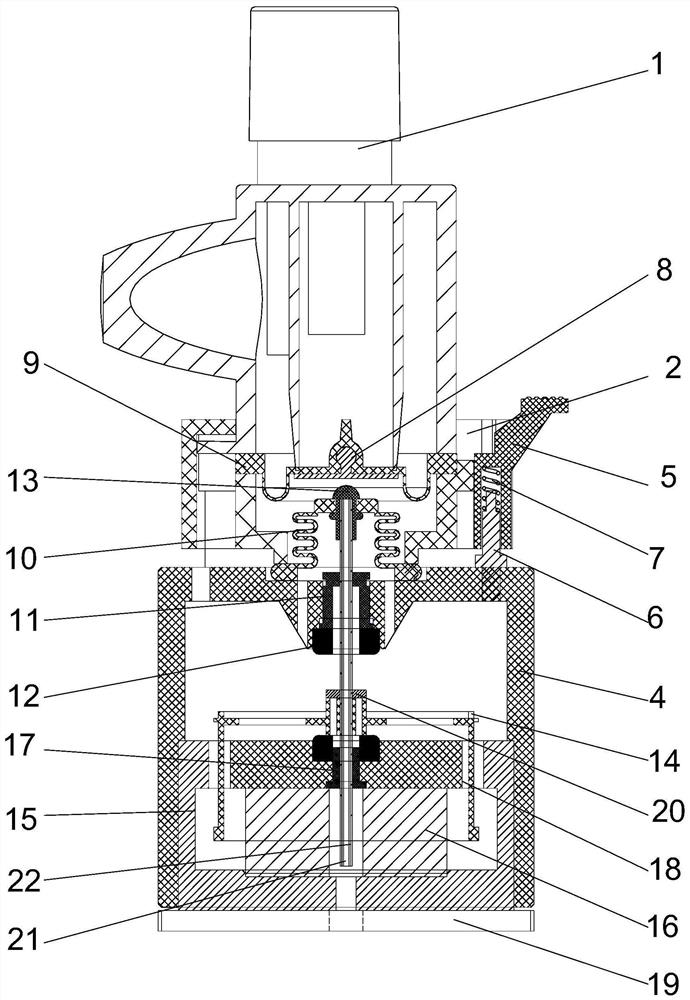

Novel PEEP valve based on electromagnetic control technology

InactiveCN113975580APressure is easy to controlAvoid repeatedly adjusting the air pressureRespiratorsPhysical medicine and rehabilitationCapillary Tubing

The invention belongs to the technical field of PEEP valves and discloses a novel PEEP valve based on an electromagnetic control technology. The novel PEEP valve comprises a valve body, a fixed seat is fixedly mounted on the wall surface of the upper bottom of the valve body, a valve seat is slidably connected in the fixed seat, an ejector pin sleeve is arranged in the fixed seat, an ejector pin is fixedly mounted in the ejector pin sleeve, a coil holder is arranged in the valve seat, a coil is wound on the side wall of the coil holder, a U-shaped cup is fixedly installed on the inner bottom wall face of the valve seat, and a magnet is magnetically attracted to the middle of the inner bottom wall face of the U-shaped cup. According to the novel PEEP valve, the magnetic field reaction is changed through the cooperation of a first capillary tube and a second capillary tube, precise control over different pressures can be completed with extremely low power consumption, gas consumption is not needed, pressure control is facilitated through electromagnetic control, the situation that the air pressure needs to be repeatedly adjusted when the air pressure is provided is avoided, the treatment efficiency is improved, the effect of improving the response speed is achieved through electromagnetic control, and the effect of saving cost is achieved while the effect is improved.

Owner:江苏奥凯医疗设备有限公司

Plastic shoe sole manufacturing device for shoe factory and manufacturing method

PendingCN108544777AIngenious structural designEasy to operateDomestic footwearPlastic shoesEngineering

The invention discloses a method for manufacturing a plastic shoe sole manufacturing device for a shoe factory. The plastic shoe sole manufacturing device comprises a workbench, a supporting rod and arotary rod. The top end of the supporting rod is rotationally connected with the rotary rod through a bearing, and a plurality of grooves are formed around the upper end of the rotary rod. One end ofa second connecting rod is fixedly connected with a baffle cover, and one end of a first connecting rod is fixedly connected with a shoe sole injection plate. According to the device, by means of therotating rotary rod, a shoe sole can be conveniently conveyed when manufactured, high-efficiency cooling is achieved, and then it is guaranteed that the shoe sole can be shaped. By means of clampingconnection of the shoe sole injection plate and the baffle cover, an operator can carry out clamping connection, demounting and mounting conveniently. By means of an elastic belt, the baffle cover canbe fixed conveniently to guarantee the stability of a shoe sole structure. the shoe sole injection plate and the baffle cover on the device can be shoe molds of different sizes, the number of shoe soles of different size can be controlled well, and then the processing proportion of different shoe sole sizes is guaranteed.

