Patents

Literature

53results about How to "High pressure accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

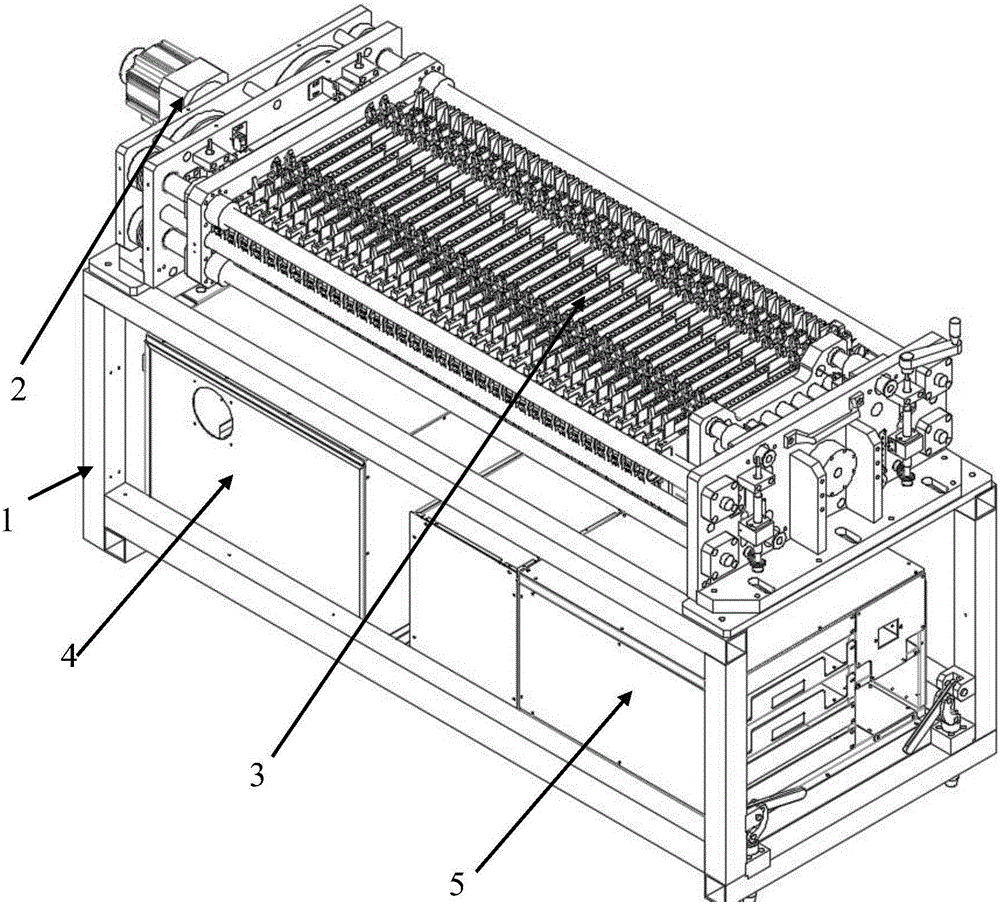

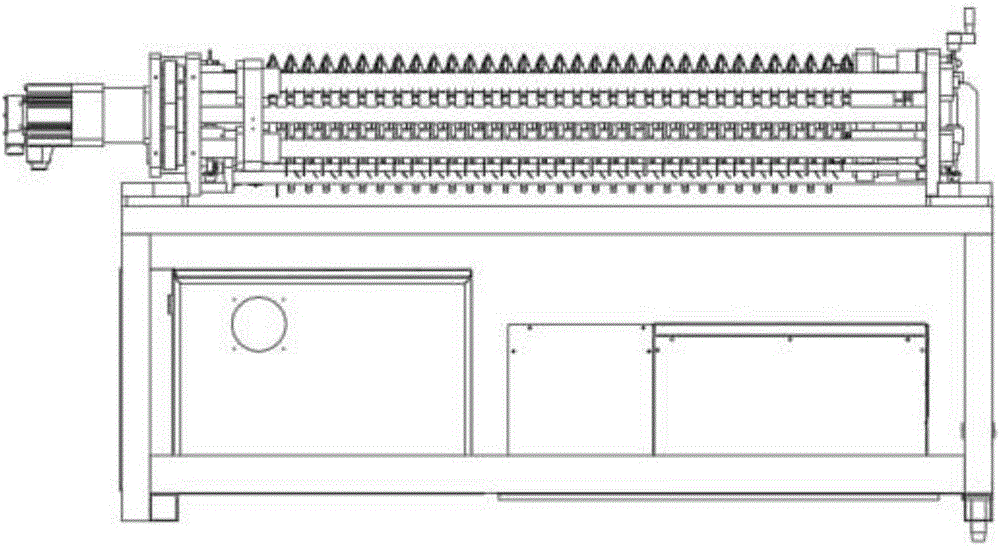

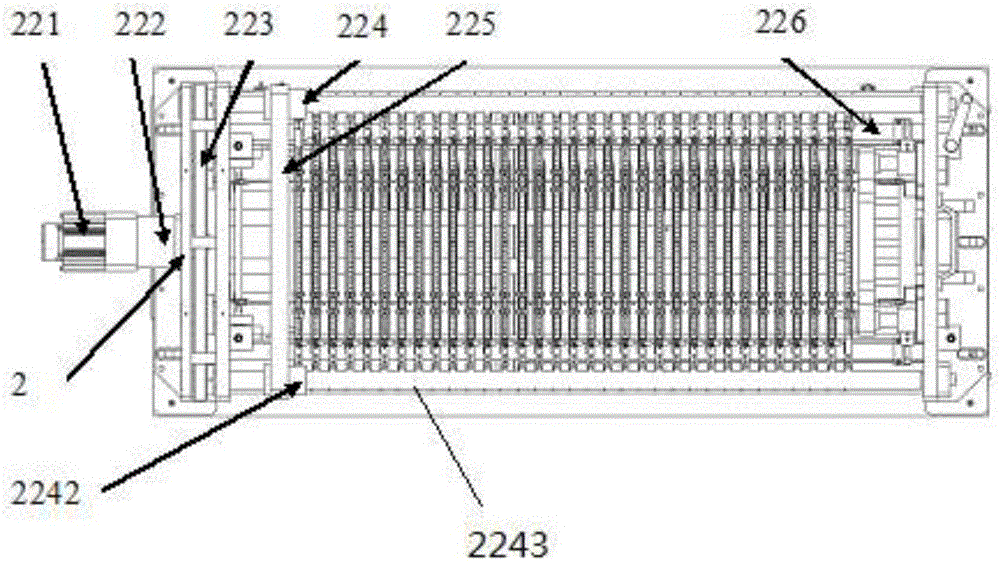

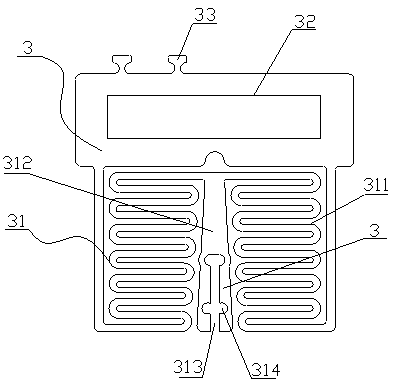

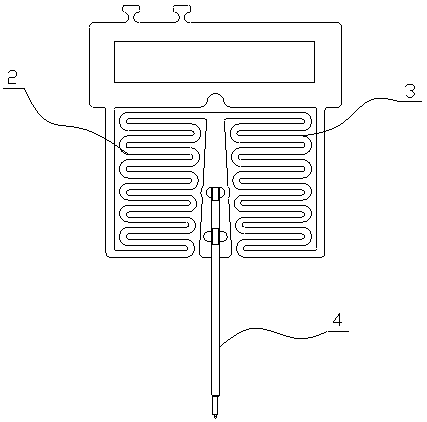

64-channel polymer lithium-ion battery formation clamp machine

PendingCN105958123AReduce transfer processIncrease productivityFinal product manufactureElectrolyte accumulators manufactureLithium electrodeEngineering

The invention discloses a 64-channel polymer lithium-ion battery formation clamp machine, which comprises a rack, a pressure control device, a 64-channel laminated board, a temperature control cabinet and a battery formation cabinet, wherein the pressure control device is arranged on the rack; the 64-channel laminated board is arranged on the pressure control device and comprises a heating plate, clamp pressure plates, temperature sensors, connection chains, silica gel plates and battery tab contact pins for clamping tabs of polymer lithium-ion batteries; a plurality of clamp pressure plates are arranged in parallel; one polymer lithium-ion battery is clamped between every two clamp pressure plates; each heating plate is attached to the surface, for clamping the corresponding polymer lithium-ion battery, of the corresponding clamp pressure plate; each silica gel plate is attached to the surface opposite to the surface on which the corresponding heating plate is arranged; each temperature sensor is arranged in the corresponding clamp pressure plate; and the end parts of the clamp pressure plates are mutually connected through the connection chains. Pressurization, heating and formation are integrated into one clamp, so that the transfer process among the procedures is reduced.

Owner:ZHEJIANG HANGKE TECH

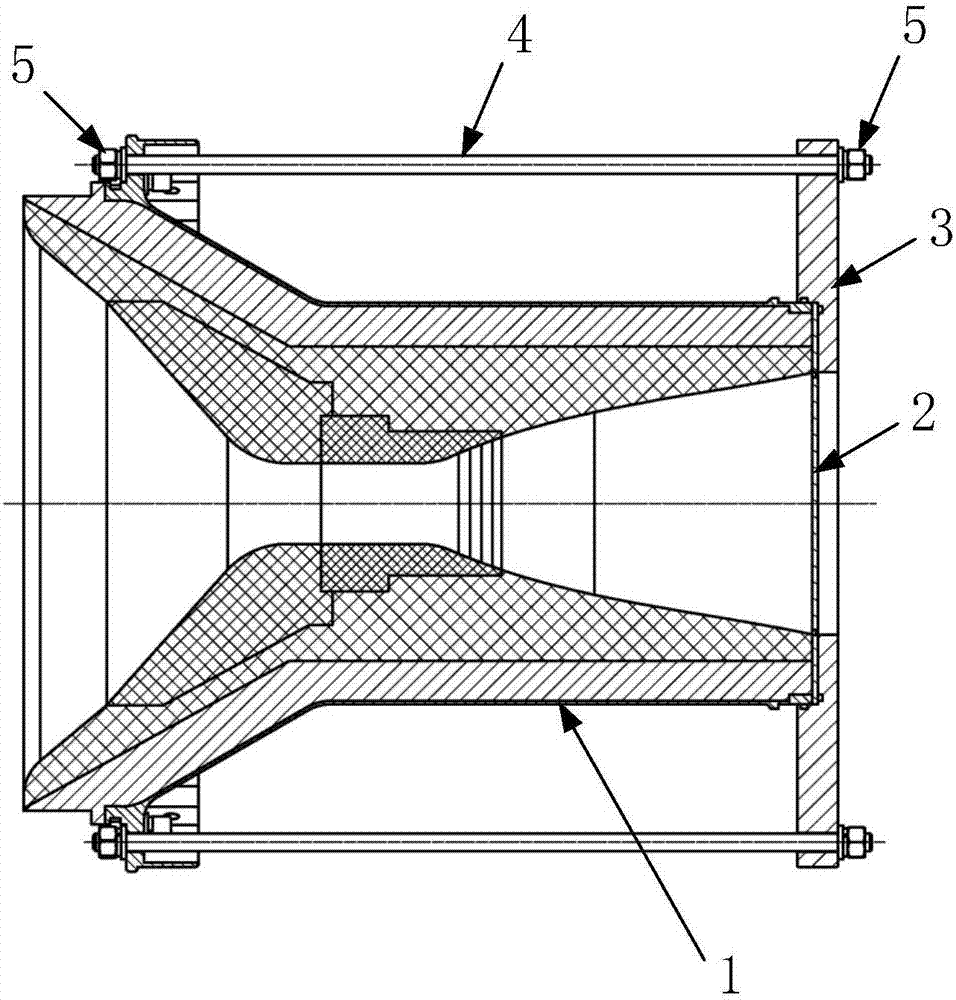

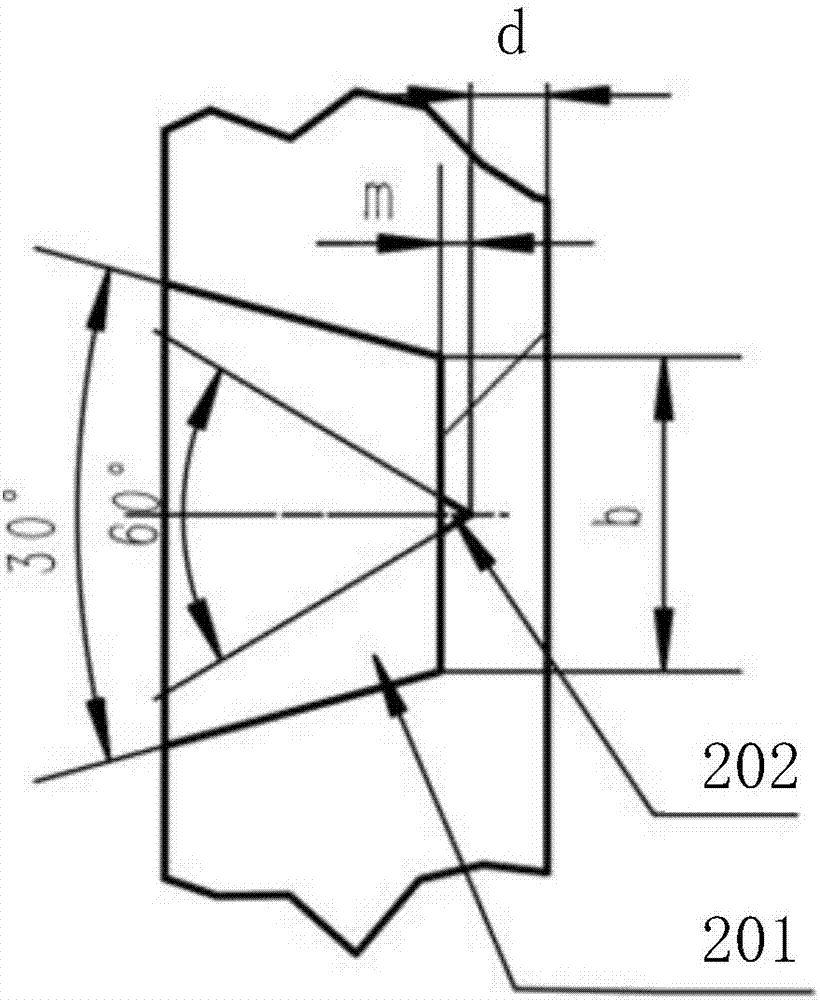

Spray pipe plug cover structure for solid-liquid rocket engine ground test

ActiveCN106930866AEasy to processImprove accuracyRocket engine plantsCombustion chamberMechanical engineering

The invention discloses a spray pipe plug cover structure for a solid-liquid rocket engine ground test. According to the spray pipe plug cover structure, the function of reliably breaking a diaphragm when the pressure intensity of a combustion chamber reaches a set value can be achieved, and the function of the diaphragm in the real working process of a spray pipe can be completely simulated in the test. The spray pipe plug cover structure comprises the diaphragm, a spray pipe plug cover and a long screw, wherein the plug cover diaphragm and a sealing ring are arranged at the end face of the outlet of the spray pipe in a combined mode and are positioned by a spray pipe plug cover tool. The diaphragm, the sealing ring and the spray pipe plug cover are positioned by a spray pipe shell and are fixedly connected and fastened to the head of the spray pipe through a long bolt so as to fix the position of the diaphragm. According to the spray pipe plug cover structure, the diaphragm, the spray pipe plug cover, a spray pipe heat insulation layer and the spray pipe shell are sealed through the sealing ring, so that the air impermeability of the combustion chamber is guaranteed; the diaphragm is convenient to process and install, and the uniformity of the breakage pressure intensity of the diaphragm is good through repeated test verification; and just the diaphragm needs to be replaced during repeated tests, and the spray pipe can be repeatedly used, so that the economical efficiency is good.

