Rounding machine for filter screen of oil filter

A technology of oil filter and filter screen, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as filter screen deformation, and achieve the effect that meets welding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

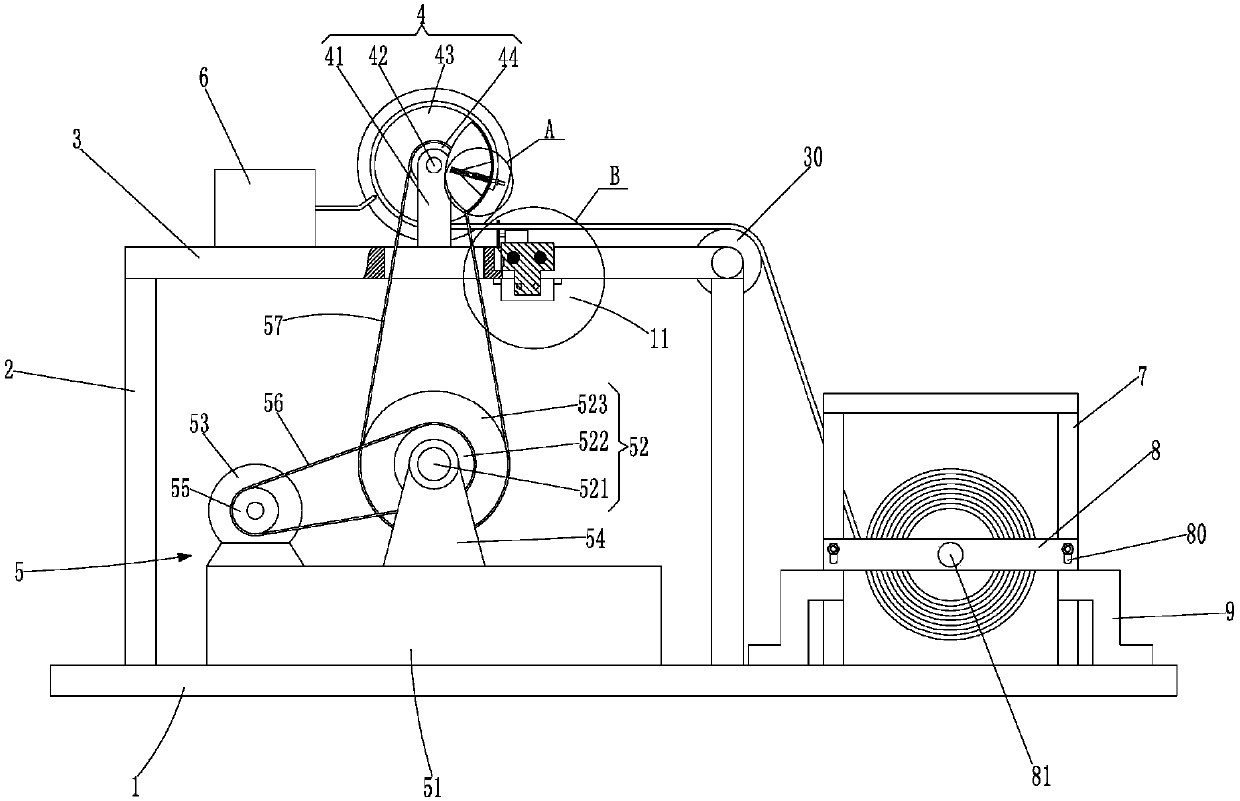

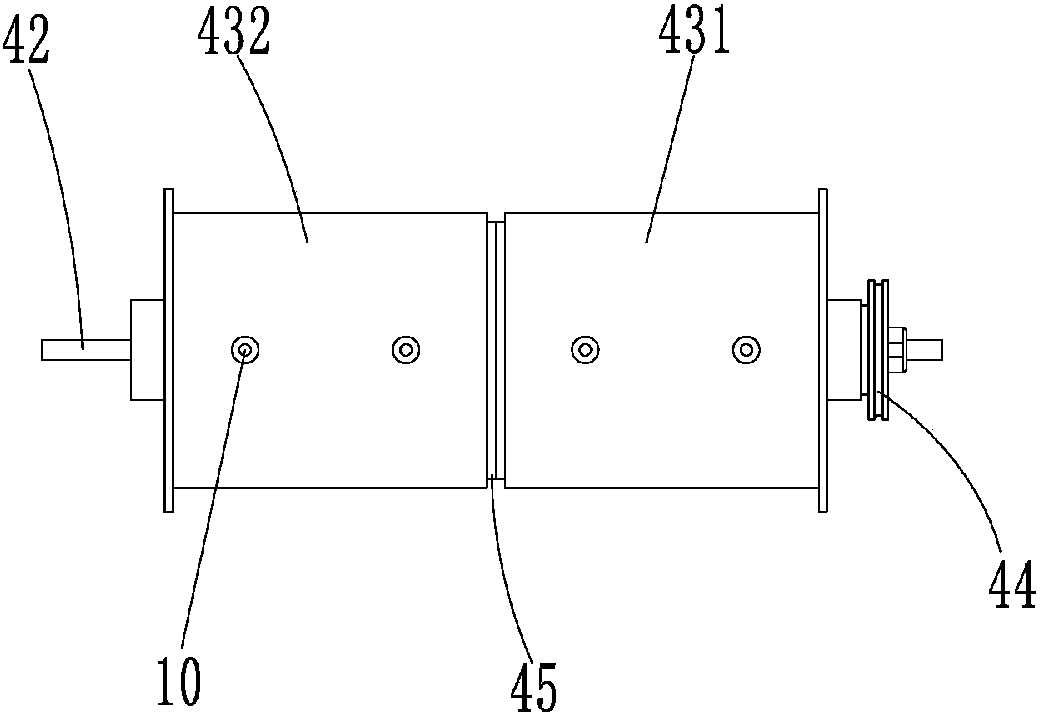

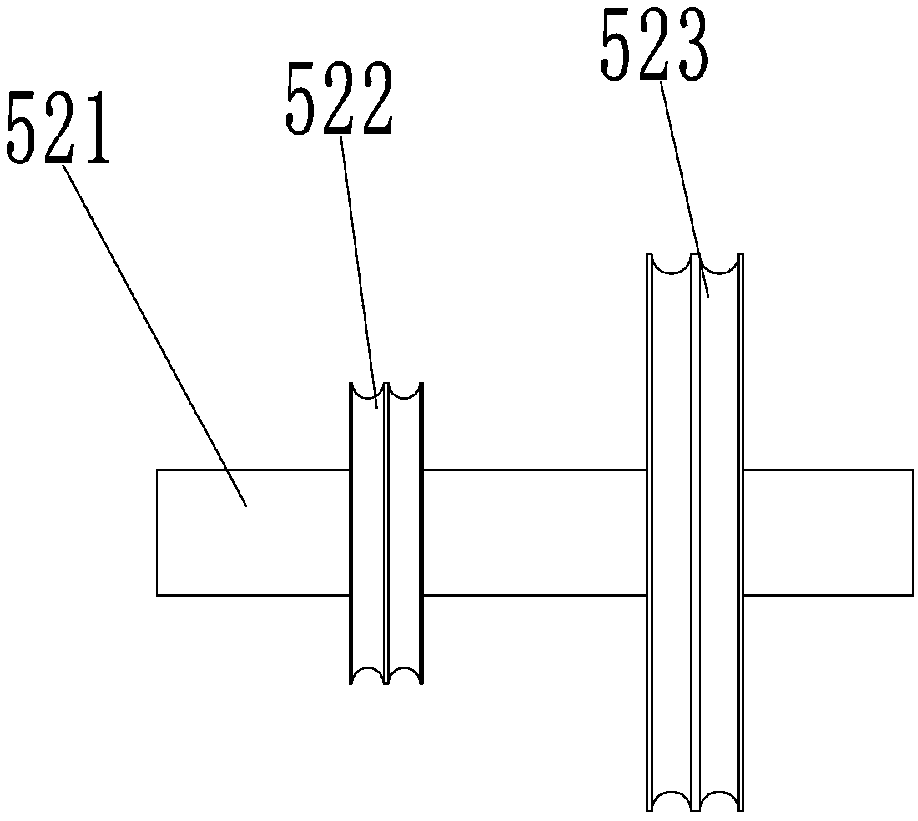

[0019] like Figure 1 to Figure 5 As shown, a round wrapping machine for the filter screen of an oil filter according to the present invention includes a base 1 on which a workbench and a raw material rack 7 are arranged side by side, wherein the raw material rack 7 includes a support frame , both sides of the support frame are provided with an adjusting plate 8, and the middle part of the adjusting plate 8 is rotated to be provided with a discharge shaft 81 for installing the filter screen raw material. 81, when the filter screen is dragged, it drives the discharge shaft 81 to rotate, thereby discharging the raw material of the filter screen; in order to support the adjustment plate 8 and ensure that the adjustment plate 8 has good bearing capacity, the There is a support frame 9 for supporting the adjustment plate 8. In order to facilitate the installation of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com