Patents

Literature

67results about How to "High accuracy of flow control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

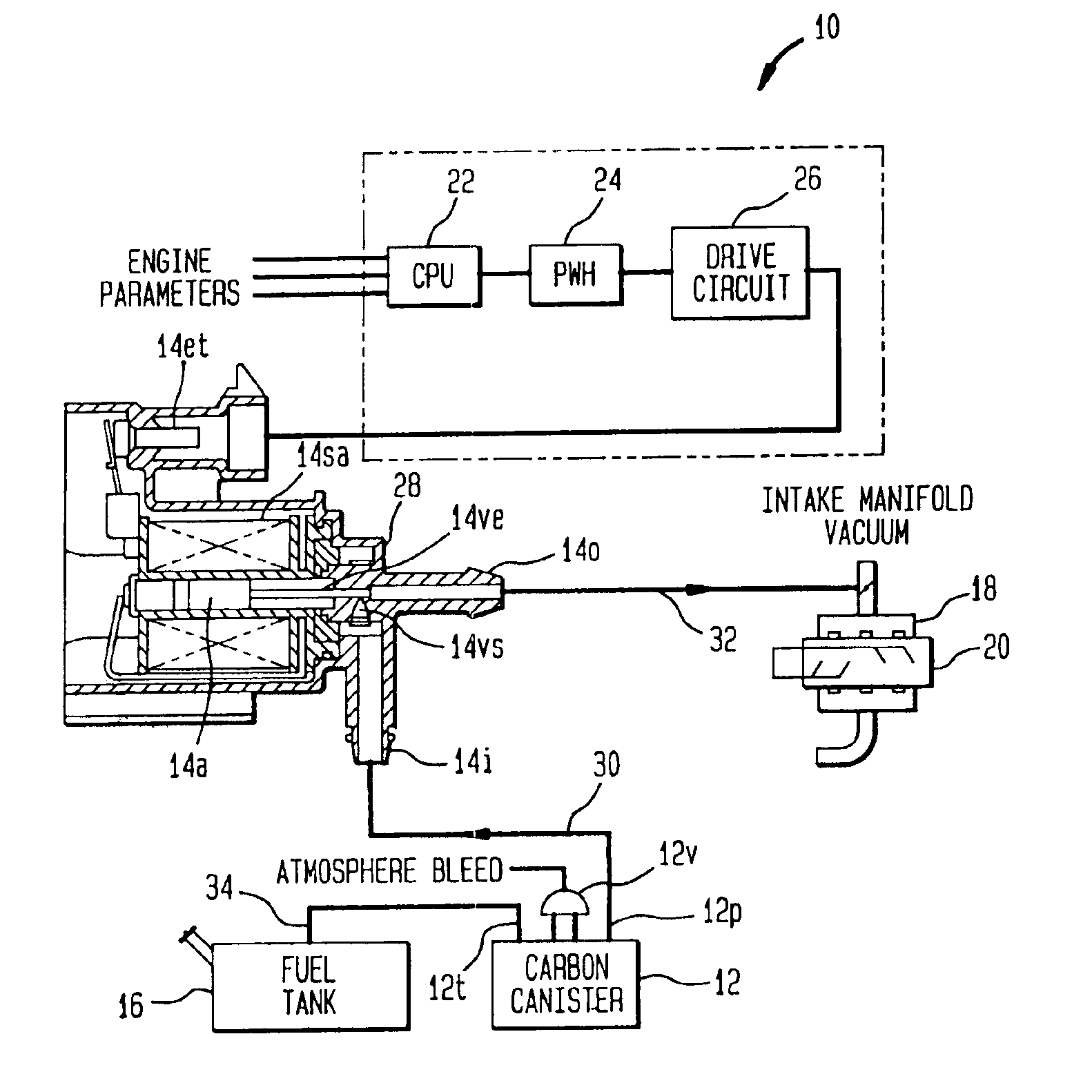

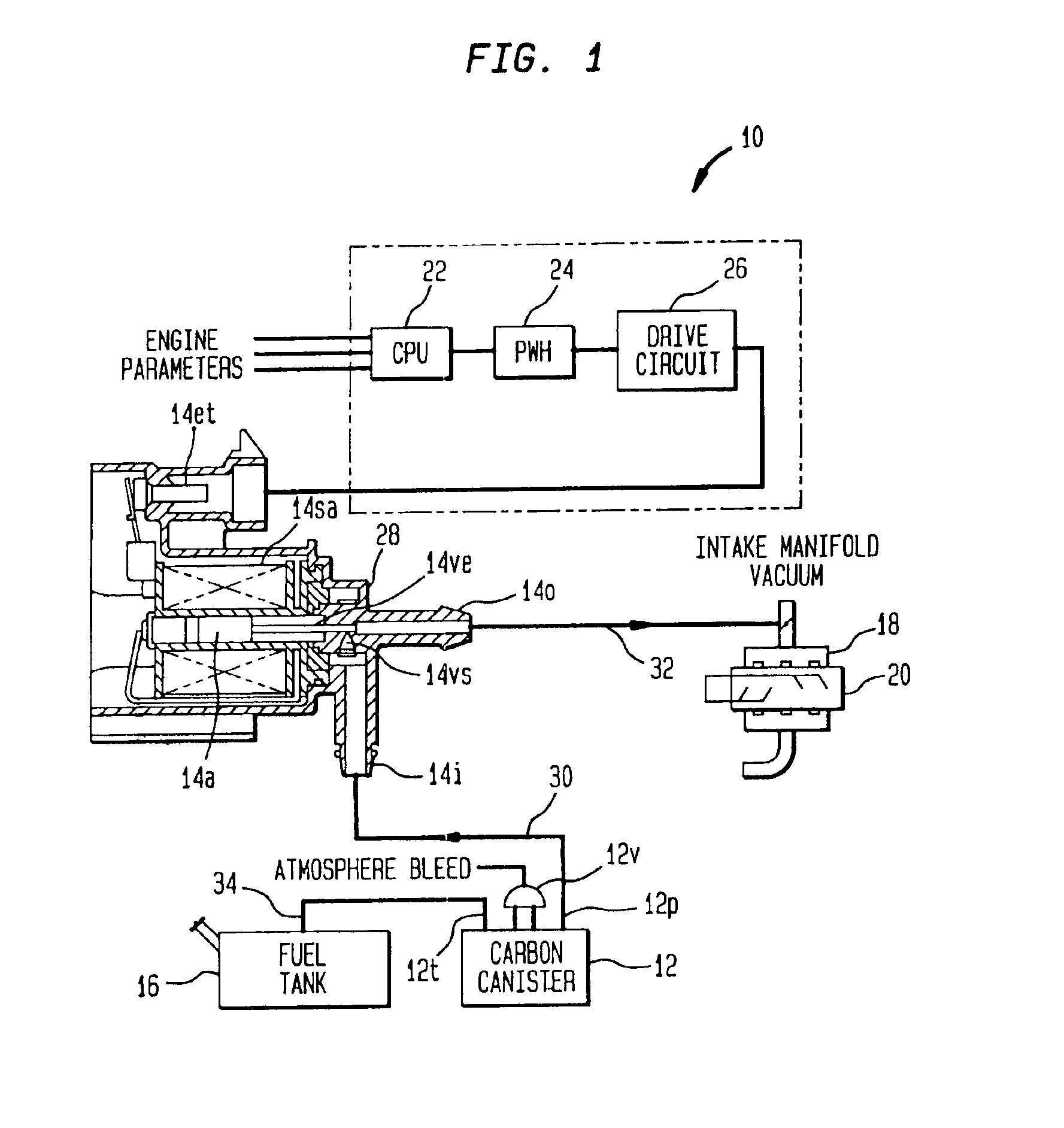

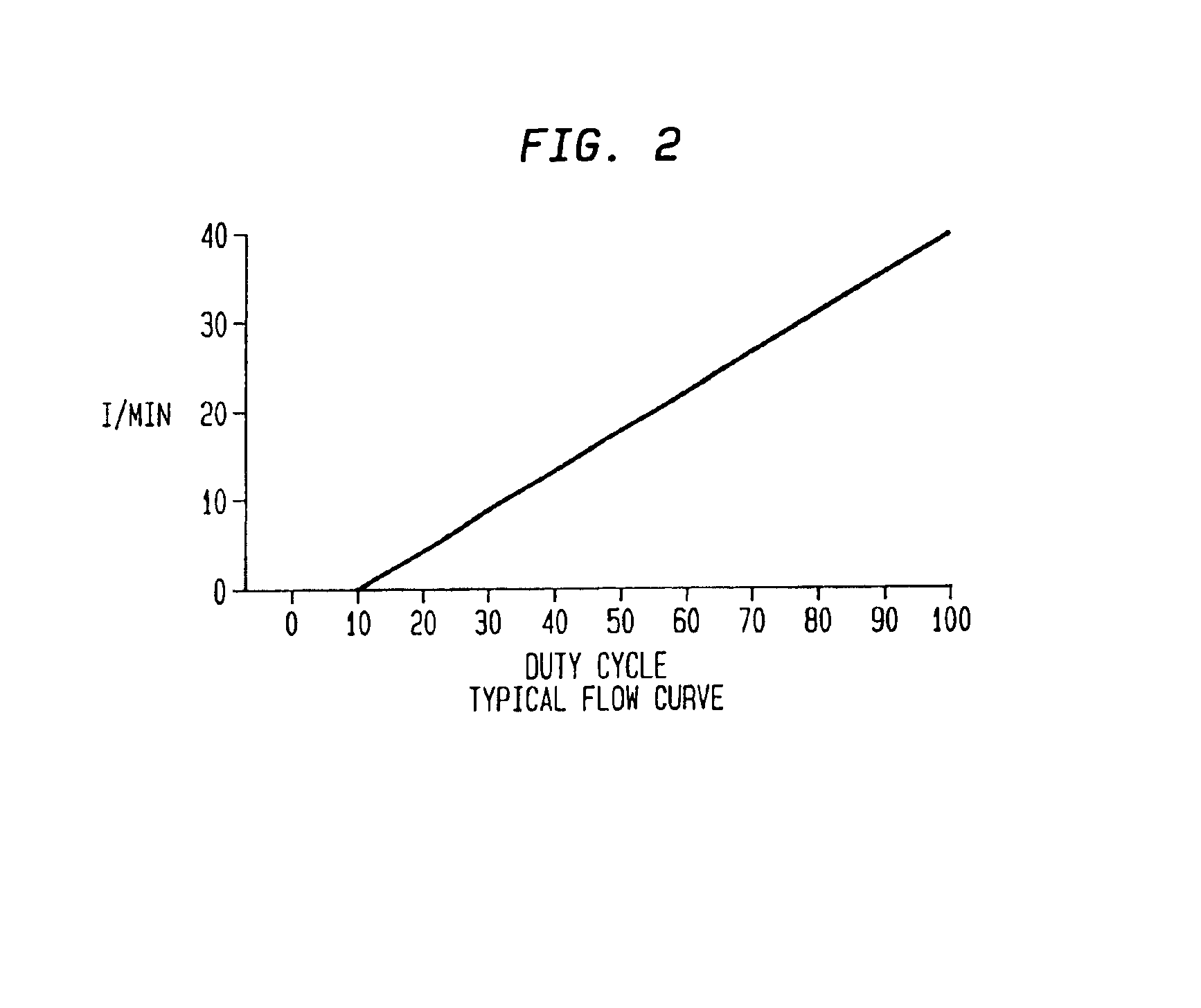

Regulated linear purge solenoid valve

InactiveUS6845755B2Improve accuracyImprove control accuracyOperating means/releasing devices for valvesNon-fuel substance addition to fuelPressure regulatorPulse waveform

A pressure regulator is associated with a solenoid-operated valve that is operated by a pulse waveform at a fundamental frequency substantially greater than the frequency response of the valve mechanism. This substantially attenuates solenoid pulsations and applies a predetermined pressure differential across the valve mechanism to accomplish improved flow control accuracy. The invention is especially advantageous for purging fuel vapor to an intake manifold of an internal combustion engine of an automotive vehicle.