Owner:BEIHANG UNIV

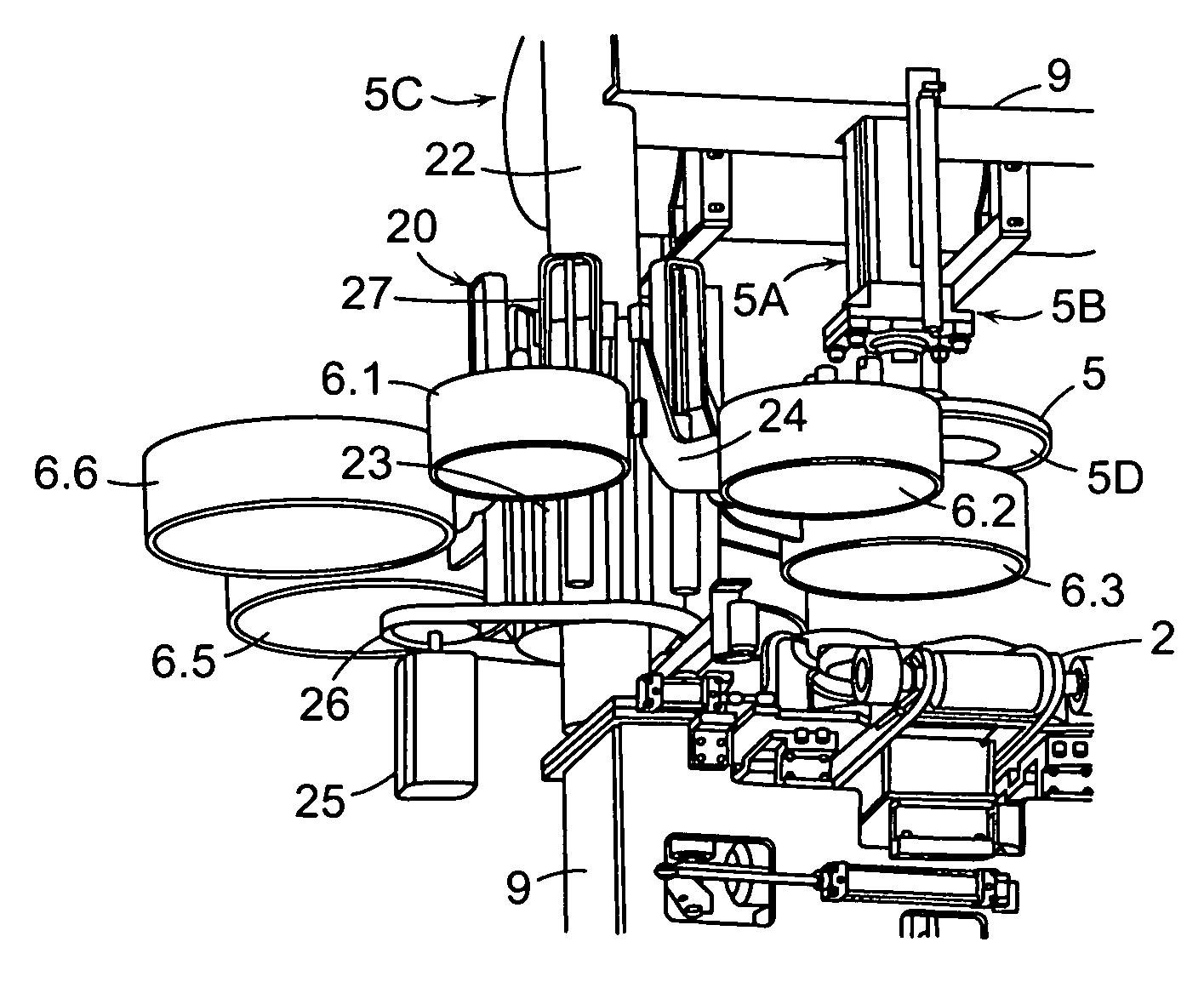

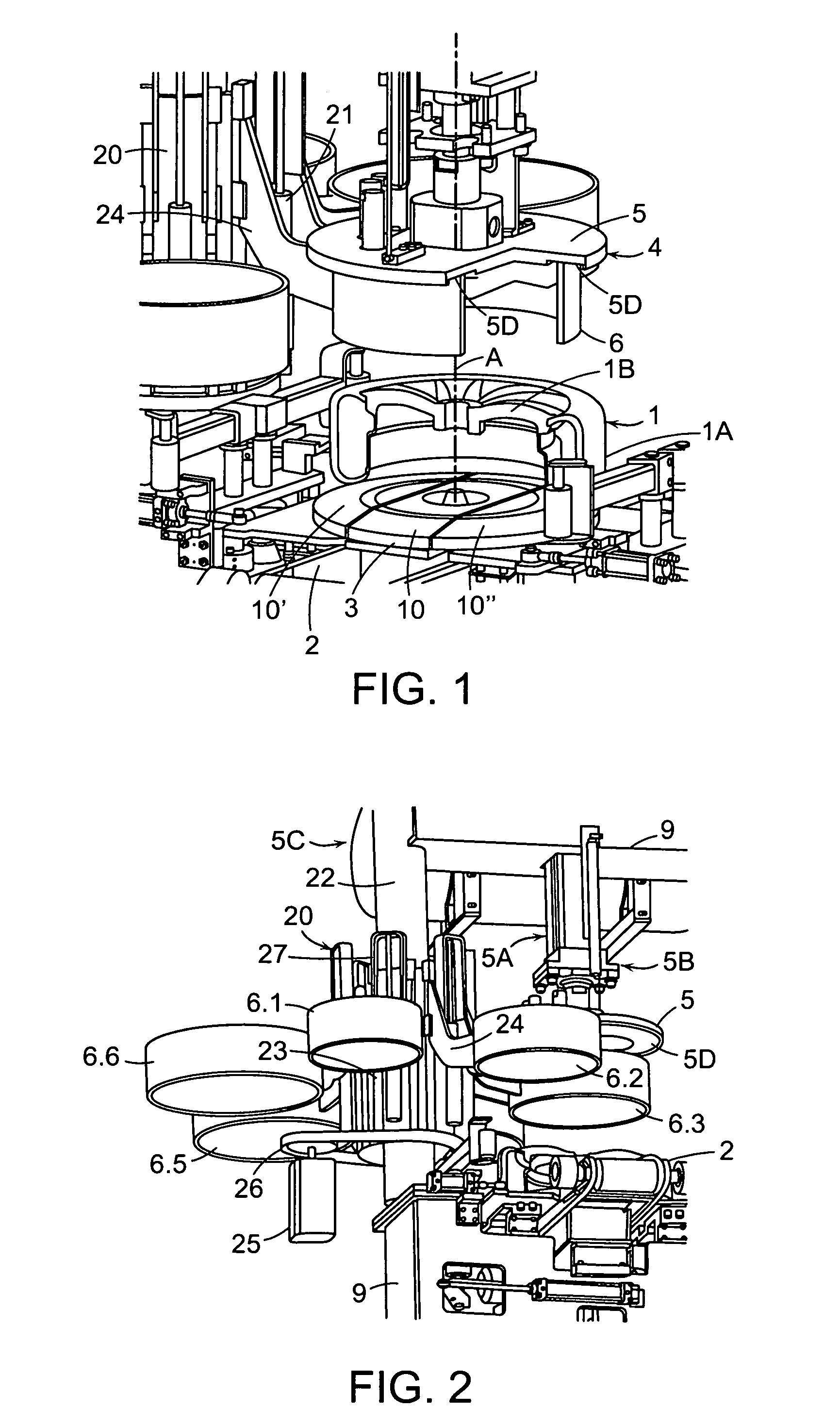

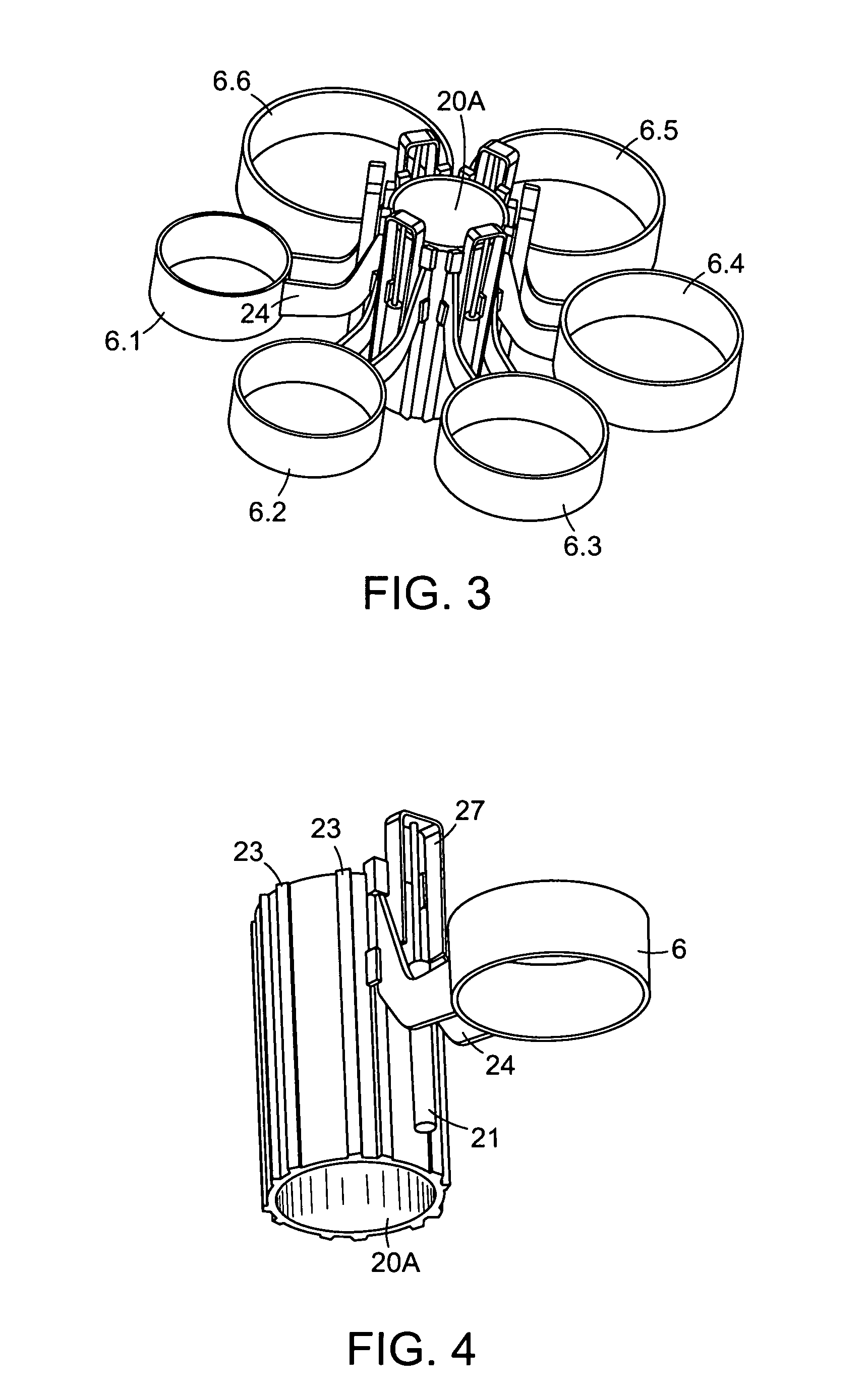

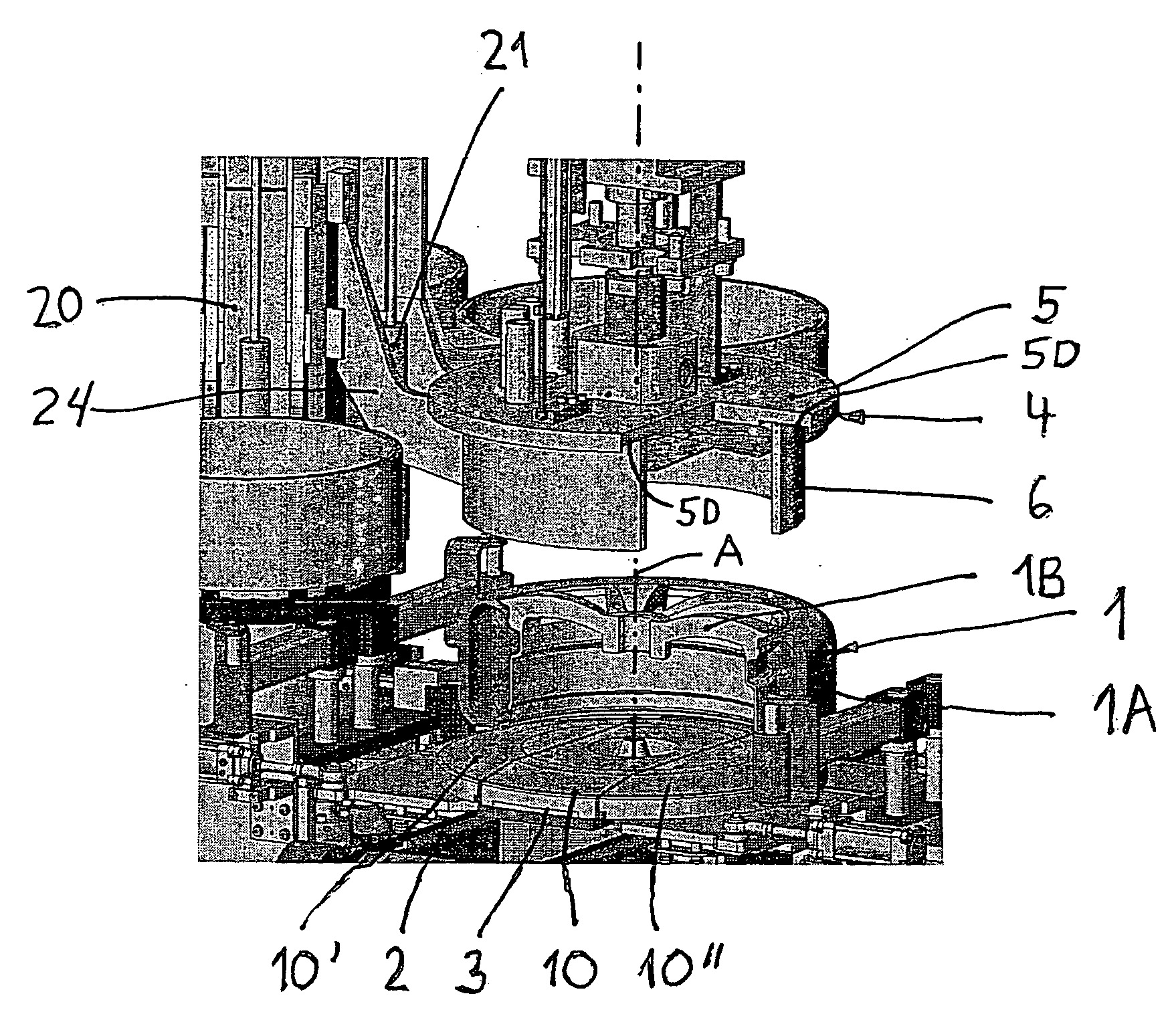

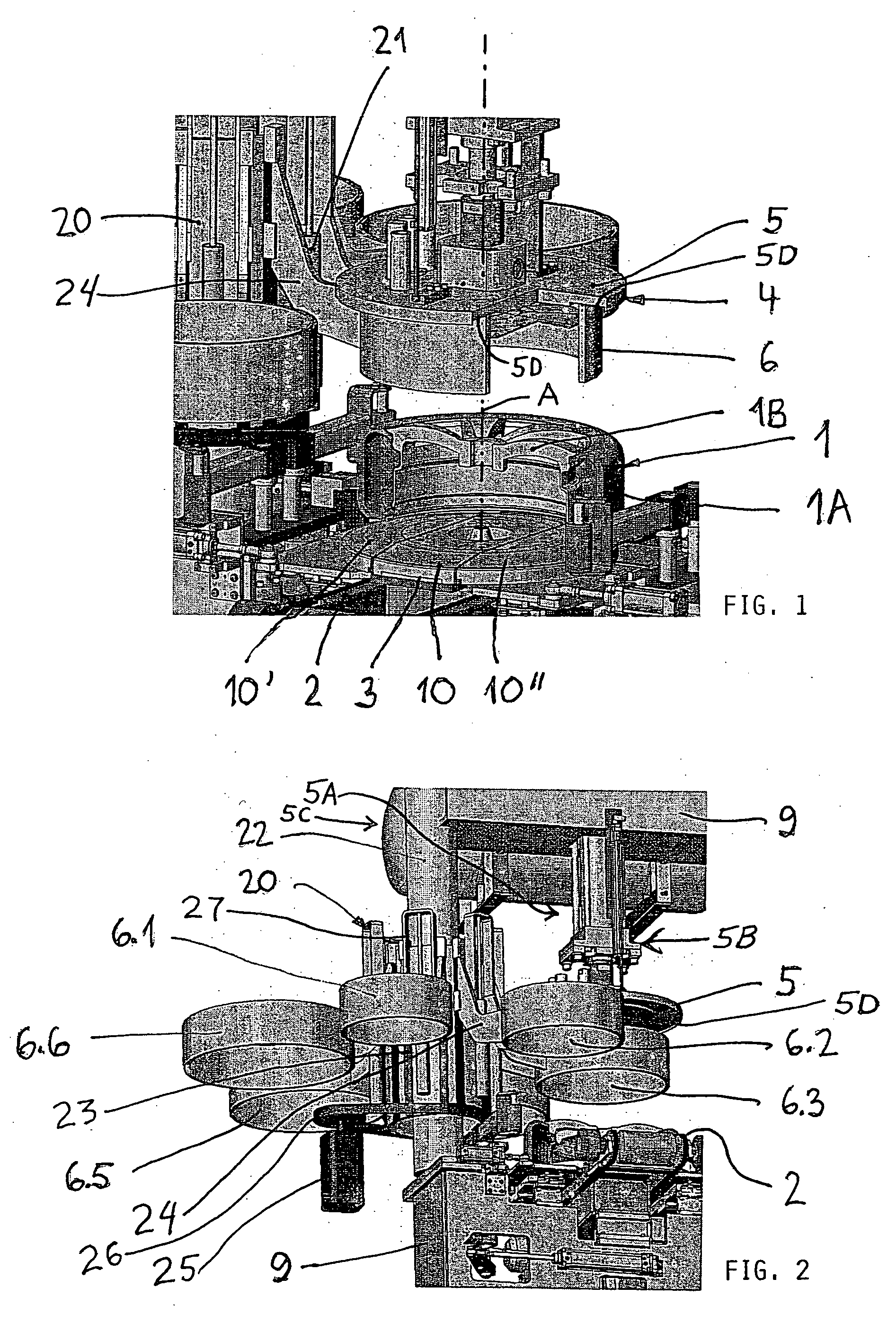

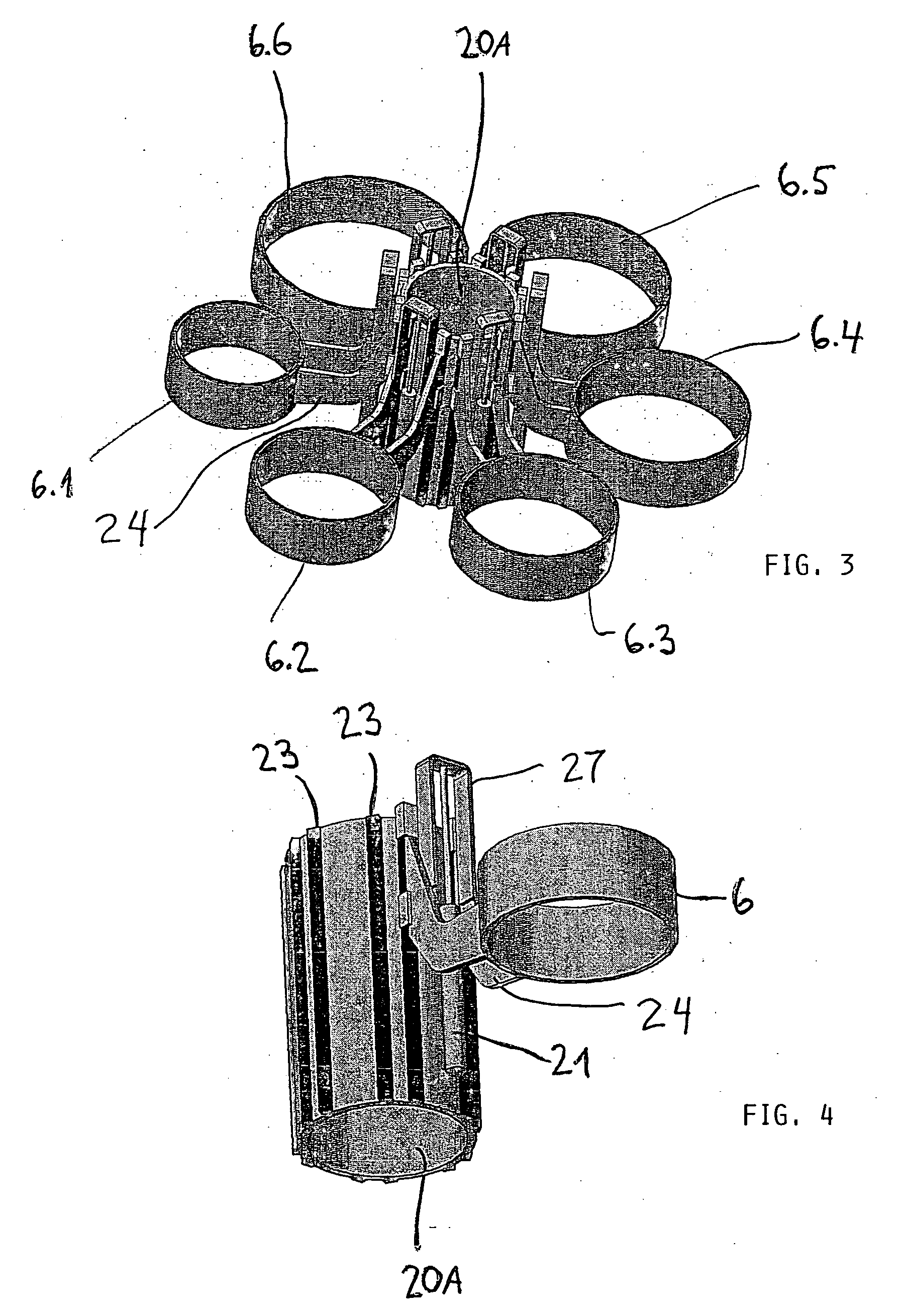

Multi-size tire filling apparatus and method

InactiveUS7506671B2Easy to measureGood reproducibilitySolid materialPackaging under special atmospheric conditionsEngineeringAtmospheric pressure

A tire filling apparatus preferably includes a support and seal arrangement on which a wheel-tire combination is supported in a horizontally lying orientation, a tire filling plate, and a plurality of differently-sized tire filling rings. Based on the diameter of the wheel-tire combination to be filled with air, a properly sized one of the filling rings is selected and positioned coaxially along the wheel axis between the tire and the filling plate. The filling plate moves toward the tire, sealingly contacts the filling ring, and presses the filling ring against the upwardly facing tire sidewall, until an open air filling gap is formed between the tire sidewall bead and the wheel rim. Pressurized air is introduced through the filling plate, the filling ring, and the open air filling gap into the tire interior, until the gap is closed by the increasing air pressure in the tire.

Owner:SCHENCK ROTEC GMBH

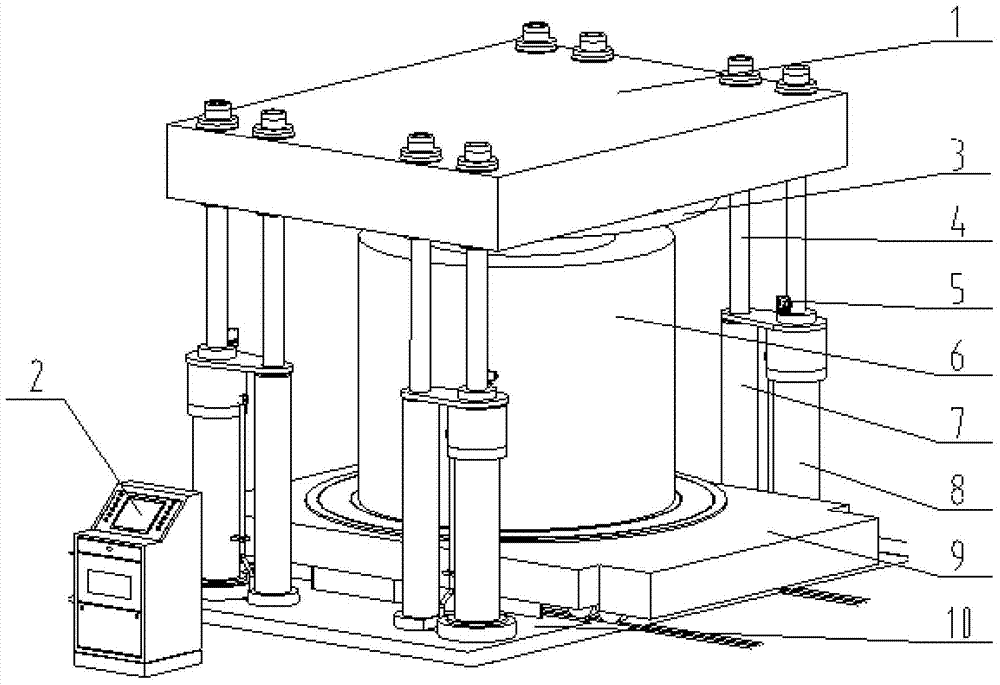

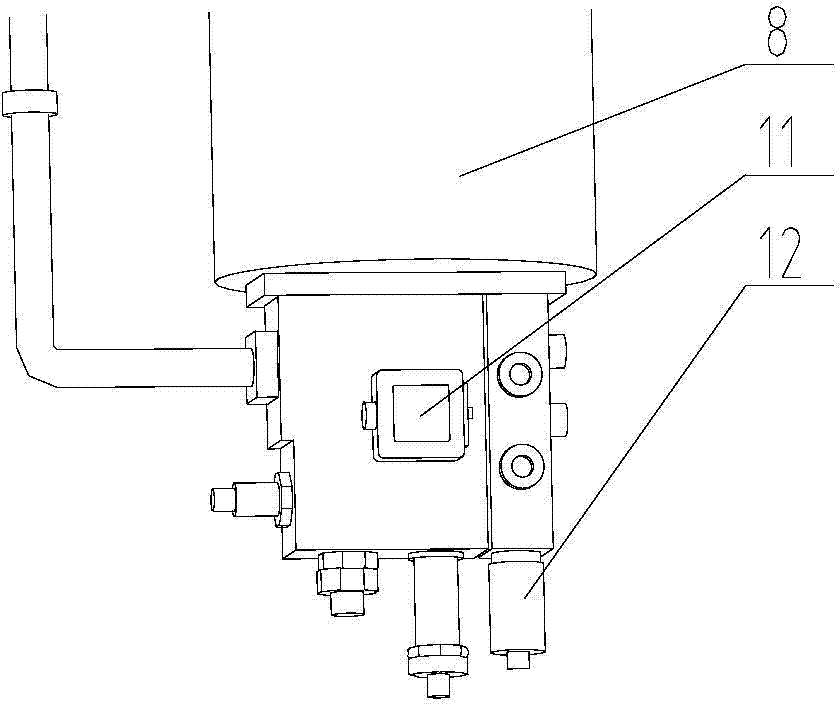

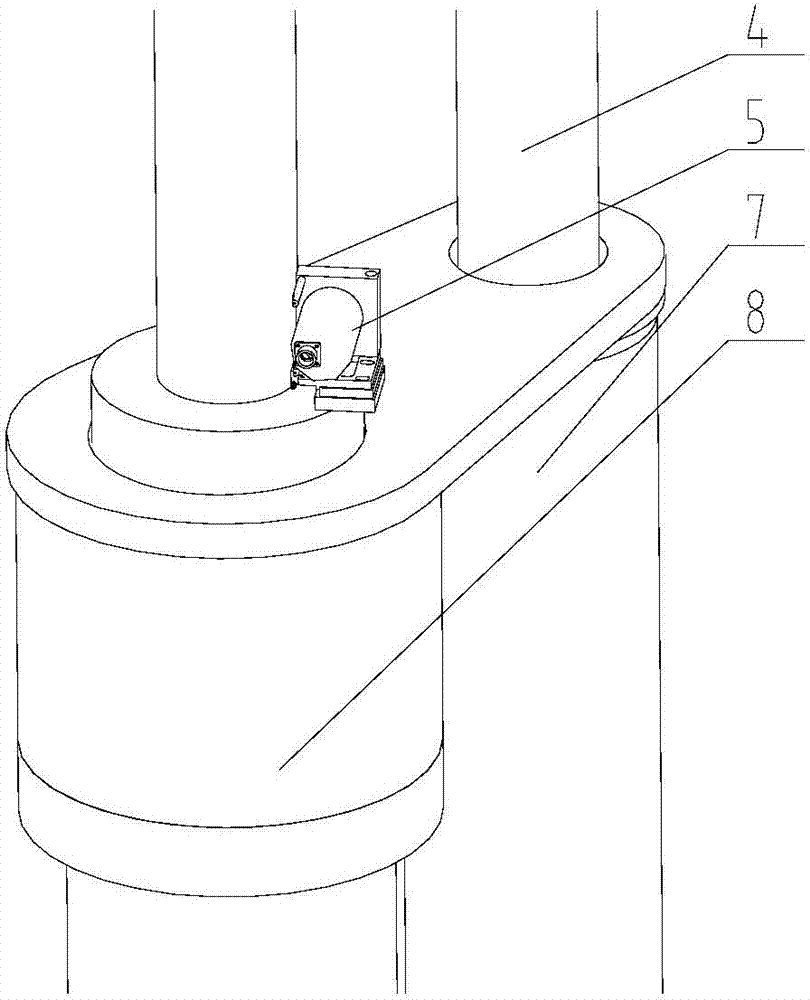

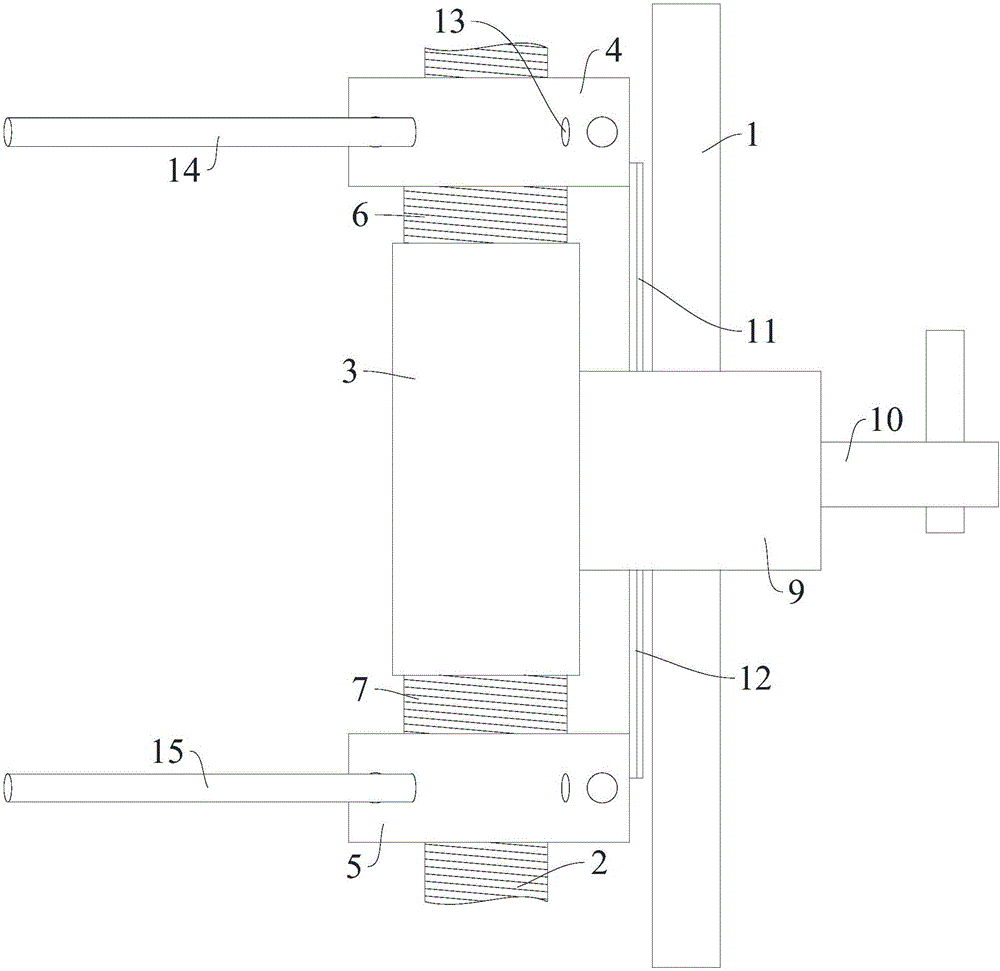

Axial pressing device used after winding of large-size transformer coil

The invention belongs to an axial pressing device used after winding of a large-size transformer coil. The device solves the problem of a large stroke of equipment by replacing a screw rod with oil cylinders, and the oil cylinders have better rigidity and strength. The parallelism of the equipment is subjected to position control by taking a rolling grating as a displacement sensor, and the position precision is fed back to an electro-hydraulic servo valve by a control system, so the high-precision synchronous control on four sets of oil cylinders is realized. The axial pressing device used after winding of the large-size transformer coil has the characteristics of being novel and unique in integral structure, concise and attractive in appearance, small in occupation area and the like. The pressed coil has precise height and accurate pressure value, the coil pressing process is safe and reliable, and the insulation of the coil can be completely kept. The axial pressing device used after the winding of the large-sized transformer coil is particularly suitable for pressing high-voltage and ultrahigh-voltage coils.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

