Spray pipe plug cover structure for solid-liquid rocket engine ground test

A ground test, solid-liquid rocket technology, applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems that are not conducive to the study of ignition and start-up performance, difficult control of nozzle rupture pressure, poor repeatability, etc., to achieve consistency Good, high accuracy, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] Below in conjunction with accompanying drawing, the patent of the present invention is described further.

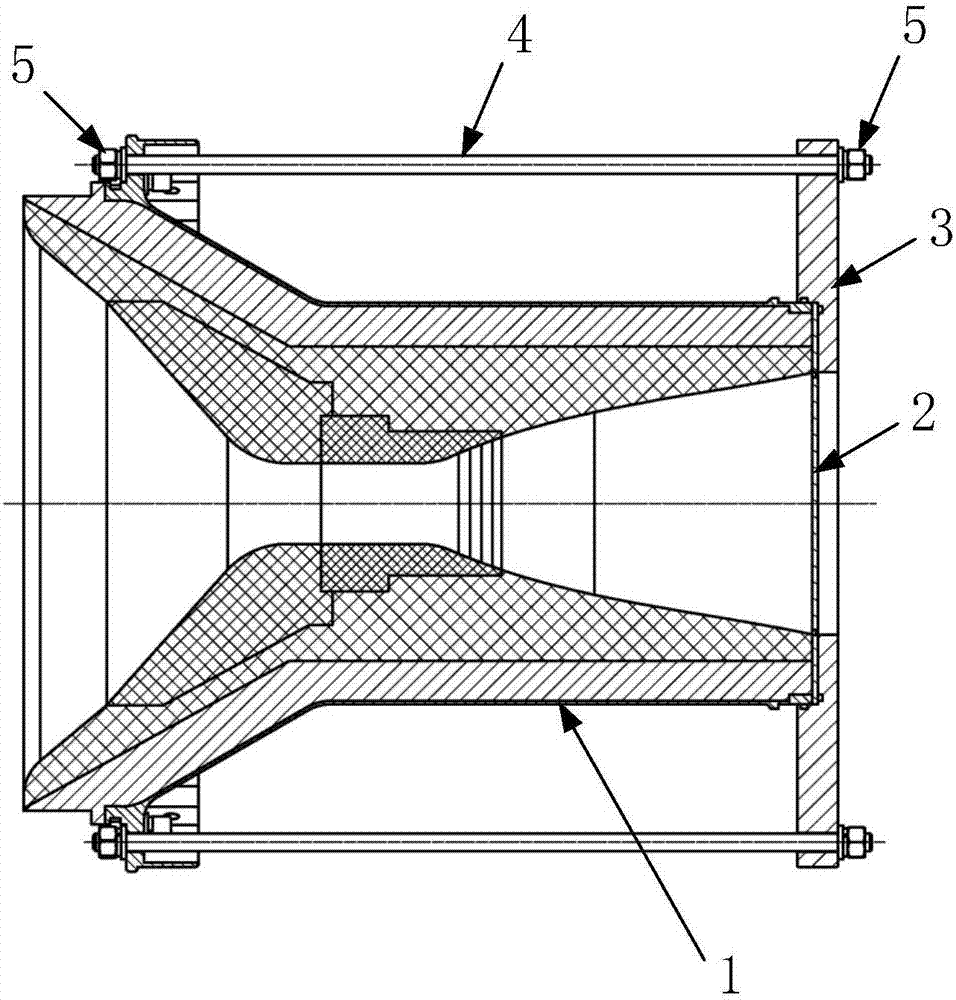

[0023] The nozzle capping structure for the ground test of the solid-liquid rocket engine of the present invention is provided with a diaphragm 2 and a nozzle cap 3 in turn at the end of the nozzle 1, such as figure 1 shown.

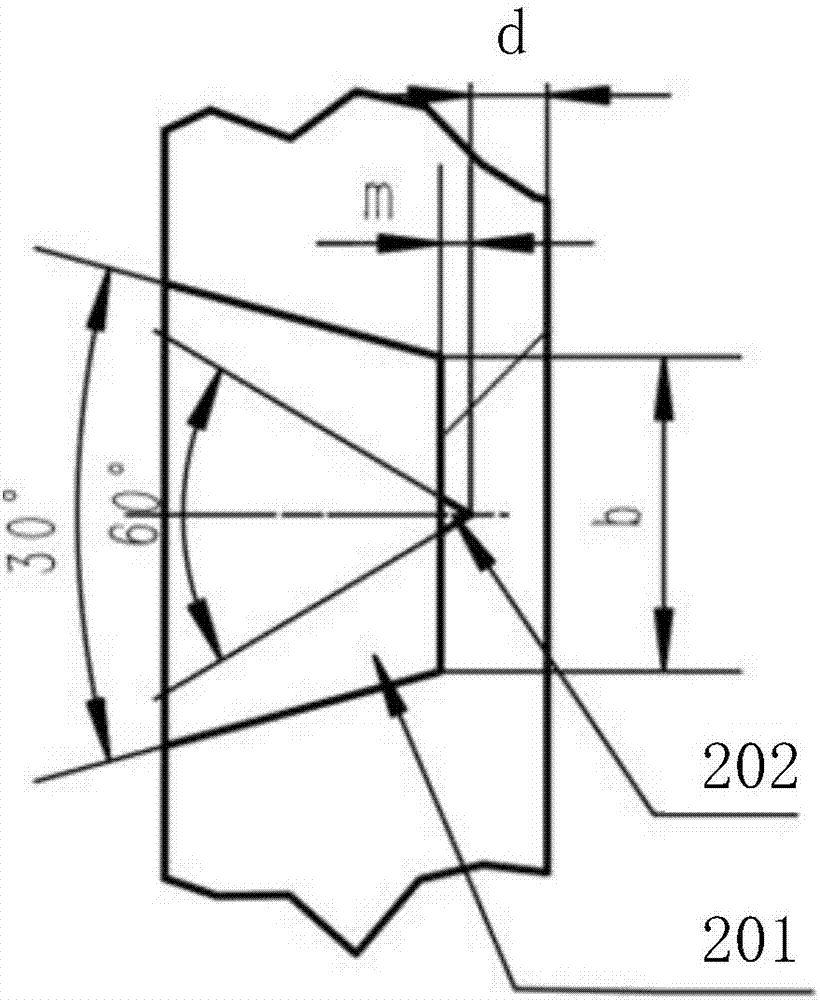

[0024] The nozzle cap 3 is an annular plate structure made of 304 stainless steel, and the diameter of the inner ring is equal to the diameter of the nozzle outlet; the inner surface of the nozzle cap 3 is located at the inner ring and is designed with a concave part to form a stepped hole surface. The end of the nozzle 1 and the diaphragm 2 are embedded in the concave part, and the positioning is realized by the stepped hole surface. At the same time, there is a sealing groove on the outer edge of the bottom surface of the concave part, and the inside is used to place an O-shaped rubber sealing ring t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com