Owner:3840620 CANADA +1

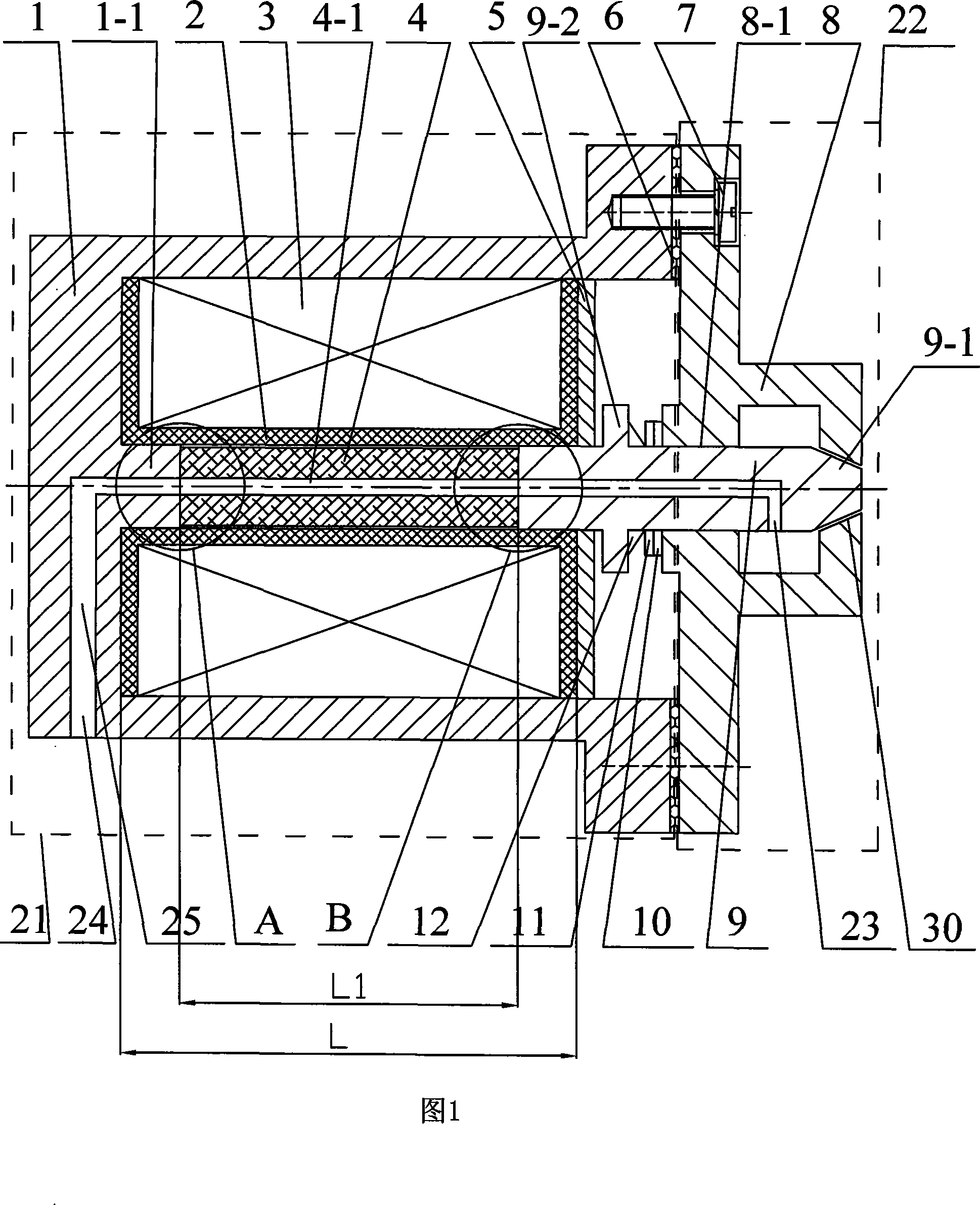