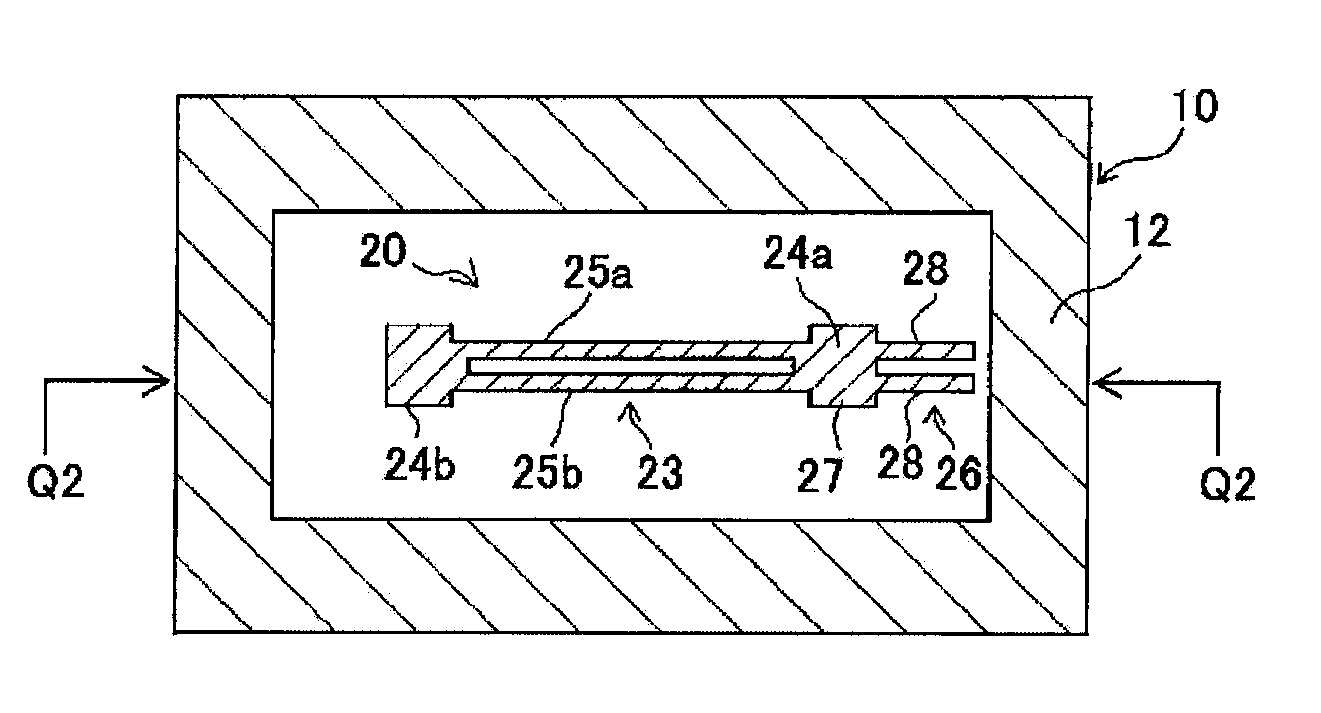

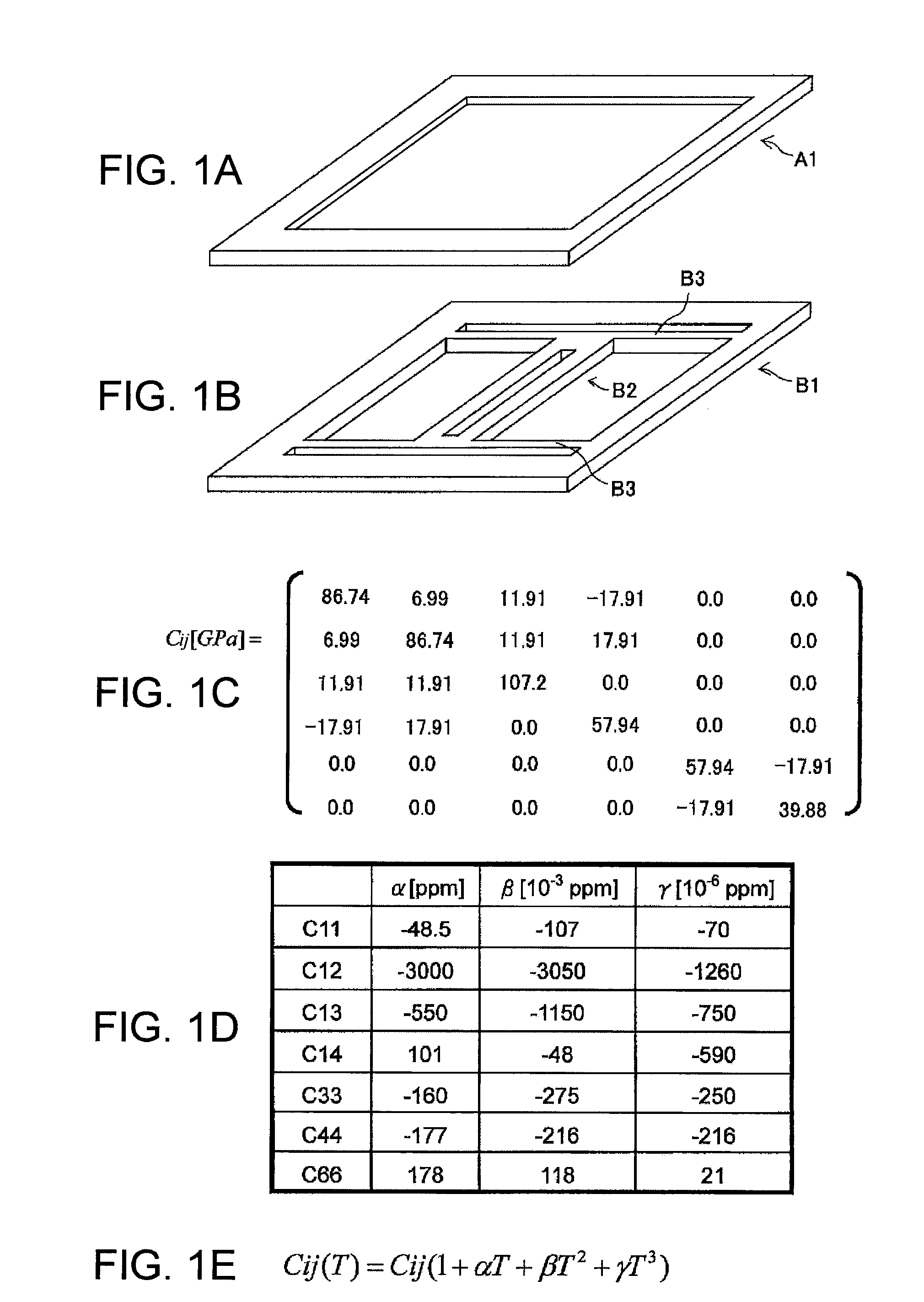

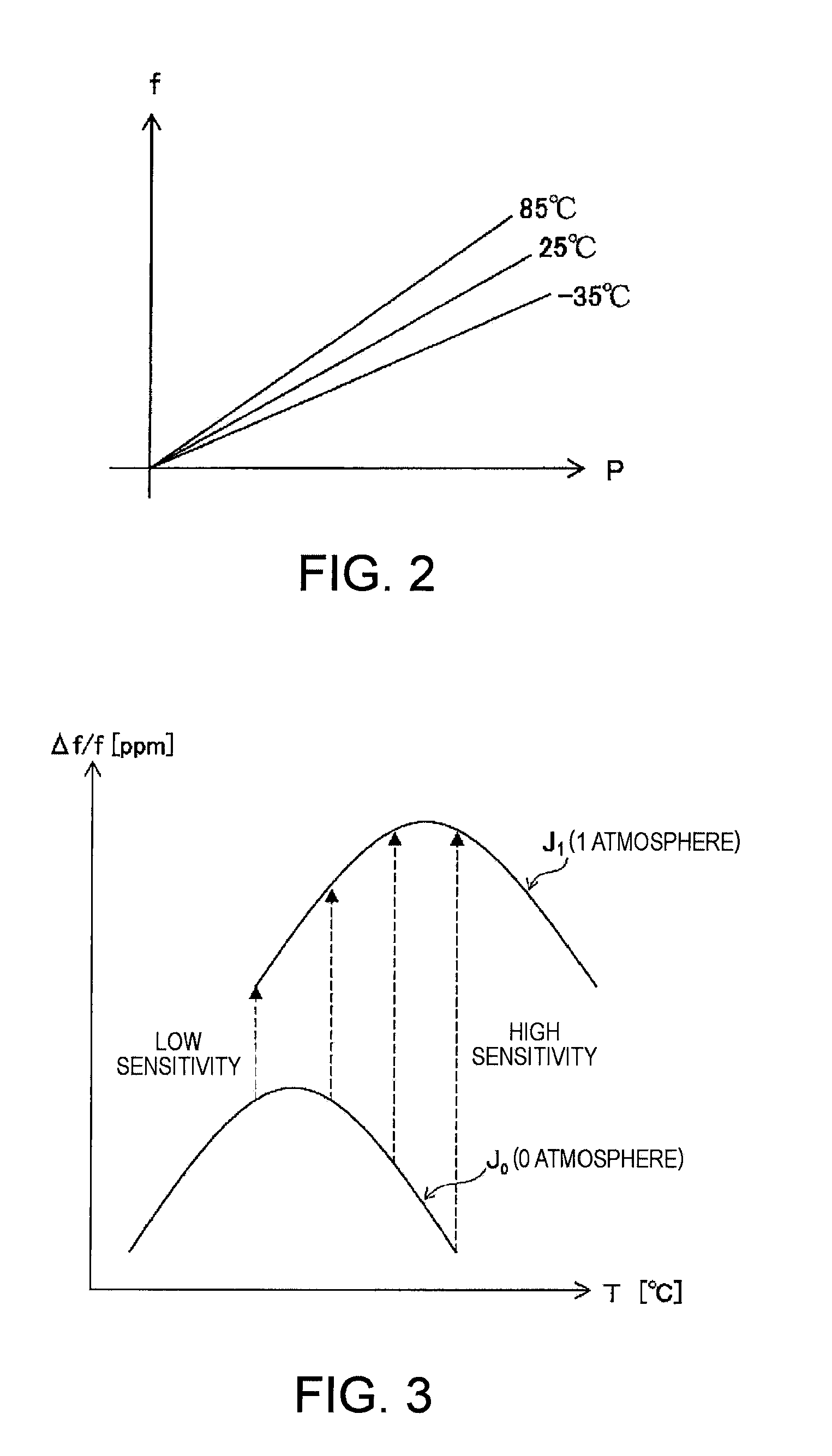

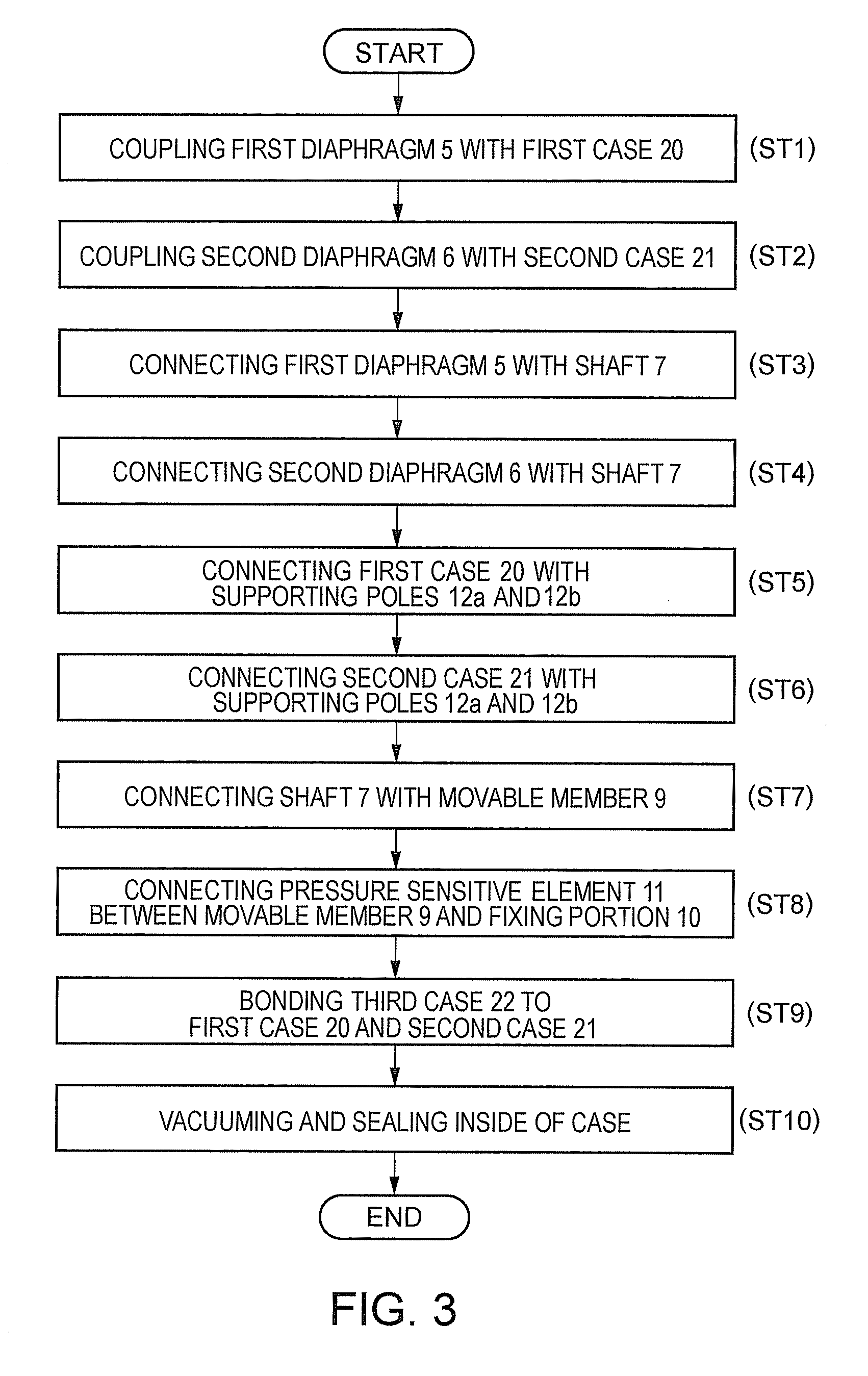

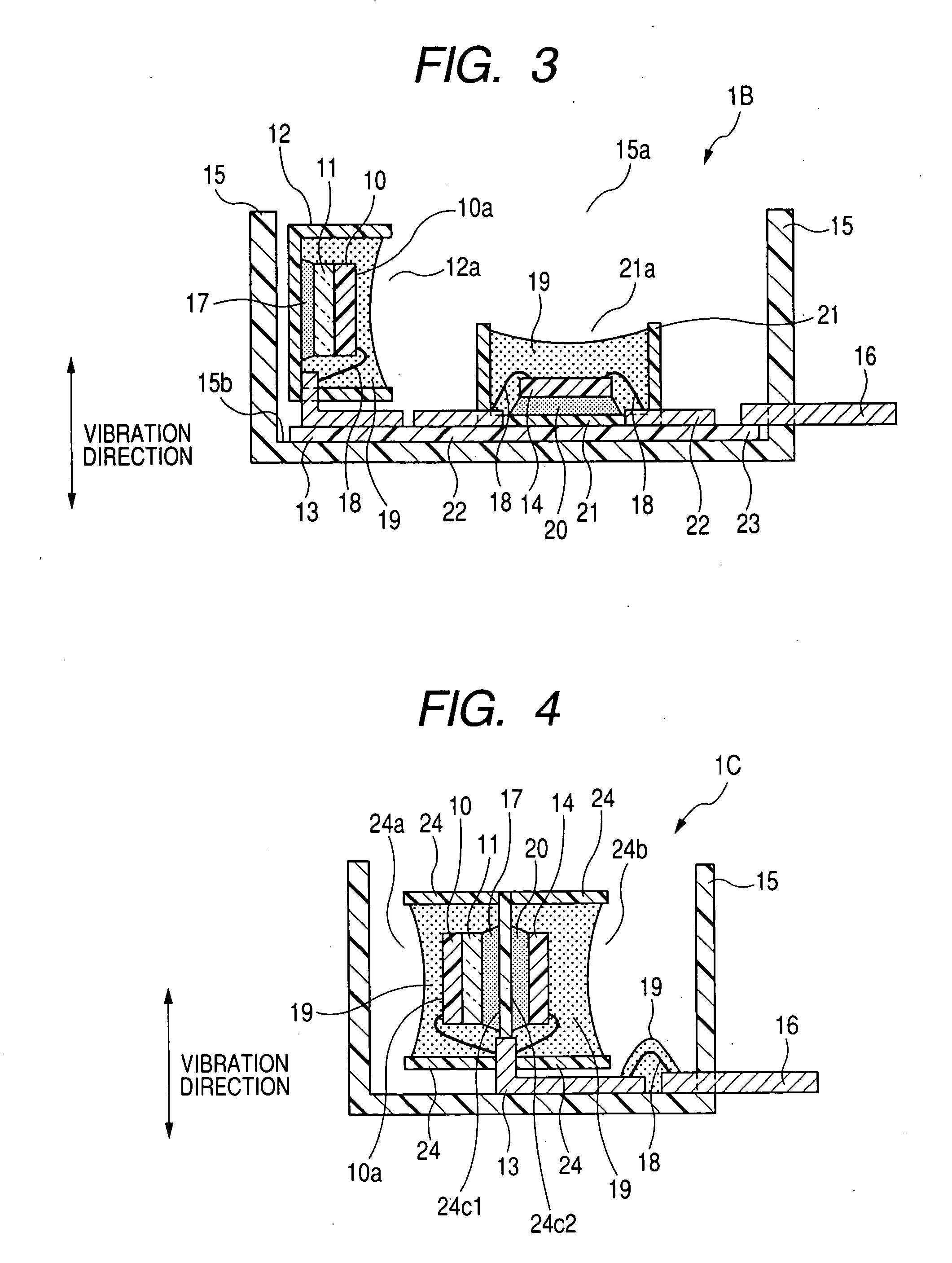

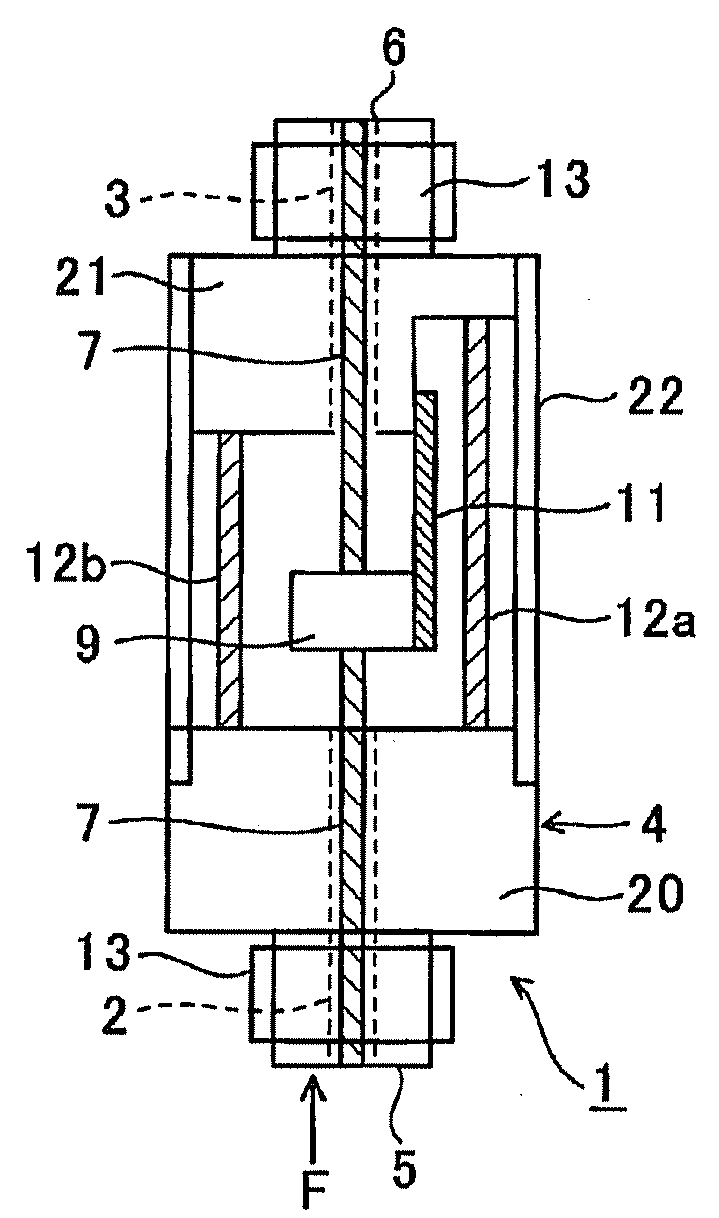

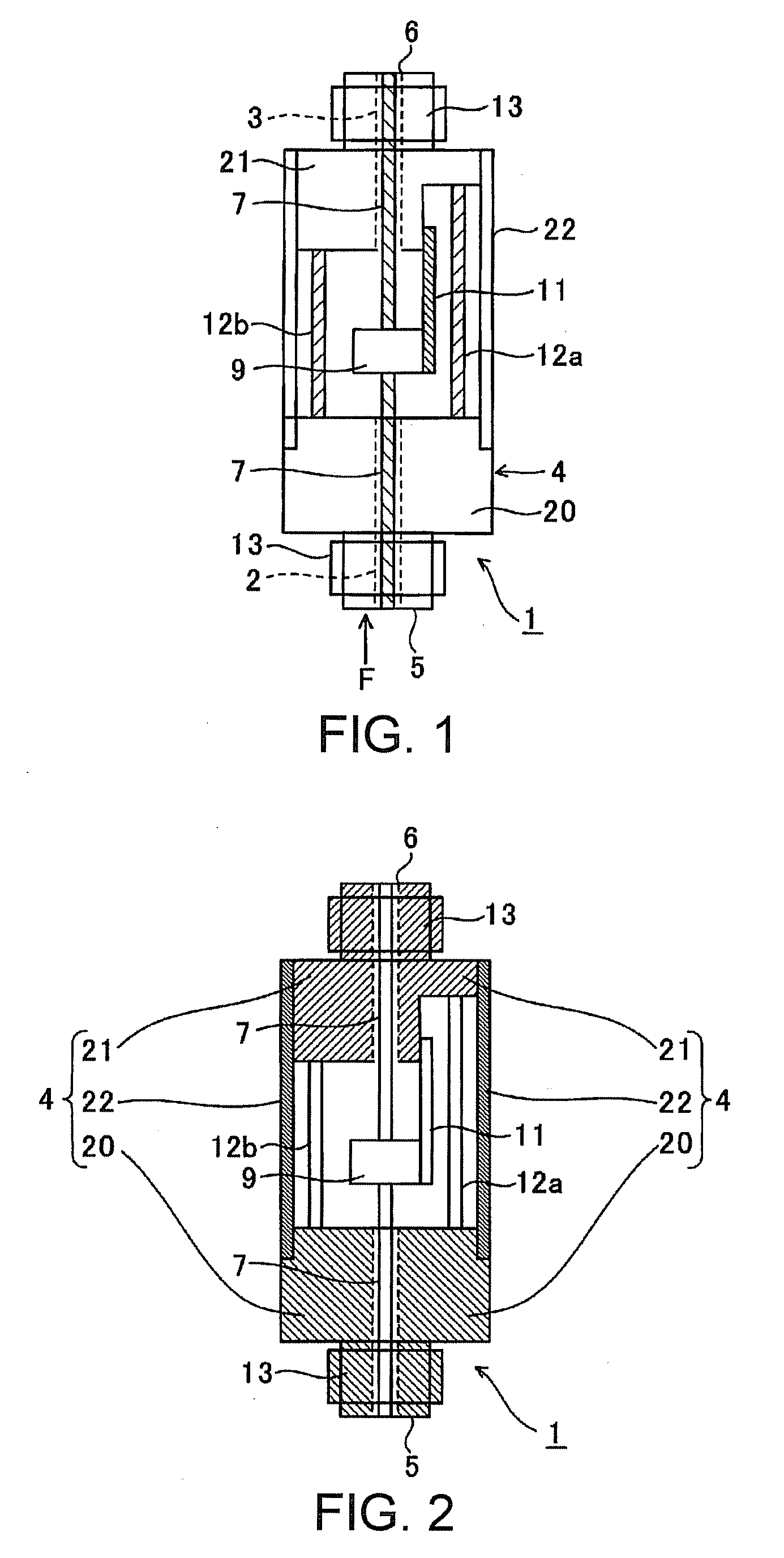

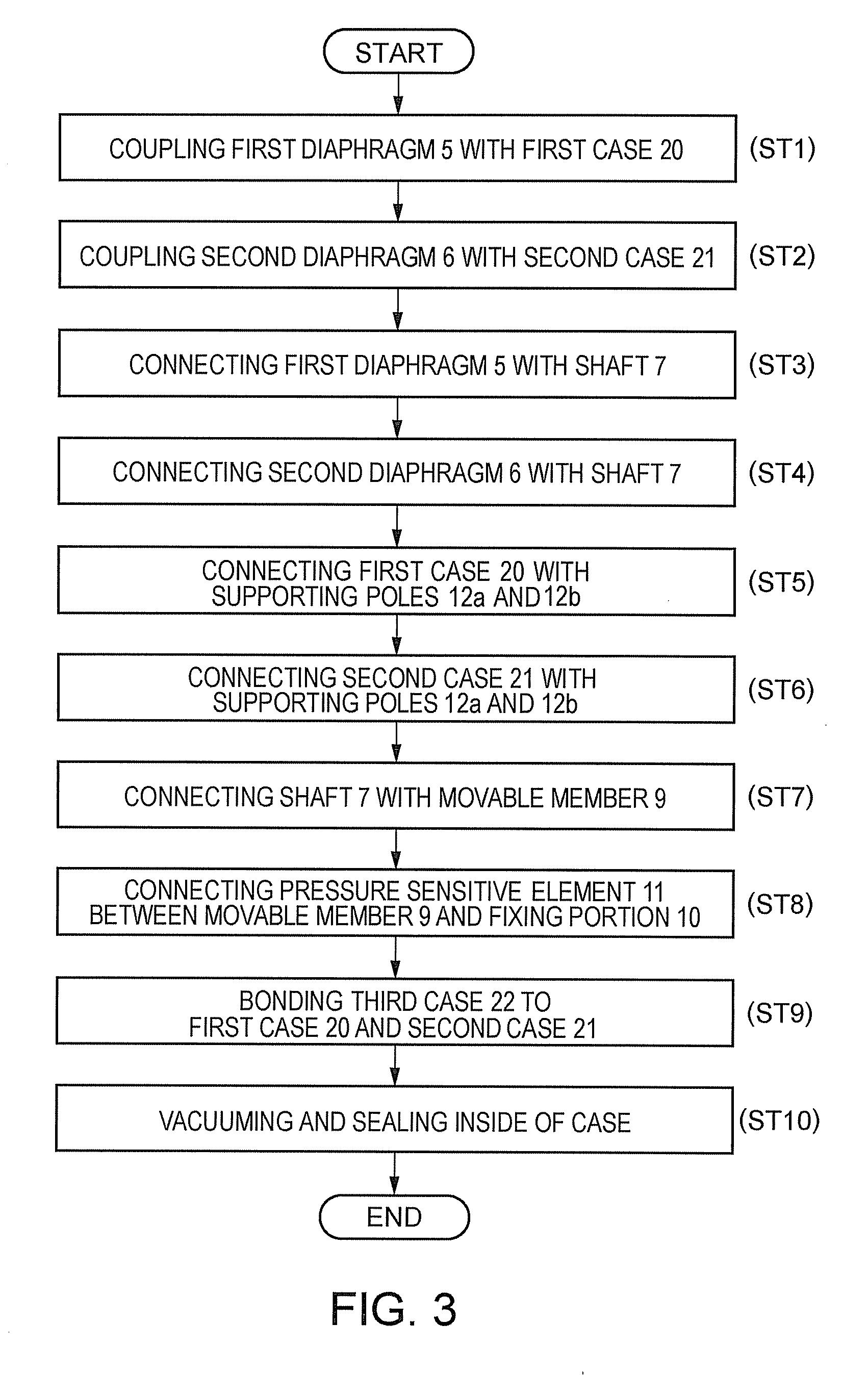

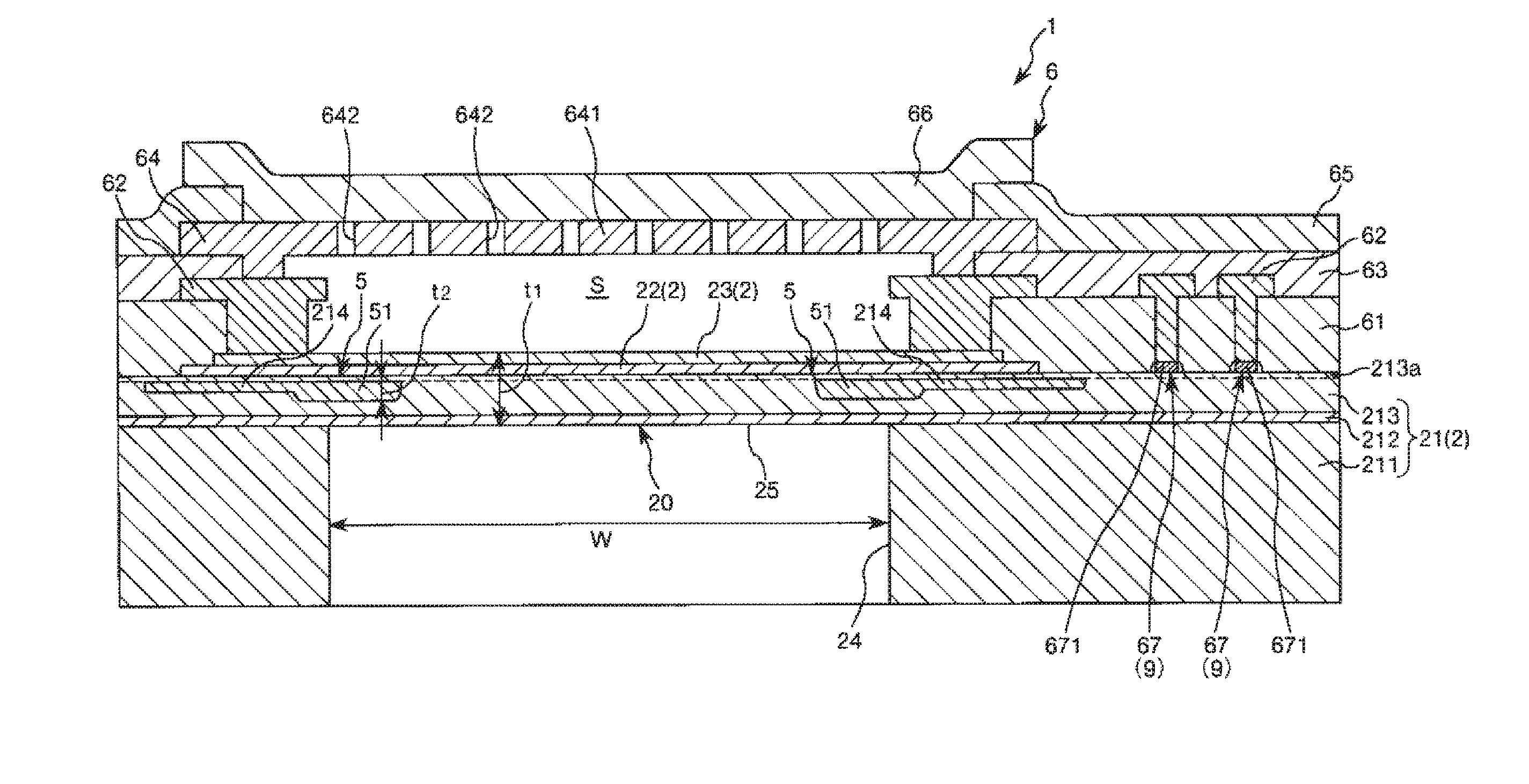

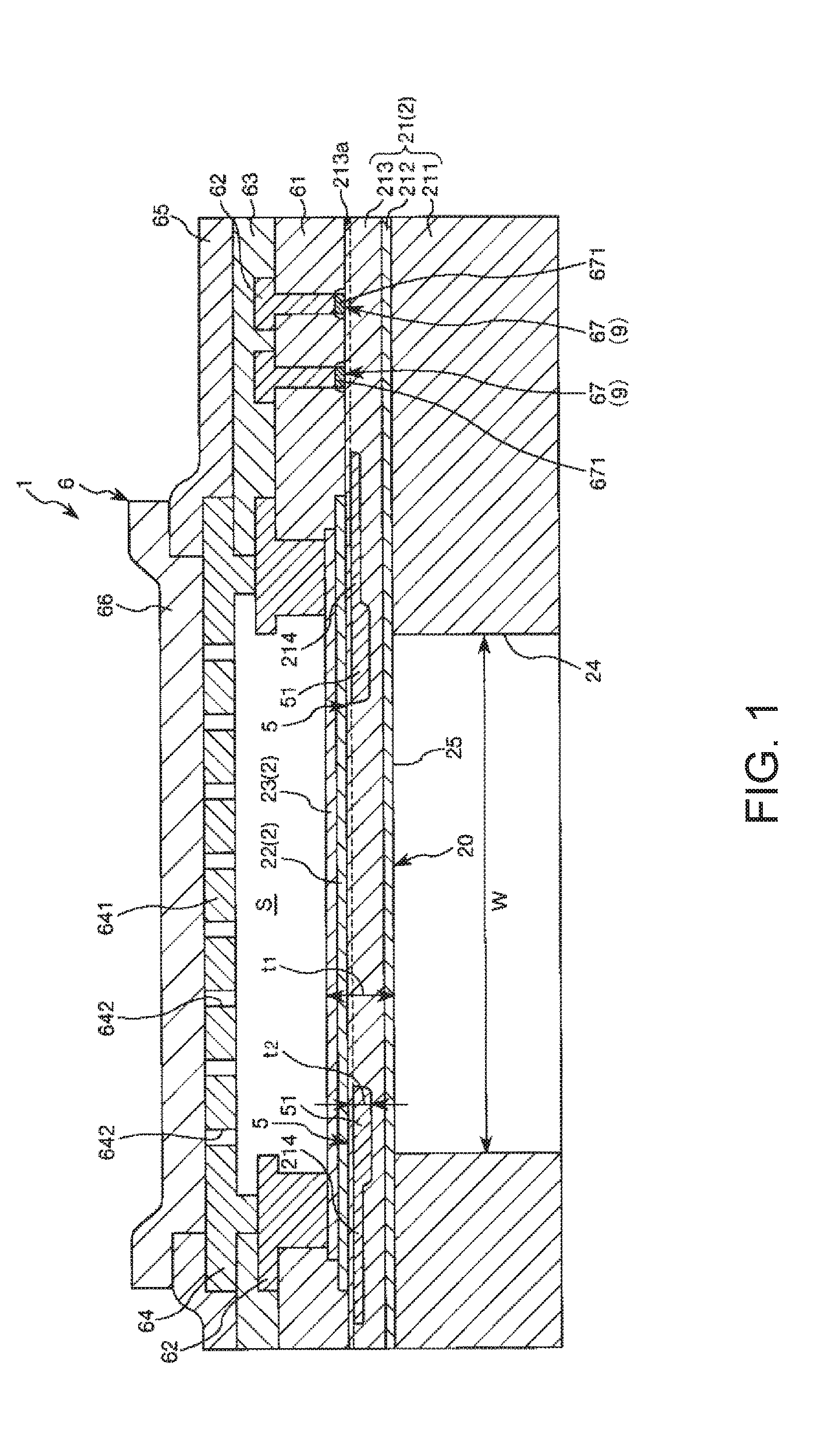

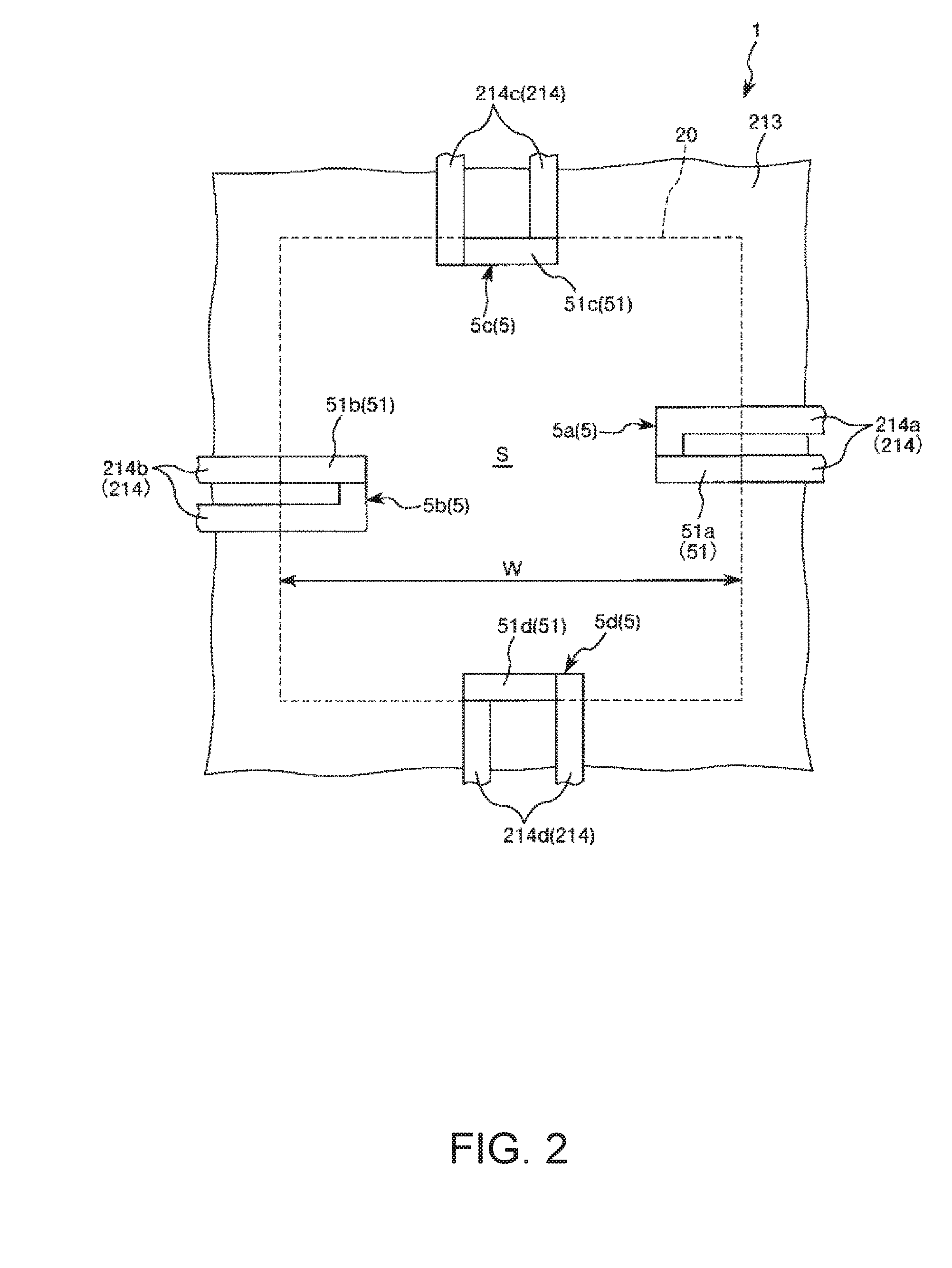

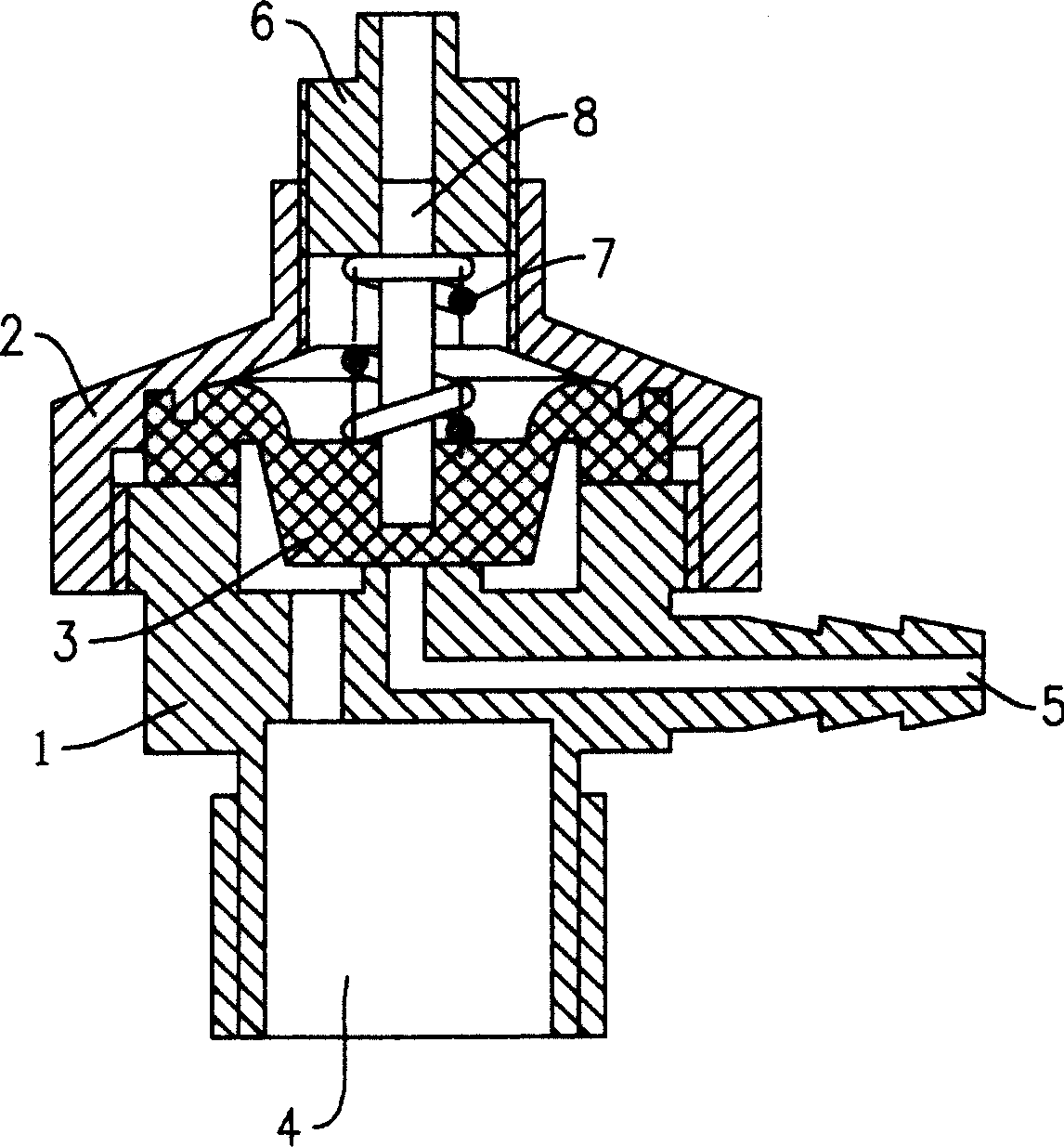

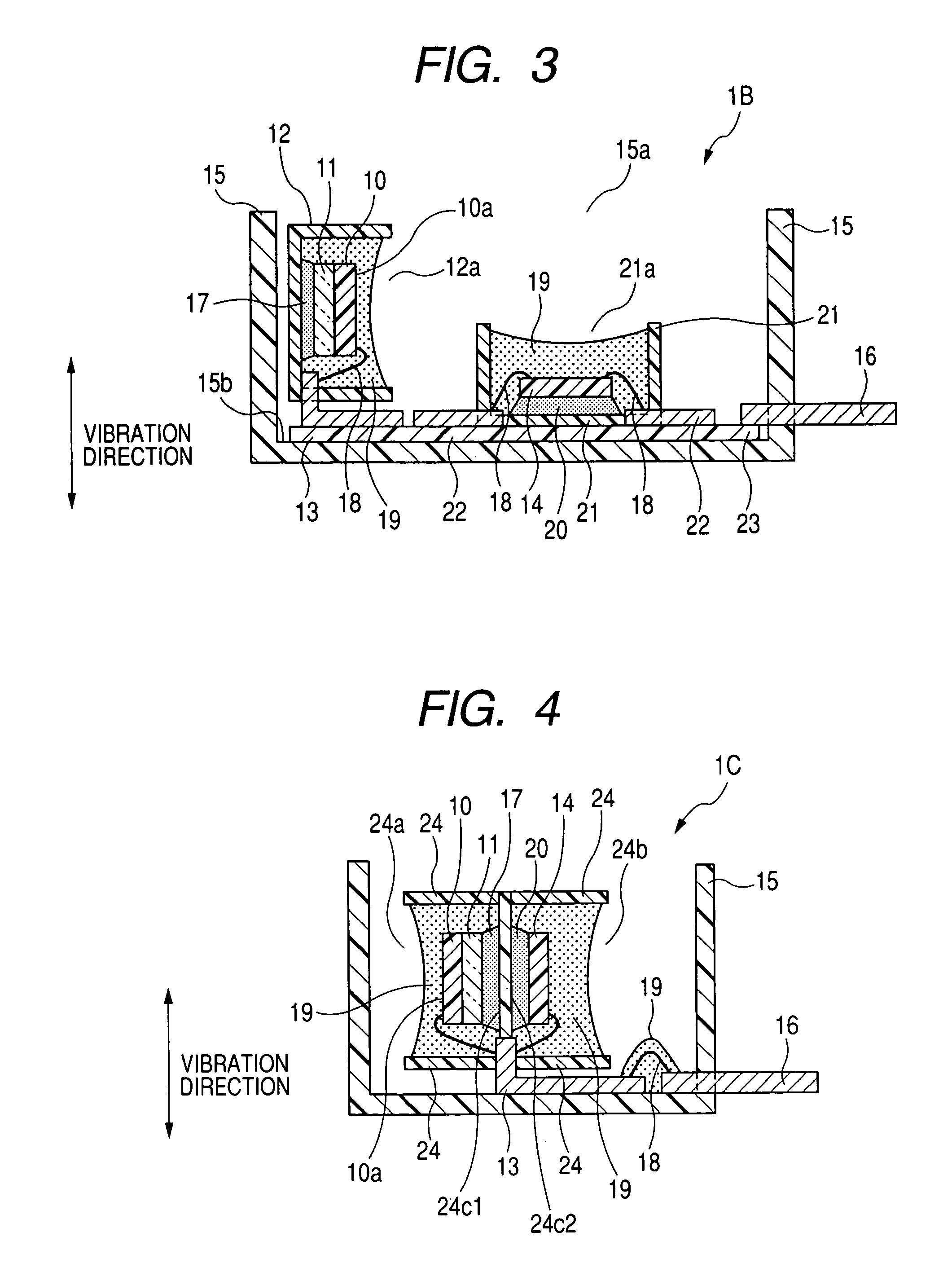

Pressure detection unit and pressure sensor

InactiveUS20100186515A1High measurement accuracyHigh pressure accuracyFluid pressure measurement using piezo-electric devicesPiezoelectric/electrostriction/magnetostriction machinesEngineeringPiezoelectric resonators

A pressure detection unit includes: a first piezoelectric resonator element having a vibrating portion and a pair of base portions connected to both ends of the vibrating portion; a second piezoelectric resonator element having a resonating arm and a base portion integrated with one end of the resonating arm; a diaphragm having a pair of supporting portions to which the base portions of the first piezoelectric resonator element are bonded; and a base disposed to be opposed to the diaphragm. In the pressure detection unit, the base portion of the second piezoelectric resonator element is joined to one of the base portions of the first piezoelectric resonator element in an identical plane.

Owner:SEIKO EPSON CORP

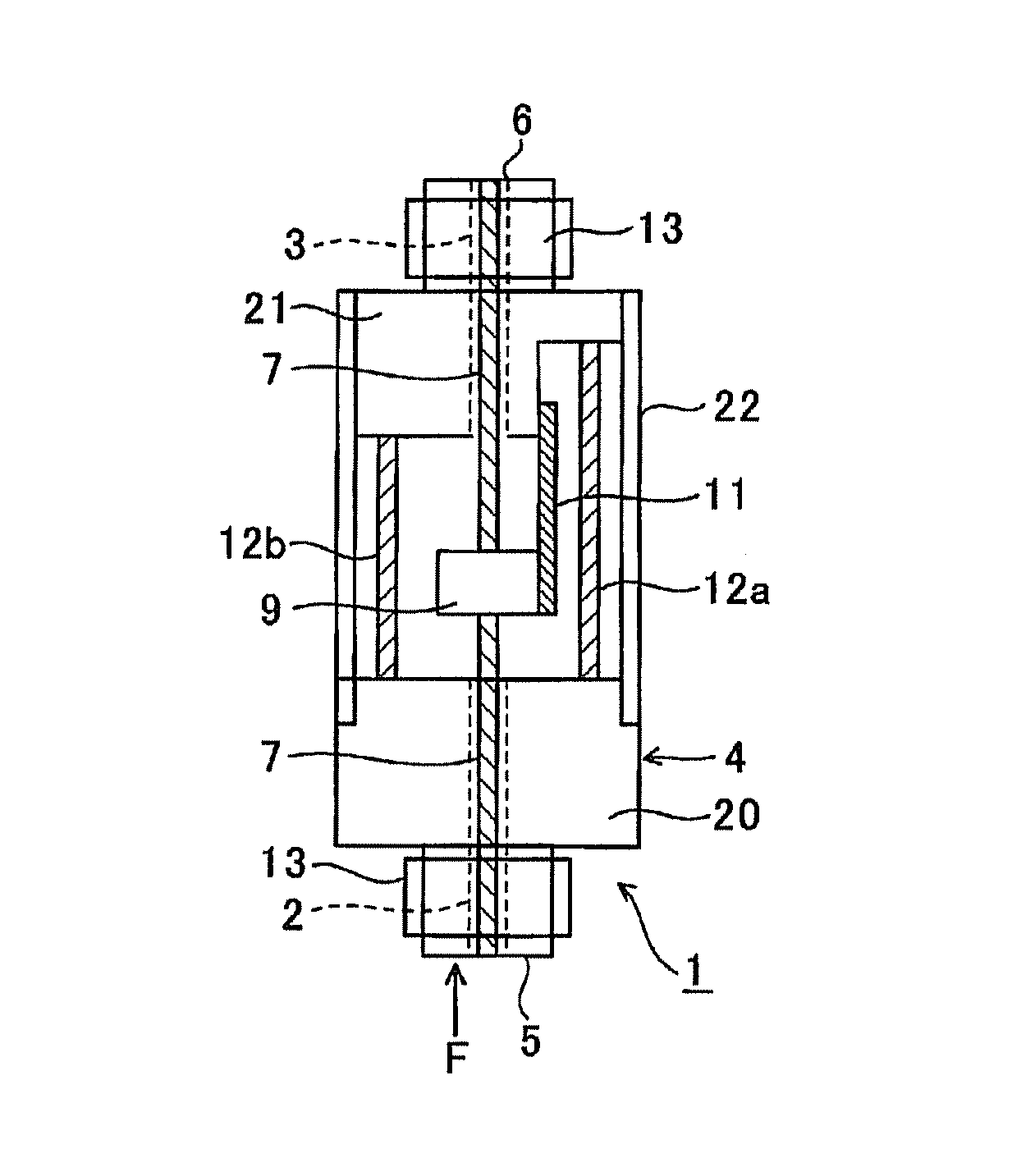

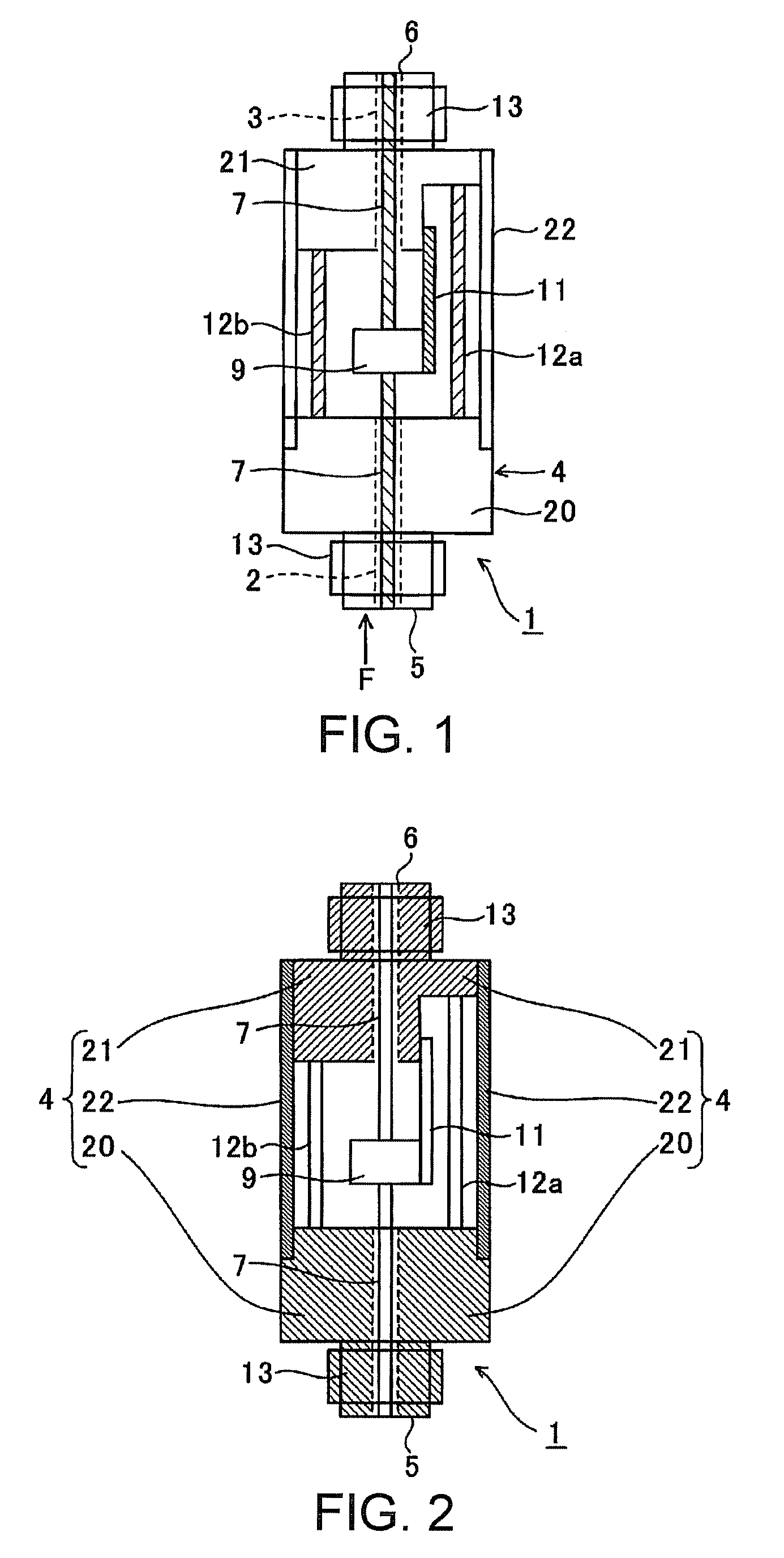

Pressure sensor

InactiveUS8015881B2High pressure accuracyFluid pressure measurement by electric/magnetic elementsPressure difference measurement between multiple valvesDiaphragm sealEngineering

A pressure sensor includes: a housing; an attachment portion coupled to the housing and having a pressure input orifice; a diaphragm sealing the pressure input orifice of the attachment portion and having a first surface that is a pressure receiving surface; and a pressure sensitive unit having a detecting axis in a direction in which a force is detected. In the sensor, an end of the pressure sensitive unit is connected to a central area of a second surface of the diaphragm, another end of the pressure sensitive unit is connected to the housing, and the detecting axis is approximately orthogonal to the pressure receiving surface.

