A continuous ice production device

A technology of ice pellets and ice making chambers, which is applied in the field of continuous ice pellet production equipment, can solve the problems of not being able to continuously produce round ice pellets, low ice pellet preparation efficiency, and easy melting of ice pellets, so as to ensure heat transfer Effect of driving temperature difference, light weight, and improving freezing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, and the content of the present invention will be illustrated by means of the following examples, rather than limiting the scope of the present invention.

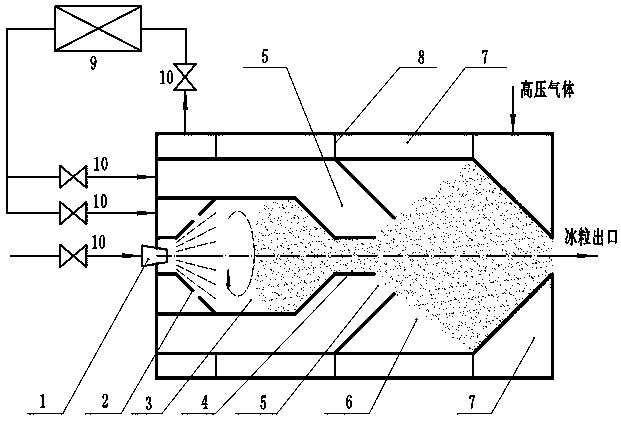

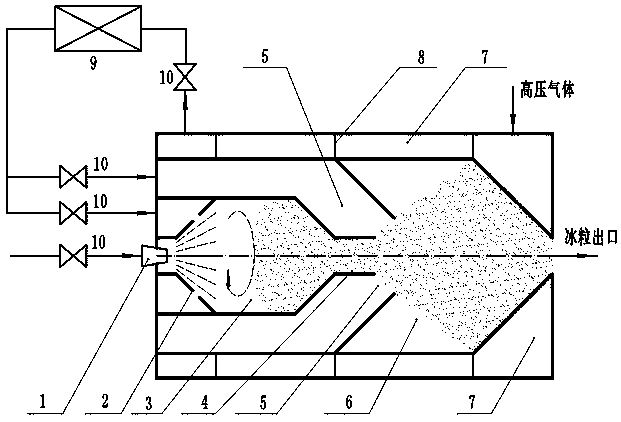

[0014] Such as figure 1 The continuous ice production device shown includes atomizing nozzle 1, swirl nozzle 2, ice making chamber 3, hollow pipe 4, hollow circulation nozzle 5, mixing chamber 6, pre-cooling chamber 7, swirl partition 8, Cryogenic refrigerator 9 and valve 10. The atomizing nozzle 1 and the swirl nozzle 2 are arranged at the front of the ice-making chamber 3, the atomizing nozzle 1 is arranged at the center, the swirl nozzle 2 is arranged around the atomizing nozzle 1, and a hollow pipe 4 is arranged at the end of the ice-making chamber 3, and the hollow pipe 4 The outside is a hollow circulation nozzle 5, the rear part of the hollow circulation nozzle 5 is a mixing chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com