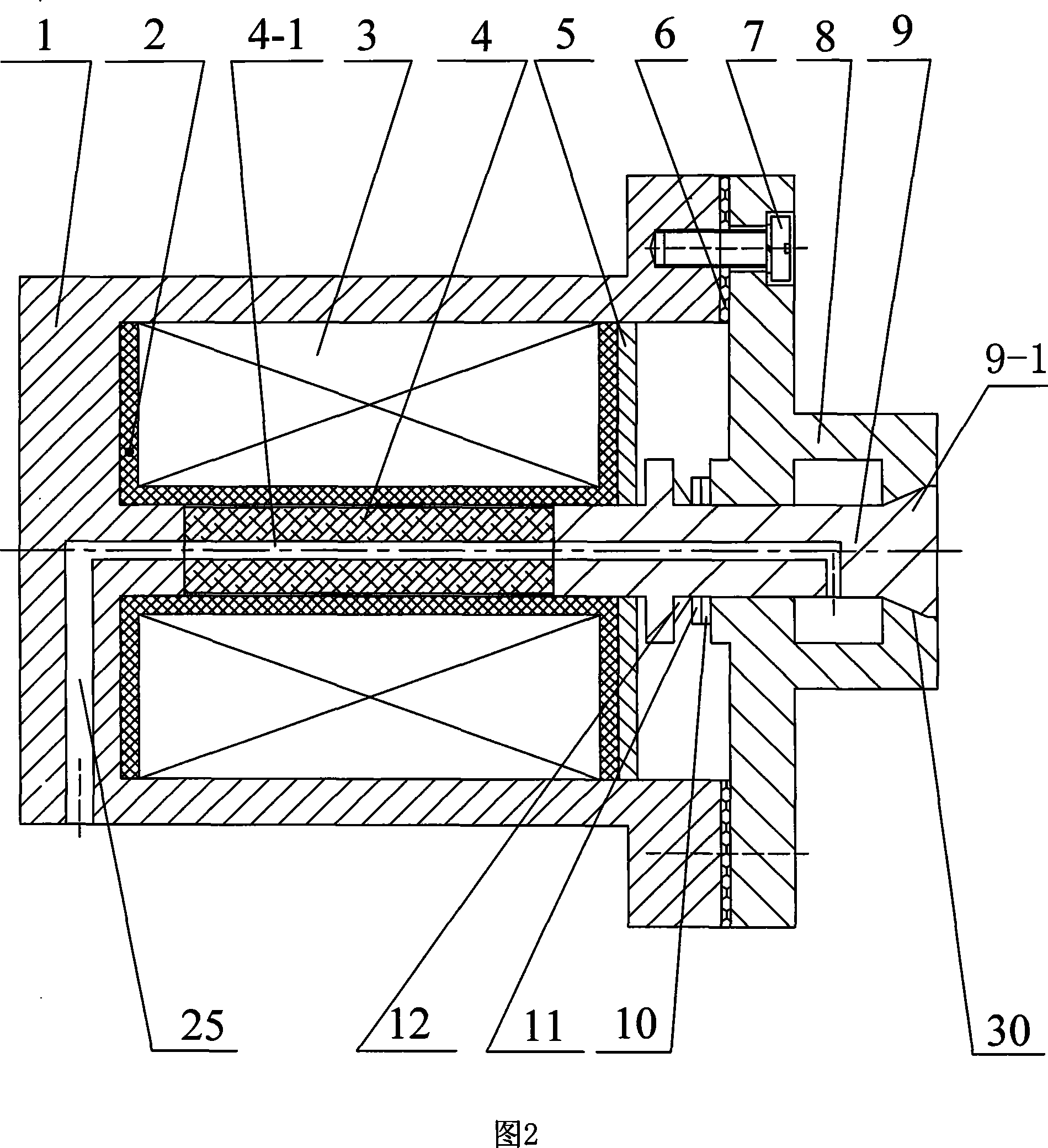