Owner:SEIKO EPSON CORP

Multi-size tire filling apparatus and method

InactiveUS20060136288A1Easy to measureGood reproducibilityCash registersSolid materialEngineeringAtmospheric pressure

A tire filling apparatus preferably includes a support and seal arrangement on which a wheel-tire combination is supported in a horizontally lying orientation, a tire filling plate, and a plurality of differently-sized tire filling rings. Based on the diameter of the wheel-tire combination to be filled with air, a properly sized one of the filling rings is selected and positioned coaxially along the wheel axis between the tire and the filling plate. The filling plate moves toward the tire, sealingly contacts the filling ring, and presses the filling ring against the upwardly facing tire sidewall, until an open air filling gap is formed between the tire sidewall bead and the wheel rim. Pressurized air is introduced through the filling plate, the filling ring, and the open air filling gap into the tire interior, until the gap is closed by the increasing air pressure in the tire.

Owner:SCHENCK ROTEC GMBH

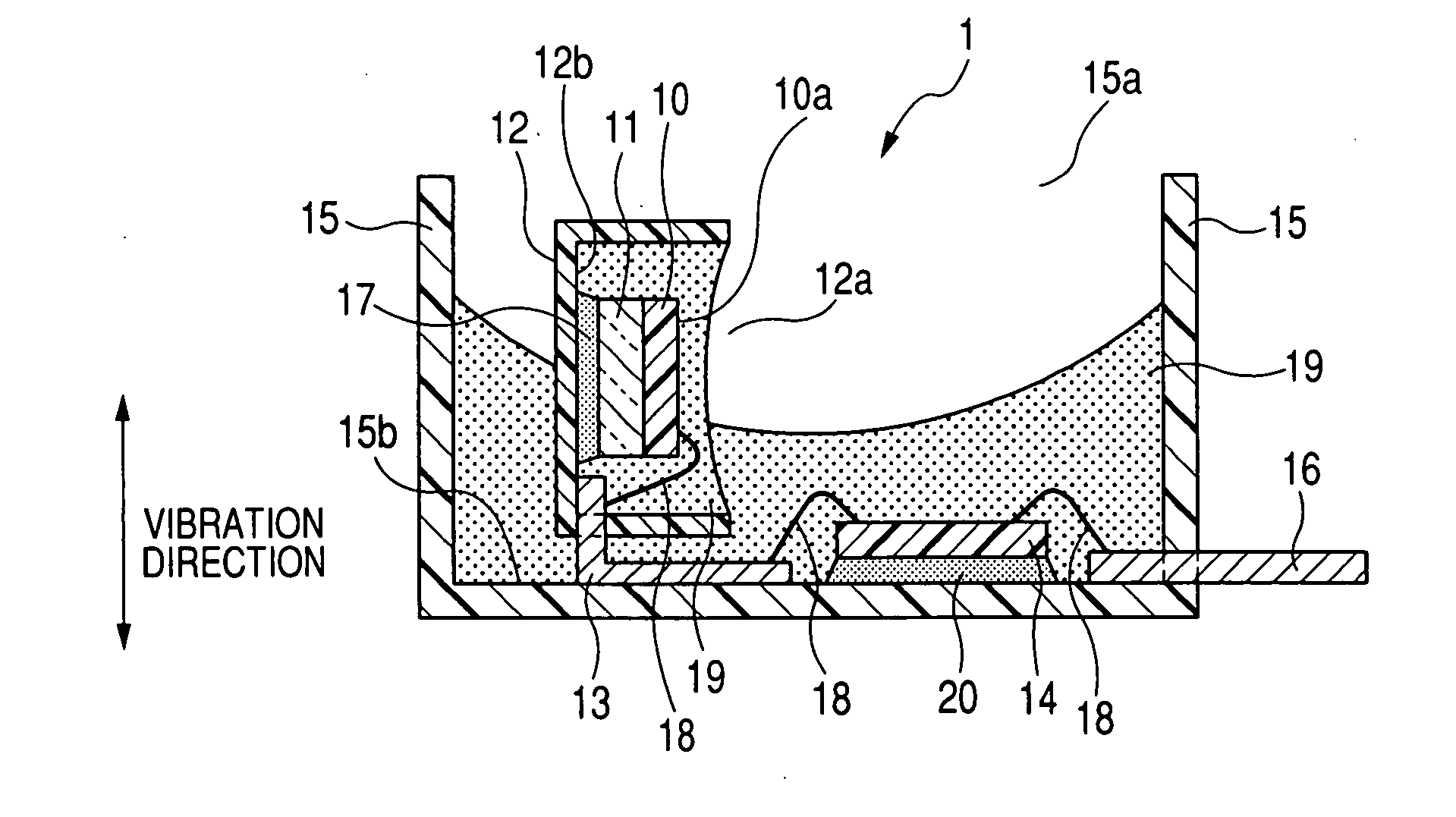

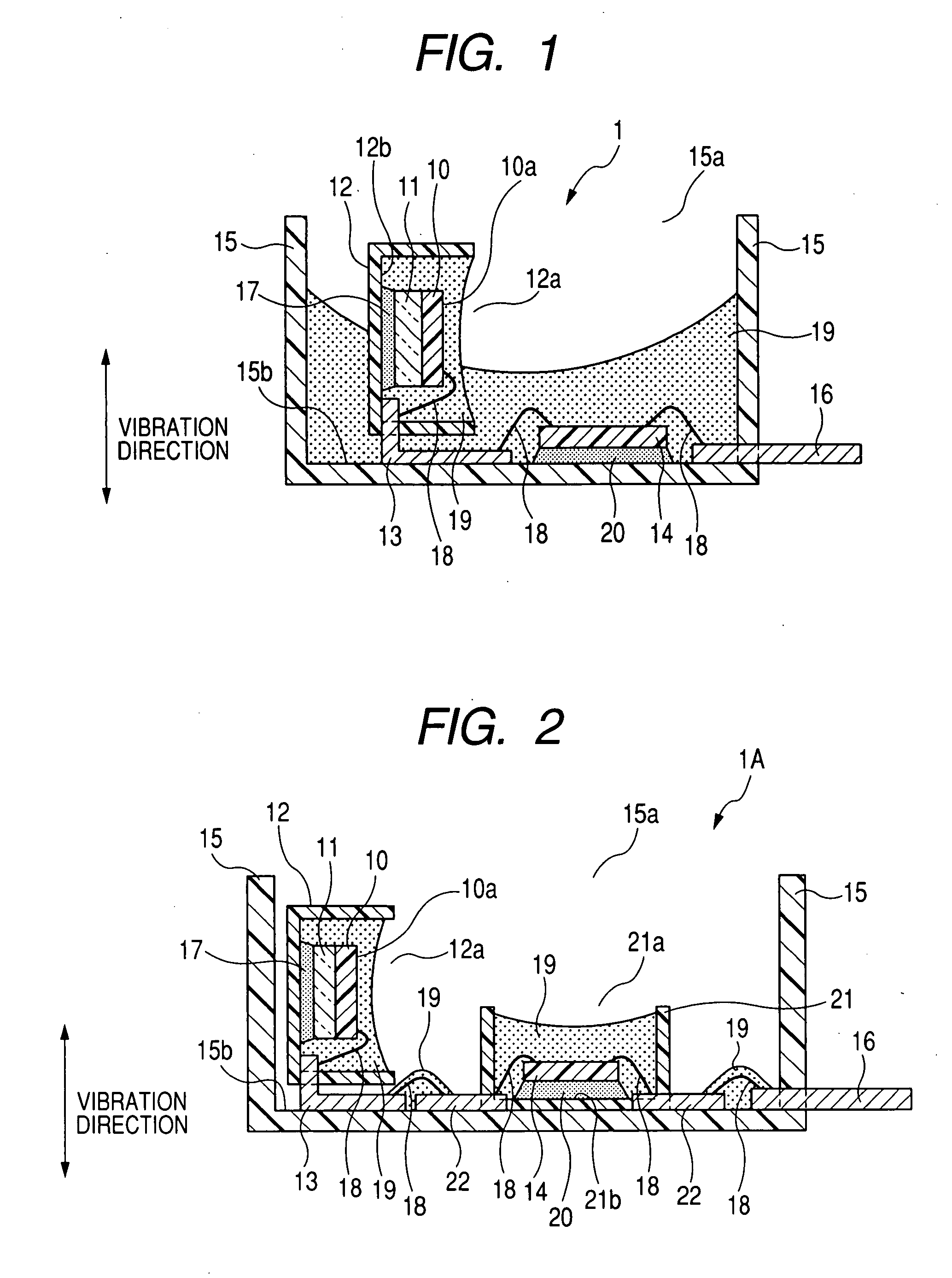

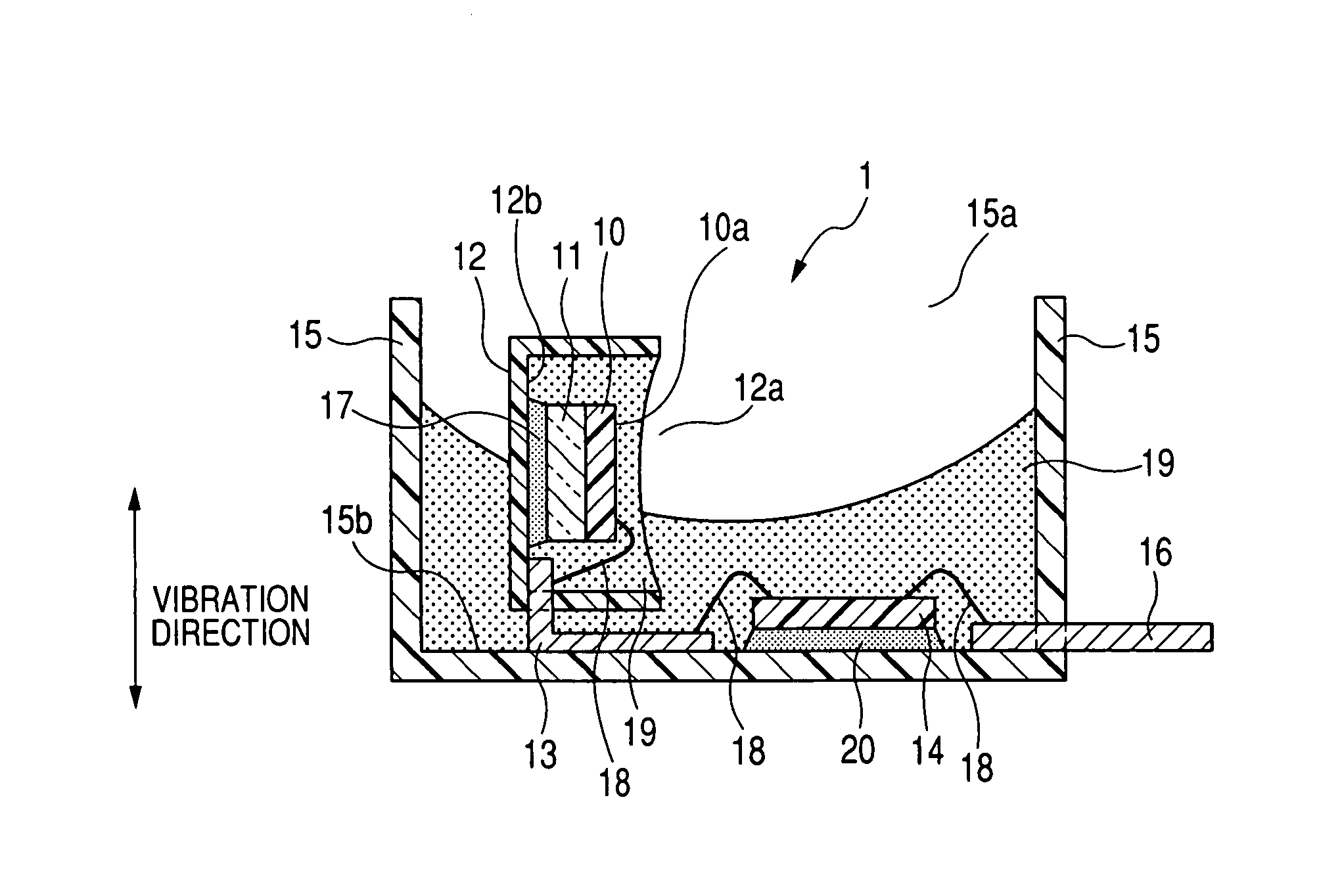

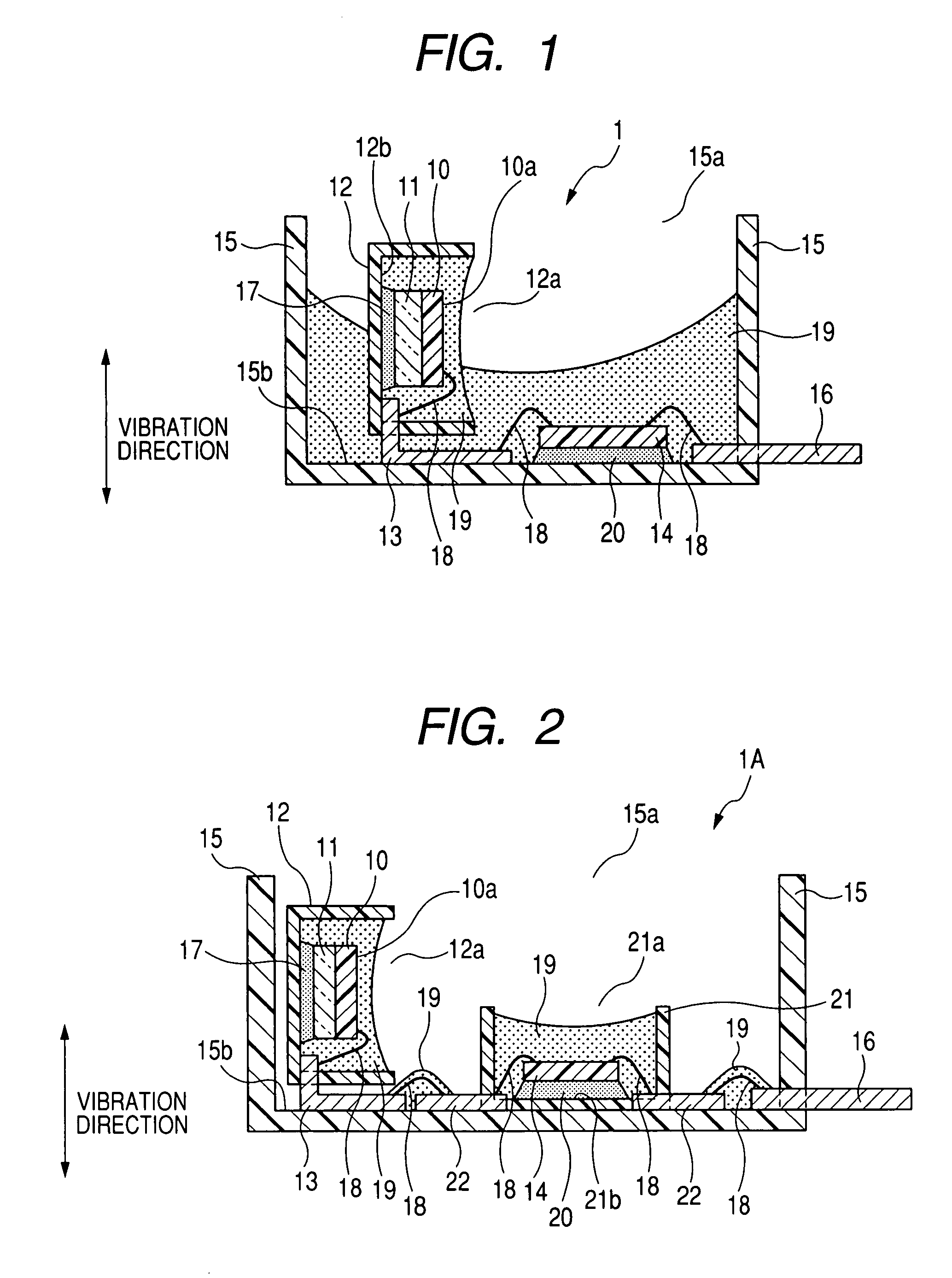

Pressure sensor having improved arrangement of sensor chip for minimizing influence external vibrations

InactiveUS20080098819A1Improve accuracyMinimize impactSolid-state devicesFluid pressure measurement by mechanical elementsEngineeringPressure sensor

A pressure sensor, which is to be used in an environment involving vibrations, includes a case and a sensor chip. The case has an inner surface that is to be disposed perpendicular to a direction of the vibrations. The sensor chip is to sense a pressure in the environment and generate a sensing signal representative of the sensed pressure. The sensor chip has a pressure-receiving surface and is secured in the case with the pressure-receiving surface perpendicular to the inner surface of the case. With such an arrangement, since the pressure-receiving surface of the sensor chip is accordingly to be parallel to the direction of the vibrations, the influence of the vibrations on the pressure-receiving surface can be minimized. Consequently, high accuracy of the pressure sensor can be ensured.

