Special drying and shaping machine for self-cleaning socks

A technology of self-cleaning and setting machine, which is applied in the direction of setting/extending circular fabrics, textiles and papermaking, drying fabrics, etc. It can solve the problems of affecting the self-cleaning function of photocatalysts, difficult adjustment of heating temperature, general setting effect, etc., to achieve Ensure self-cleaning performance, avoid waste, and ensure the effect of drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

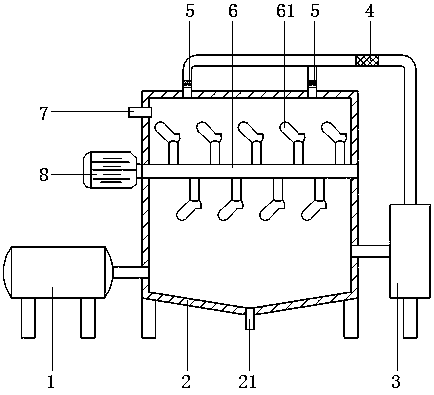

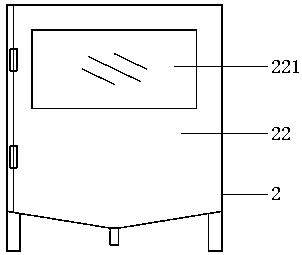

[0025] refer to Figure 1 ~ Figure 2 , the present invention is achieved in this way: a special drying and setting machine for self-cleaning socks, which includes a steam generator 1, a box body 2 and a hot blast stove 3, the output end of the steam generator 1 and the hot blast stove 3 The output ends of the outlets are respectively connected to the lower end of the box body 2 through the delivery pipeline, and the top of the box body 2 is provided with some exhaust fans 5 and connected to the input end of the hot blast stove 3 through the delivery pipeline; To the rotating shaft 6 that is arranged horizontally, one end of the rotating shaft 6 is connected with the driving motor 8 provided on one side of the casing 2, and the rotating shaft 6 is positioned on the outer circular surface of the casing 2 to be provided with some stocking rods 61, the The bottom of the box body 2 is conical and the center of the bottom is provided with a drain port 21 .

[0026] refer to figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com