Electric pneumatic coupled pressure foot of automatic drilling tail end executor and control method

An end effector and pneumatic coupling technology, which is applied in the direction of manufacturing tools, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problems of affecting the quality of hole making, damaging the workpiece, increasing the pressing force, etc., to achieve The effect of simple and compact structure, avoiding co-action, and high pressure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

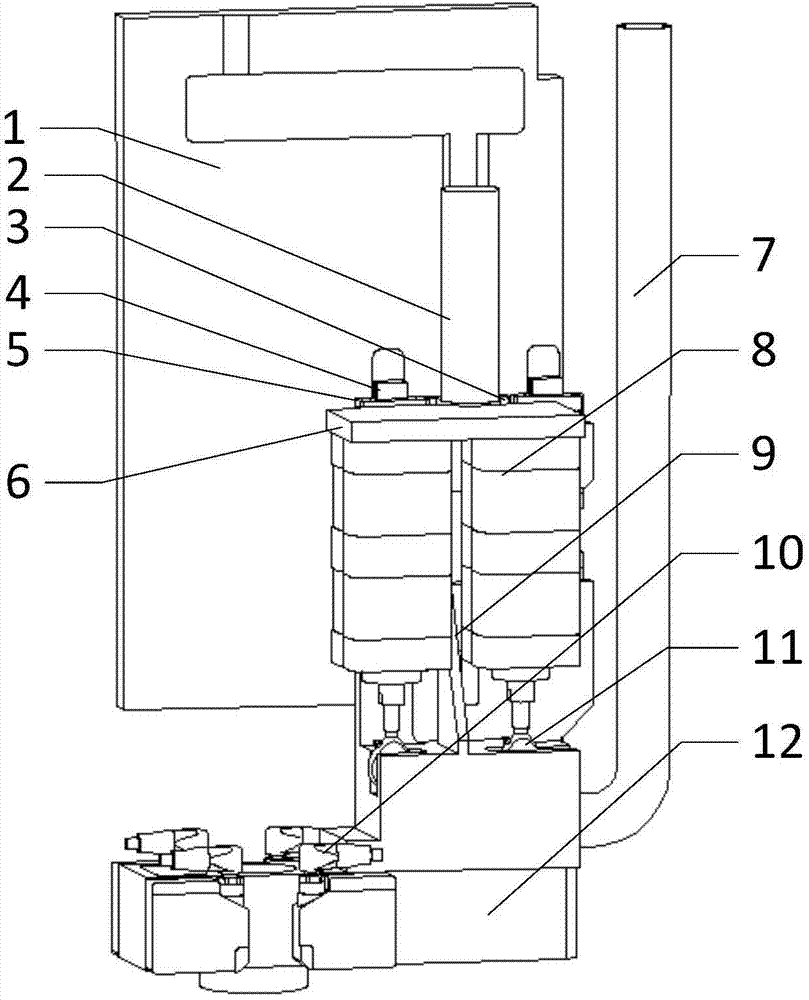

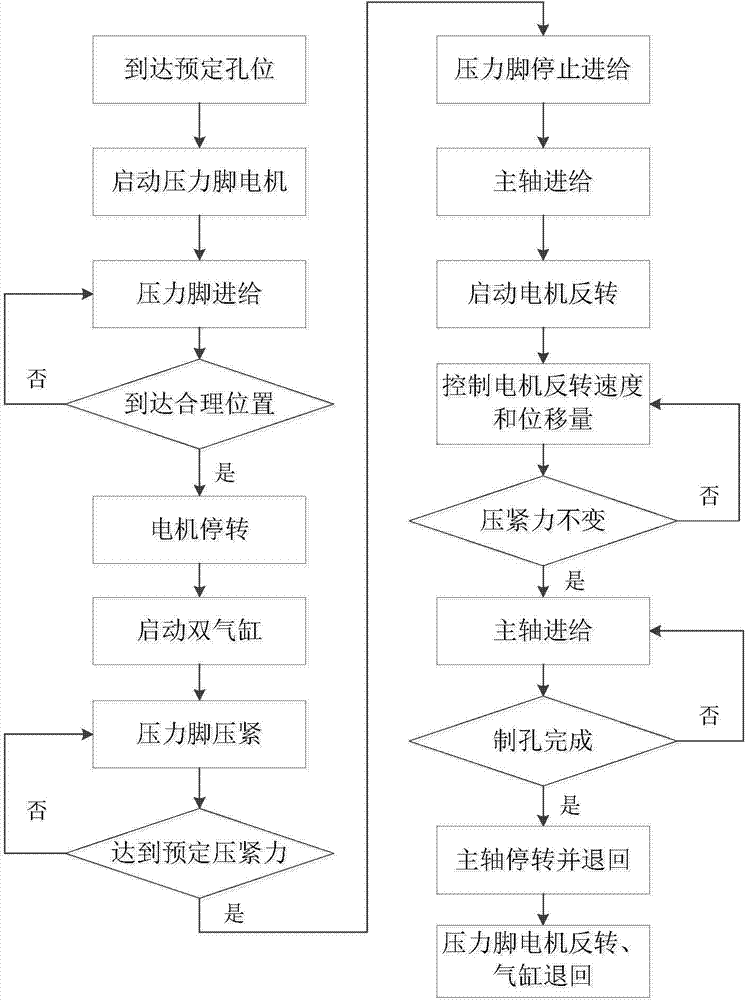

[0026] Such as figure 1 The pressure foot of the electro-pneumatic coupling of the automatic hole-making end effector shown is installed on the spindle base plate 1, the hole-making spindle is installed on the spindle base plate 1, and the spindle base plate 1 is installed on the internal cross slide of the end effector, and the hole is made The main shaft is fed with the movement of the main shaft bottom plate 1 on the cross slide. The pressure foot includes a pressure foot body and a pressure foot servo system. The pressure foot body is connected to the pressure foot base 12. The pressure foot servo system includes a servo motor 2 and a drive cylinder 8 1. The upper computer that controls the servo motor 2 and the drive cylinder 8, the upper computer is installed on the end effector controller, the servo motor 2 drives the ball screw, the first screw connecting plate 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com