Owner:DENSO CORP

Pressure sensor

InactiveUS20090241679A1High measurement accuracyLarge thermal expansion coefficientFluid pressure measurement using piezo-electric devicesPressure difference measurement between multiple valvesDiaphragm sealEngineering

A pressure sensor includes: a housing; an attachment portion coupled to the housing and having a pressure input orifice; a diaphragm sealing the pressure input orifice of the attachment portion and having a first surface that is a pressure receiving surface; and a pressure sensitive unit having a detecting axis in a direction in which a force is detected. In the sensor, an end of the pressure sensitive unit is connected to a central area of a second surface of the diaphragm, another end of the pressure sensitive unit is connected to the housing, and the detecting axis is approximately orthogonal to the pressure receiving surface.

Owner:SEIKO EPSON CORP

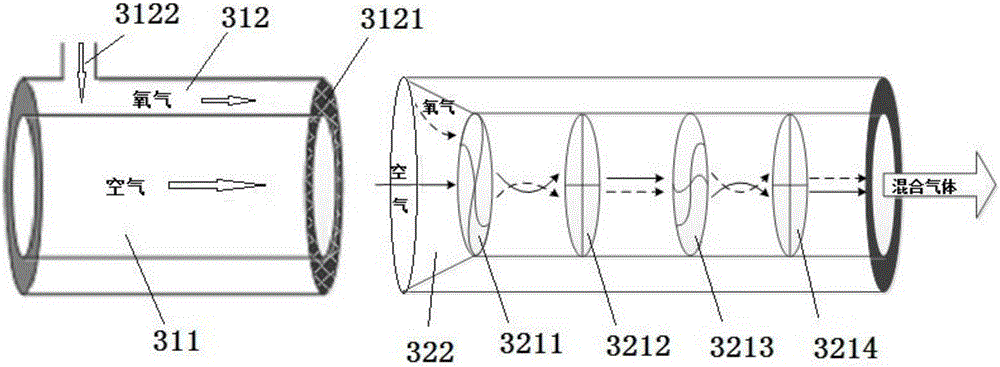

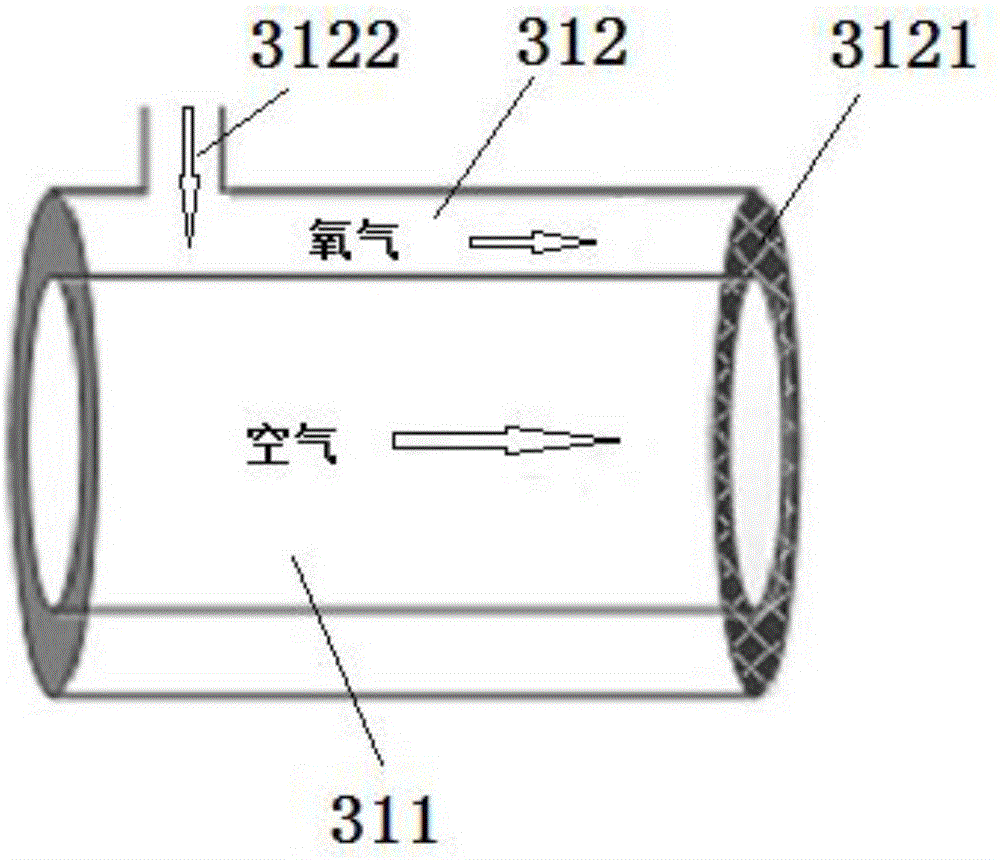

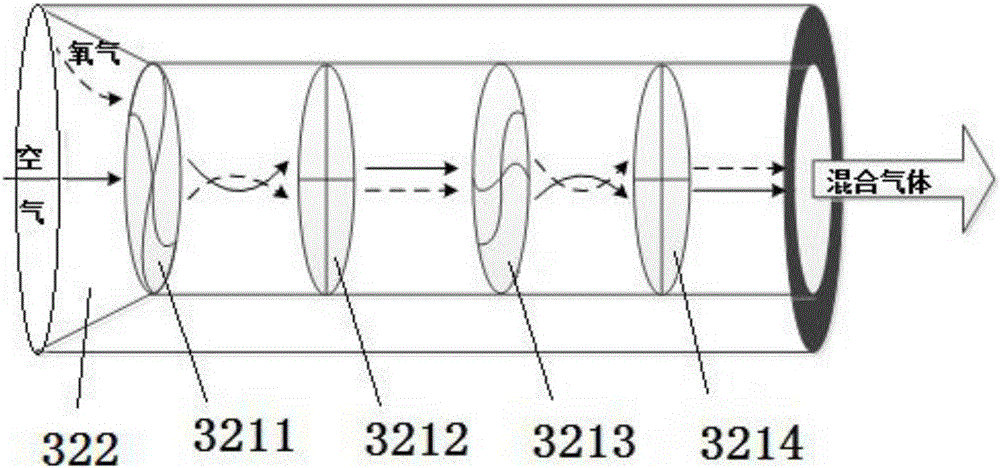

Air-oxygen mixing airway for respirator, respirator and method

Disclosed are an air-oxygen mixing airway for a respirator, the respirator and a method. The air-oxygen mixing airway comprises an anti-turbulence member and an air-oxygen mixing cavity, the anti-turbulence member comprises an oxygen way and an air way, two ends of the air way are open, the left end of the oxygen way is closed while the right end of the same is provided with an oxygen barrier piece, and an oxygen inlet is arranged on the outer side of the oxygen barrier piece. The respirator comprises an oxygen way, an air way and an air-oxygen mixing chamber provided with the air-oxygen mixing airway, an oxygen miniature proportional valve, an oxygen flow sensor and an air intercepting member are arranged on the oxygen way, a fan, an air pressure adjusting valve, an air flow sensor and an air intercepting member are arranged on the air way, and opening degree of the oxygen valve is adjusted to adjust oxygen flowing speed according to oxygen concentration of mixed gas needing to be output and air flowing speed measured by the air flow sensor. The anti-turbulence member is adopted in the air-oxygen mixing airway, and can cooperate with the flow sensors which are high in accuracy and low in power consumption, and the oxygen barrier piece is utilized, so that accuracy of air-oxygen mixed gas can be improved.

Owner:HUNAN MICOME ZHONGJIN MEDICAL SCI & TECH DEV CO LTD

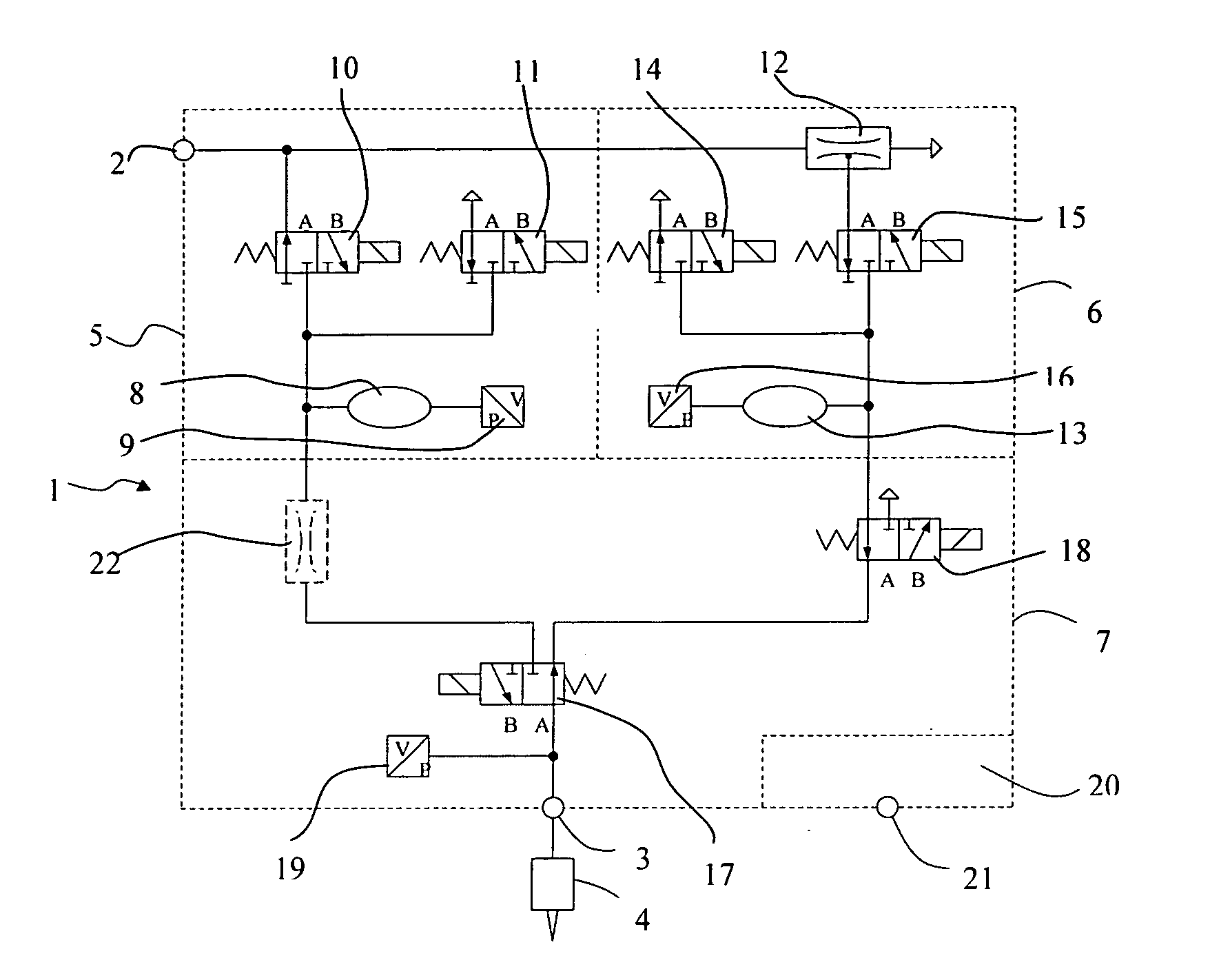

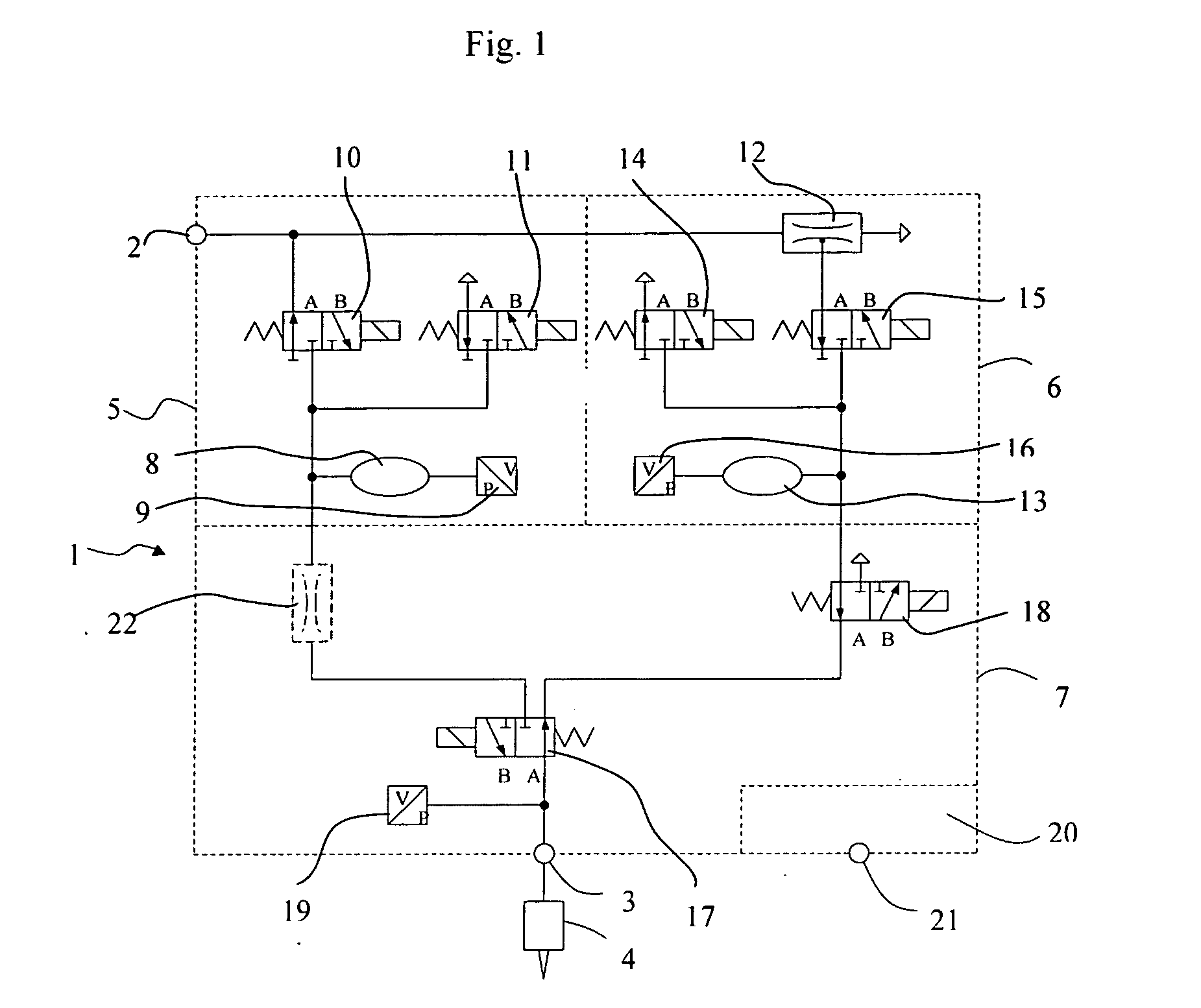

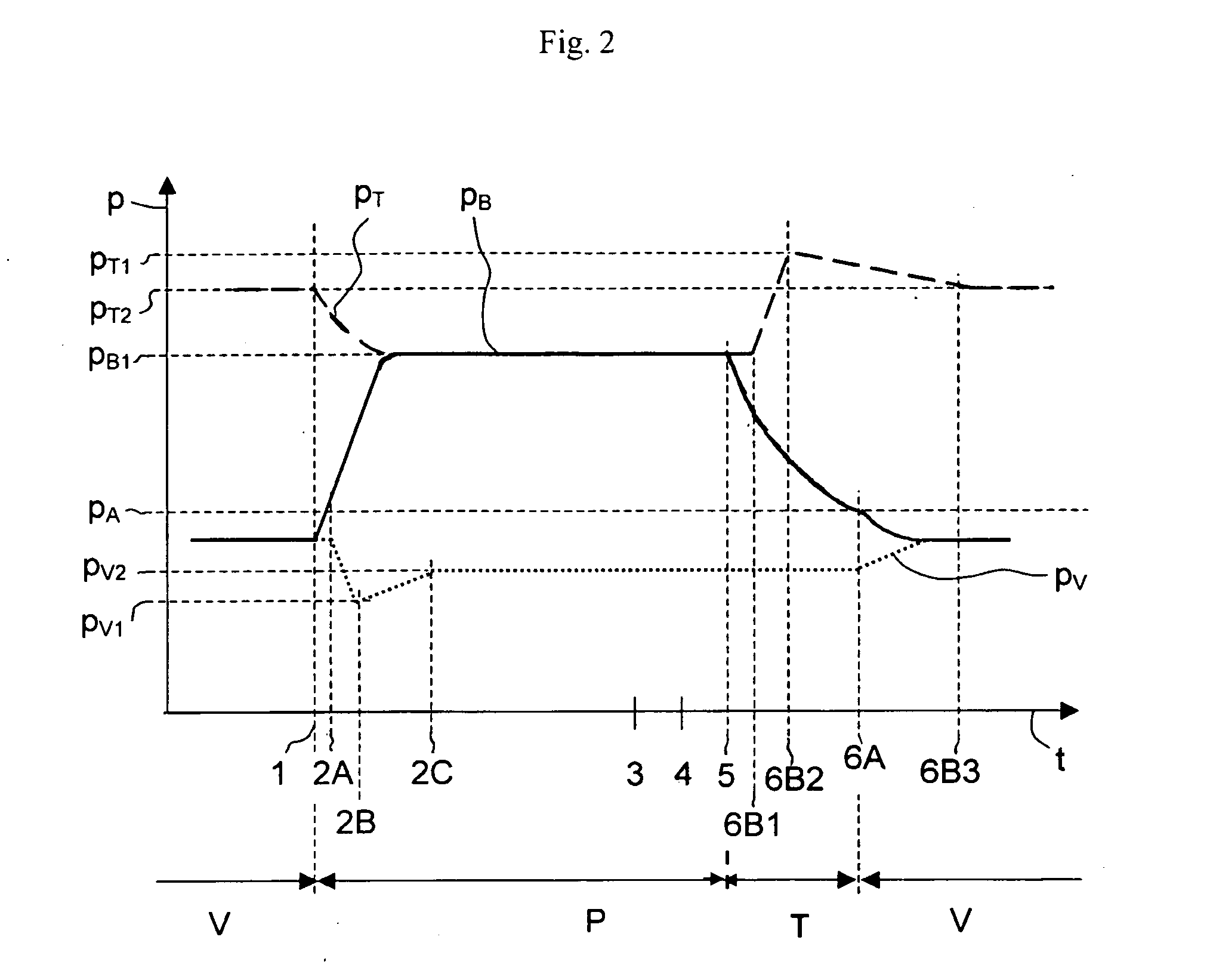

Method for operating a pneumatic device for the metered delivery of a liquid and pneumatic device

ActiveUS20060225786A1Easy to operateHigh pressure accuracyOpening closed containersBottle/container closureInlet valveBiomedical engineering

The invention concerns the operation of a pneumatic device for the metered delivery of a liquid and a pneumatic device particularly suited for operation in accordance with the invention. The pneumatic device has a pressure tank that can be connected to a compressed air source by means of an inlet valve and with the surroundings by means of an outlet valve. For delivery of the liquid, a pressure pulse is applied to the liquid container containing the liquid in that the pressure tank is temporarily connected to the liquid container via a changeover valve. After the end of the pressure pulse, the pressure prevailing in the pressure tank is increased to a value that is greater than the set value to be achieved during the pressure pulse.

Owner:ESEC

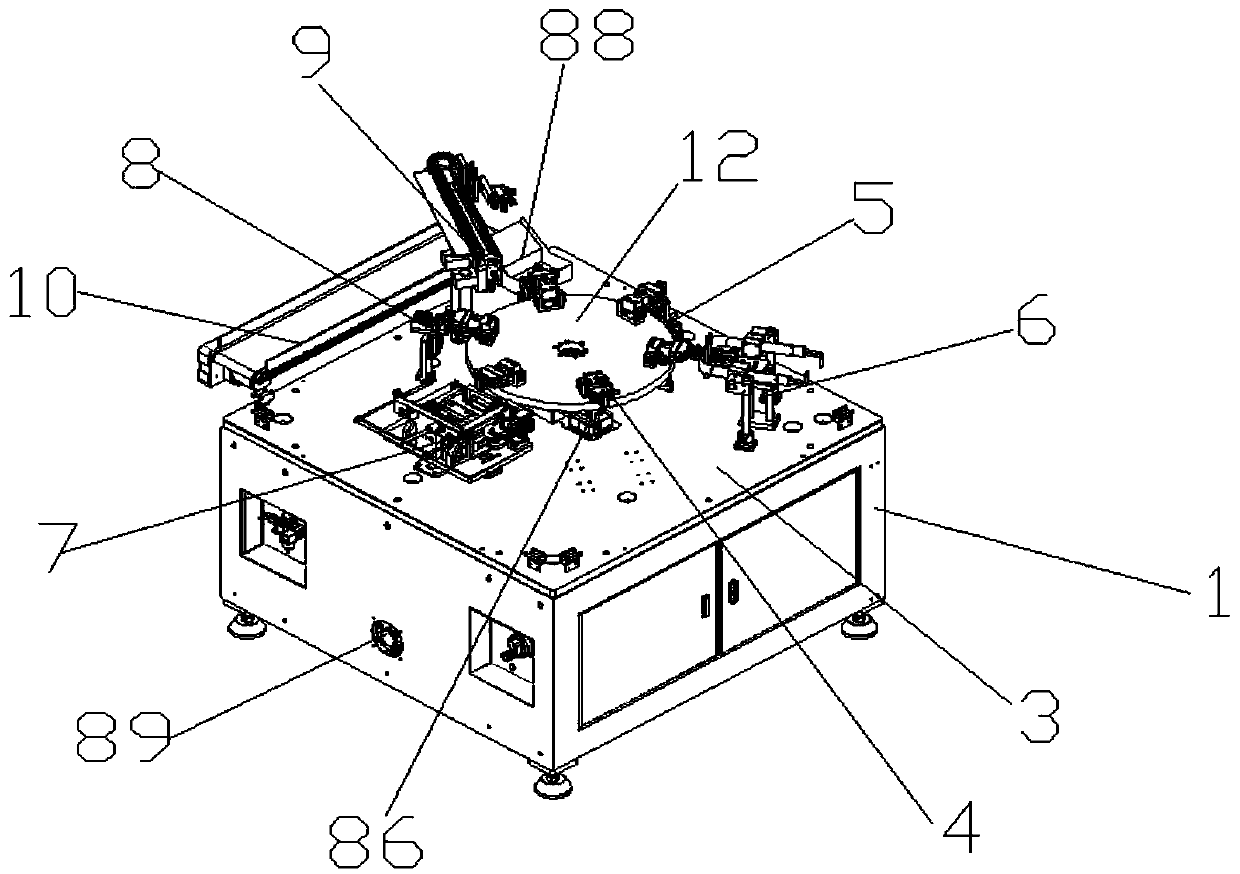

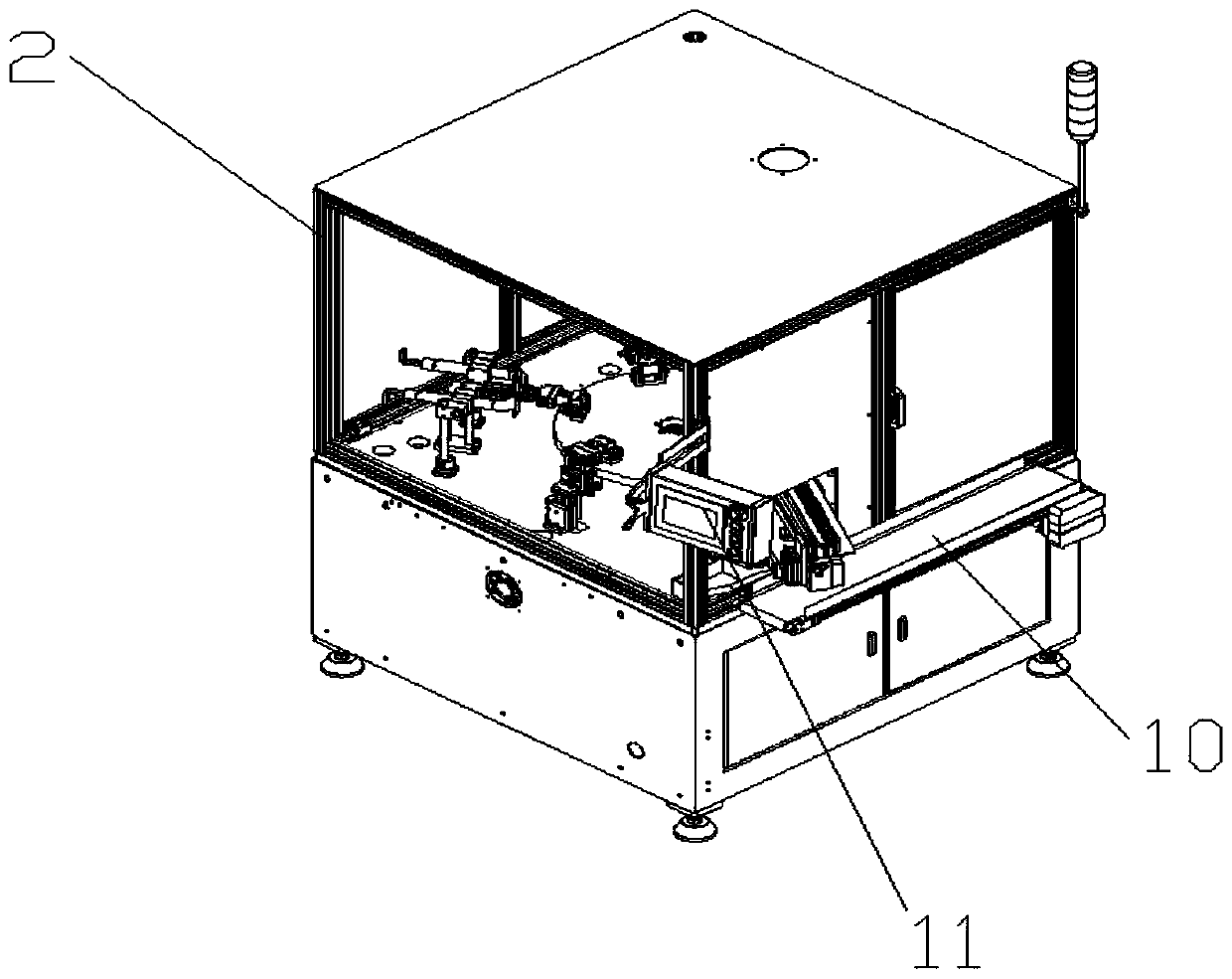

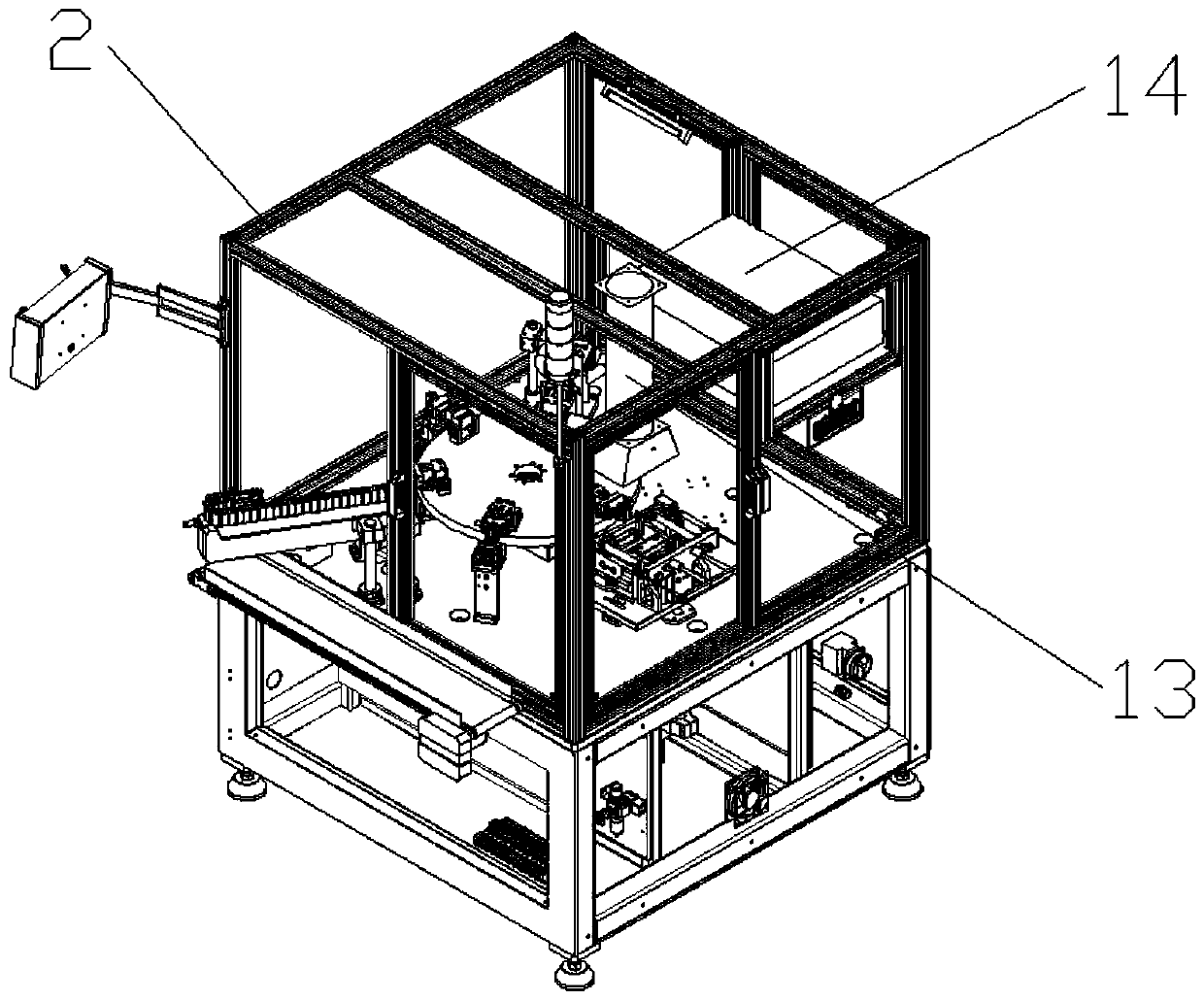

Novel segmented stator core turnplate welding machine

InactiveCN109877409ASolve the real problemIncrease productivityManufacturing stator/rotor bodiesSoldering auxillary devicesManipulatorWorkbench

Owner:杭州直尚智能设备有限公司

Method for manufacturing resistive element, method for manufacturing pressure sensor element, pressure sensor element, pressure sensor, altimeter, electronic apparatus, and moving object

ActiveUS20160347604A1Improve accuracyReduce noiseDecorative surface effectsFluid pressure measurement by electric/magnetic elementsEngineeringRapid thermal annealing

A method for manufacturing a resistive element includes: preparing a substrate including an n-type silicon layer; doping the silicon layer with an impurity to thereby form a resistive region; heat-treating the resistive region by any of rapid thermal annealing, flash lamp annealing, and excimer laser annealing; and epitaxially growing silicon on the resistive region to thereby form a covering layer.