Owner:许泽政

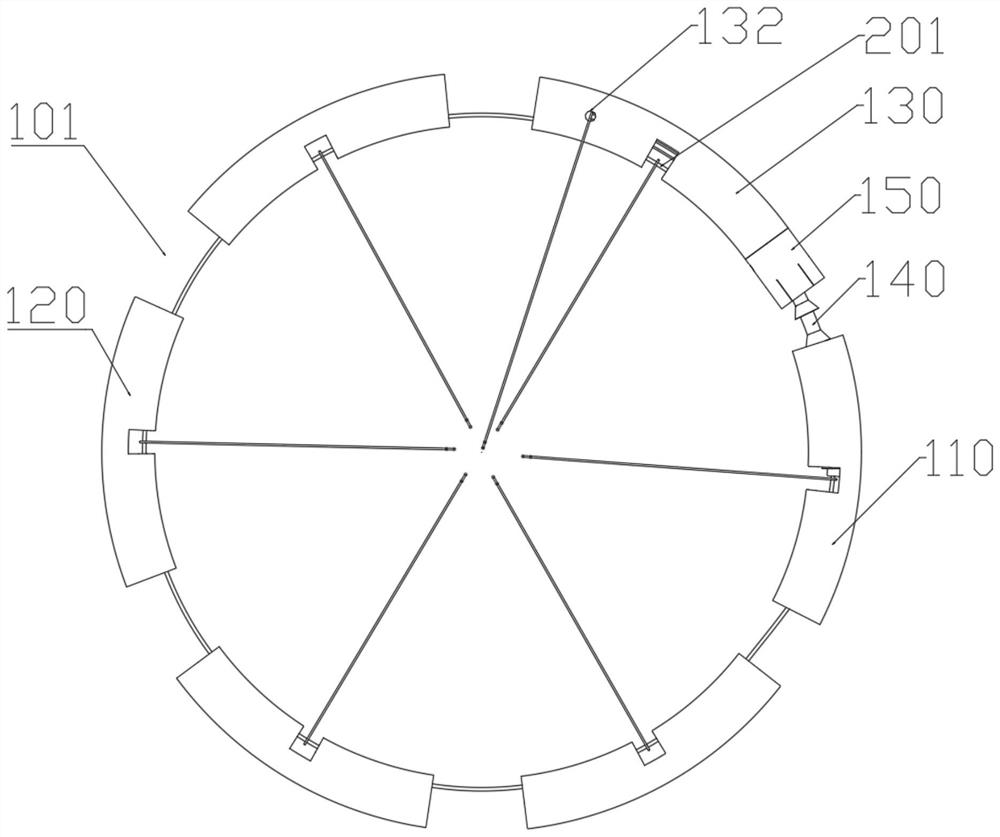

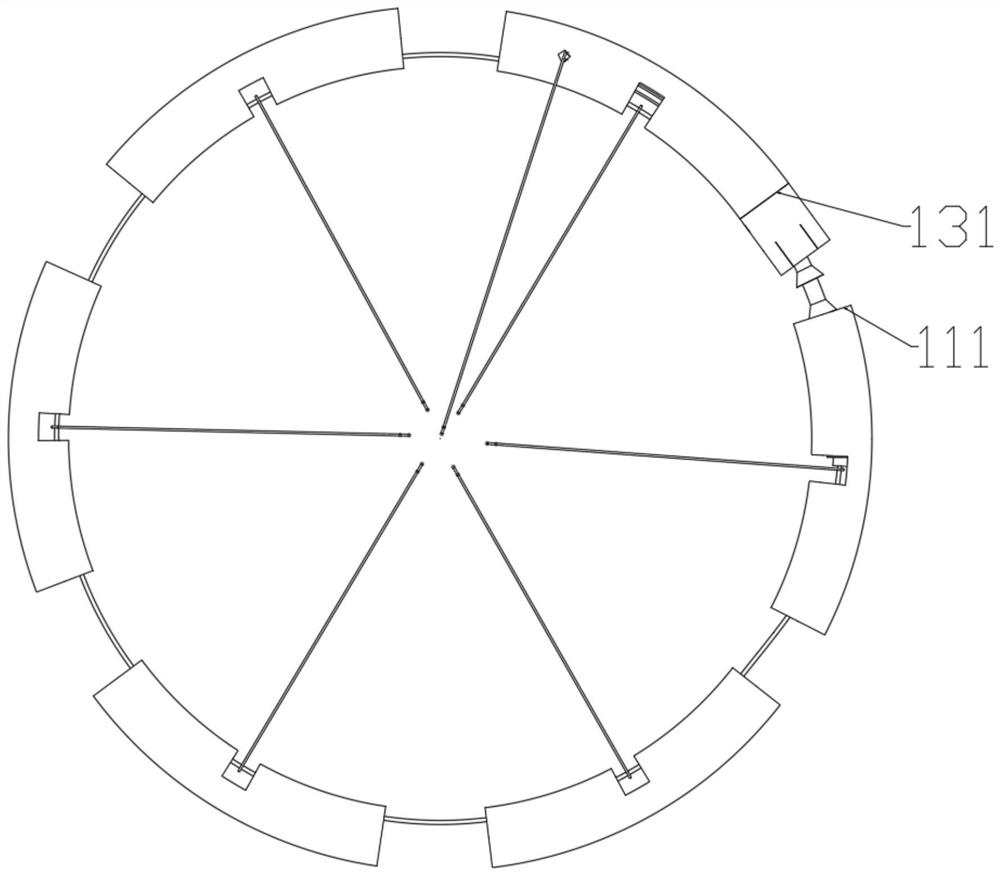

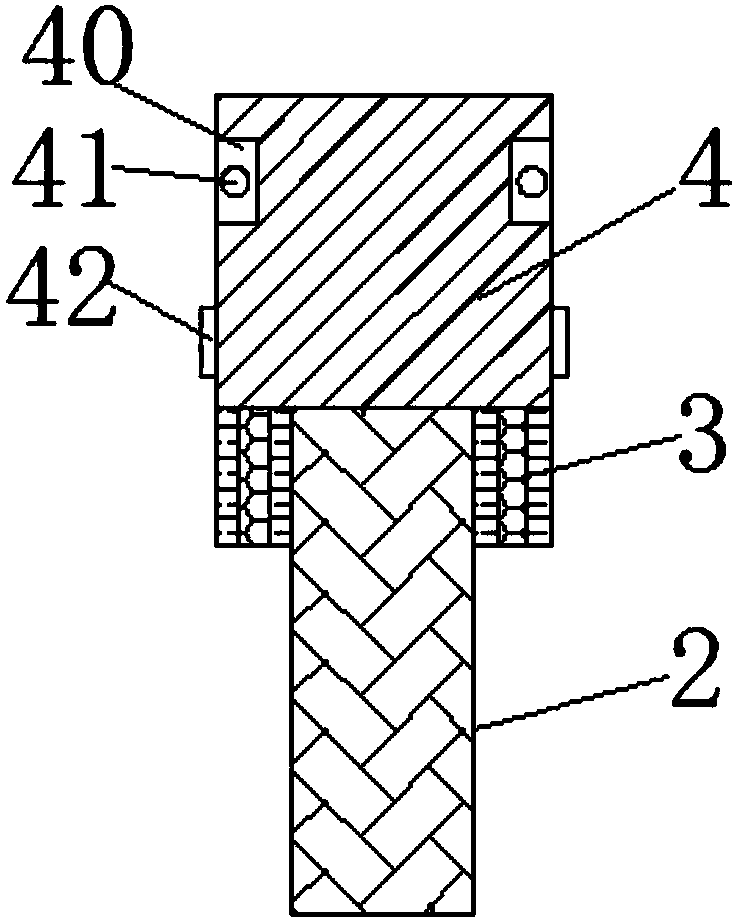

Chemical barrel opening shaping equipment and operation method

InactiveCN113442413AGuaranteed stereotypesImprove operating method efficiencyDomestic articlesSynchronous controlElectric machinery

The invention provides chemical barrel opening shaping equipment and an operation method. The chemical barrel opening shaping equipment comprises a fixed seat, a plurality of fixed plates and movable plates which are arranged in a matrix mode are arranged on the fixed seat, chemical barrels are placed between the fixed plates and the movable plates, dovetail blocks are arranged at the lower ends of the movable plates, dovetail grooves are formed in the fixed seat, and the movable plates relatively slide in the dovetail grooves through the dovetail blocks. Threaded holes are formed in the fixed plates and the movable plates, threaded rods penetrating through all the threaded holes are arranged in the threaded holes, supporting columns are further arranged at the upper end of the fixed seat, a lifting table moving horizontally and vertically is arranged on the supporting columns, a motor is arranged at the lower end of the vertical lifting table, a heating rod is arranged at the lower end of the motor, and a shaping element is connected to the lower end of the heating rod. The lifting platform and the motor are separately connected with a control box, and the motor and the control box are separately connected with a power supply. The chemical barrel opening shaping equipment and the operation method have the advantages of synchronous fixing, synchronous limiting, synchronous control and synchronous shaping of a barrel opening of a chemical barrel.

Owner:陕西中特塑料容器有限公司

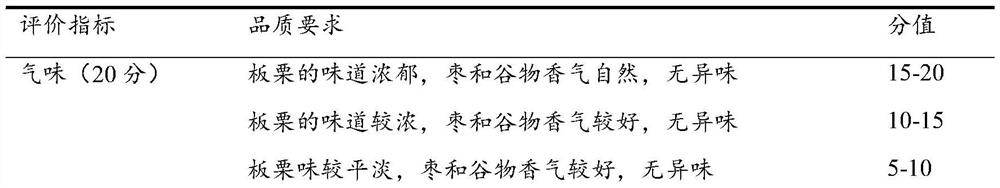

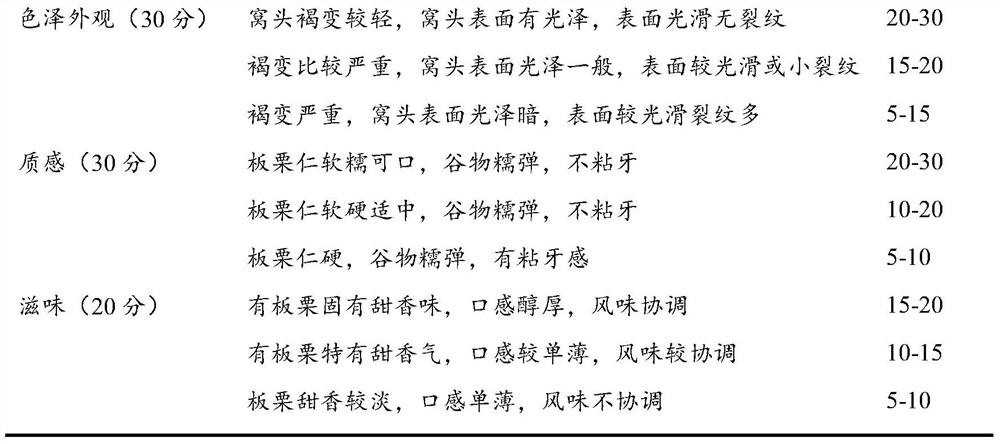

Chinese chestnut steamed corn bread and preparation method thereof

PendingCN114128861AFull of nutritionDelicate meatFood ingredient as mouthfeel improving agentBiotechnologyCorn flour

