Soft calendering roller equipment for improving smoothness of paper and soft calendering method

A technology of soft calendering and smoothness, applied in calenders, papermaking, paper machines, etc., can solve problems such as high manufacturing and operating costs, poor contact, and complicated sealing structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

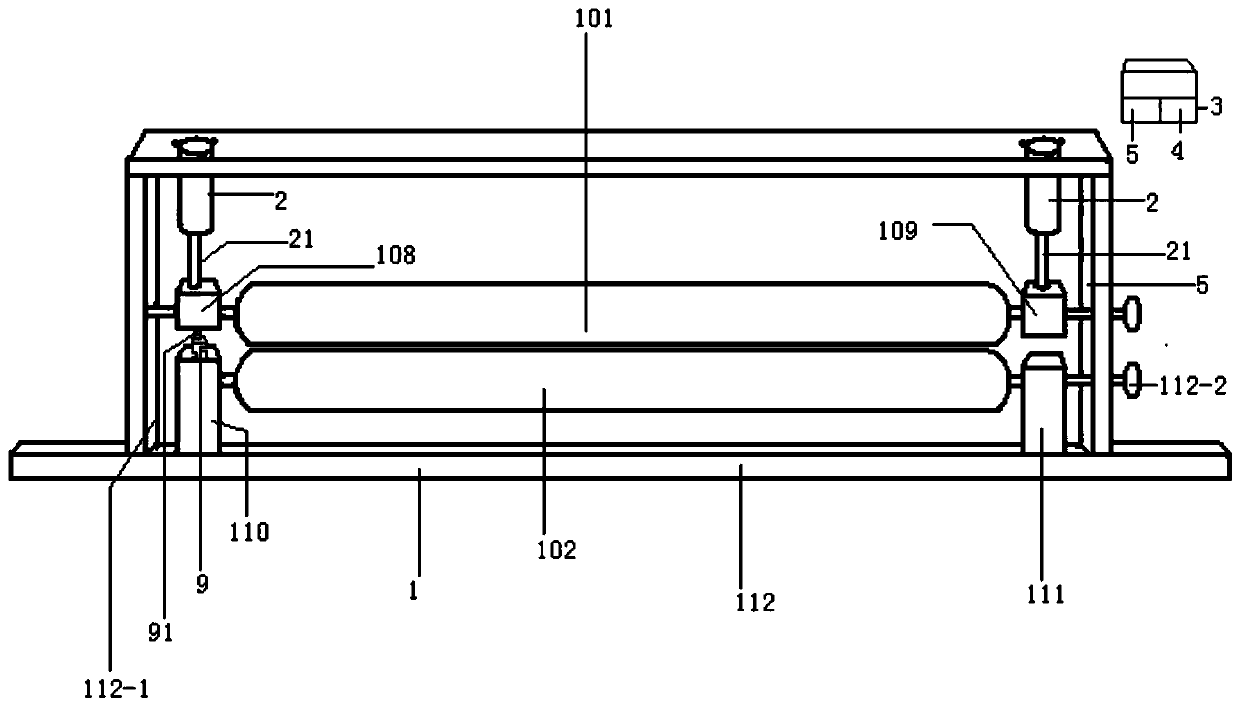

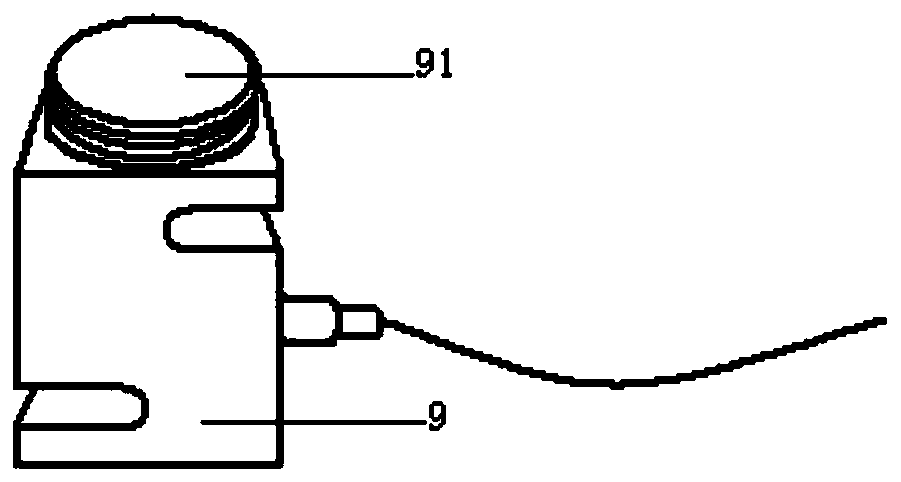

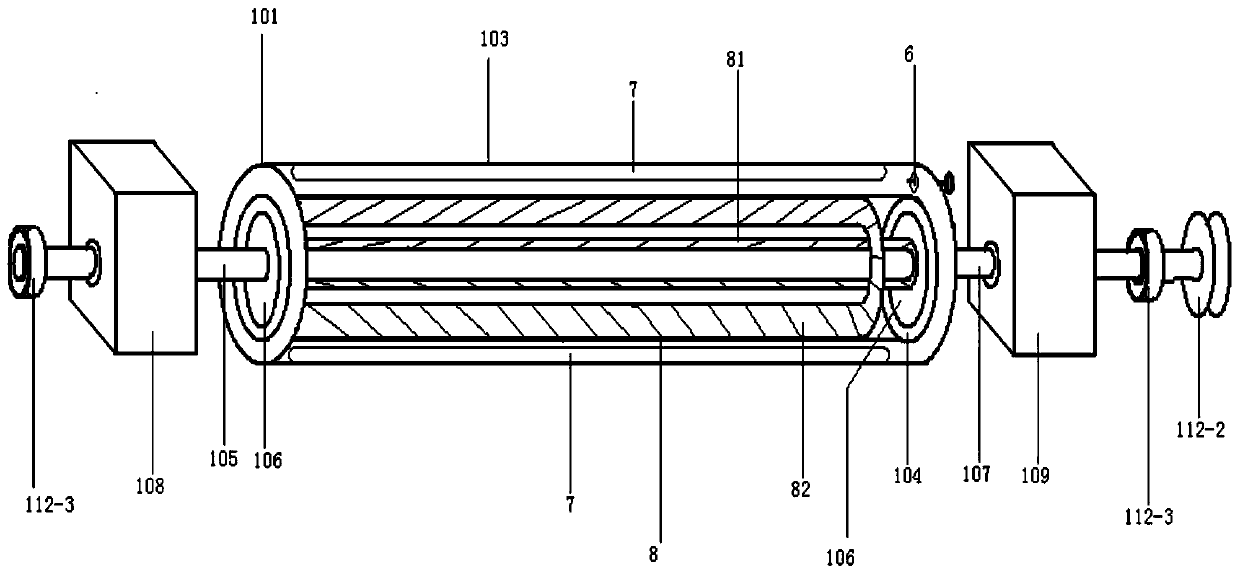

[0027] figure 1 , 2 , shown in 3, a kind of soft calender roll equipment that improves paper smoothness, comprises the soft calender roll equipment body 1 of paper machine, hydraulic oil pump, hydraulic oil cylinder 2, solenoid valve, hydraulic oil pipe, switching power supply 5, temperature control Switch 6, electric heating tube 7, the soft calender roll of soft calender roll equipment body 1 is divided into upper soft calender roll 101 and lower soft calender roll 102, and also has self-induction power generation heating mechanism 8, pressure monitoring switch 9, Data processing module 4, the rollers of the upper and lower soft calender rollers 101 and 102 of the soft calender roll equipment body are divided into inner and outer layers, in which three electric heating tubes 7 are distributed in a ring and pass through the screw nut and the The fixing clips are horizontally installed inside the roller outer layer 103 of the upper soft calendering roll 101, and the other thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com