Owner:SEIKO EPSON CORP

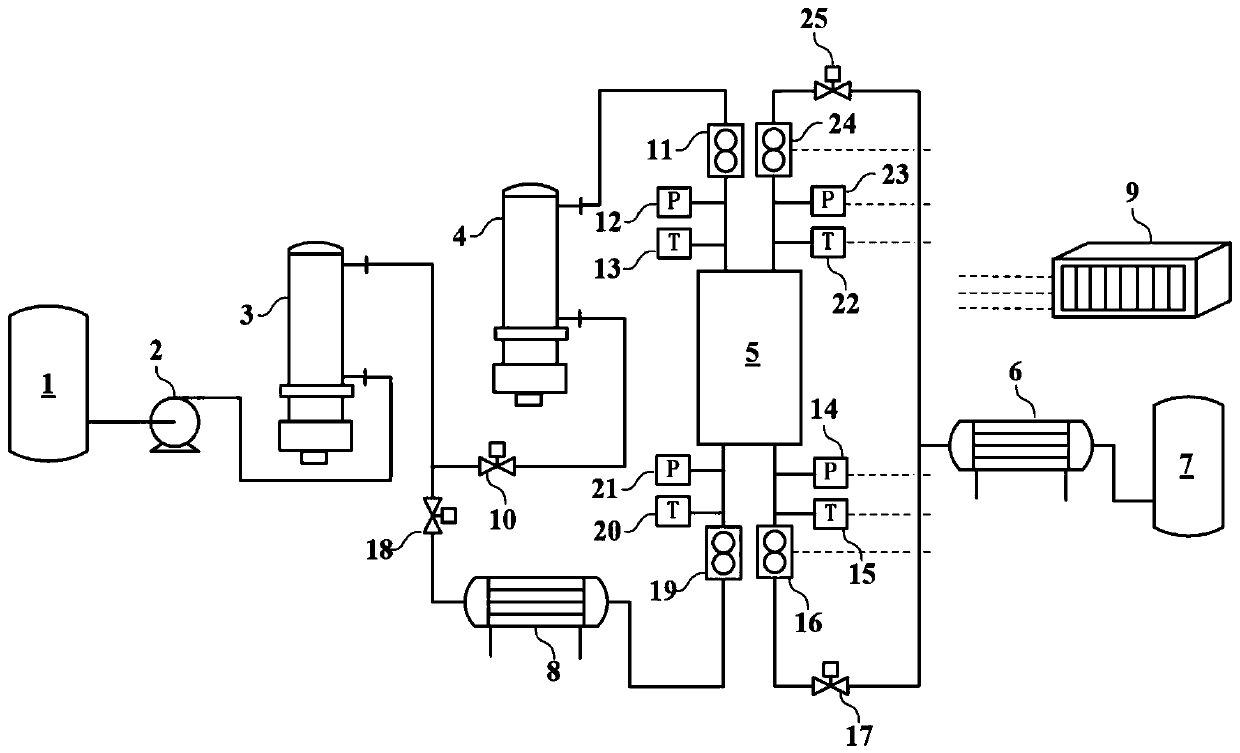

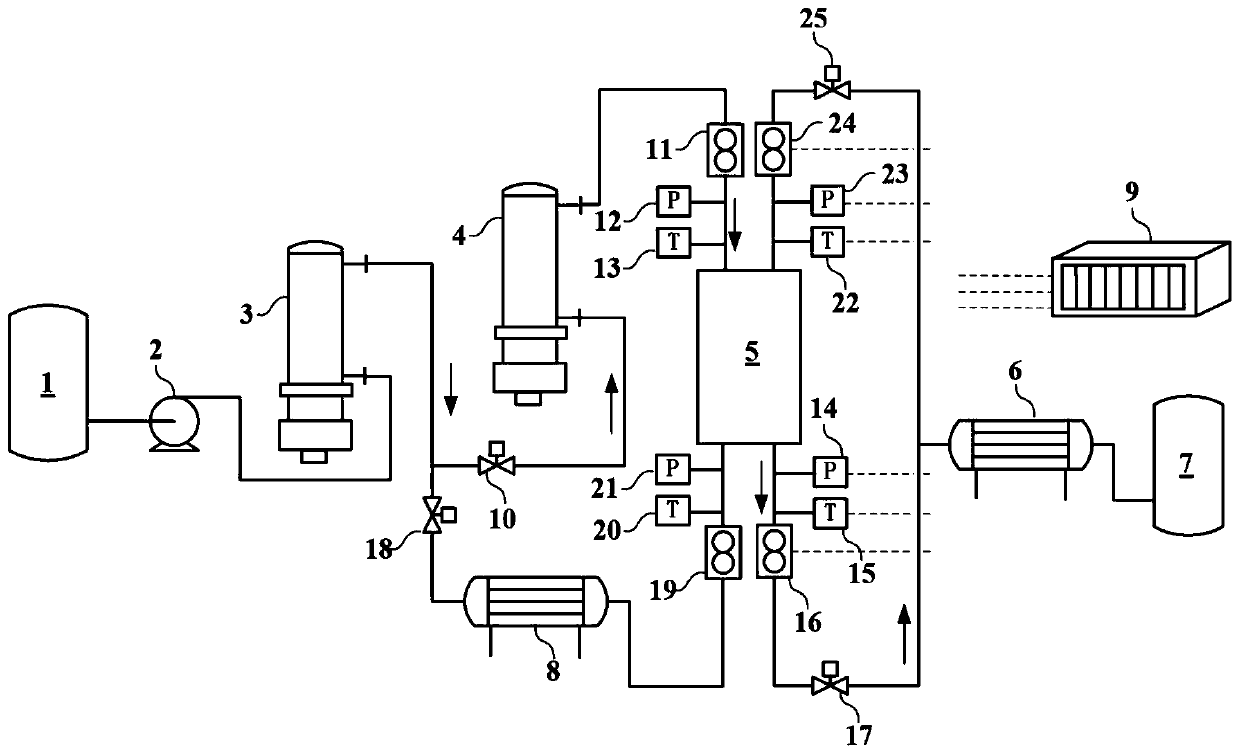

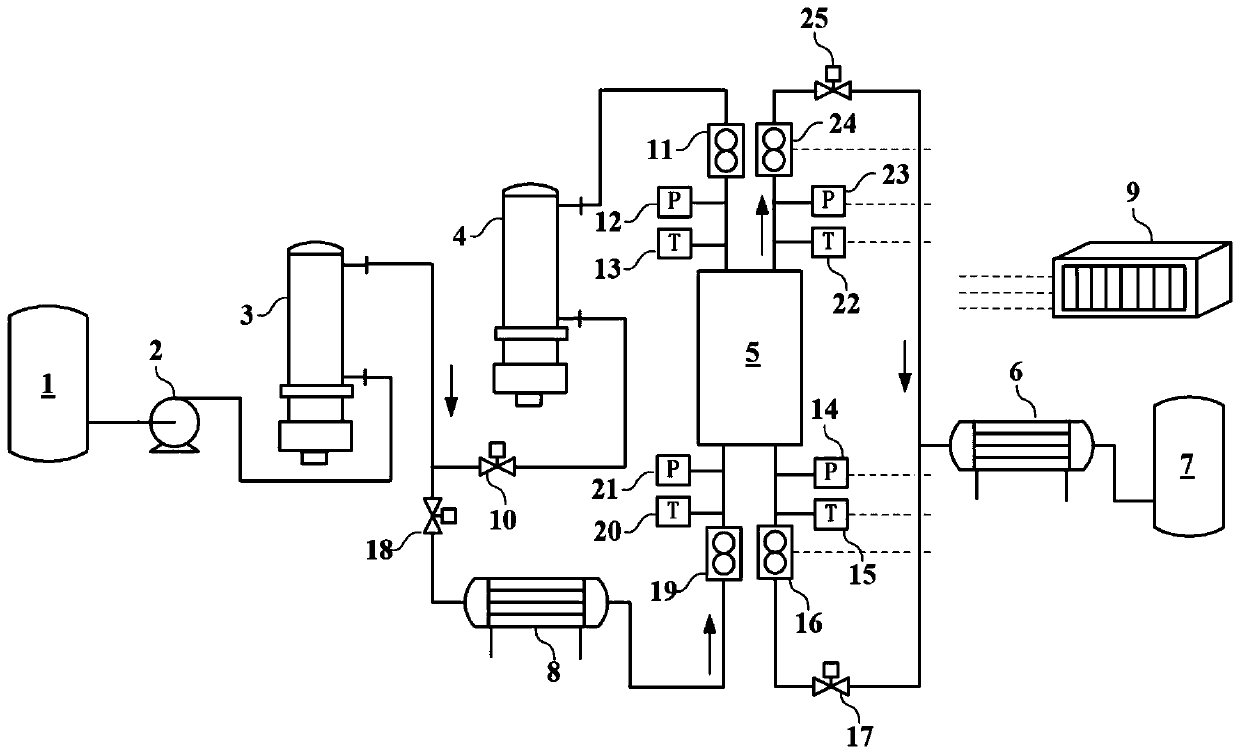

Performance test system of heat storage equipment taking steam as working medium

ActiveCN111307479AHigh pressure accuracyHigh accuracy of flow controlStructural/machines measurementControl systemData acquisition

The invention discloses a performance test system of heat storage equipment taking steam as a working medium. The system can carry out performance test experiment and evaluation on the heat storage performance of the heat storage equipment taking the steam as the medium. The system is composed of an electric steam generator, an electric superheater, a heat exchanger, a data acquisition and controlsystem, tested equipment, a pump valve assembly, a state parameter measuring instrument and the like. According to the system, high-temperature steam heat storage / release conditions of different scales and working condition parameters can be realized, unstable heat energy working conditions such as industrial waste heat can be simulated, and research, development and test of heat storage key components in the compressed air energy storage system can be met.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Pressure safety valve

InactiveCN101078446AHigh pressure accuracyAchieve sealingEqualizing valvesSafety valvesSafety valveVALVE PORT

The invention discloses a pressure safety valve, comprising valve body, valve cover set on the port end of said valve body, hollow cavity formed by said valve body and the valve cover, flow inlet path and flow outlet path connected with said hollow cavity respectively, and control device set in the hollow cavity to control connection and disconnection of said flow inlet path and flow outlet path. The control device comprises a valve pad and force device, which can apply force to the valve pad. The valve pad is attached to the port end of flow outlet path in the hollow cavity. The opening direction of said flow inlet path in said hollow cavity is corresponding with the moving direction of said valve pad. By controlling flow outlet path the valve pad realizes connection and disconnection of flow inlet path and flow outlet path. Because the valve pad can be made as large as possible in the range the hollow cavity allows, the force on valve pad can be enlarged so that pressure accuracy of pressure safety valve opening can be improved greatly.

Owner:范绍魁

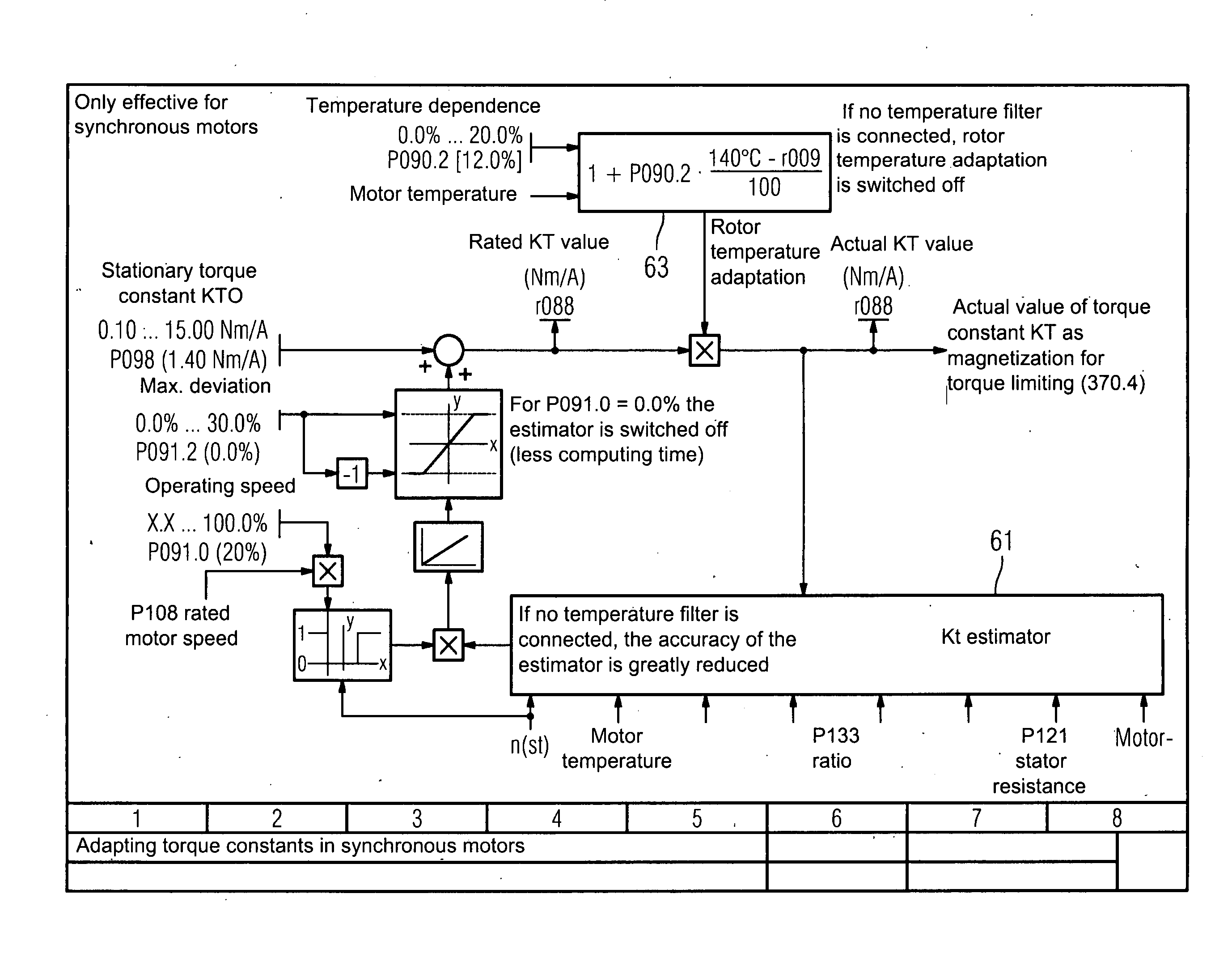

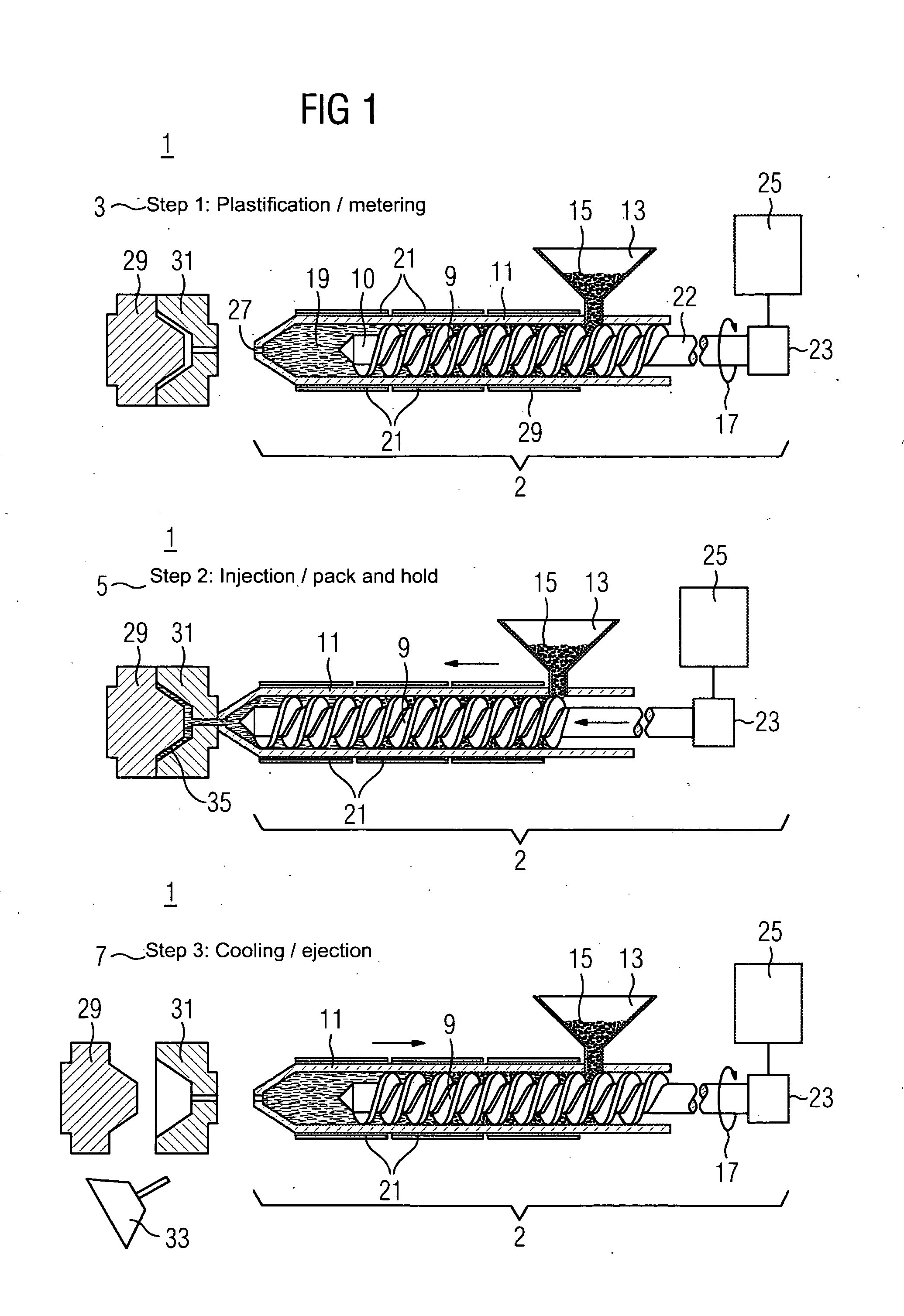

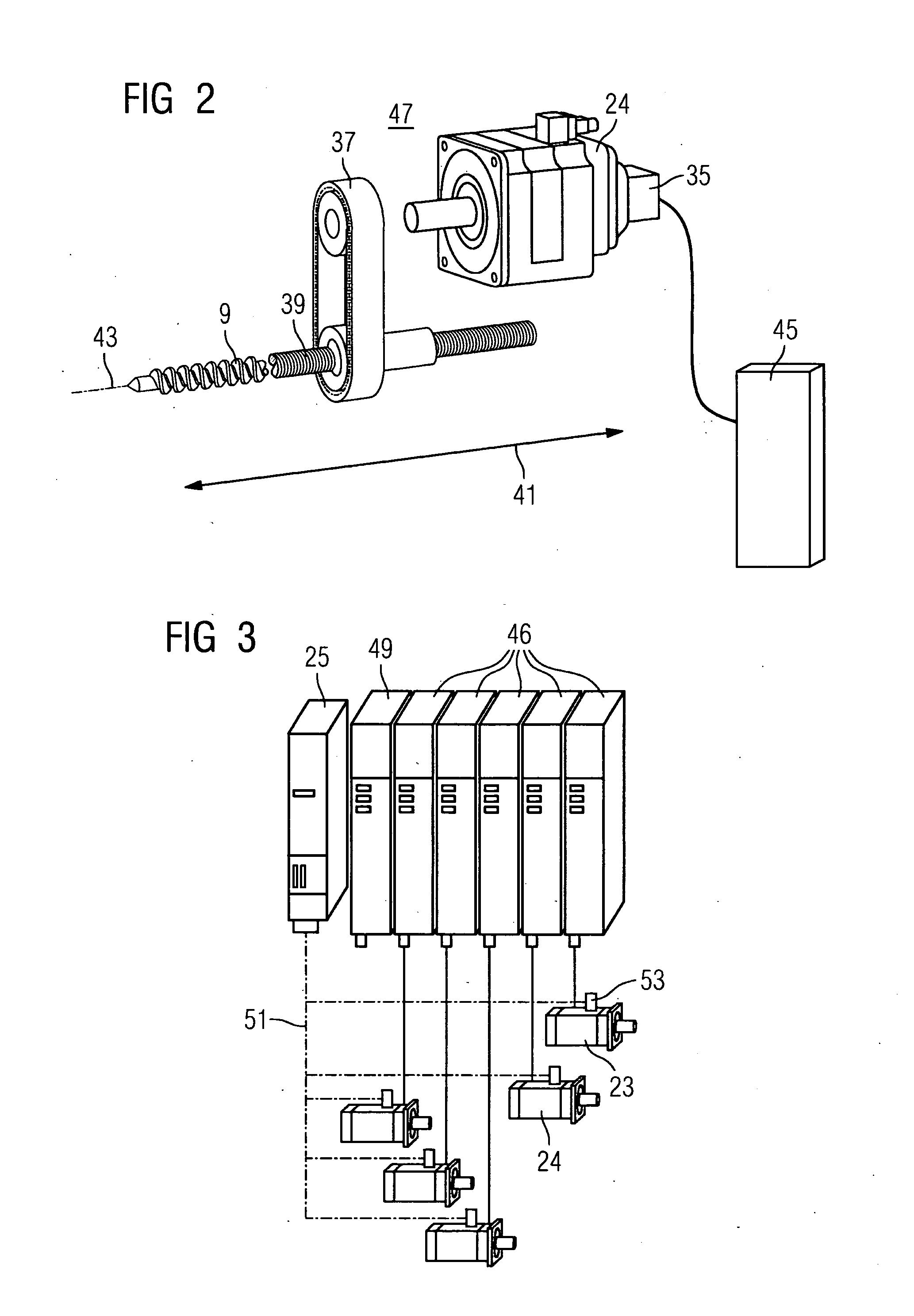

Injection Device of an Injection Molding Machine and Method for the Operation Thereof

InactiveUS20090065962A1Low costHigh pressure accuracyAuxillary shaping apparatusInjection pressureOperating point

There is described a device and a method for operating an injection device for an injection molding machine which is provided with an extruder screw that is driven by an electric machine. Acceleration values and / or values depending on an operating point of the electric machine are used for calculating an injection pressure and / or a ram pressure, thus dispensing with the need for a pressure sensor.

Owner:SIEMENS AG

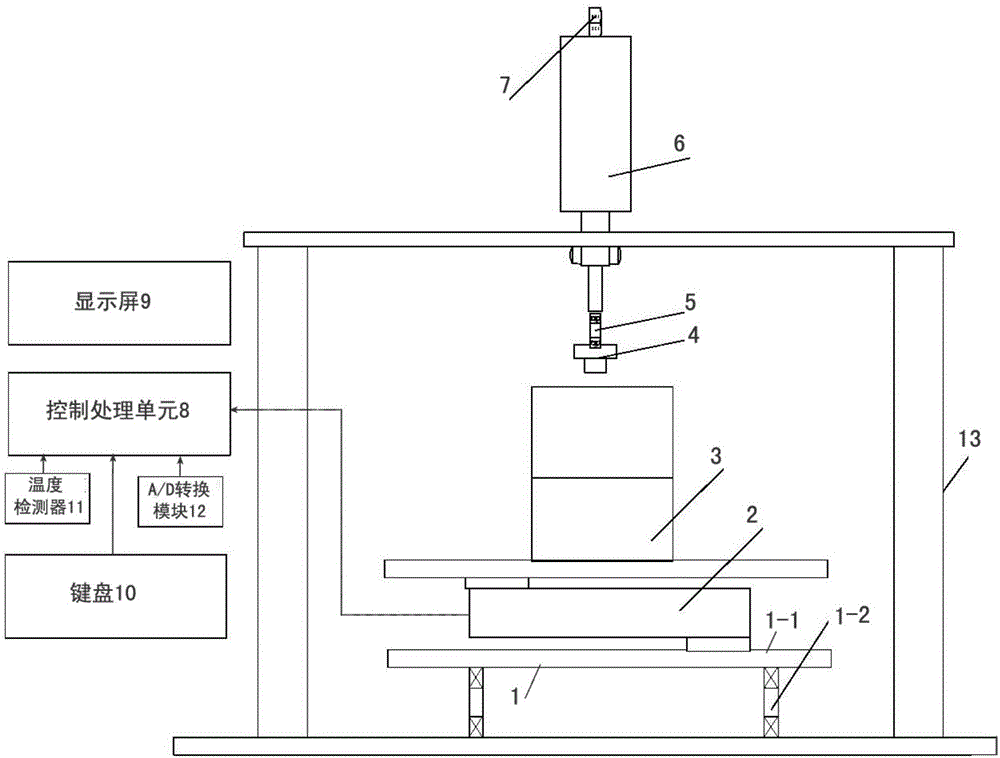

Gel strength measuring method and device

ActiveCN106442138AReduce displacementHigh precisionMaterial strength using tensile/compressive forcesComputer moduleEngineering

The invention relates to a gel strength measuring method and device. The method is characterized by including the steps: 1) preparing the measuring device and gel solution with the weight percentage content of 1.5%; 2) placing the gel solution on a gravity sensing platform of the measuring device; 3) making zero for weight data of the measuring device by a data reset key of a keyboard of the measuring device; 4) adjusting a tightening adjustment screw of the measuring device, enabling a detecting head to pressure on the surface of gel to be detected, and driving the detecting head to apply pressure to the surface of the gel by a spiral expansion joint; 5) acquiring information of the surface of the gel bearing the pressure by the aid of a gravity sensor of the bottom surface of the gravity sensing platform, converting the information by an A / D (analog to digital) conversion module of the measuring device, transmitting the converted information to a control processing unit, and processing the information; 6) locking maximum pressure born by the surface of the gel before being broken and duration time bearing the maximum pressure by the control processing unit when the gel is broken by gravity. The measuring method has the advantages that the measuring device is simple in structure, high in accuracy and efficiency, short in measuring time and the like.