The invention discloses Chinese chestnut steamed corn bread and a preparation method thereof. The Chinese chestnut steamed corn bread comprises the following raw materials in parts by weight: 500-800 parts of crushed Chinese chestnut kernels, 500 parts of mixed powder, 100 parts of crushed red dates, 80-120 parts of xylitol and 500 parts of purified water, wherein the mixed powder comprises glutinous rice flour and corn flour, and the weight ratio of the glutinous rice flour to the corn flour is (2: 1)-(1: 2); the average particle size of the crushed Chinese chestnut kernels is 2-7mm. The Chinese chestnut steamed corn bread is prepared through raw material pretreatment, raw material mixing, dough kneading, steamed corn bread preparation through a model and steaming. By adopting the raw materials, the nutritional value of the Chinese chestnut steamed corn bread is improved, and the taste of the Chinese chestnut steamed corn bread is enriched; meanwhile, the looseness of corn flour is utilized to improve viscosity, and the adhesiveness of glutinous rice flour is utilized to improve the problem that Chinese chestnut grains are not easy to form; and the prepared steamed corn bread is soft, glutinous and delicious.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

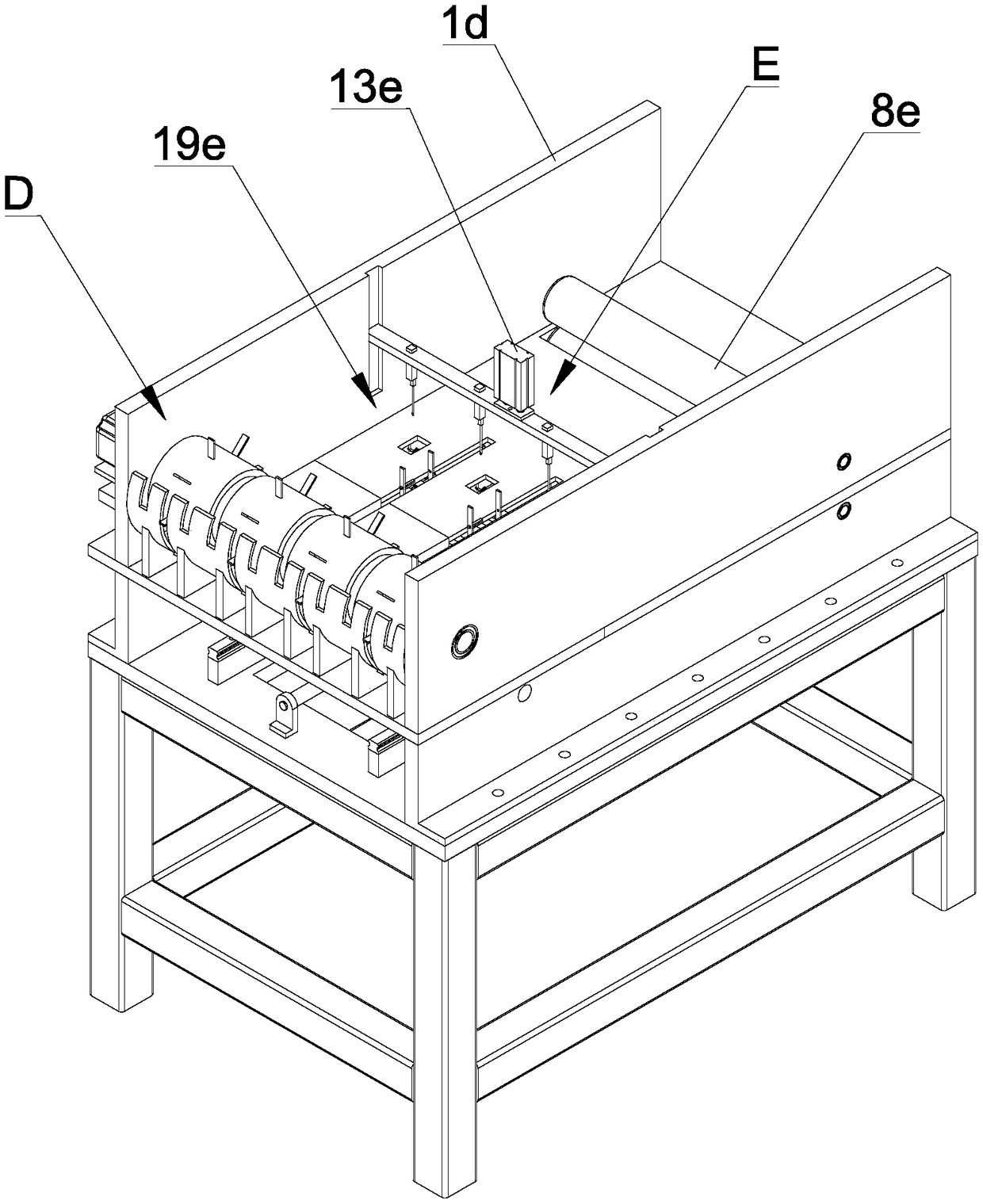

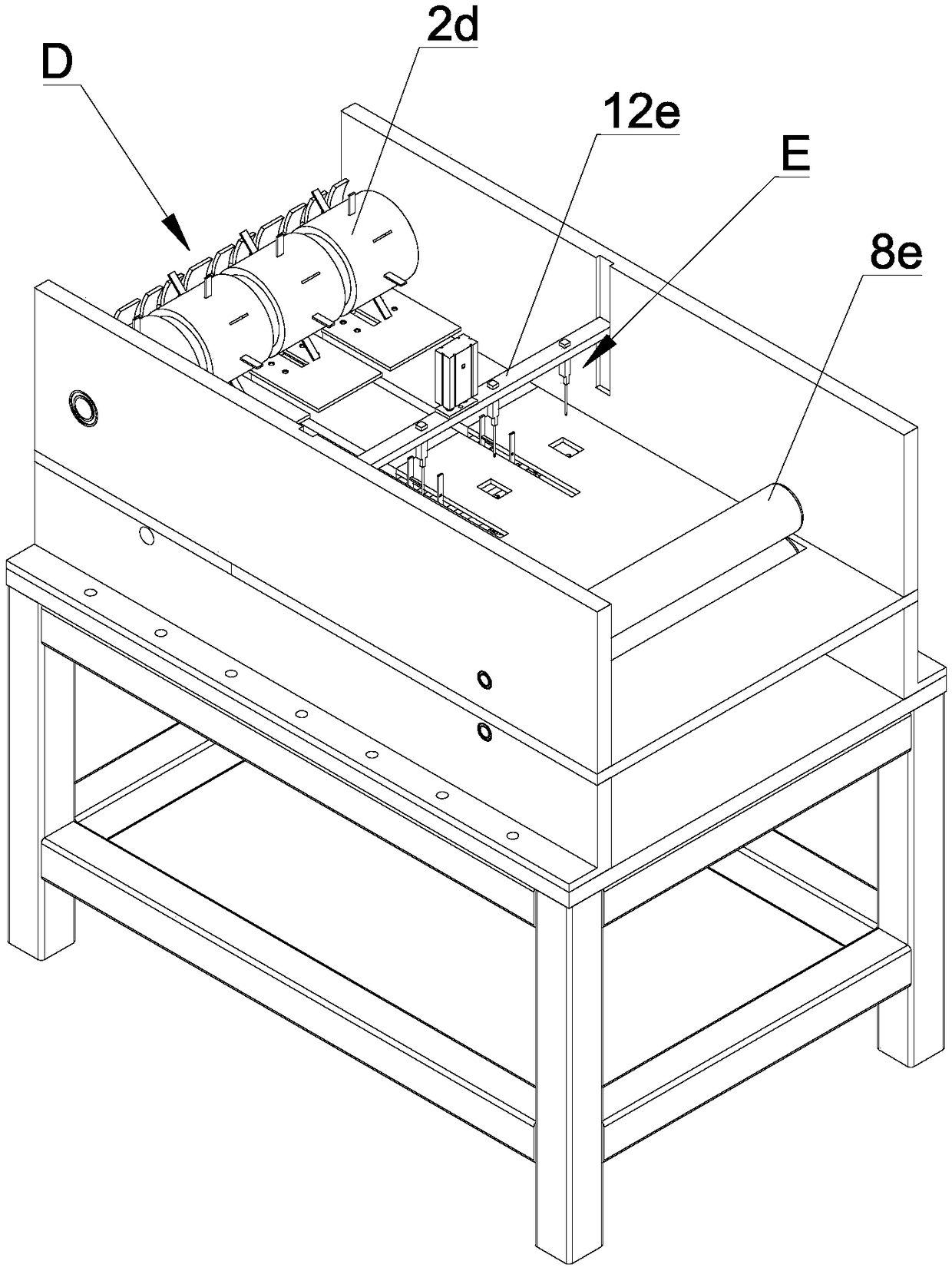

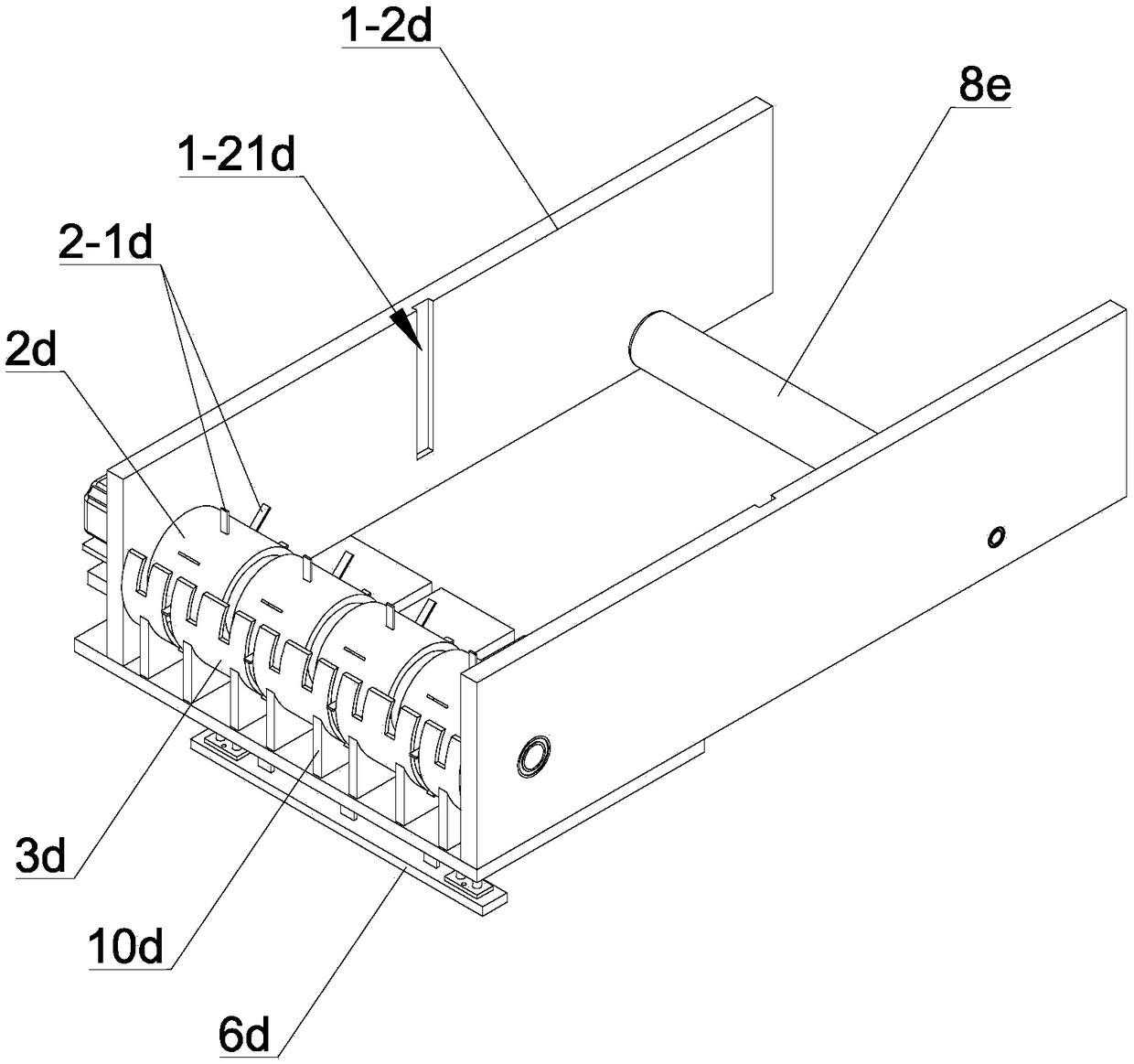

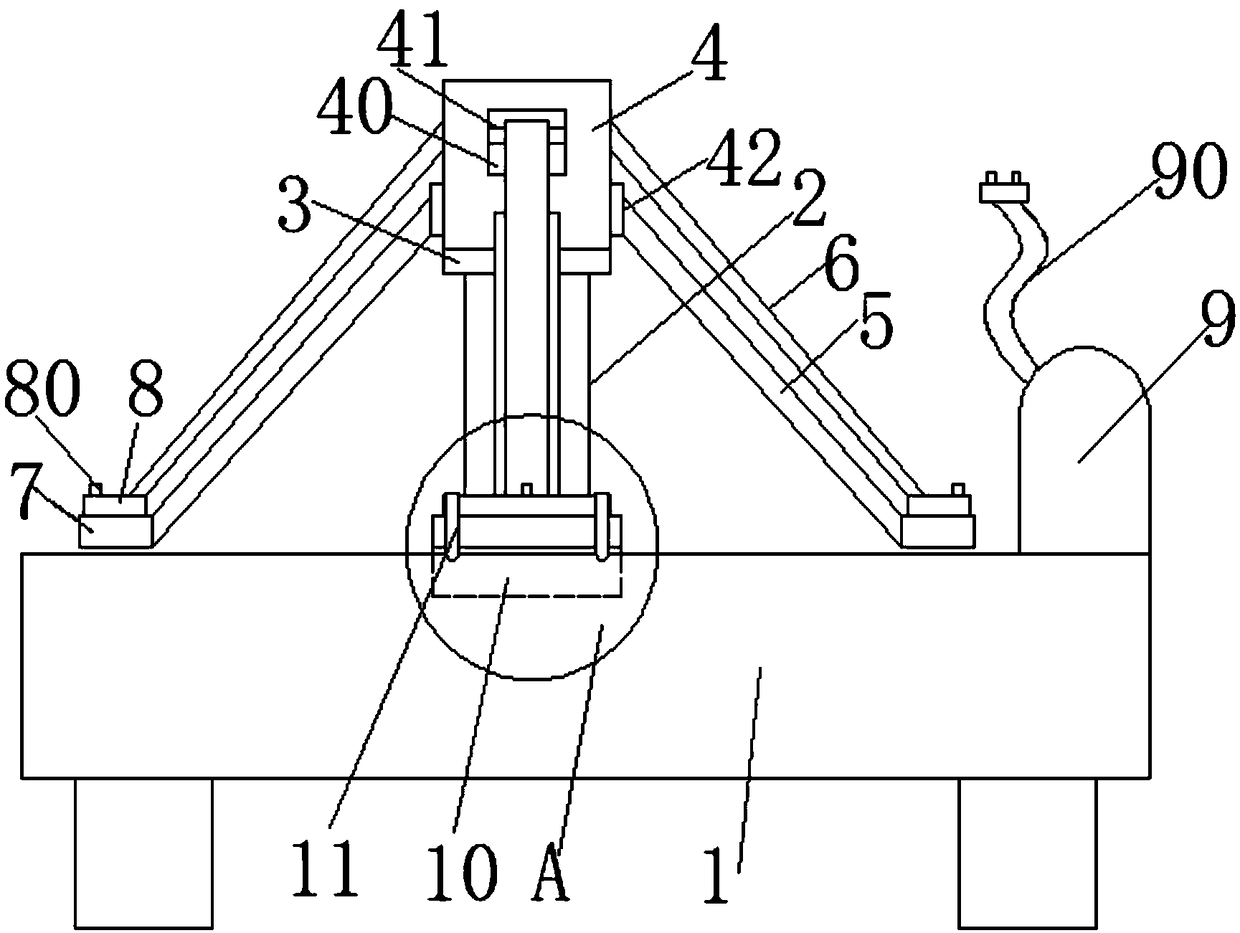

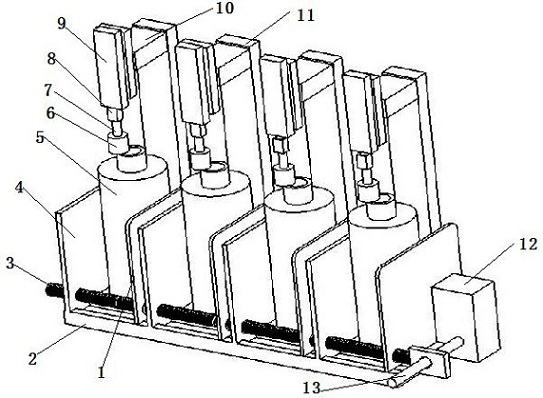

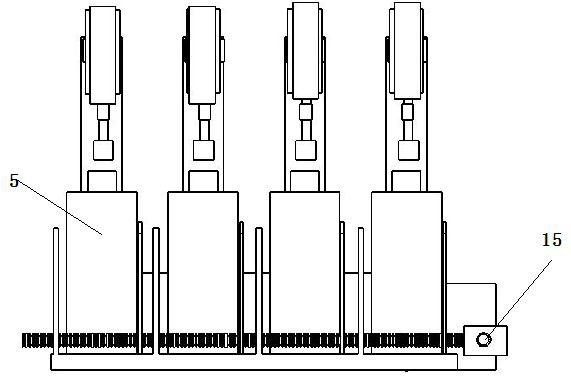

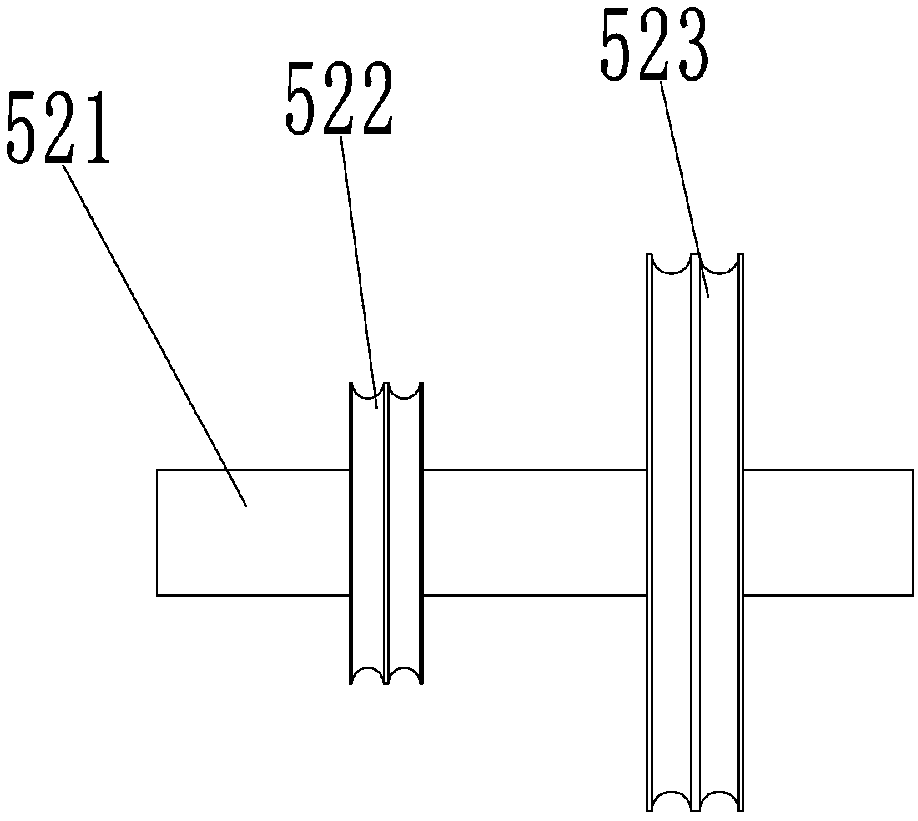

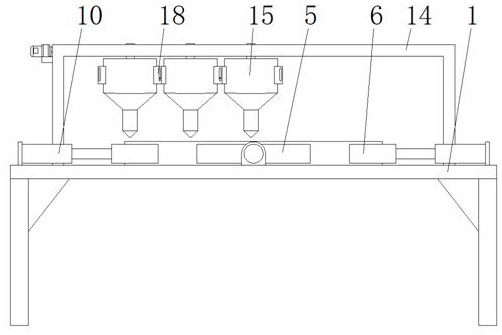

A precise weaving device for a straw weaving machine

InactiveCN109249494BImprove surface qualityAvoid deformationCane mechanical workingStructural engineeringIndustrial engineering

The invention discloses an accurate braiding device of a straw braiding machine. The accurate braiding device comprises a middle setting mechanism and a braiding device. The middle setting mechanism comprises a setting roll, a limit setting plate and a guide driving mechanism; a plurality of guide blocks are arranged on the setting roll along the circumferential directions; the limit setting plateencircles the outer side of the setting roll, and a setting cavity is formed by gaps between the limit setting plate and the outer circumferential surface of the setting roll; the braiding device comprises a braiding transmitting mechanism and a sewing mechanism; the braiding transmitting mechanism comprises a transverse transmitting mechanism, adaptive fixing mechanisms and a lifting transmitting mechanism, and the adaptive fixing mechanisms comprise fixing clips and adaptive driving mechanisms; the adaptive driving mechanisms comprise loosening driving components and compression springs; the sewing mechanism comprises a sewing plate and sewing assemblies. The accurate braiding device has the advantages that straw bundles can be set by the accurate braiding device in transmitting procedures, the set straw bundles can be accurately conveyed into braiding stations and can be fixed, and accordingly the braiding quality can be guaranteed.

