A precise weaving device for a straw weaving machine

A weaving machine and straw technology, which is applied in the field of straw recycling and processing equipment, can solve the problems of lack of fixation and positioning, difficulty in ensuring the quality of straw mats, poor shape consistency and neatness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

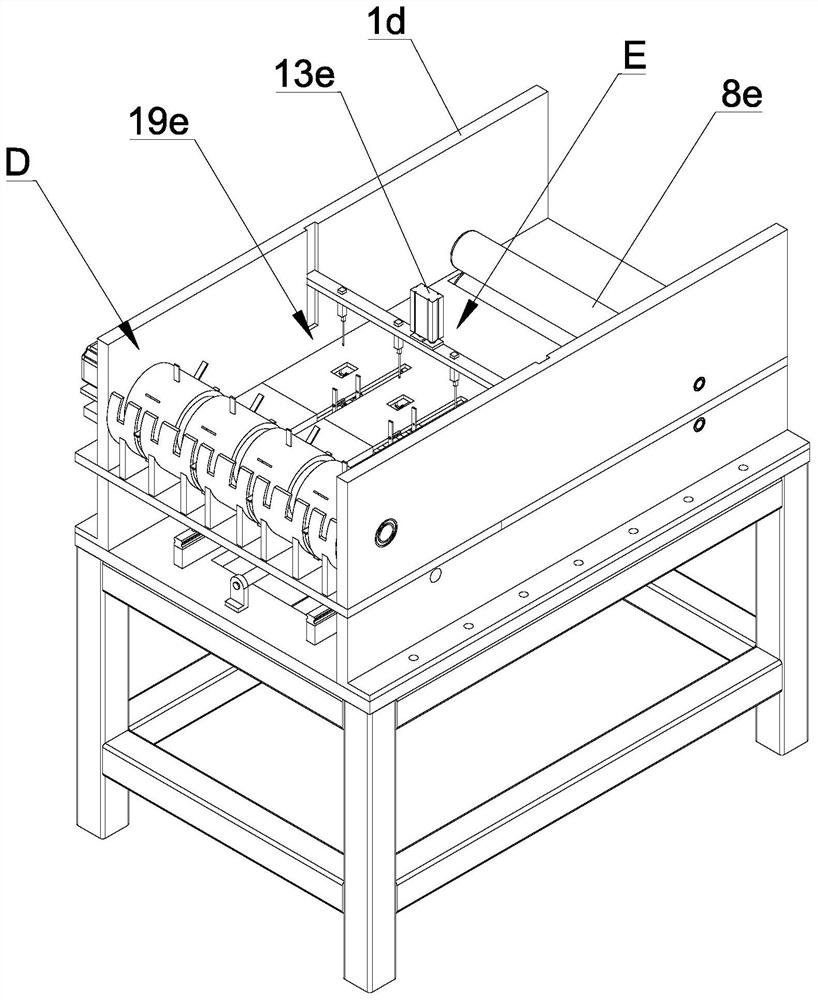

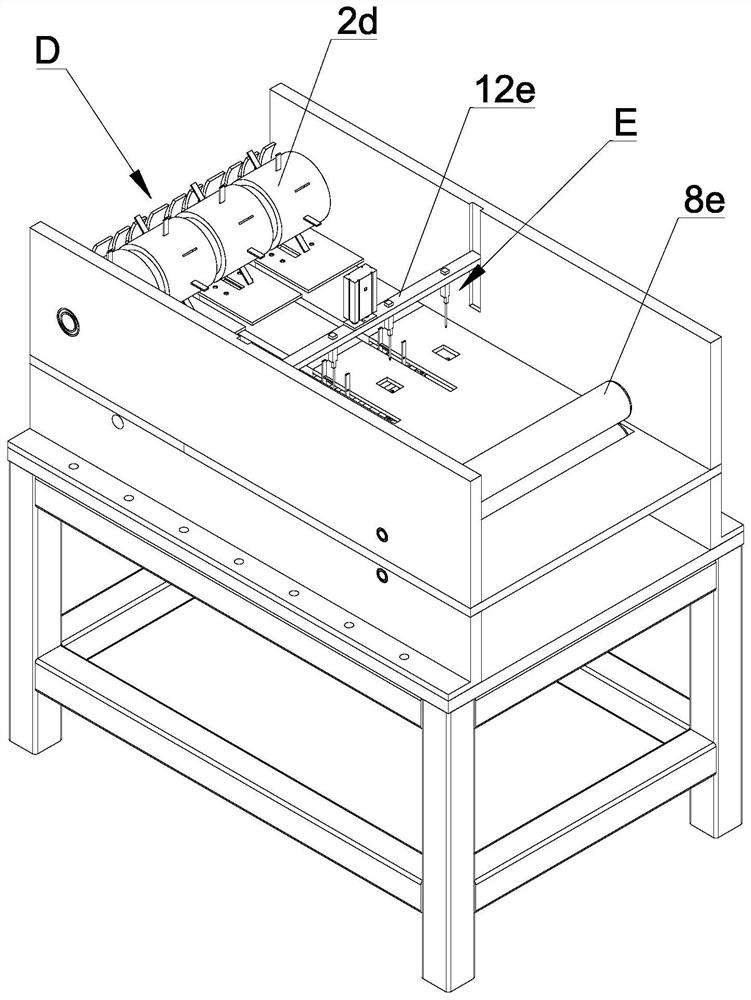

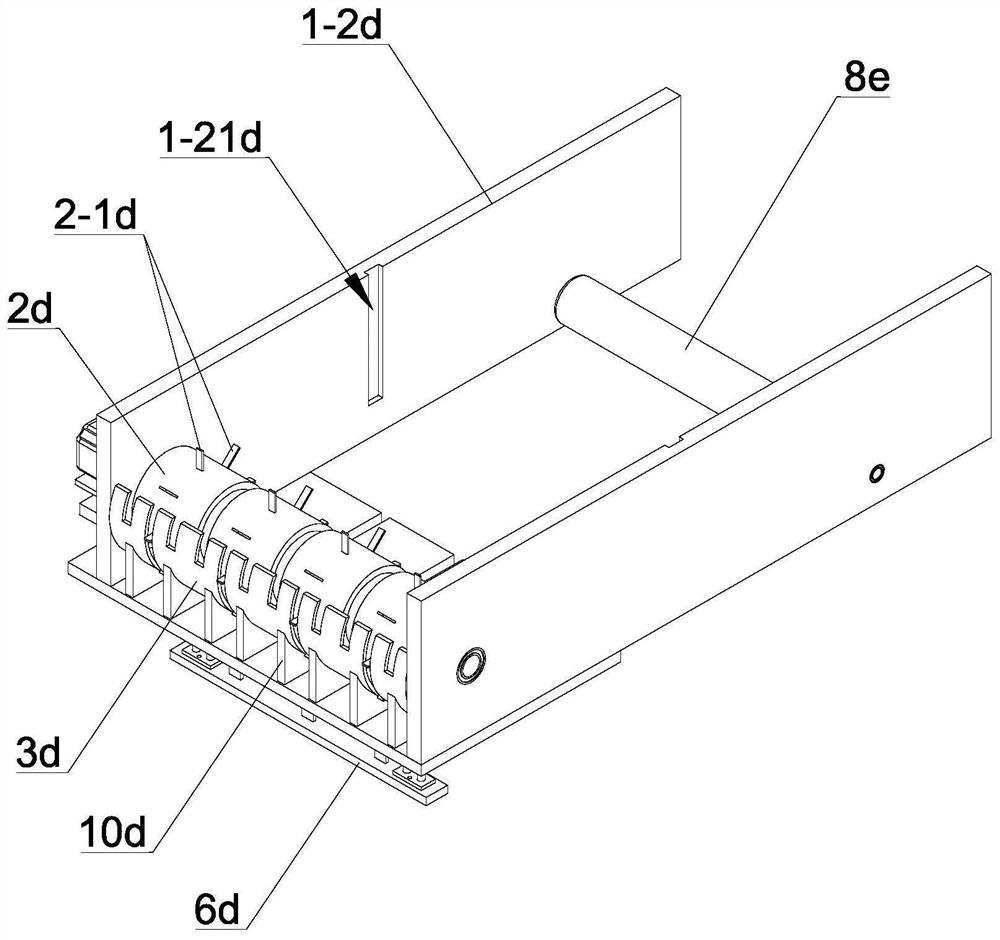

[0054] see Figure 1-5 , the precise weaving device of the straw weaving machine in this embodiment, including an intermediate shaping mechanism D for shaping the bundled straw bundles and a braiding device E for braiding the shaped straw bundles, the intermediate shaping The mechanism D is arranged between the conveying device and the weaving device E; the intermediate shaping mechanism D includes a fixed frame 1d, a shaping roller 2d arranged on the fixing frame 1d, a limiting shaping plate 3d, and a mechanism for driving the shaping roller 2d to rotate. Material guide driving mechanism; multiple groups of material guide blocks 2-1d are provided along the circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com