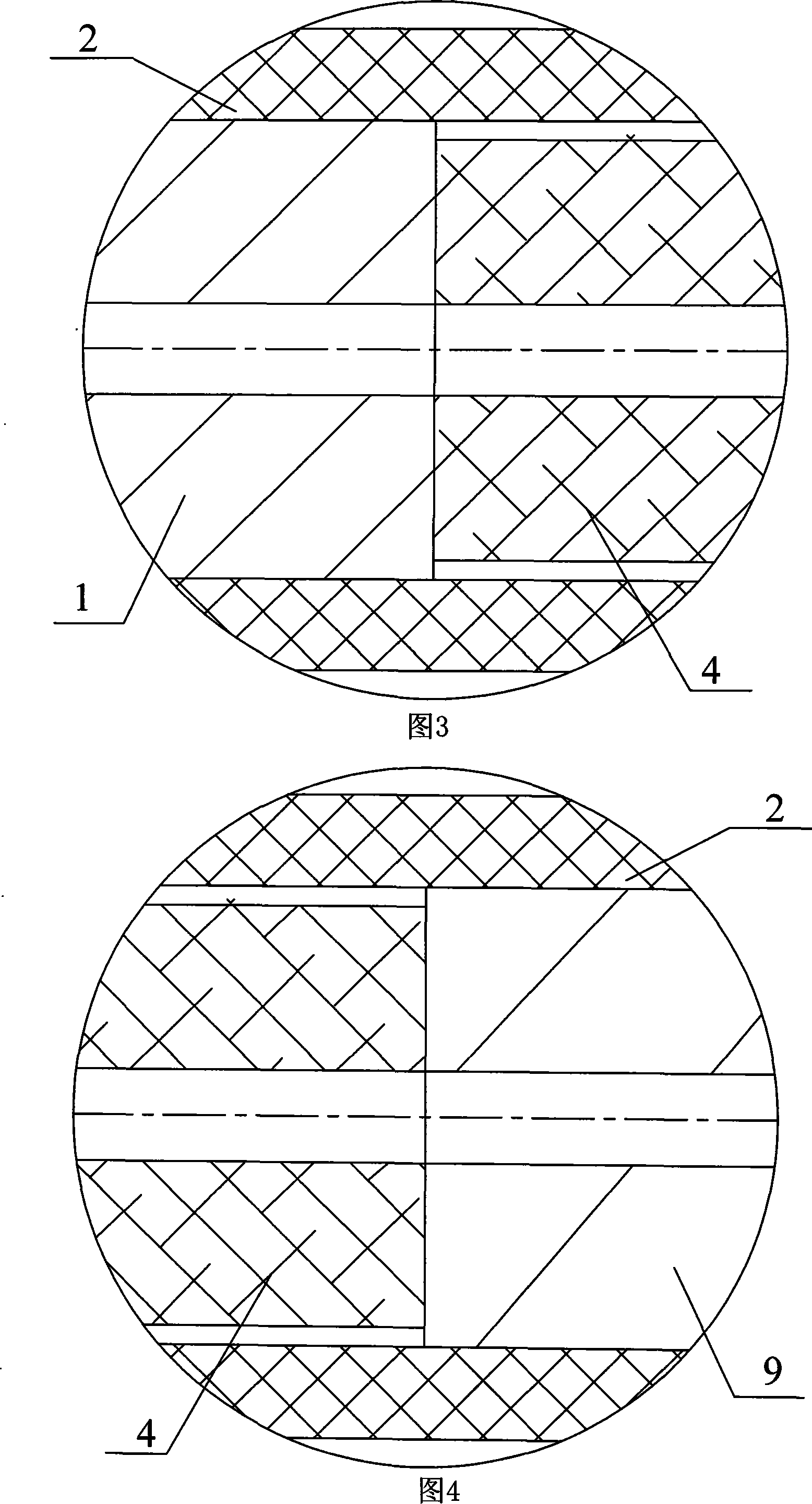

