Elastic speed reducing and cooling food processing extrusion forming machine

A food processing and molding machine technology, applied in the field of food processing, can solve the problems of easy change of shape, unfavorable food packaging, and inability to obtain complete cooling, so as to avoid backlog deformation and ensure the effect of processing needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

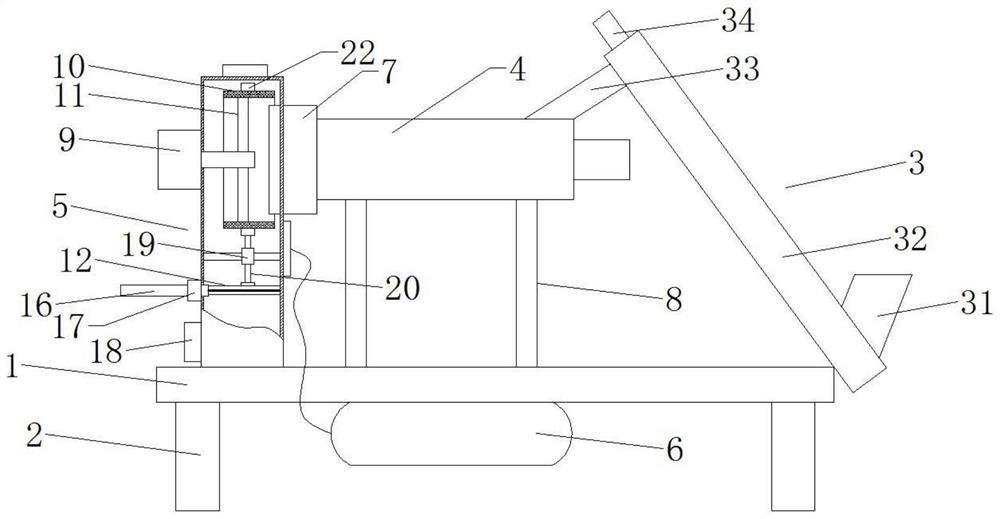

[0020] Please refer to the figure, in an embodiment of the present invention, a food processing extrusion molding machine with elastic deceleration, temperature reduction and cooling includes a base 1, legs 2, a feeding mechanism 3, an extrusion cylinder 4 and a cooling box 5; the legs 2 is fixed on the four corners of the lower side of the base 1, the base 1 is supported by the legs 2, the extrusion cylinder 4 is horizontally arranged above the base 1, and is fixed on the base 1 by the bracket 8, and the extrusion cylinder 4 is provided with a spiral blade , the raw material is pushed to move to the right in the extrusion cylinder 4; the feeding mechanism 3 fixed on the base 1 is arranged at the right end of the extrusion cylinder 4, and the food raw material is sent from the bottom to the extrusion cylinder 4; the feeding mechanism 3. It includes a delivery tube 32 with a cylindrical structure. The delivery tube 32 is placed obliquely. The lower end is connected with an upwar...