Owner:湖南广播电视大学

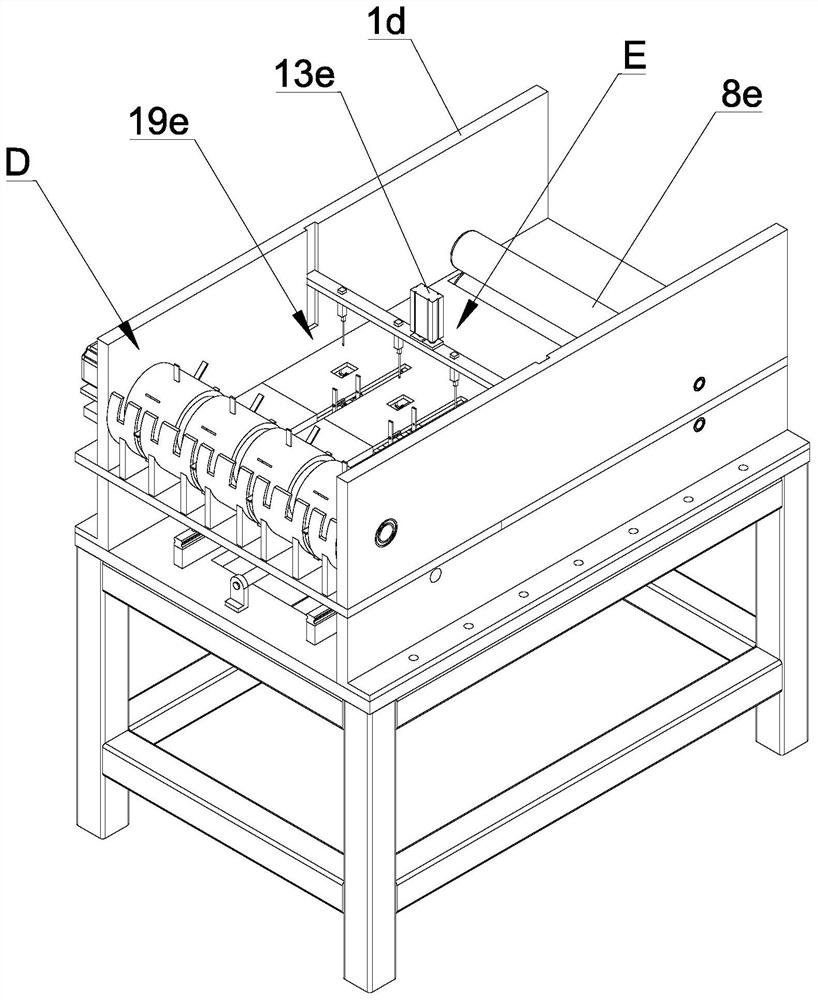

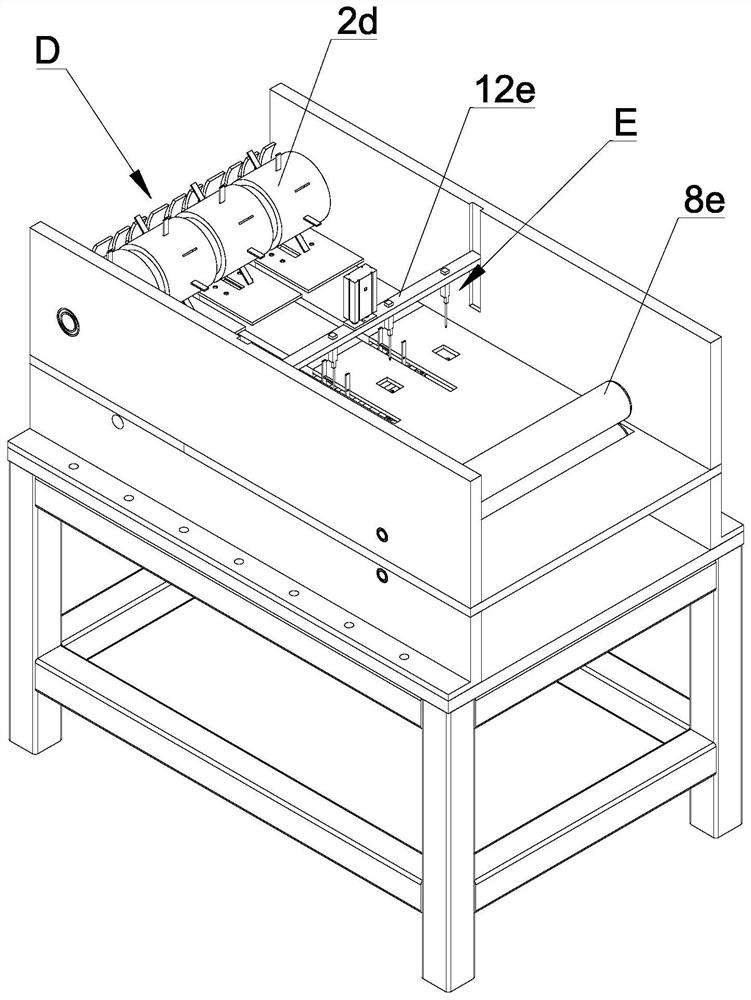

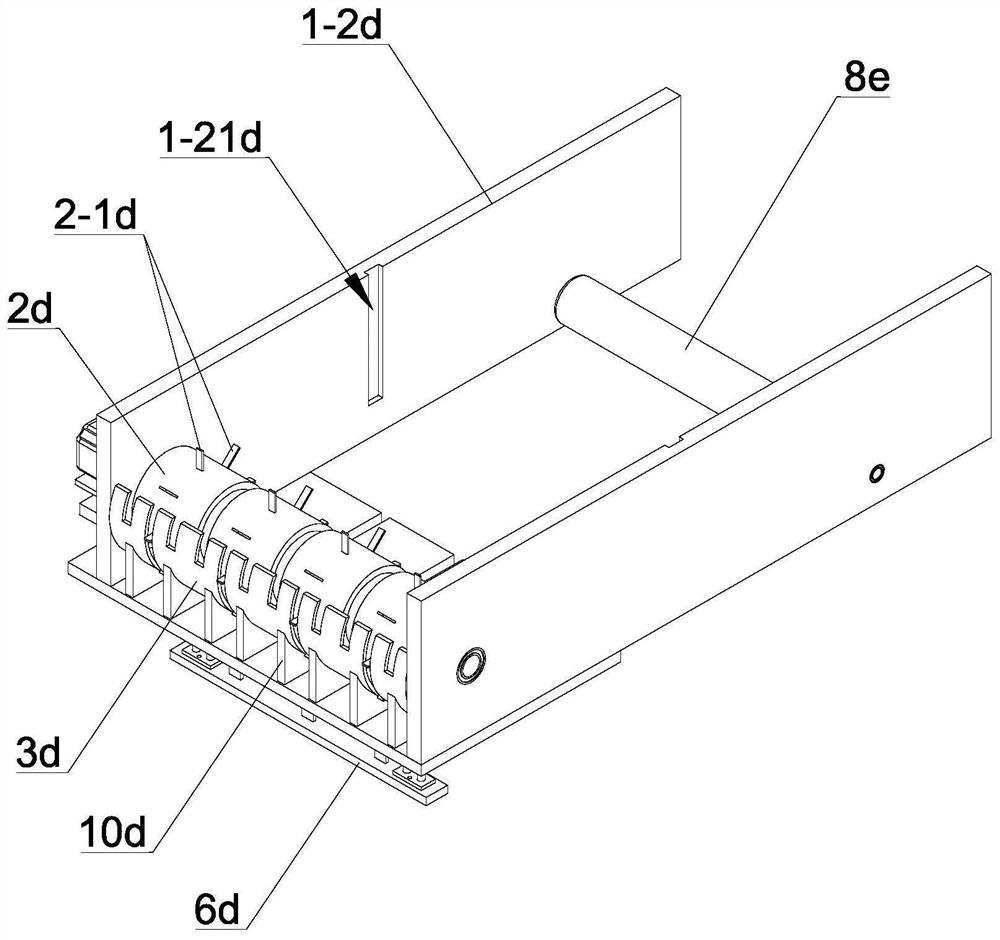

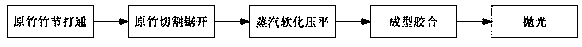

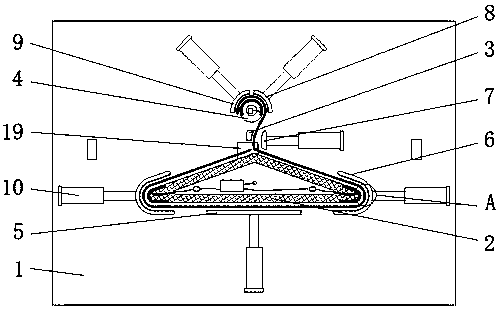

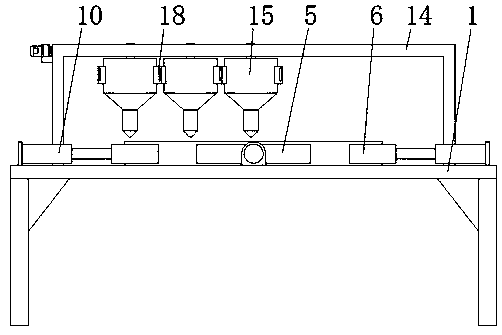

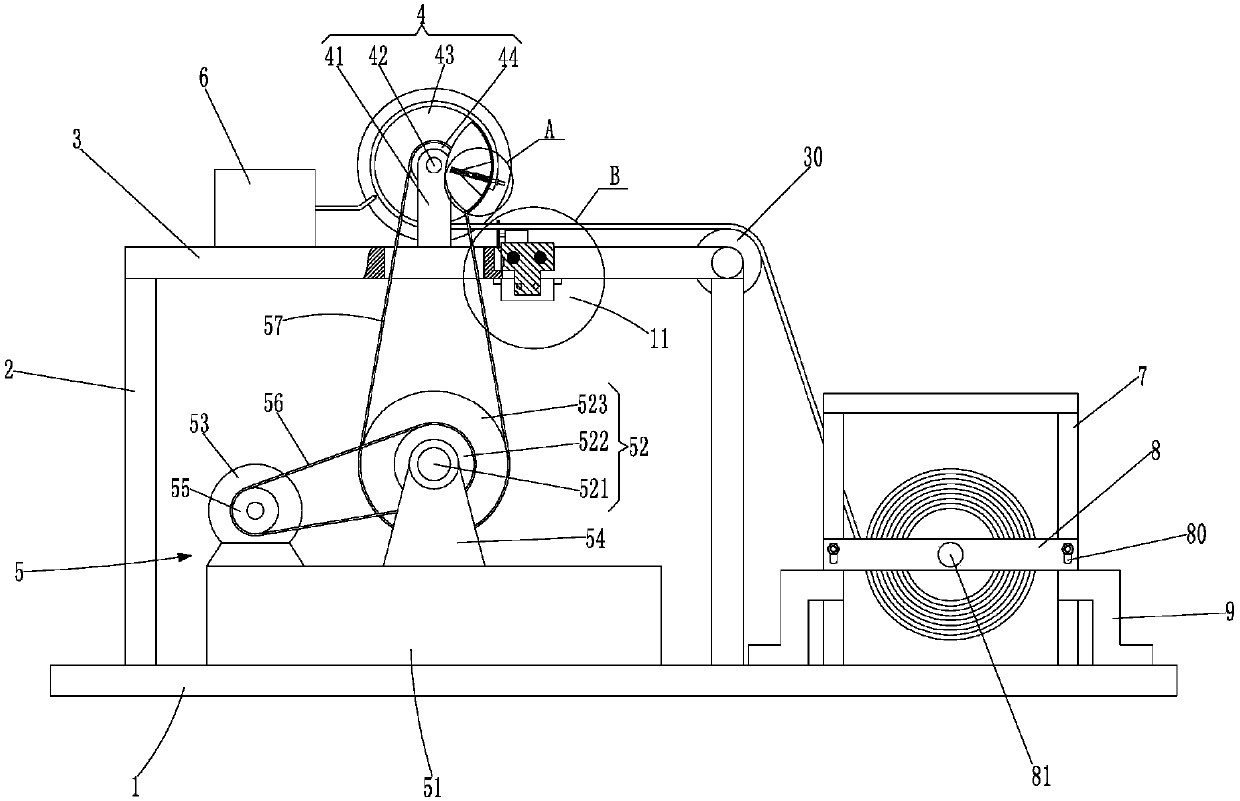

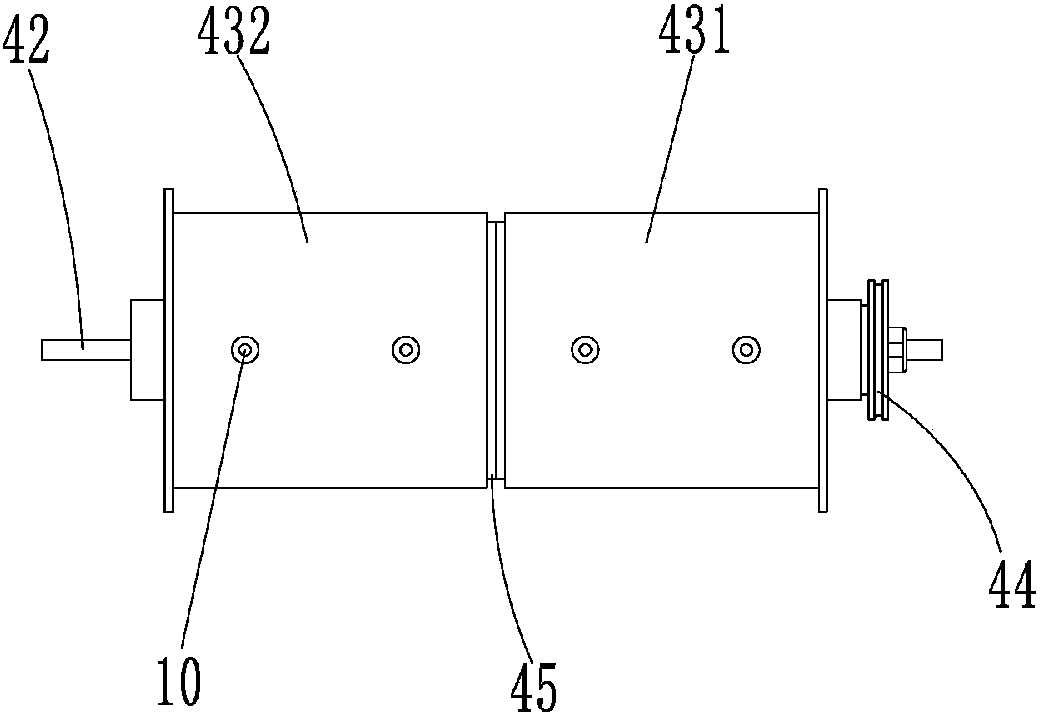

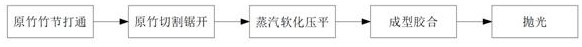

Production method and mold of bamboo clothes hanger

ActiveCN111452177AGuaranteed stabilityAvoid deformation and detachmentAdhesive application devicesMechanical engineeringClothes hanger

The invention discloses a production method and a mold of a bamboo clothes hanger. The production method of the bamboo clothes hanger comprises the following steps: (1) bamboo joints in raw bamboos are broken through; (2) the broken-through raw bamboos are correspondingly sawed to form all arc bamboo strips; (3) the arc bamboo strips are cut into needed specifications for once molding on a moldingmold; (4) end seals are glued for shaping; and (5) the molded clothes hanger is polished; and after all the sawed arc bamboo strips in the step (2) are softened by high-temperature steam, the arc bamboo strips are flattened. The production method and the mold of the bamboo clothes hanger are beneficial to guarantee of the stability of the whole structure of the bamboo clothes hanger, can preventdeformation of the bamboo clothes hanger, are not easy to separate, can guarantee the service life of the bamboo clothes hanger, meanwhile, have no need to stop during glue adding, can guarantee sufficient use of bonding glue, and are beneficial to guarantee of the production efficiency.

Owner:黎志生

A kind of production process of anti-wrinkle hot water bag leather

ActiveCN110154492BPaste evenlyGuaranteed stereotypesLaminationLamination apparatusPolymer scienceEngineering

The invention discloses a production process of anti-wrinkle hot water bag leather, which belongs to the technical field of PVC leather processing. It includes four steps (a) base cloth opening and shaping; (b) paste on the base cloth; (c) preparation of PVC leather and lamination with the base cloth; (d) cooling and coiling; Excessive stretching, and ensure the appropriate temperature and paste amount, so that after the hot water bag leather is made into a hot water bag, there will be no wrinkling, edge warping, delamination and other phenomena.

Owner:四川金路高新材料有限公司

Processing method of functional collar

PendingCN113953682AFast processingEasy to processHeating/cooling textile fabricsLaser beam welding apparatusProcess engineeringLaser cutting

