A method and device for controlling pinch rollers

A pinch roll and control pinch technology, which is applied in the direction of rolling mill control devices, manufacturing tools, metal rolling, etc., can solve the problems that the surface quality of the strip steel cannot be guaranteed, and the pinch roll surface is easily damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

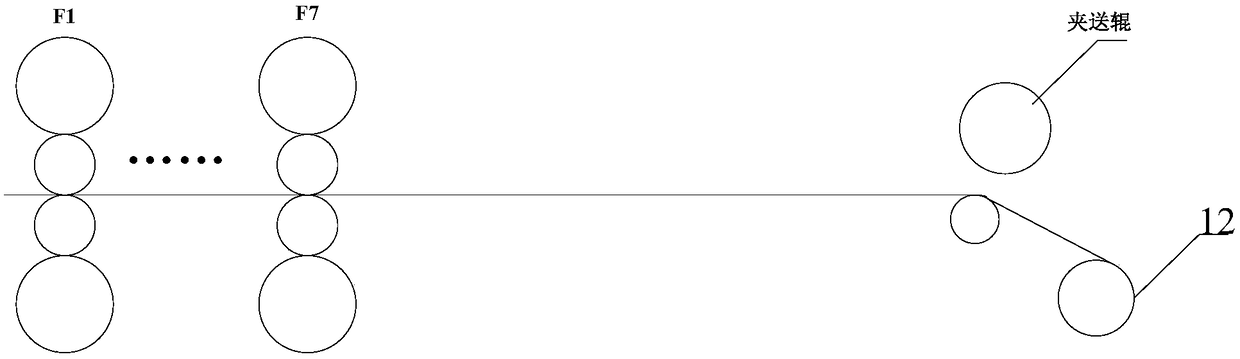

[0031] Before introducing the specific implementation method of this article, here is the production process of the hot rolling production line, such as figure 1 As shown, the hot rolling production line includes: a finishing stand 11 and a coiler 12. The finishing stand includes seven finishing mills, namely: F1 stand, F2 stand, F3 stand, F4 stand, F5 stand Frame, F6 frame, F7 frame; after the strip is finished rolling by the finishing frame, the finished product is coiled by the coiler 12. Among them, a thermal detector is also provided on the production line before the coiler 12.

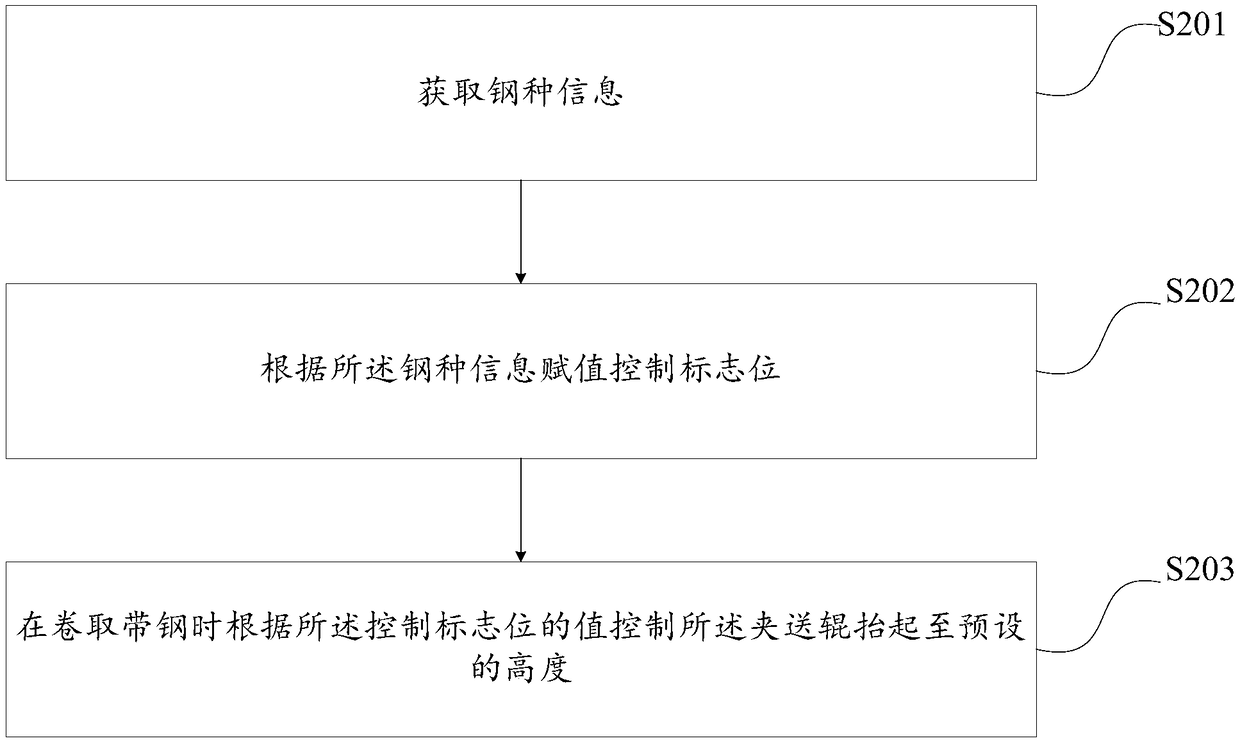

[0032] This embodiment provides a method for controlling the pinch roller, such as figure 2 As shown, the method includes:

[0033] S201, obtaining steel grade information.

[0034] In this step, the primary control system reads steel grade information from the steel grade information database PDI. The steel grade information includes parameters such as steel grade model, strip thickness, strip width,...

Embodiment 2

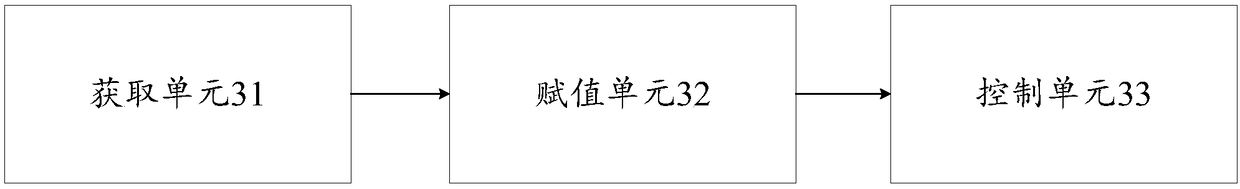

[0042] Corresponding to the first embodiment, this embodiment also provides a device for controlling the pinch roller, see image 3 , The device includes: an acquisition unit 31, an assignment unit 32, and a control unit 33; wherein,

[0043] The acquiring unit 31 is used to acquire steel grade information; the acquiring unit 31 belongs to a primary control system, and the acquiring unit 31 reads steel grade information from the steel grade information database PDI, and the steel grade information includes: steel grade Parameters such as model, strip thickness, strip width, target rolling temperature, etc. Wherein, the first-level control system is used to issue instructions, and the first-level control system is a PLC control system.

[0044] The assignment unit 32 is used to assign the control flag bit according to the steel grade information; here, because each steel grade is different, the corresponding rolling process is also different. Therefore, after the acquisition unit 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com