Axial pressing device used after winding of large-size transformer coil

A technology of transformer coil and compression device, which is applied in the direction of coil manufacturing, etc., can solve the problems of low parallel precision of the movable platen and lower platen of the equipment, the equipment cannot adapt to large eccentric loads, and it is difficult to realize closed-loop control, etc., and achieves a novel overall structure of the equipment. Unique, simple and beautiful appearance, the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

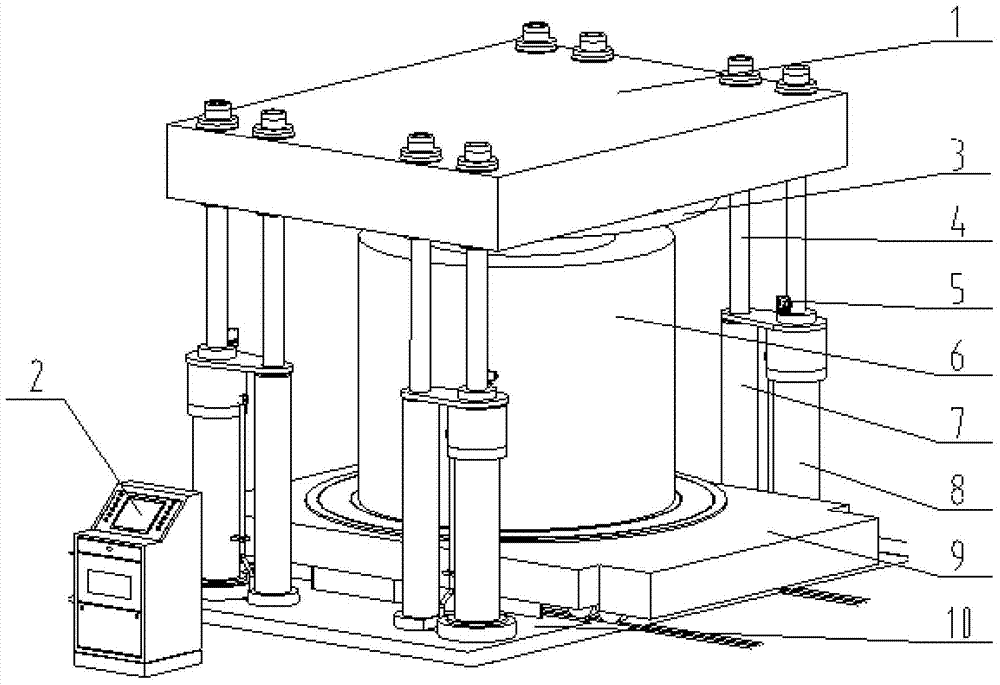

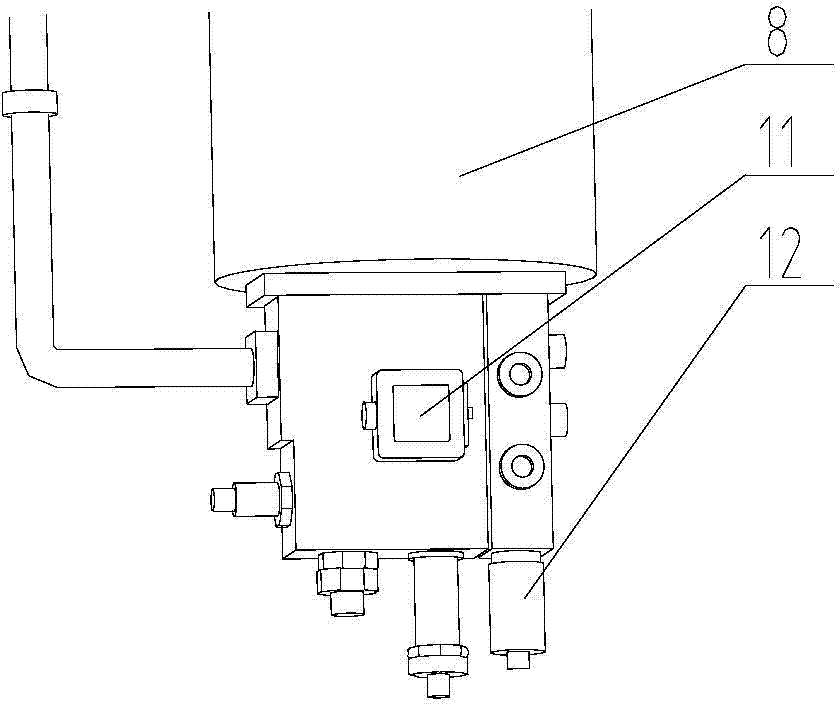

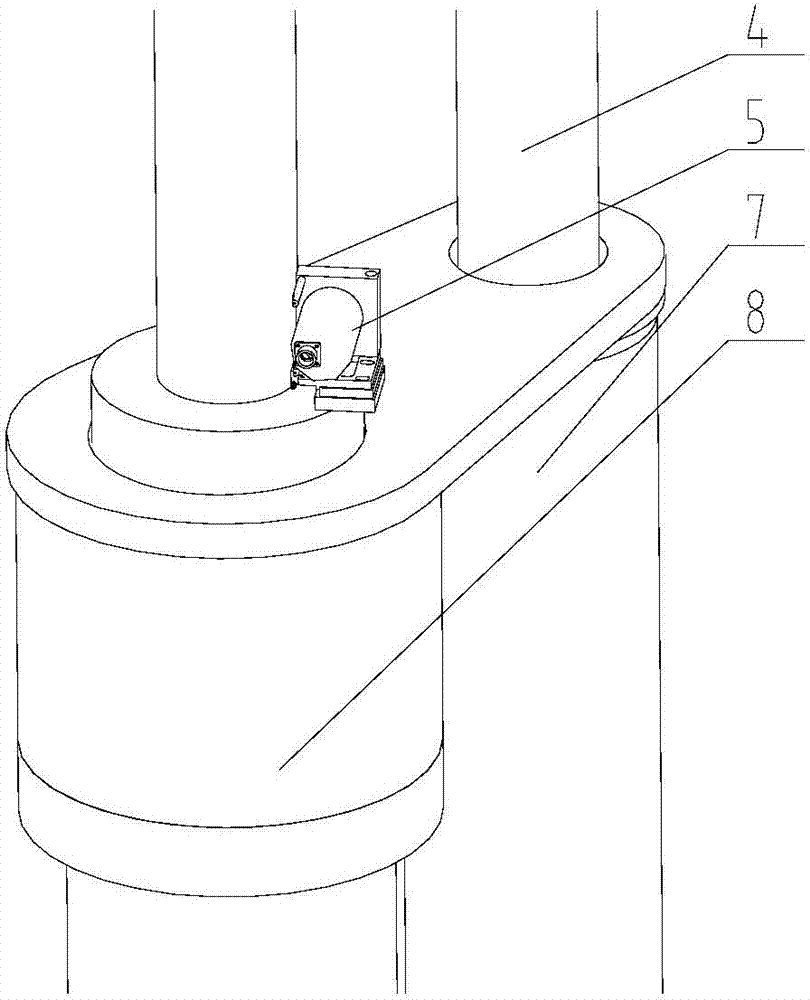

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

[0022] See attached Figure 1~4 As shown, the axial compression device used for winding large transformer coils is characterized in that: the device includes a rectangular lower platform 10 and an upper platform 1. The lower platform 10 is installed in the foundation foundation, and the The foundation is firmly connected. A pressure platform 3 is installed under the upper platform 1, and four oil cylinders 8 are connected between the lower platform 10 and the upper platform 1. The four oil cylinders 8 are symmetrically distributed at the four right-angle positions of the lower platform 10 and the upper platform 1, Each cylinder 8 is fixed to the lower platform 10 by high-strength bolts and flanges 16. The maximum stroke of the piston rods of the four cylinders 8 is 3m. The rated pressure of the device is designed to be 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com