The invention relates to the technical field of collar processing, and discloses a processing method of a functional collar. The processing method comprises the following specific steps: S1, drawing the appearance and the shape of a collar needing to be processed and produced according to requirements, S2, selecting proper cloth, and enabling the surface of the cloth to be clean and free of other sundries such as a thread residue, S3, adjusting cutting parameters of a laser machine, so that the cutting parameters of the laser cutting machine is enabled to be more suitable for cutting cloth, and S4, placing the cloth on a workbench of the laser cutting machine, and manually positioning the cloth through an operator, so that the operator can more smoothly cut the cloth according to the drawn graph through the laser cutting machine. According to the processing method of the functional collar, the fabric is subjected to high-temperature press molding and shaping through a press, so that the shaping of the fabric is smoother, the processing speed of an operator on the collar is improved to a certain extent, and the operator can process the collar more conveniently.

Owner:陈衍宏

Rounding machine for filter screen of oil filter

PendingCN107813145AMeet the installation requirementsIncrease turning forceOther manufacturing equipments/toolsStructural engineeringMachine

The invention provides a rounding machine for a filter screen of an oil filter. The rounding machine comprises a machine seat, and a worktable and a raw material frame are arranged on the machine seatside by side. The worktable comprises a rectangular frame fixedly connected to the machine seat, and a reversing roller is rotatably arranged on the side, close to the raw material frame, of the rectangular frame. A mounting plate is fixedly connected to the rectangular frame, and a rounding mechanism is arranged in the middle of the mounting plate. A driving mechanism is arranged on the position, located inside the rectangular frame, of the machine seat, and the driving mechanism drives the rounding mechanism to round the filter screen. A shearing mechanism for shearing-off the filter screenis arranged on the position, close to a rotating mechanism, of the mounting plate, and a spot welder aligned with a step structure is further arranged on the mounting plate. The problems that when anexisting filter screen is rounded, joint participation of multiple persons is needed, thus the processing efficiency is low, and in the rounding process, the filter screen is prone to deforming are solved.

