Nitrogen-doped mesoporous carbon supported platinum catalyst as well as preparation method and application thereof

A technology of nitrogen-doped mesoporous carbon and nitrogen-doped porous carbon, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, and can solve the problem of low catalytic activity and selectivity of catalysts and the loss of catalytically active substances , unable to meet the catalytic conditions and other problems, to achieve good catalytic activity and selectivity, ensure catalytic performance, and ensure the effect of reducing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a nitrogen-doped mesoporous carbon-supported platinum catalyst, comprising the following steps:

[0025] The magnesium source solution is mixed with the nitrogen source, and then evaporated and foamed sequentially to obtain a foam;

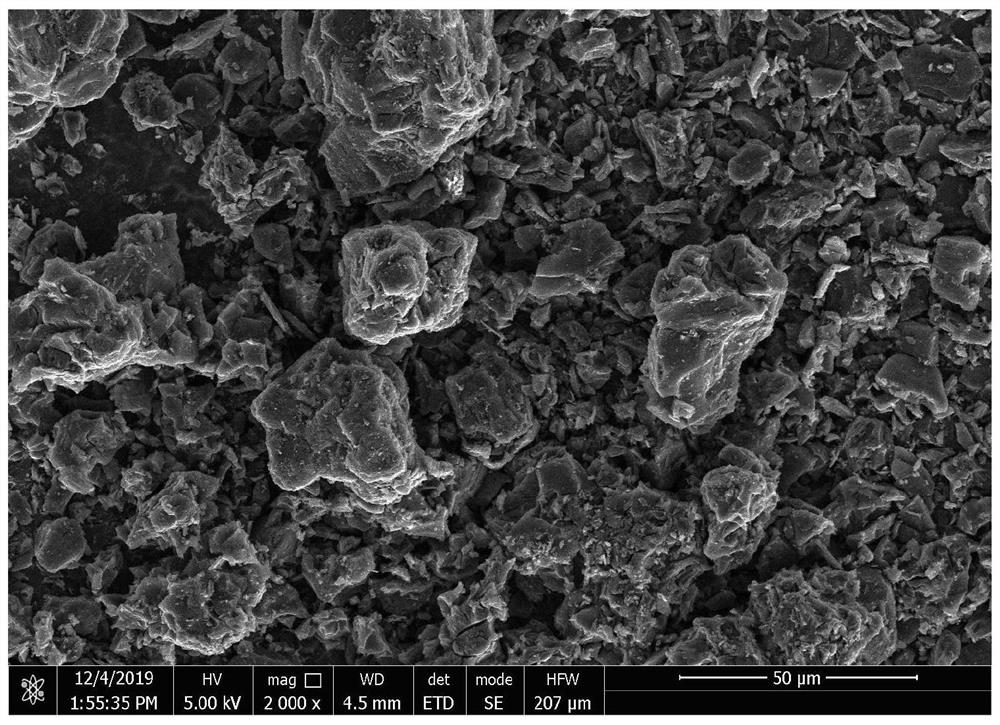

[0026] Sequentially crushing and calcining the foam to obtain a calcined material;

[0027] Pickling, washing and drying the calcined material in sequence to obtain a nitrogen-doped porous carbon material;

[0028] The nitrogen-doped porous carbon material is sequentially subjected to Pt loading and reduction treatment to obtain the nitrogen-doped mesoporous carbon-supported platinum catalyst.

[0029] In the present invention, unless otherwise specified, each component is a commercially available product well known to those skilled in the art.

[0030] In the invention, the magnesium source solution is mixed with the nitrogen source, followed by evaporation and foaming treatment in sequence t...