Owner:GUANGDONG OCEAN UNIVERSITY +1

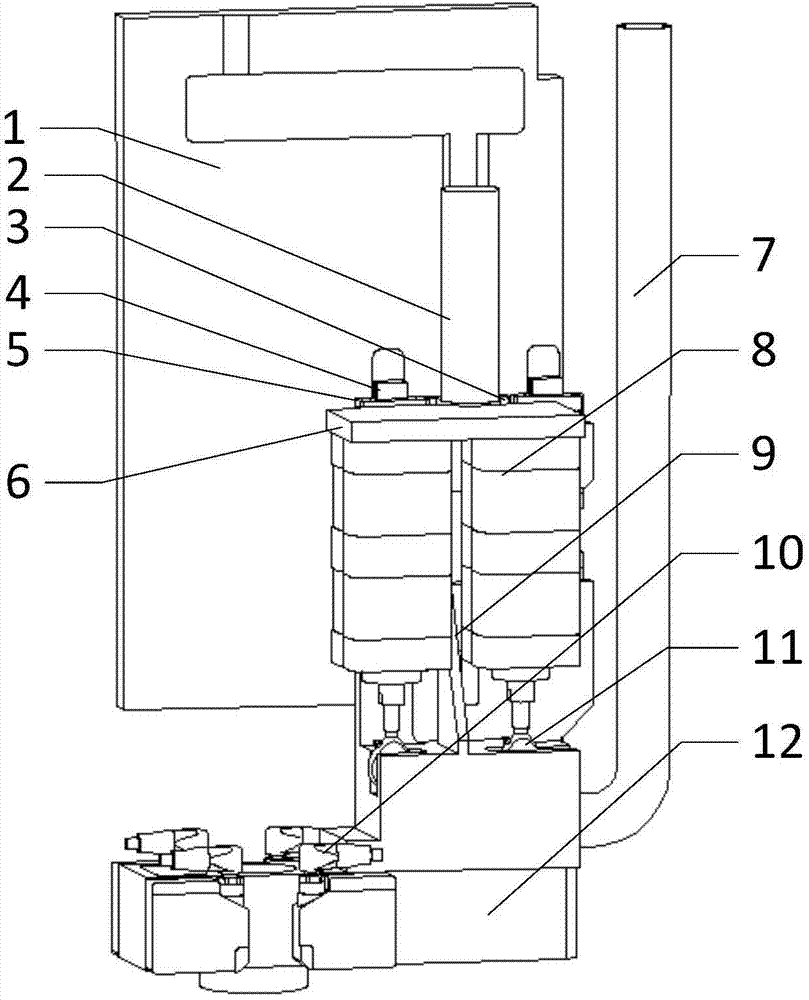

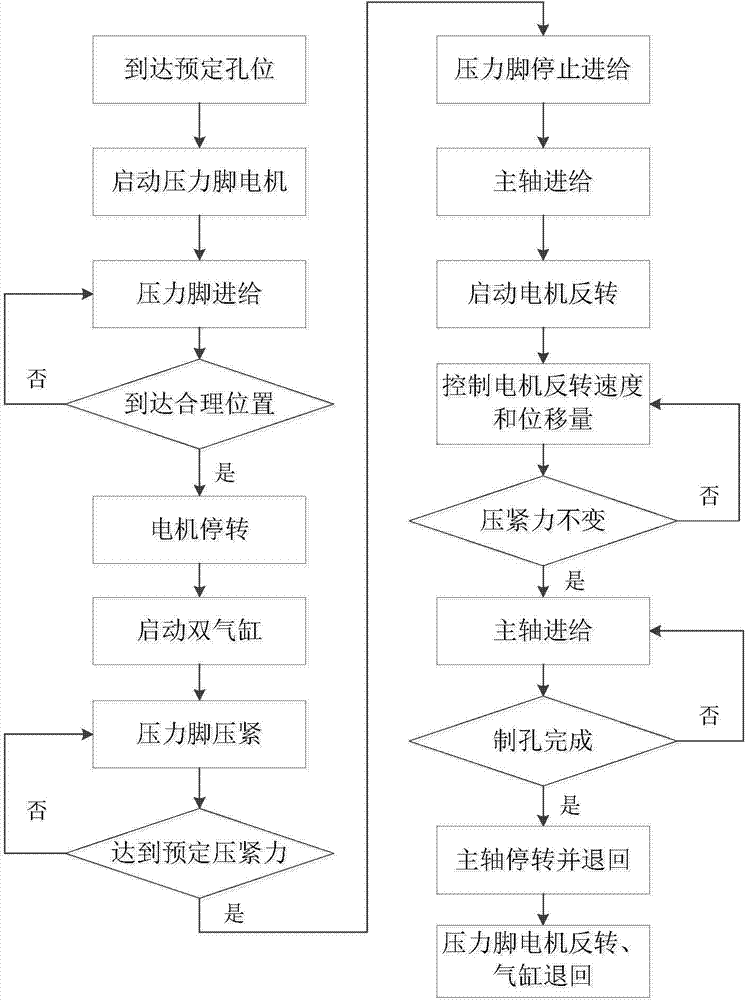

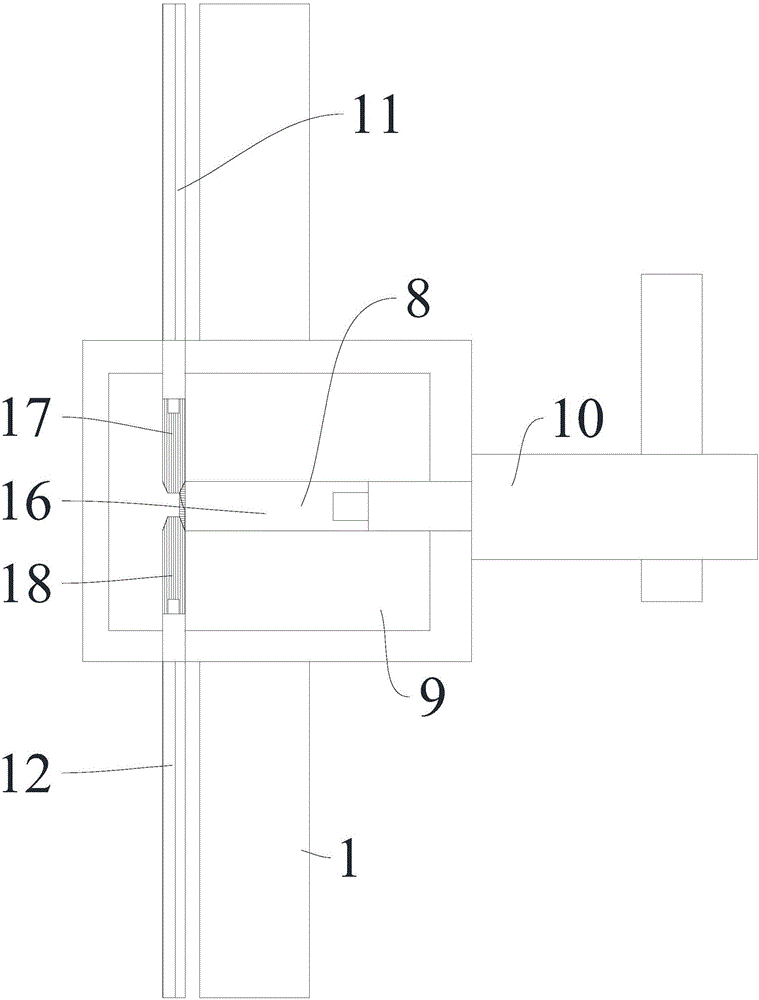

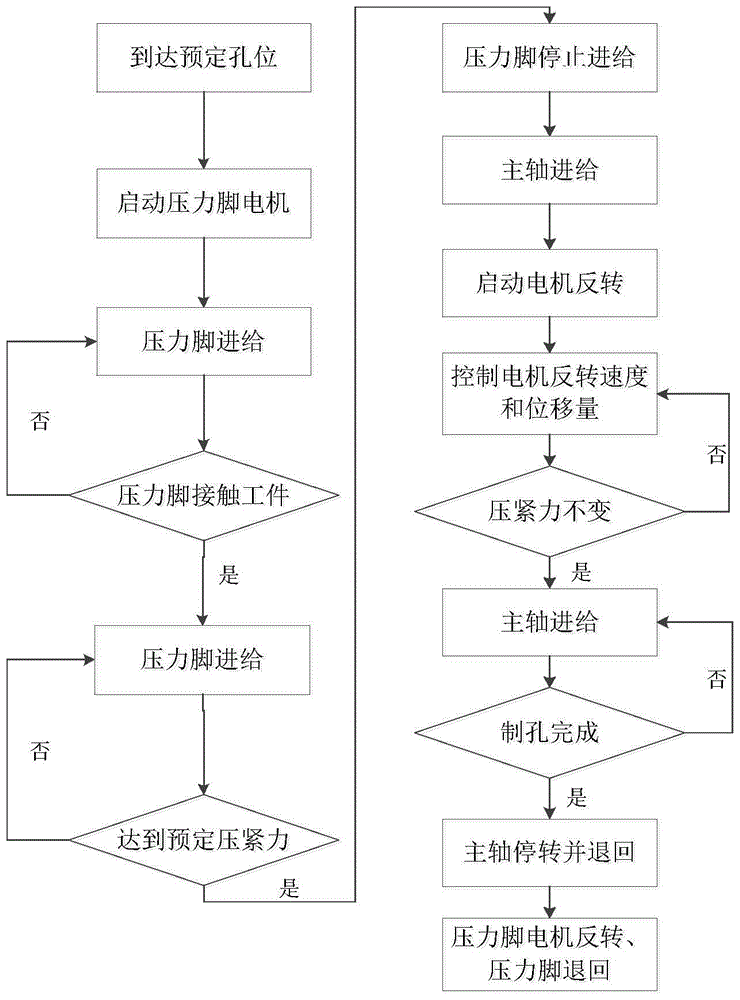

Electric pneumatic coupled pressure foot of automatic drilling tail end executor and control method

ActiveCN104741662ACompact structureAvoid synergyPositioning apparatusBoring/drilling componentsMotor driveBall screw

An electric pneumatic coupled pressure foot of an automatic drilling tail end executor is installed on a spindle base plate, wherein a drilling spindle is installed on the spindle base plate, the spindle base plate is installed on an internal cross sliding table of the tail end executor, and the drilling spindle performs feed with movements of the spindle base plate on the cross sliding table. The electric pneumatic coupled pressure foot is characterized in that the pressure foot comprises a pressure foot body and a pressure foot servo system, the pressure foot body is connected with a pressure foot base, and the pressure foot servo system comprises a servo motor, driving air cylinders, a control servo motor and an upper computer for the driving air cylinders. The upper computer is installed on a tail end executor controller, the servo motor drives a ball screw, a first least screw connecting plate is fixed to a lead screw, the driving air cylinders are symmetrically arranged on two sides of the lead screw and are installed at the bottom of the first least screw connecting plate, the output ends of the driving air cylinder are connected with the pressure foot body, and the first least screw connecting plate is installed on guide rails through slide blocks.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

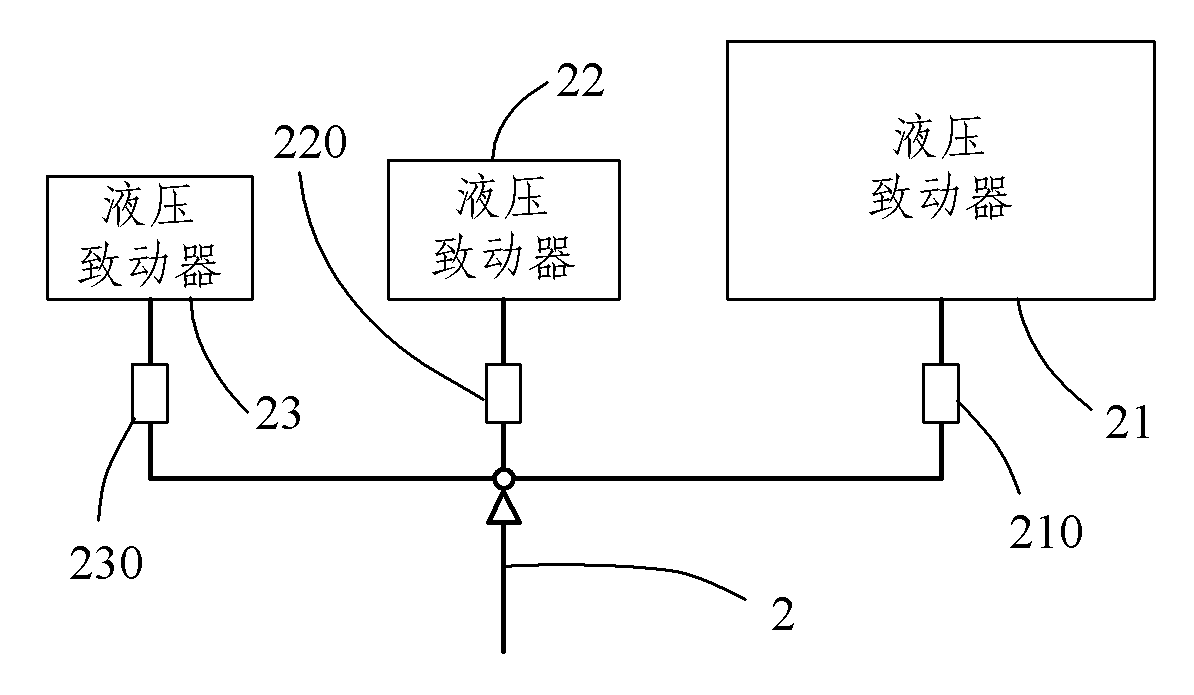

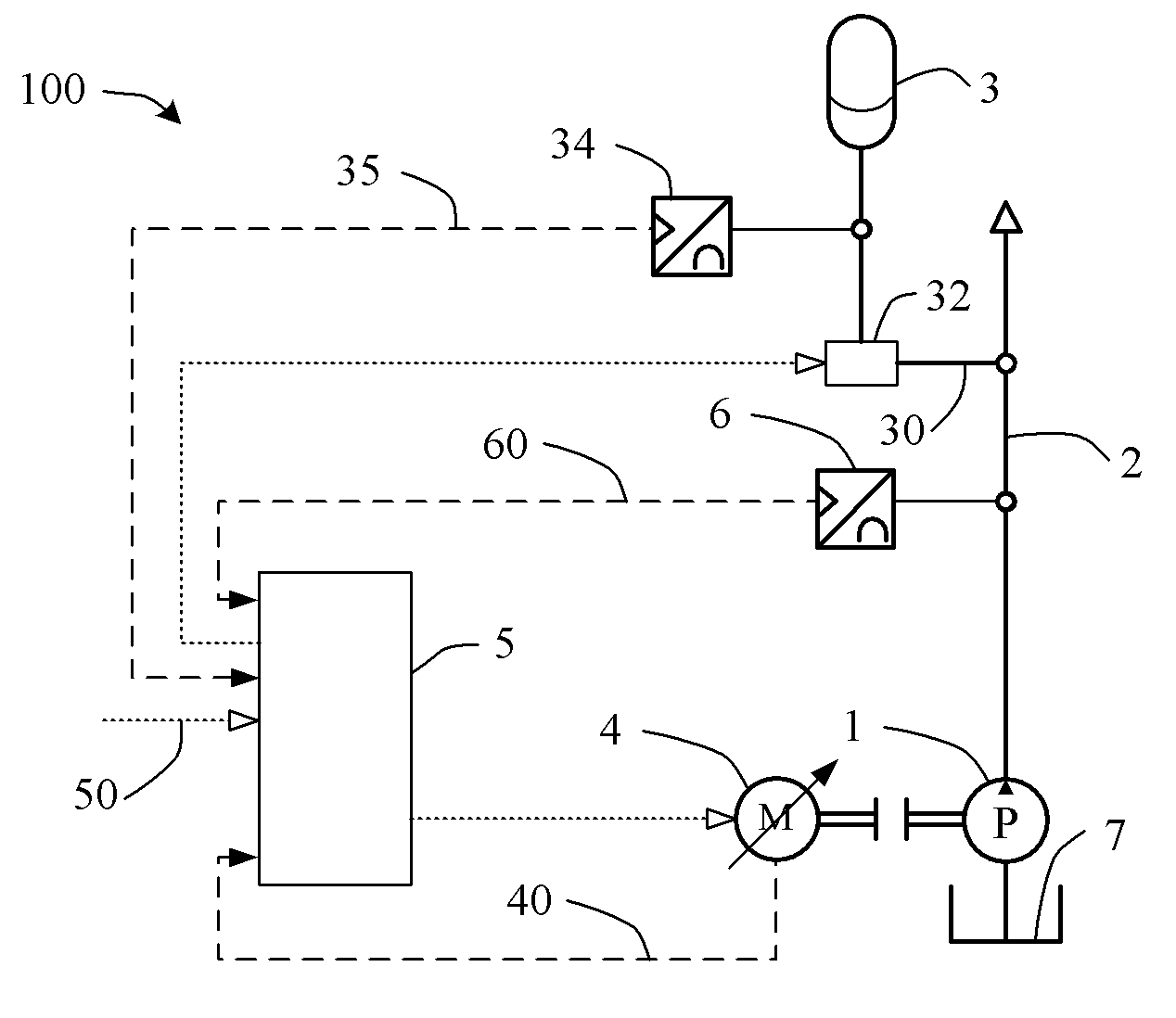

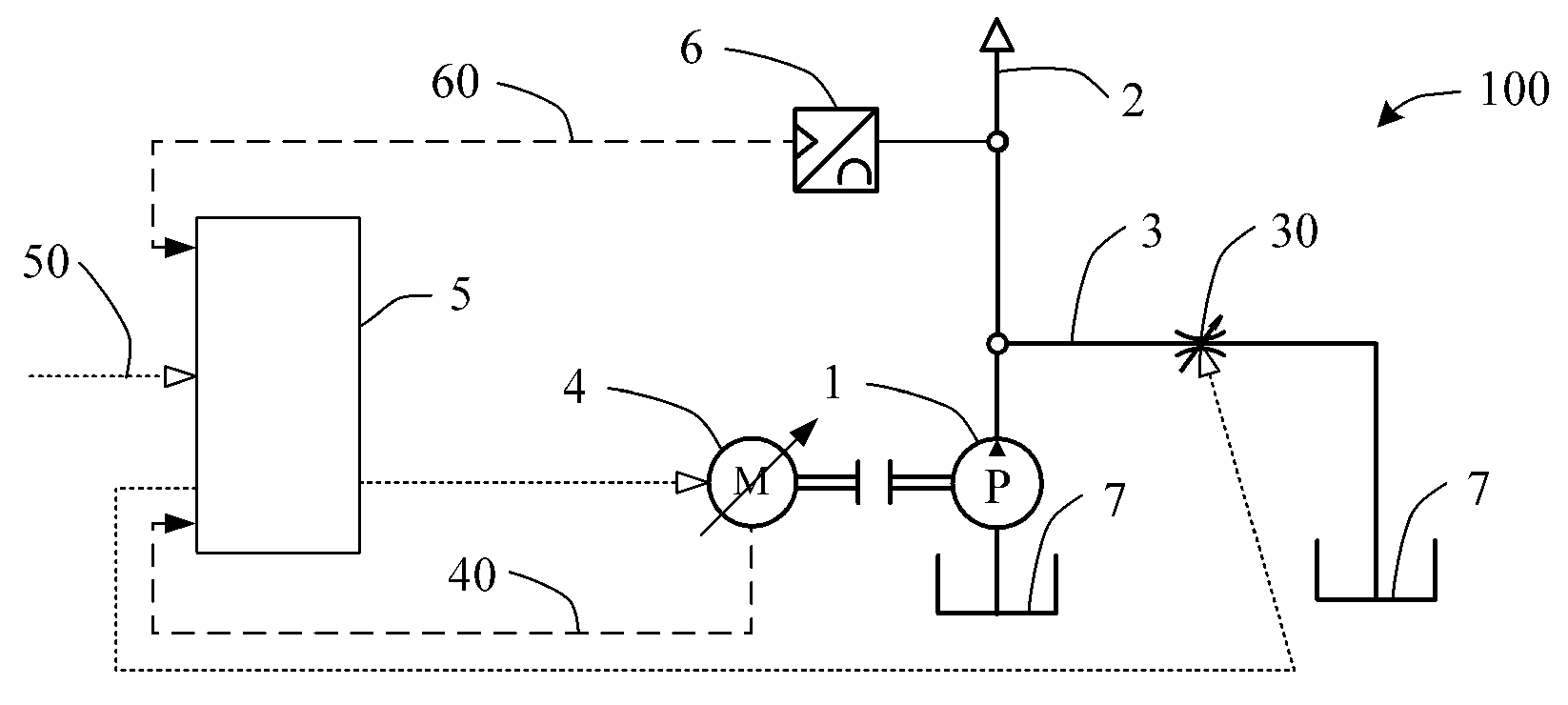

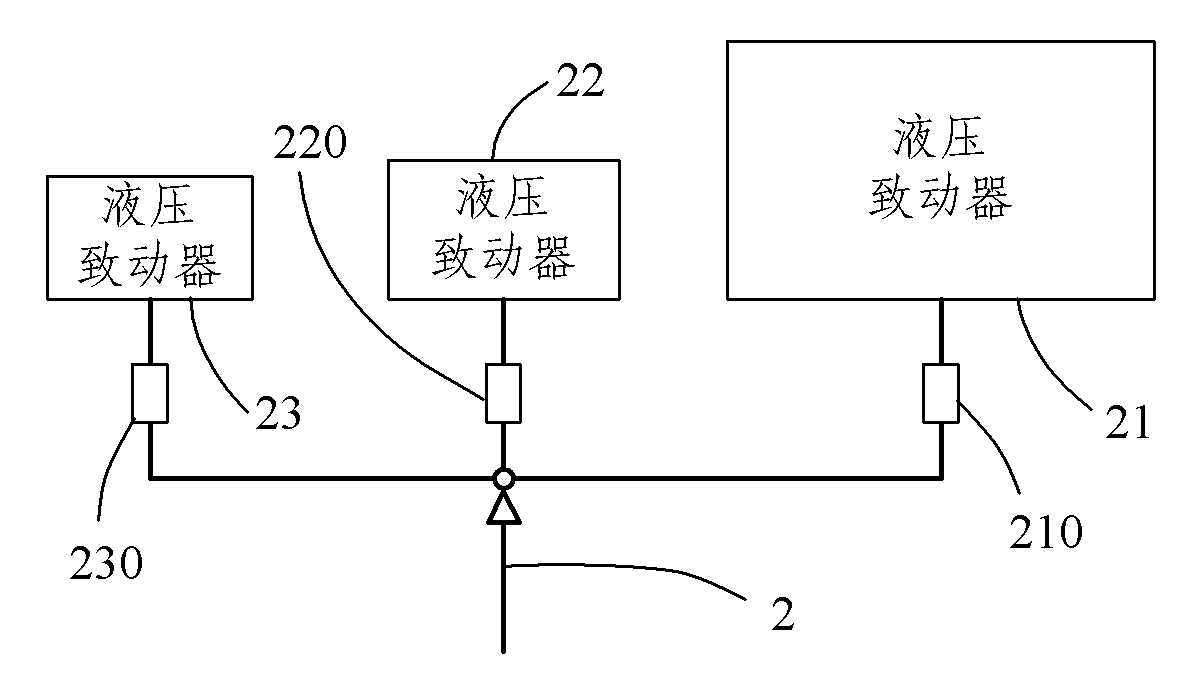

Hydraulic driving device and system

The invention discloses a hydraulic driving device and system. The hydraulic driving device comprises a hydraulic pump, an energy accumulator and a control unit; wherein the hydraulic pump pumps hydraulic fluid into a hydraulic output line from a liquid storing device; the energy accumulator is connected to the hydraulic output line by an energy accumulation line; a flow control device is arranged in the energy accumulation line; the control unit adjusts the flow of the hydraulic fluid passing by the energy accumulation line by controlling the flow control device according to operation conditions. In the hydraulic driving system, the hydraulic output line is connected to one or more hydraulic actuators. Therefore, the flow and pressure of hydraulic fluid passing by the energy accumulation line can be adjusted by the hydraulic driving device and system according to the operation conditions in real time, the work efficiency is improved, energy consumption is reduced, and the pressure precision is improved.

Owner:BOSCH REXROTH (CHANGZHOU) CO LTD

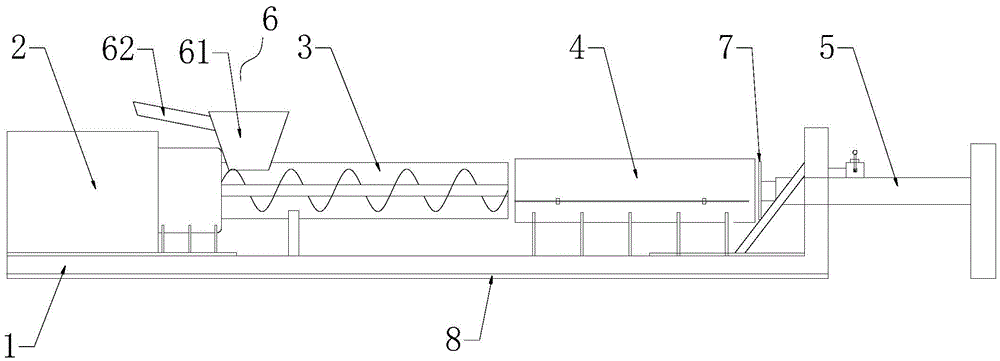

Bagging machine

InactiveCN105584648ASimple structureEasy to operateSolid materialPackaging automatic controlHydraulic cylinderEngineering

The invention id suitable for the technical field of automatic equipment, and provides a bagging machine. The bagging machine comprises a base as well as a drive device, a feeding device, a bag bin and a pressure measuring device which are sequentially arranged on the base, wherein the drive device drives the feeding device to rotate; a feeding bin is arranged on the feeding device; the discharge hole of the feeding device is provided with the barrel-shaped bag bin; the tail end of the bag bin is provided with the pressure measuring device; the pressure measuring device comprises a hydraulic cylinder; the end part of the piston rod of the hydraulic cylinder is provided with a platform; and the platform can enter the bag bin in a telescopic mode. The bagging machine is simple in structure, is easy to operate, and is low in manufacturing cost; automatic bagging is realized through a packing auger conveying device, and pressure in a bag is measured in real time by the pressure measuring time, so that automatic filling with constant pressure is realized, and therefore, the bagging speed is high, the labor power is saved, the problem that the degree of tightness of the bagging is uneven is effectively solved, and the pressure precision is high.

Owner:徐述山

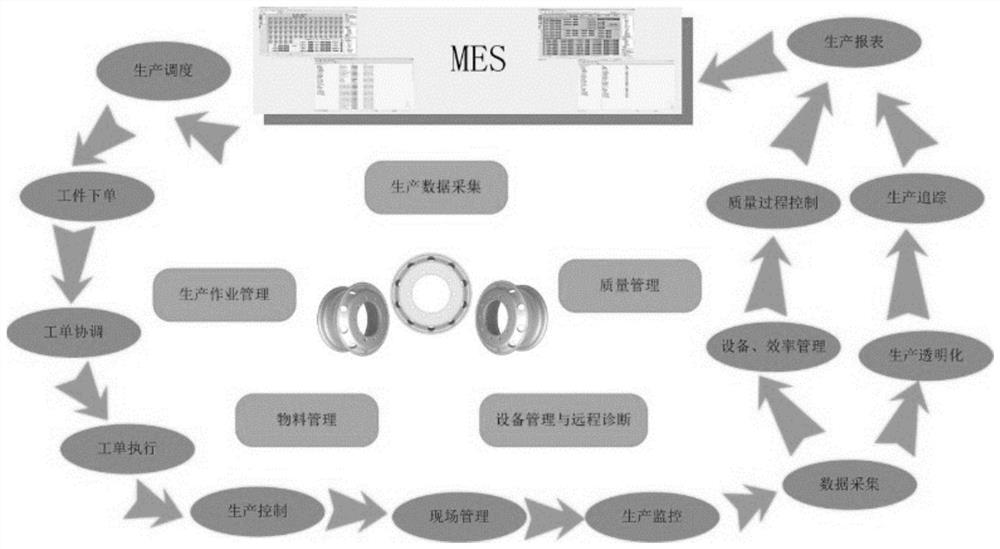

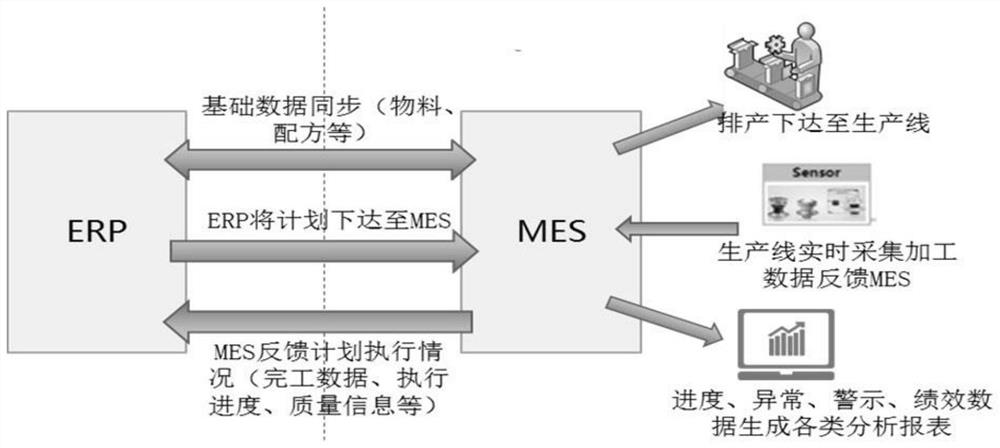

Intelligent control system for forging and pressing line

PendingCN112987671ARealize the formulation of process parametersOptimal control of production operationsTotal factory controlProgramme total factory controlIntelligent managementMechanical engineering

The invention provides a forging and pressing line intelligent control system which comprises an intelligent mold recognition unit used for recognizing parameter information of molds of a forging and pressing line, storing the parameter information and making preparations for subsequent calling of the parameter information. and a workshop intelligent management unit, which can receive the parameter information, form forging and pressing line process data including the parameter information, analyze the forging and pressing line process data, formulate process parameters of the forging and pressing line, and transmit the process parameters to the forging and pressing line to control the production operation of the forging and pressing line.