Embodiment 2

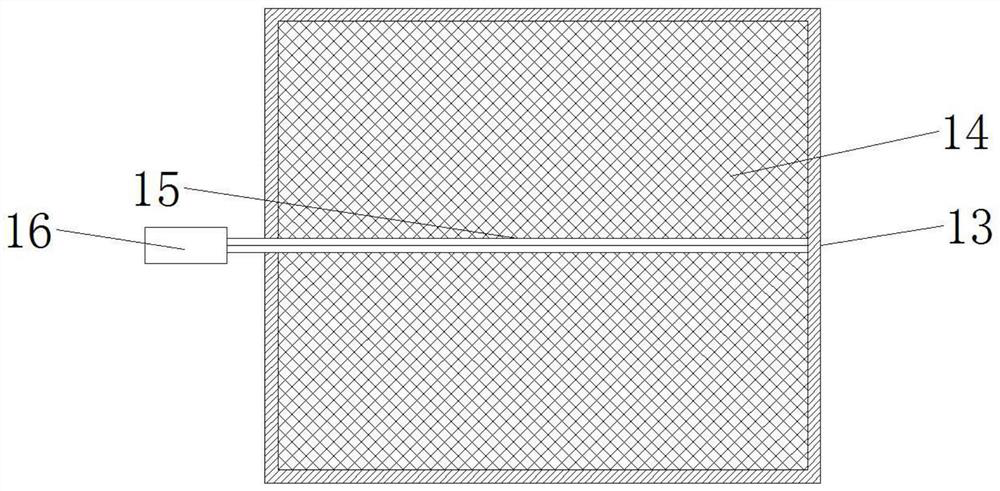

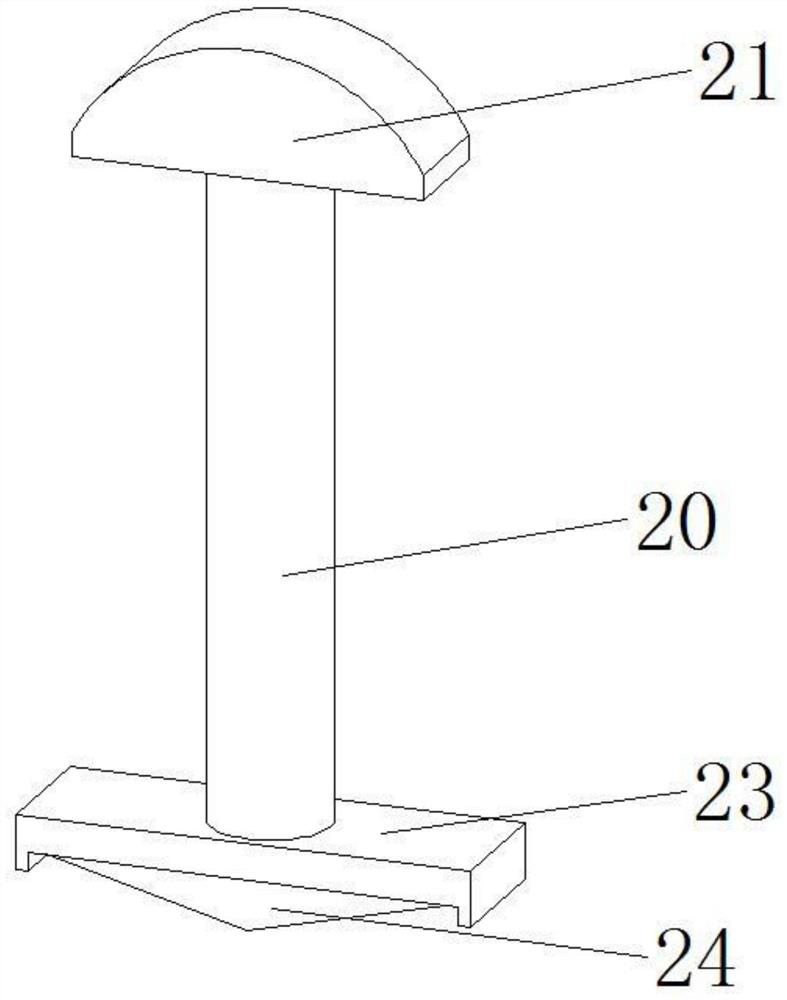

[0025]On the basis of Embodiment 1, a sliding rod 20 moving in the vertical direction is arranged above the elastic deceleration mechanism 12, and the outer side of the sliding rod 20 is provided with a sliding sleeve 19 fixed on the inner wall of the cooling box 5. Bar 20 slides in sliding sleeve 19, guarantees that slide bar 20 only moves on the vertical direction, and slide bar 20 is positioned at the top between two deceleration nets 14, is fixed with contact block 21 at the upper end of slide bar 20, and contact block 21 The top of the top of the contact block 21 is set to an arc surface, and a rotary push block 22 is fixedly installed on the side wall of the corresponding material receiving net cylinder 10 above the contact block 21. The outer surface of the rotary push block 22 is also set to an arc surface, and the rotary push block 22 Contact with the contact block 21 when the net cylinder 10 rotates to the bottom, push the contact block 21 downward, and move the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com