Embodiment 1

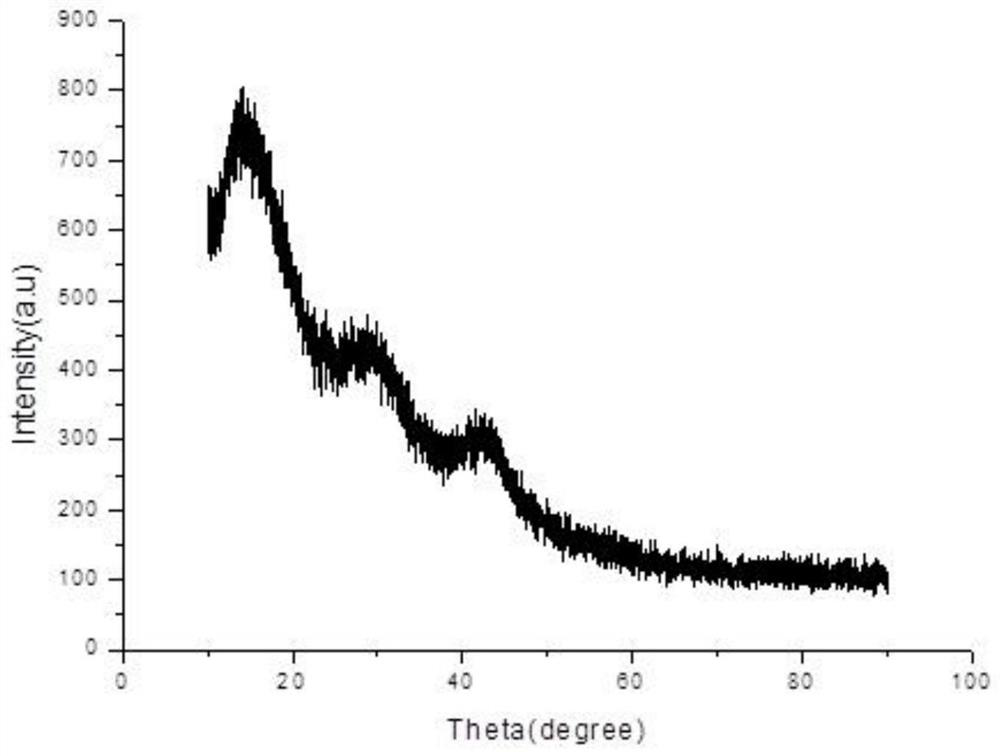

[0046] Dissolve 703.4g of magnesium citrate nonahydrate (100mmol) in 20mL of deionized water to obtain a magnesium citrate solution; mix and stir the resulting magnesium citrate solution with 1.2012g of urea (20mmol) for 10min and evaporate in a water bath at 90°C for 6 After removing most of the water for ~8 hours, heat it in an oven at 140°C for 4 hours to make it fully foamed to obtain a foam; after grinding the obtained foam, calcinate it at 700°C under a nitrogen atmosphere for 4 hours to obtain a calcined material ; Reflux the obtained calcined material with a 3mol / L hydrochloric acid solution at 85°C for 6 hours to remove MgO in the calcined material, wash the product with distilled water until neutral, and dry it in an oven at 100°C for 12 hours to obtain a nitrogen-doped porous carbon material;

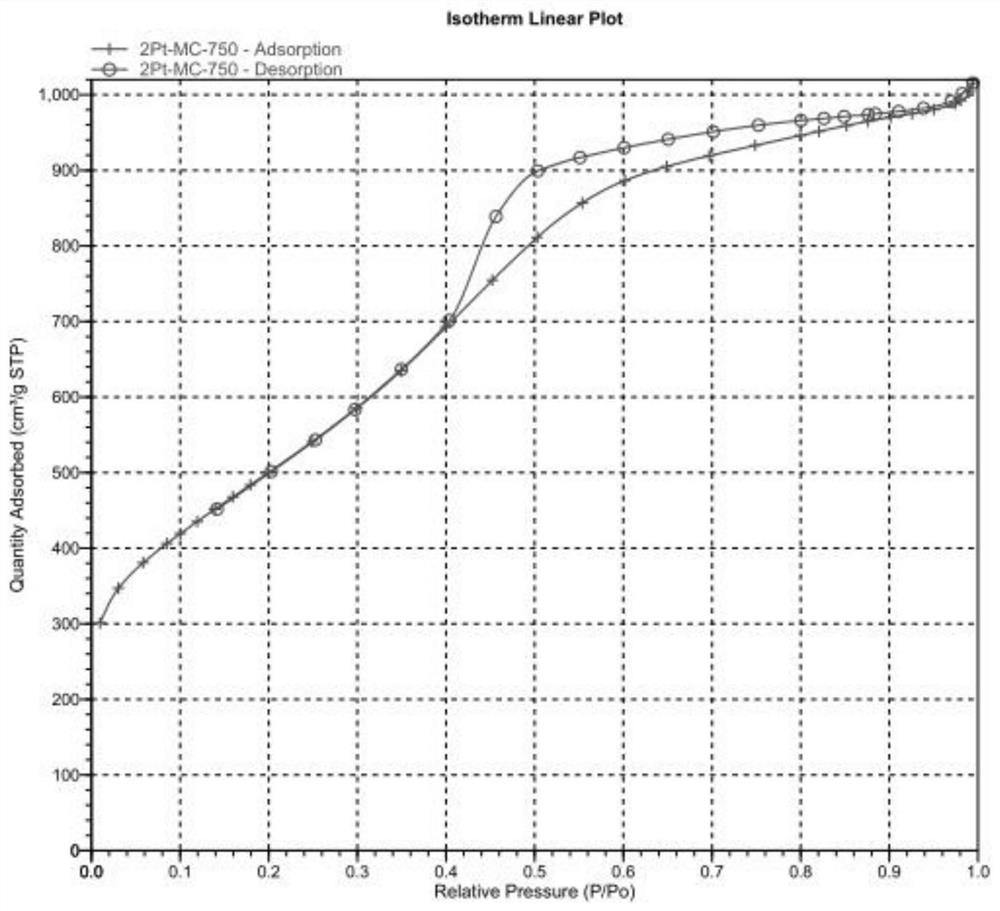

[0047] 3g of nitrogen-doped porous carbon material, 0.06g of Pt aqueous solution (Pt mass concentration: 2%) and 20mL of deionized water were ultrasonically dissolved for 3 mi...

Embodiment 2

[0055] Dissolve 703.4g of magnesium citrate nonahydrate (100mmol) in 20mL of deionized water to obtain a magnesium citrate solution; mix and stir the resulting magnesium citrate solution with 1.2012g of urea (20mmol) for 10min and evaporate in a water bath at 70°C for 6 After ~8h to remove most of the water, heat it in an oven at 140°C for 4h to fully foam to obtain a foam; after grinding the obtained foam, calcinate at 900°C under a nitrogen atmosphere for 4h to obtain a calcined material ; Reflux the obtained calcined material with a 3mol / L hydrochloric acid solution at 85°C for 6 hours to remove MgO in the calcined material, wash the product with distilled water until neutral, and dry it in an oven at 100°C for 12 hours to obtain a nitrogen-doped porous carbon material;

[0056] 3g of nitrogen-doped porous carbon material, 0.06g of Pt aqueous solution (Pt mass concentration: 2%) and 20mL of deionized water were ultrasonically dissolved for 3 minutes to make them evenly disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com