Surface printing technology for multi-edge-angle polygonal flexible hose

A surface printing, polygonal technology, applied in the direction of printing, printing devices, etc., can solve the problems of inability to print pictures and texts, and the printing quality cannot be achieved, and achieve the effect of adhesion fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

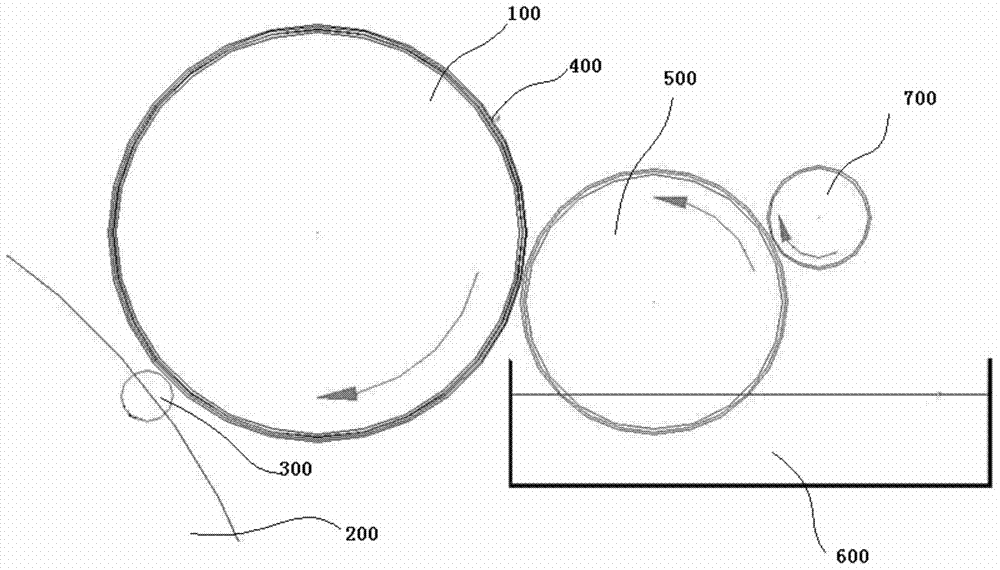

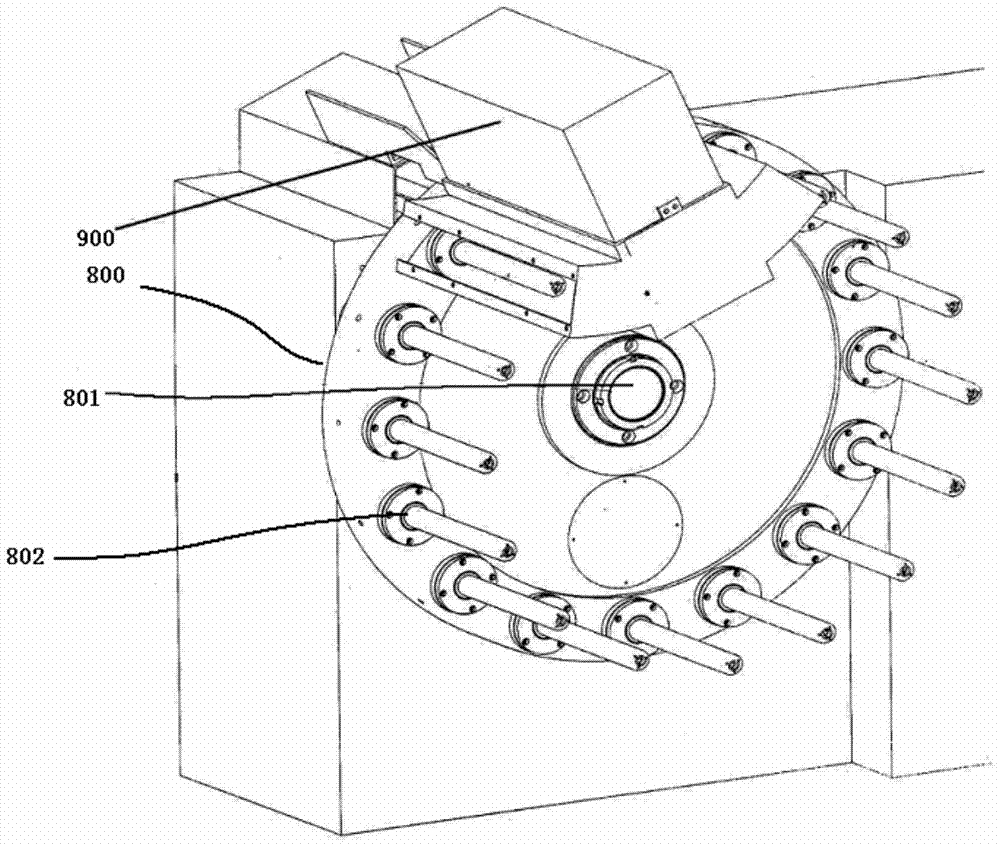

[0029] The surface printing process of multi-angular and polygonal hose comprises the following steps: pre-press processing and printing.

[0030] (1) Prepress processing

[0031] 1) Select the design originals of printed photos or pictures provided by customers; select pictures and photos suitable for multi-sided and angular hoses (such as photo contrast, layers, image clarity, and memory)

[0032] 2) Perform image gray balance processing on photos or pictures provided by customers, and select and process pre-press elements according to the characteristics of the printing equipment of the enterprise. (such as line number, shape, compensation, etc.)

[0033] 3) Output the processed image to plate-making film or direct CDI plate-making. The num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com