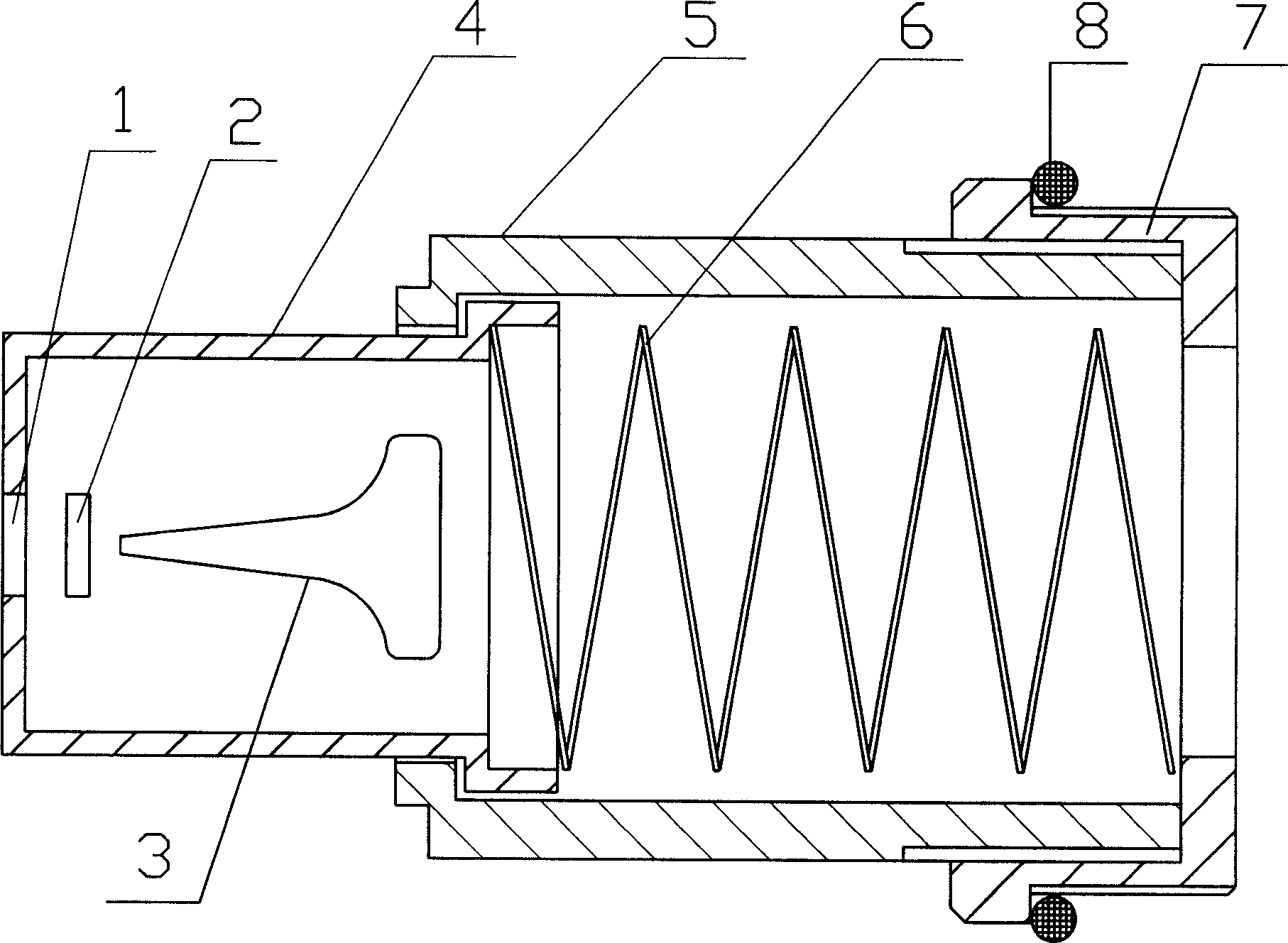

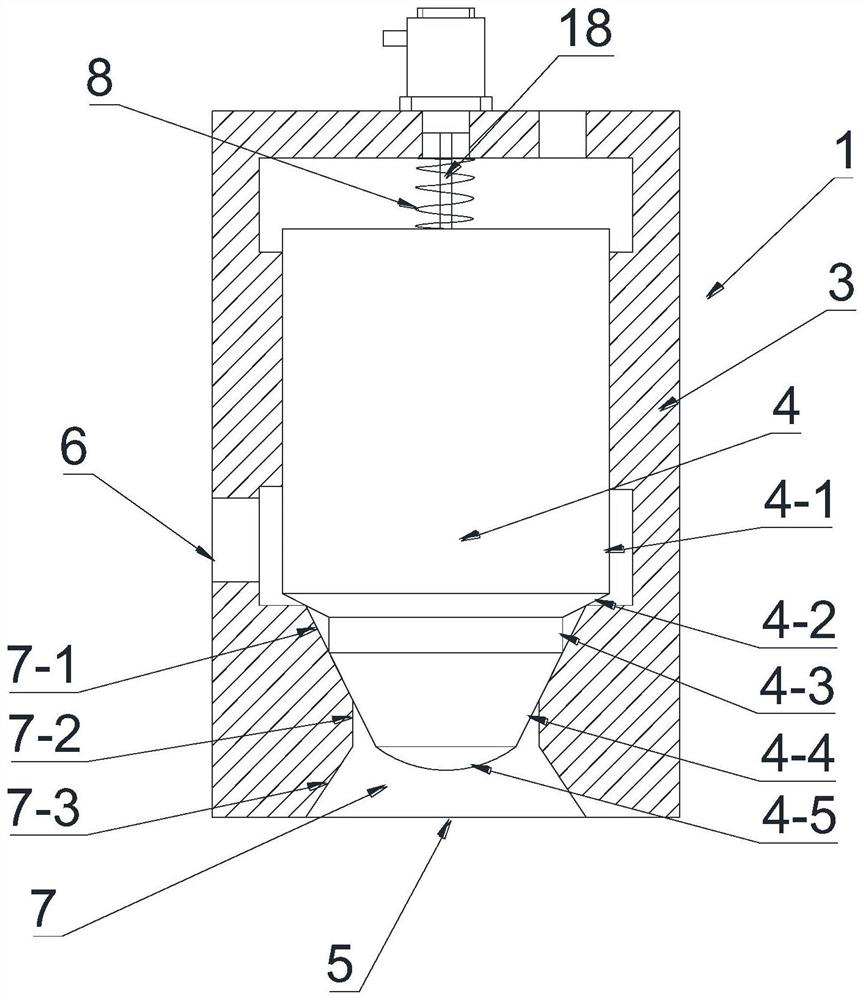

