Winding structure for lithium ion battery and manufacturing process thereof

A technology of lithium-ion battery and preparation process, which is applied in the field of lithium-ion battery winding structure and its preparation process, to achieve uniform stress, improve production efficiency, and eliminate stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

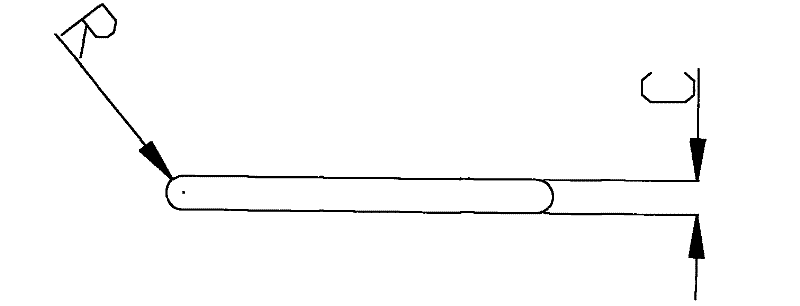

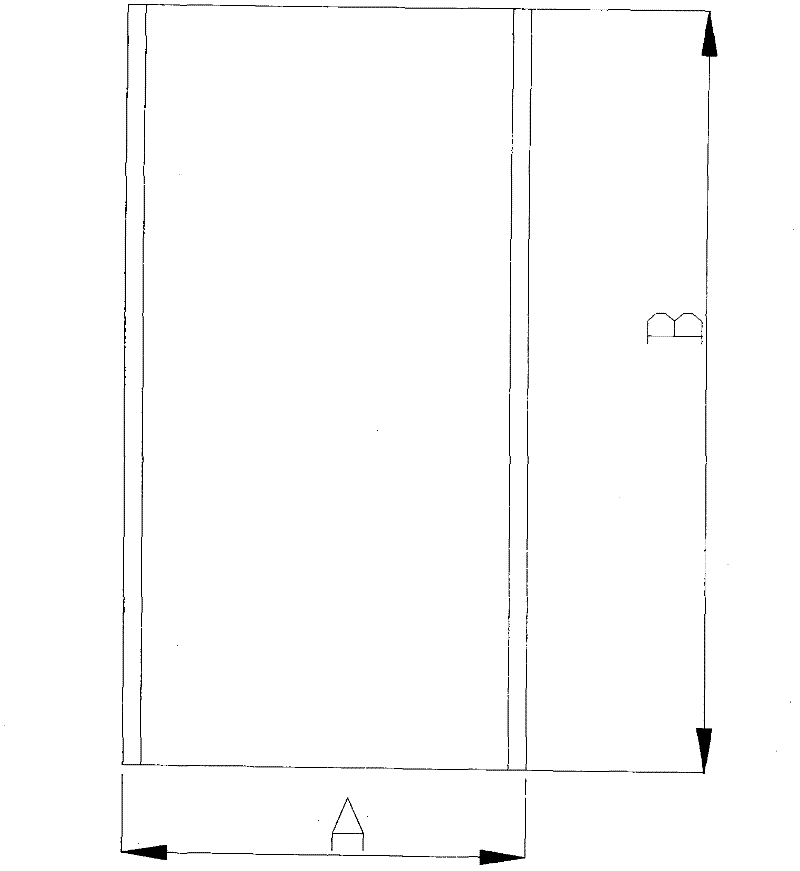

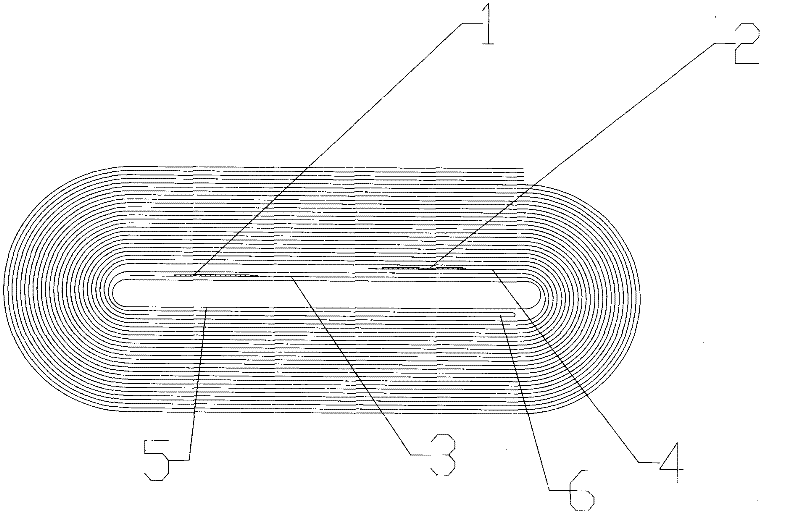

[0027] A battery cell structure of a soft-packaged lithium-ion secondary battery, the battery cell is composed of a positive pole piece 4, a negative pole piece 3, a separator 6, and a winding core 5. An aluminum tab 2 is welded on the positive pole piece 4, and the negative pole piece The pole piece 3 is welded with a nickel lug 1, and the inner ring of the isolation film 6 is provided with a winding core 5, the winding core 5 is made of polymer PVDF, a track-shaped winding core, a monomer structure, and a thickness of 0.5 mm. The fillet at both ends is 0.25mm, see figure 1 , the length B of the winding core is the width 79mm of the positive pole piece 4, and the width A of the winding core is 32mm, see figure 2 , the present embodiment takes the semi-automatic winding type flexible packaging lithium-ion battery 904589 (thickness 9.0mm, width 45.0mm, length 89.0mm) as an example. Such as figure 1 As shown, it is completed according to the following steps: a. Wind the posit...

Embodiment 2

[0029] A battery cell structure of a soft-packaged lithium-ion secondary battery, the battery cell is composed of a positive pole piece 4, a negative pole piece 3, a separator 6, and a winding core 5. An aluminum tab 2 is welded on the positive pole piece 4, and the negative pole piece The pole piece 3 is welded with a nickel lug 1, and the inner ring of the isolation film 6 is provided with a winding core 5, the winding core 5 is made of polymer PEO, a track-shaped winding core, a monomer structure, and a thickness of 0.5mm. The fillet at both ends is 0.25mm, see figure 1 , the length B of the winding core is the width 79mm of the positive pole piece 4, and the width A of the winding core is 32mm, see figure 2 , the present embodiment takes the semi-automatic winding type flexible packaging lithium-ion battery 904589 (thickness 9.0mm, width 45.0mm, length 89.0mm) as an example. Complete according to the following steps: a. Wind the positive pole piece 4, the negative pole p...

Embodiment 3

[0031] A battery cell structure of a soft-packaged lithium-ion secondary battery, the battery cell is composed of a positive pole piece 4, a negative pole piece 3, a separator 6, and a winding core 5. An aluminum tab 2 is welded on the positive pole piece 4, and the negative pole piece The pole piece 3 is welded with a nickel lug 1, and the inner ring of the isolation film 6 is provided with a winding core 5, the winding core 5 is made of polymer PMMA, a track-shaped winding core, a monomer structure, and a thickness of 0.5mm. The fillet at both ends is 0.25mm, see figure 1 , the length B of the winding core is the width 79mm of the positive pole piece 4, and the width A of the winding core is 32mm, see figure 2 , the present embodiment takes the semi-automatic winding type flexible packaging lithium-ion battery 904589 (thickness 9.0mm, width 45.0mm, length 89.0mm) as an example. Complete according to the following steps: a. Wind the positive pole piece 4, the negative pole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com