Owner:重庆海国科技有限公司

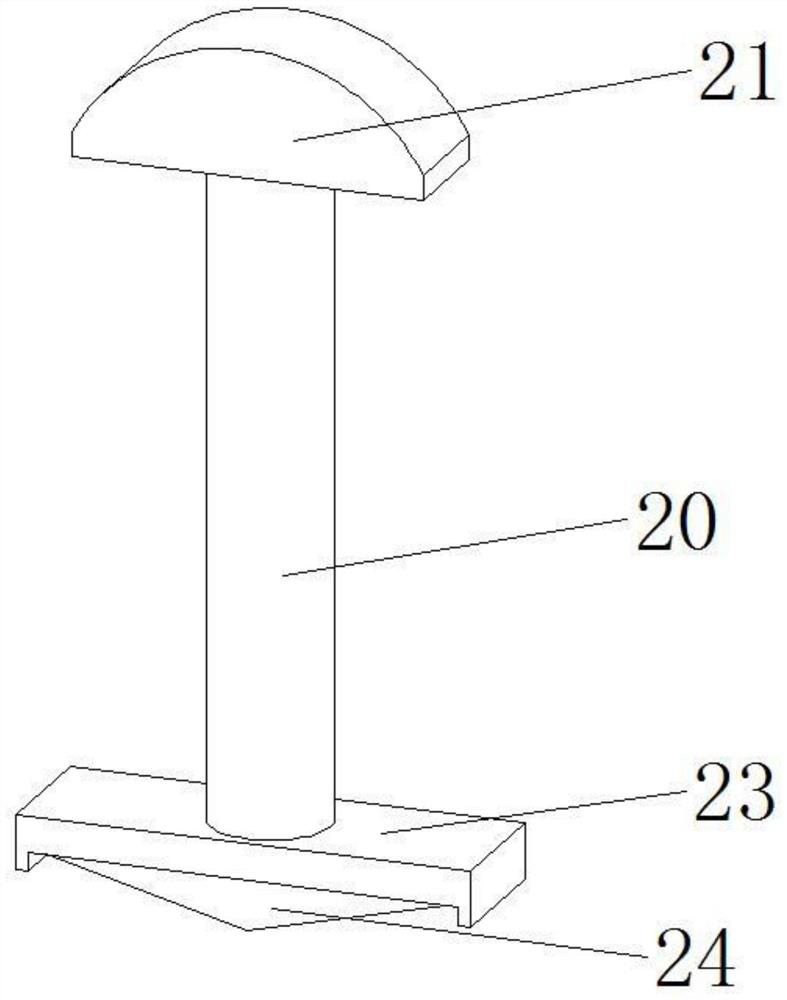

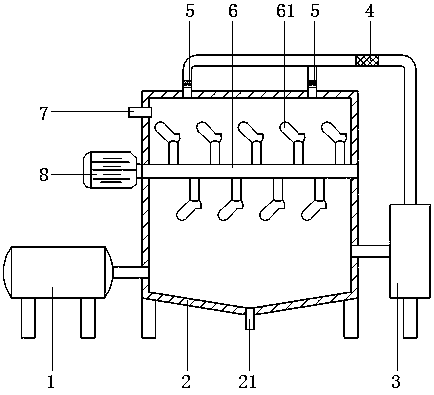

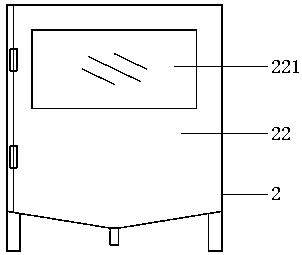

Special drying and shaping machine for self-cleaning socks

InactiveCN110485099AAvoid deformationGuaranteed stereotypesTextiles drying apparatusShaping/stretching tubular fabricsSOCKSPulp and paper industry

The invention provides a special drying and shaping machine for self-cleaning socks. The special drying and shaping machine comprises a steam generator, a tank body and a hot-blast stove, wherein output ends of the steam generator and hot-blast stove are connected with the lower end of the tank body through conveying pipelines respectively, and the top of the tank body is provided with a pluralityof exhaust fans and connected with an input end of the hot-blast stove through a conveying pipeline; the tank body is internally and rotatably connected with a rotating shaft, the rotating shaft is axially and horizontally arranged and provided with a sock supporting bar, one end of the rotating shaft is connected with a drive motor at one side of the tank body, the bottom of the tank body is conical, and the center of the bottom of the tank body is provided with a drainage port. The special drying and shaping machine adopts the rotating shaft arranged in the tank body and provided with the sock supporting bar to be combined with a structure communicated with the steam generator and the hot-blast stove, thereby overcoming the defect of a bad shaping effect of simple heating in the prior art, avoiding the situation that the contact between the socks affects the steam shaping effect, being conductive to reducing the wastage of the heat energy, integrating shaping and drying work, and greatly improving the production efficiency; the special drying and shaping machine is widely applied to matched use of the shaping and drying work of the socks.

Owner:湖南莎丽袜业股份有限公司

Self-shaping elastic medical bandage for general surgery

InactiveCN112190393AEasy to useBind firmlyPlastersAdhesive dressingsMedical equipmentDressing change

The invention provides a self-shaping elastic medical bandage for general surgery, belongs to the technical field of medical equipment for general surgery, and aims at solving the problems that the present bandage cannot be stably wrapped on the affected part of a patient, it is inconvenient to replace the medicine bag and reuse. The self-shaping elastic medical bandage comprises a breathable belt, both side of the breathable belt are provided with a plurality of binding belts I and a plurality of binding belts II respectively, a storage space is arranged in the breathable belt, a dressing change layer is detachably placed in the storage space, the breathable belt is bonded with a covering sheet, and two annular shaping rods are arranged inside the breathable belt, the breathable belt is provided with an adhesive covering layer, and a skin adhesive is prefabricated between the adhesive covering layer and the breathable belt. The invention provided medical bandage can be conveniently and rapidly bound to an affected part of a patient, and the binding is stable; and the medical bandage can be folded into a shape conforming to the affected part according to the position of an affectedpart through cooperation of the breathable belt and the shaping rod, the shaking is avoided and fitting is firm. The dressing change layer is convenient to replace the medicine bag, the dressing change layer can also be replaced, the breathable belt can be reused, which is energy-saving and environmentally friendly.

Owner:周琴

A pattern printing device for fabric bags that facilitates the replacement of templates

ActiveCN110884248BEasy to replaceTimely and effective dryingRotary pressesPrinting press partsTextile printerDry box

Owner:浙江同盟工艺品有限公司

A kind of production method and mold of bamboo clothes hanger

ActiveCN111452177BGuaranteed stabilityAvoid deformation and detachmentAdhesive application devicesAdhesive gluePulp and paper industry

The invention discloses a production method and a mold of a bamboo clothes hanger. The production method of the bamboo clothes hanger comprises the following steps: Step 1: Open up the bamboo joints in the original bamboo; Step 2: Saw the opened original bamboo to form Each arc-shaped bamboo strip; step 3: divide the arc-shaped bamboo strip into required specifications, and form it on the molding mold at one time; step 4: glue the end seal to shape; step 5: polish the formed hanger, and After the sawn curved bamboo strips in step 2 are softened by high-temperature steam, the curved bamboo strips are flattened. The production method and mold of the bamboo clothes hanger are beneficial to ensure the stability of the overall structure of the bamboo clothes hanger, can avoid deformation of the bamboo clothes hanger, are not easy to detach, can ensure the service life of the bamboo clothes hanger, and do not need to stop work when adding glue, and can guarantee Adequate use of adhesive is beneficial to ensure production efficiency.

Owner:黎志生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com