Owner:TIANJIN SINO GERMAN VOCATIONAL TECHNICAL COLLEGE

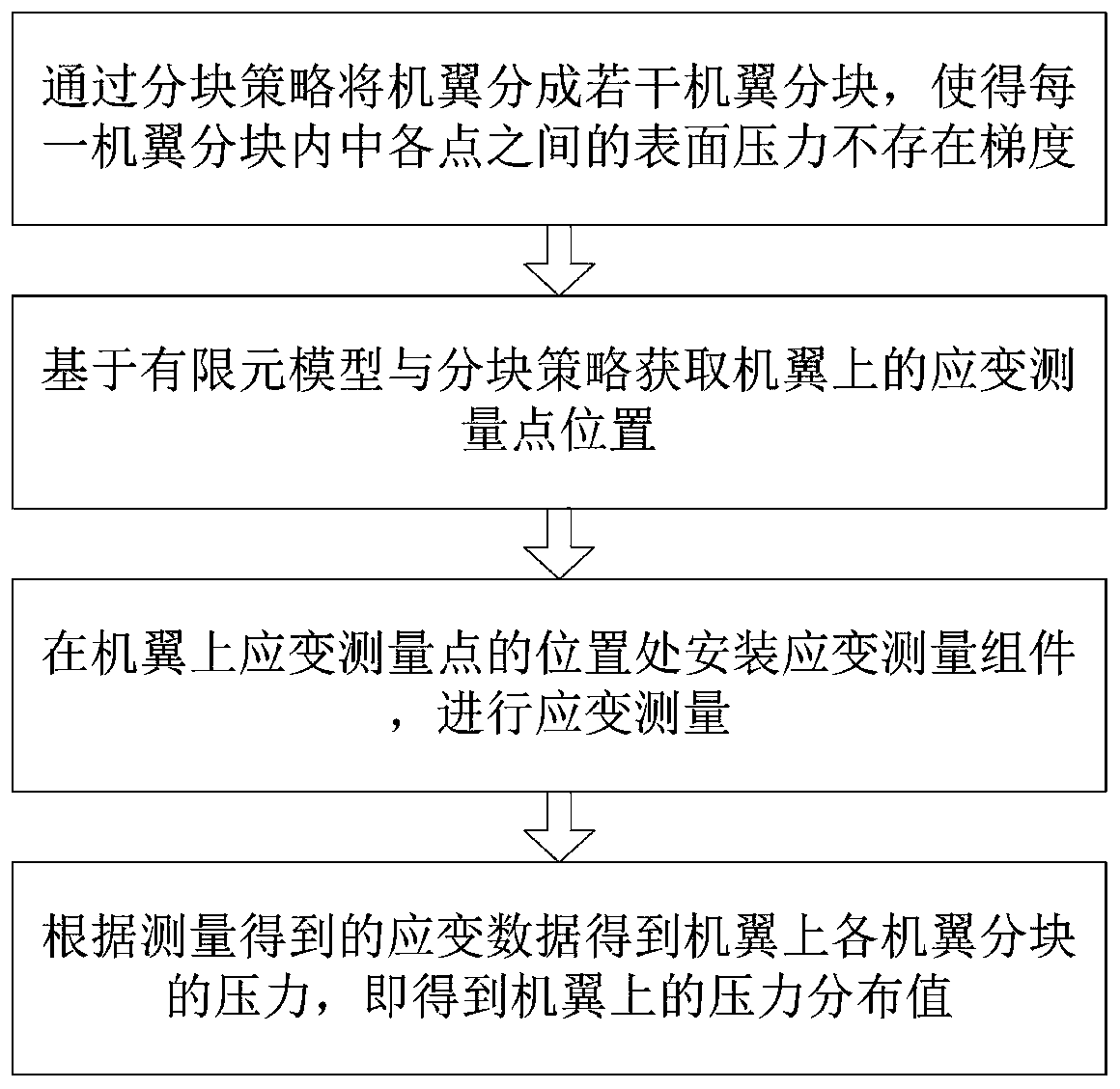

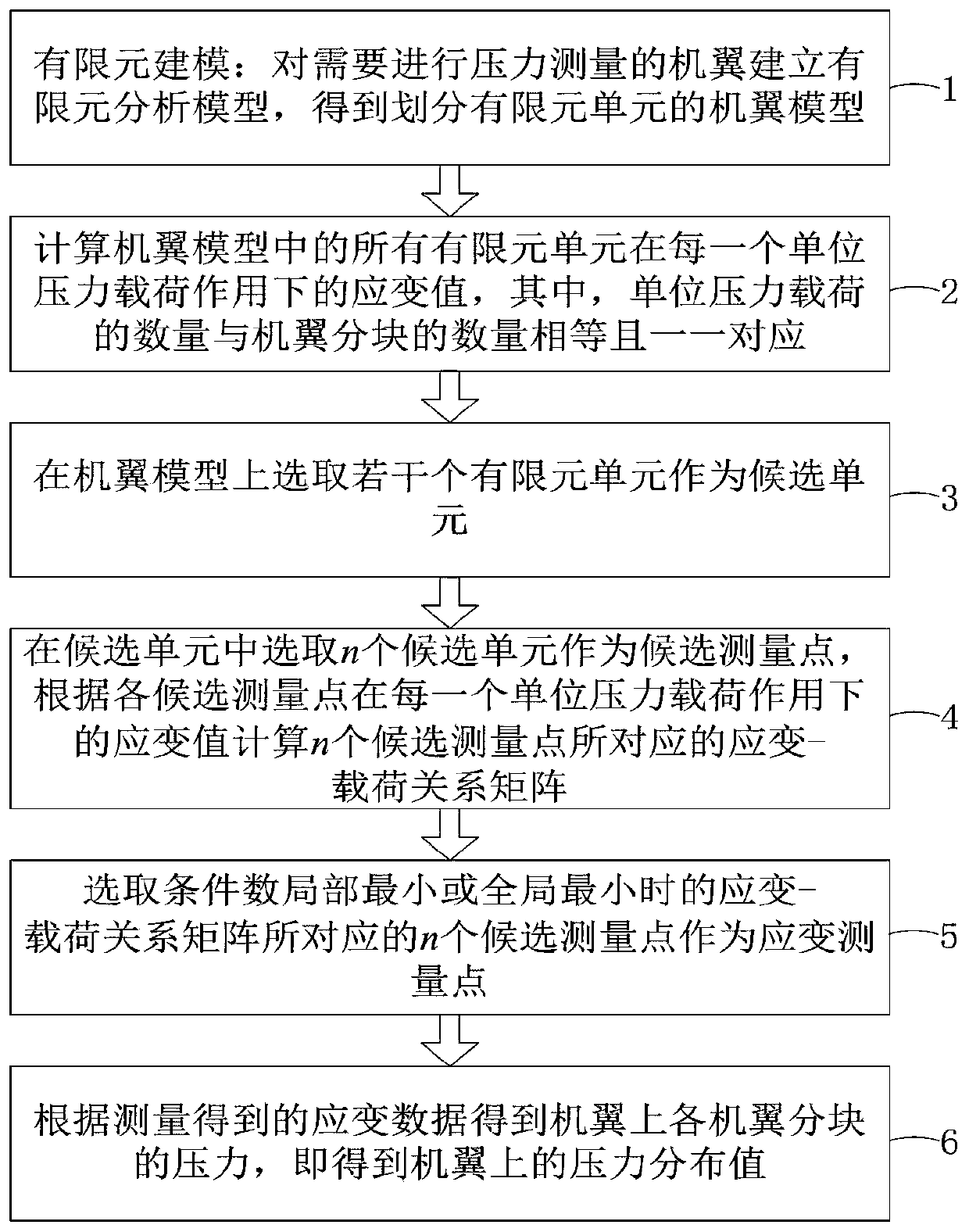

Method, system and device for measuring surface pressure of wing

ActiveCN110763424AHigh pressure accuracyImprove economyAerodynamic testingFluid pressure measurement by electric/magnetic elementsElement modelClassical mechanics

The invention discloses a method, system and device for measuring surface pressure of a wing, and the method comprises the following steps of the first step, dividing the wing into a plurality of wingblocks by a block division strategy, so that there is no gradient in the surface pressure between each point in each wing block; the second step, obtaining the position of a strain measurement pointon the wing based on the finite element model and the block strategy; the third step, installing a strain measurement component at the position of the strain measurement point on the wing to perform the strain measurement; and the fourth step, obtaining the pressure of each wing block on the wing according to the measured strain data, that is, obtaining a pressure distribution value on the wing. By dividing the wing into a plurality of wing blocks by the block division strategy, obtaining the position of the strain measurement point on the wing by using the finite element model and its calculation results, and reversely calculating the actual pressure value of the wing during the work process by combining the measurement of the actual strain of the strain measurement point on the wing, theprecision of the surface pressure obtained of the wing is high, the implementation method is convenient, the economy is high, and the efficiency is high.

Owner:CHINA POWER IND INTERNET CO LTD

Pressure sensor having improved arrangement of sensor chip for minimizing influence of external vibrations

InactiveUS7490520B2Minimize impactHigh pressure accuracyFluid pressure measurement using elastically-deformable gaugesSolid-state devicesEngineeringPressure sensor

Owner:DENSO CORP

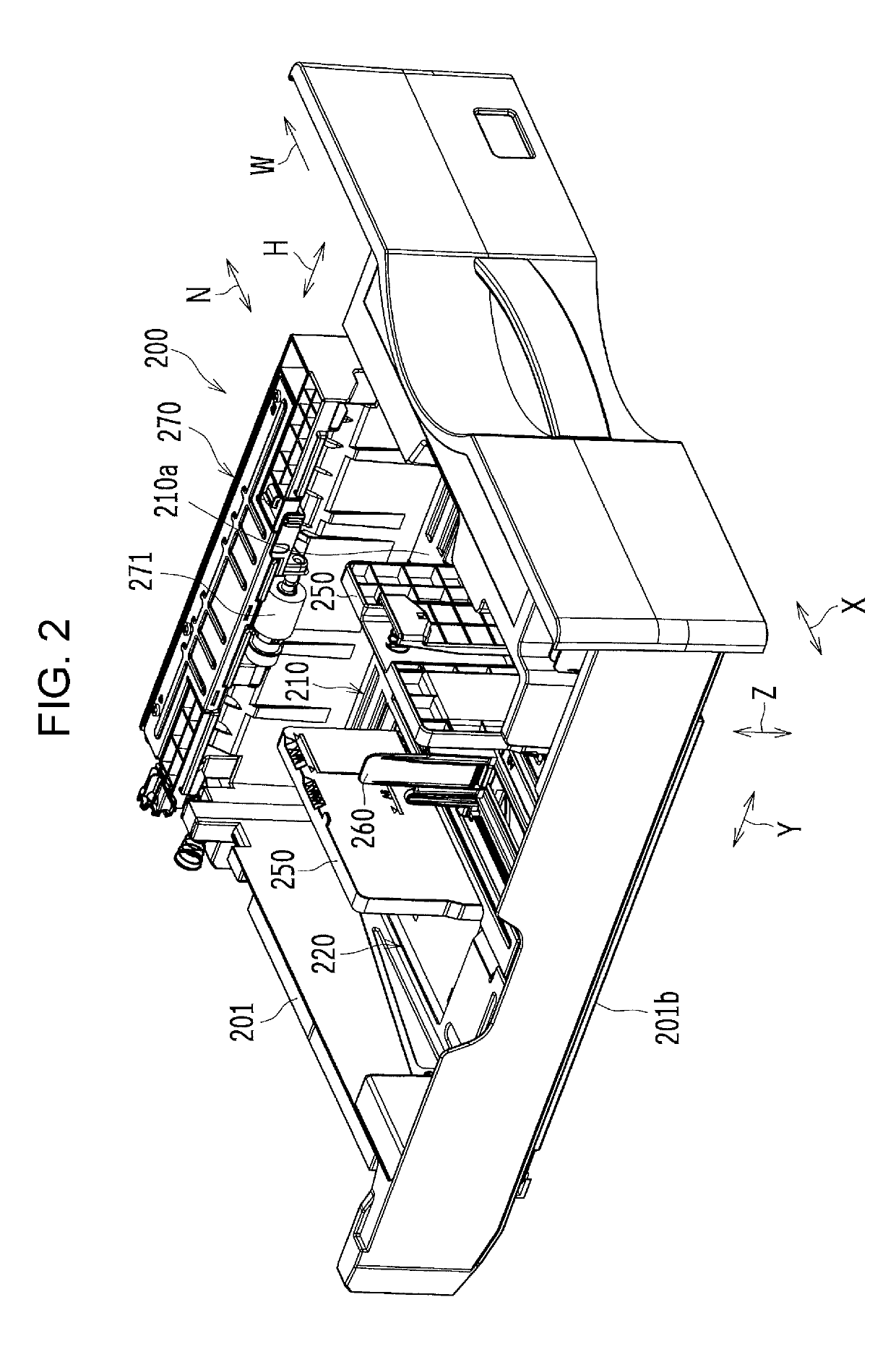

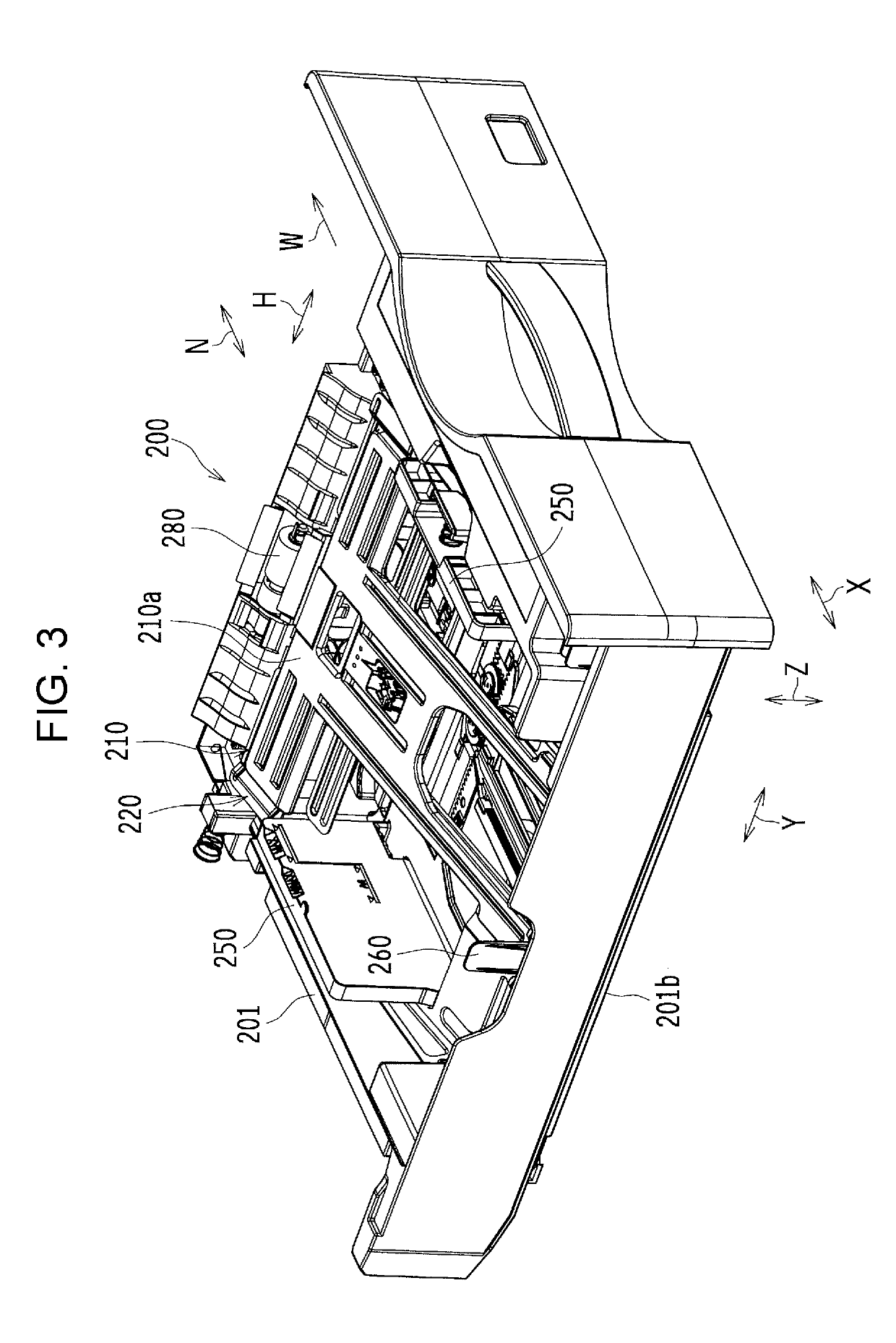

Sheet accommodating device and image forming apparatus including the same

ActiveUS10494206B2High pressure accuracyElectrographic process apparatusArticle separationEngineeringImaging equipment

Owner:SHARP KK

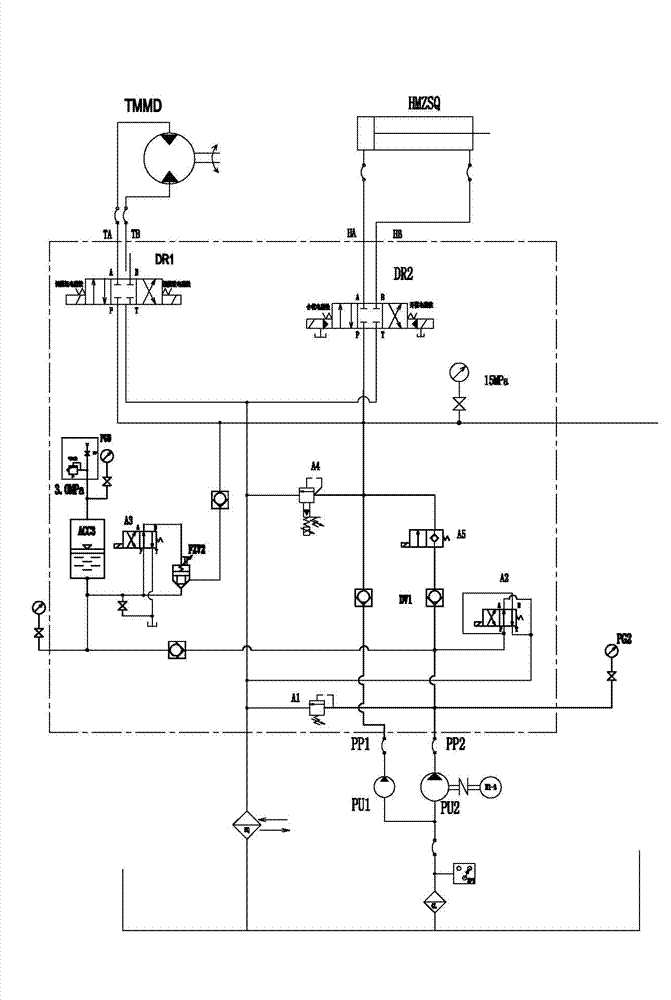

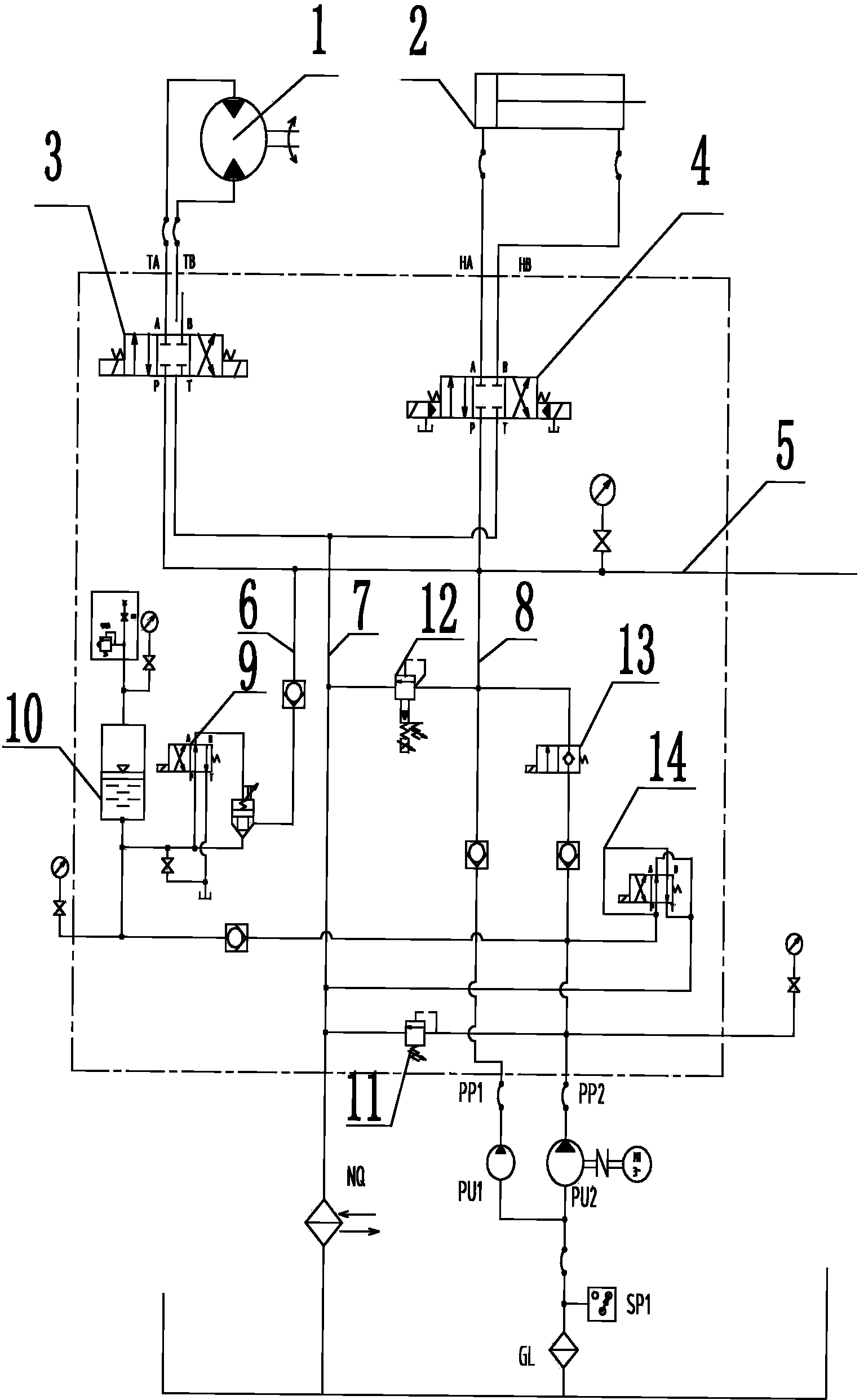

Environmental-friendly energy-saving die-casting machine electrohydraulic control system and energy-saving method

The invention relates to an environmental-friendly energy-saving die-casting machine electrohydraulic control system, which is characterized in that the system comprises a large oil pump (PU2), a small oil pump (PU1), a die closing valve (DR2) and a die adjusting valve (DR1), the output end of large oil pump (PU2) is respectively connected with the oil inlet passages of the die closing valve (DR2) and the die adjusting valve (DR1) through a solenoid valve (A5) and a proportional overflow valve (A4), an unloading valve (A2) is additionally connected at the outlet end of the large oil pump (PU2), the output end of the unloading valve (A2) is communicated with the oil inlet end of an energy storage device (ACC3), and the output end of the energy storage device (ACC3) is respectively connected with the oil inlet passages of the die closing valve (DR2) and the die adjusting valve (DR1) through a solenoid valve (A3). The environmental-friendly energy-saving die-casting machine electrohydraulic control system has the advantages that the motor power and the pump displacement are reduced by 50 percent, approximate 50-60 percent of energy can be saved, the action stability is high, the response sensitivity is high and the like.

Owner:YIXING JIACHEN DIE CASTING MACHINE MFG

Lateral support pressing mechanism for numerical control bending machine

The invention relates to the technical field of forging, in particular to a lateral support pressing mechanism for a numerical control bending machine. The mechanism comprises a fixed bracket fixed on one side of a lower mold of the numerical control bending machine, and a longitudinal lead screw positioned between the fixed bracket and the lower mold of the numerical control bending machine; the longitudinal lead screw is coated with a main cylinder; an upper fixed mounting base is arranged at the upper end of the main cylinder; and a lower fixed mounting base is arranged at the lower end of the main cylinder. The lateral support pressing mechanism for the numerical control bending machine respectively performs fixed connection for an upper pressing rod and a lower support rod through threaded connection of the upper and lower ends of the main cylinder with the upper fixed connecting base and the lower fixed connecting base with internal thread connecting holes on the surfaces, respectively adjusts gaps between the upper and lower fixed connecting bases through linkage of a control rod on a control base with a transmission rod, can freely adjust the height according to the workpiece thickness, further improves the support pressing precision, and promotes the production efficiency.

Owner:黄石华强数控机床有限公司

Hydraulic drive device and system

InactiveCN103790873AFlow adjustableHigh pressure accuracyServomotorsHydraulic pumpControl engineering

The invention discloses a hydraulic drive device and system. The device comprises a hydraulic pump, a hydraulic bypass and a control unit. The hydraulic pump pumps hydraulic fluids from a reservoir to a hydraulic outputting line, the hydraulic bypass is connected with the reservoir through the hydraulic outputting line, an adjustable flow unit is arranged in the hydraulic bypass, and the control unit controls the flow unit to adjust the flow of the hydraulic fluids in the hydraulic bypass according to operation conditions. According to the hydraulic drive system, the hydraulic outputting line is connected with one or more hydraulic actuators. By means of the hydraulic drive device and system, the flow of the hydraulic fluids in the hydraulic bypass can be adjusted, the pressure accuracy is improved, and energy is saved.

Owner:BOSCH REXROTH (CHANGZHOU) CO LTD

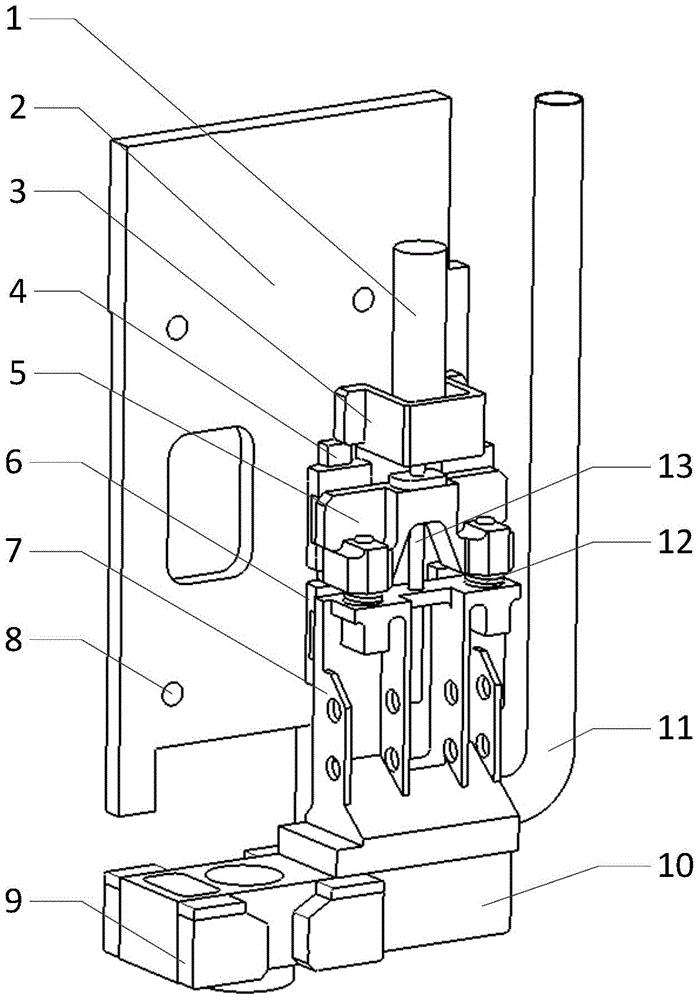

Electric and spring coupling pressure foot and control method of automatic hole-making end effector

ActiveCN104647111BCompact structureExtended service lifeFeeding apparatusPositioning apparatusCouplingBall screw

The invention relates to an electric and spring coupling pressure pin of an automatic hole manufacturing tail end actuator. The electric and spring coupling pressure pin is arranged on a main shaft bottom plate, a hole manufacturing main shaft is arranged on the main shaft bottom plate, the main shaft bottom plate is arranged on an inside cross slide table of the tail end actuator, and the hole manufacturing main shaft moves on the cross slide table for feeding. The electric and spring coupling pressure pin is characterized in that the pressure pin comprises a pressure pin body and a pressure pin servo system, wherein the pressure pin body is connected with a pressure fin base through a pressure pin connecting seat, the pressure pin connecting seat is arranged on a guide rail of the main shaft bottom plate through a first slide block, the pressure pin servo system comprises a servo motor and an upper computer for controlling the servo motor, the upper computer is arranged on a tail end actuator controller, the servo motor drives a ball screw, a screw rod connecting plate is fixedly arranged on the screw rod, springs are symmetrically arranged at two sides of the screw rod, are connected with the bottom of the screw rod connecting plate and are connected with the pressure pin body, the screw rod connecting plate is arranged on the guide rail through a second slide block, the second slide block and the first slide block share one guide rail, and the second slide block is positioned above the first slide block.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Novel hydraulic control system of die casting machine

The invention relates to a novel hydraulic control system of a die casting machine. The system comprises a die adjustment motor and a shutoff oil cylinder. The die adjustment motor is connected with a die adjustment valve, the shutoff oil cylinder is connected with a shutoff valve, the die adjustment valve and the shutoff valve are connected through a main circuit, branch circuits, namely a first branch circuit, a second branch circuit and a third branch circuit, are arranged on the main circuit, and a first electromagnetic valve and an energy storing device are arranged on the first branch circuit. Energy is saved, a hydraulic pipeline can be protected, pressure and flow precision can be improved, speed is increased, efficiency is improved, and noise is reduced.

Owner:YIXING JIACHEN DIE CASTING MACHINE MFG

Contact type semiconductor material test head

ActiveCN108663553ASimple structureFew partsElectrical measurement instrument detailsSemiconductor characterisationEngineeringContact type

The invention discloses a contact type semiconductor material test head which comprises a shell and a probe combination arranged in the shell; wherein the probe combination comprises flat tension spring sand probes; and the two sides of each flat tension spring are symmetric. Each flat tension spring comprises a spring end at the lower part and an extending end at the upper part, the probe is fixed at the center of the spring end, and the extending end is in a hollow flat plate shape. A plurality of flat tension springs are overlapped together and arranged in the shell through the extending ends, the spring ends of the flat tension springs are arranged at the lower part of the shell, and an insulating film isolation layer is arranged between every two adjacent flat tension springs. The spring end of each flat tension spring comprises spring parts arranged on the two sides and a middle part arranged between the two spring parts, a vertical clamping groove is formed in the center of themiddle part, and the probe is arranged in a vertical clamping groove arranged in the center of the middle part. According to the invention, the lateral force is completely eliminated, the structure issimple, the number of parts is small, and the distance between the probes can be greatly reduced. The negative influence on the overall test precision caused by the edge effect in the test is reduced, the test precision is high, the cost is low, and the service life is long.

Owner:SHIPELE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com