Hydraulic drives and systems

A driving device, hydraulic technology, applied in the direction of fluid pressure actuating device, servo motor, mechanical equipment, etc., can solve the problems of slow response of hydraulic actuator, difficult to meet the expected requirements, etc., to increase the compression volume and increase the pressure. Accuracy, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to help those skilled in the art to accurately understand the subject matter claimed by the present invention, specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

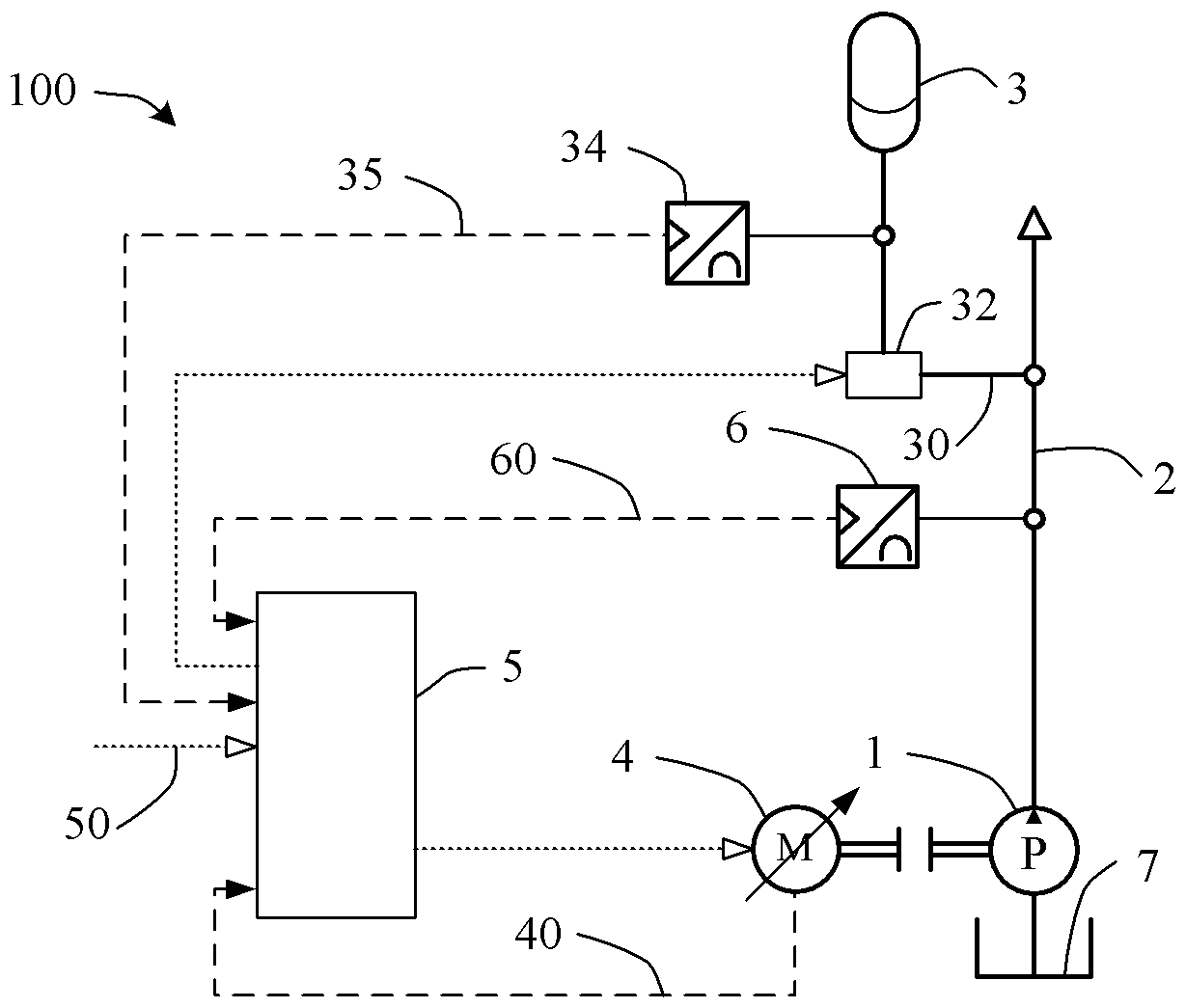

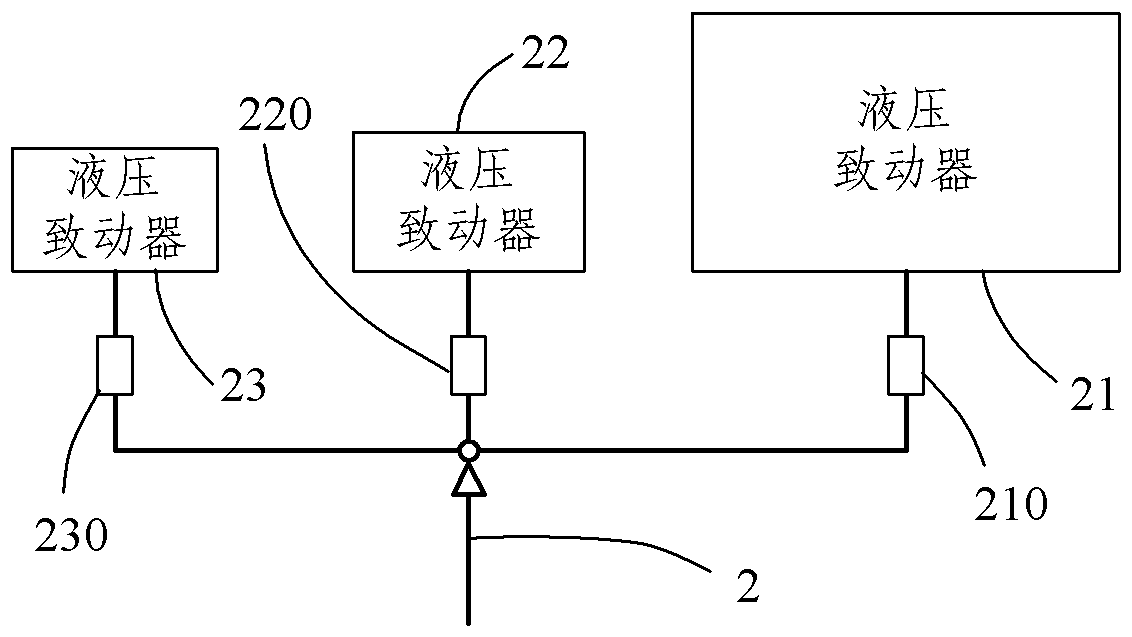

[0027] figure 1 A schematic diagram showing a hydraulic drive device according to a specific embodiment of the present invention, such as figure 1 As shown, a hydraulic drive device 100 according to a specific embodiment of the present invention includes a hydraulic pump 1, an accumulator 3, and a control unit 5. Among them, the hydraulic pump 1 pumps hydraulic fluid from the reservoir 7 into the hydraulic output line 2 for connecting to the hydraulic actuator to be driven. The accumulator 3 is connected to the hydraulic output line 2 through the accumulator line 30. The accumulator line 30 is provided with a flow control device 32. The flow control device 32 may be a system, a valve or other devices. The control unit 5 controls t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com