Micro-concave roller pressing formation device

A press forming and concave roll technology, which is applied in the field of pressing lathes in micro concave roll forming equipment, can solve the problems of low pressing precision and complex counterweight, and achieve the effects of tight and reliable design, elimination of abnormal force, and improvement of product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

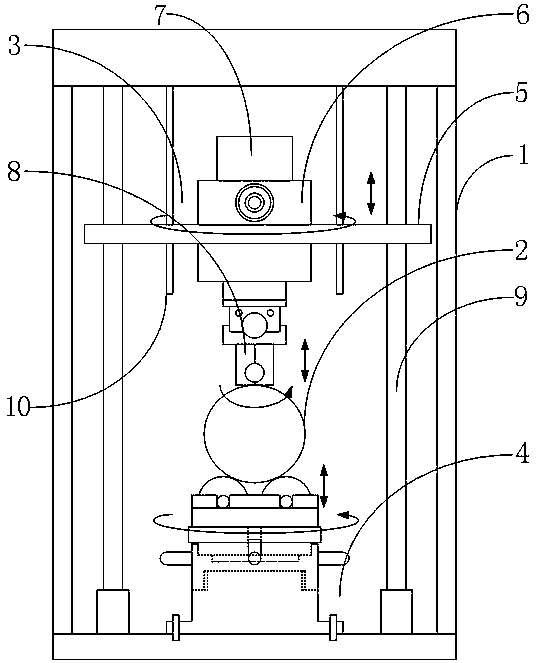

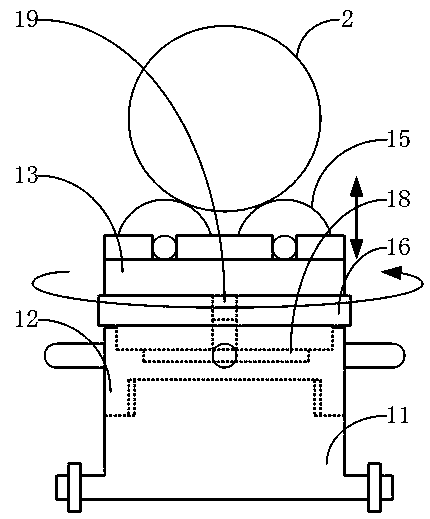

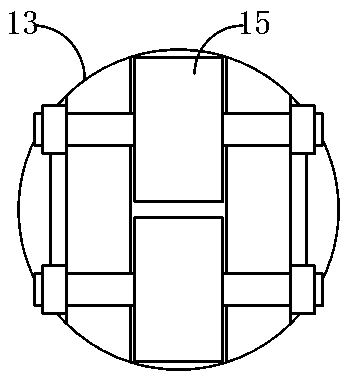

[0031] The invention provides micro concave roll press forming equipment. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

[0032] Micro concave roller press molding equipment, such as Figure 1 to Figure 4 As shown, the frame base body 1 is included, and the frame base body 1 is movably arranged on the carriage platform, and the frame base body 1 has a linear reciprocating movement along the axial direction of the dimple roller 2 .

[0033] That is, the dimpled roller 2 is driven to rotate, and the frame base 1 moves linearly and reciprocally to press and shape the layout of the dimpled roller 2 .

[0034] The frame base 1 is provided with a pneumatic knife holder mechanism 3 for pressing and forming the layout of the dimpled roller 2 and a floating support mechanism 4 for floatingly supporting the dimpled roller 2 .

[0035] Among them, the pneu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com