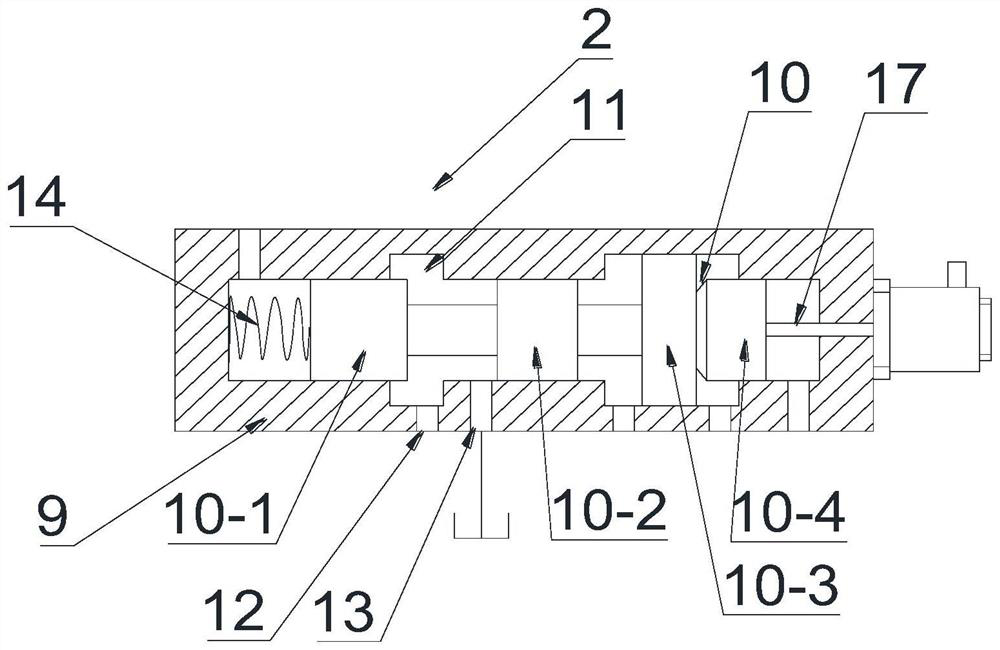

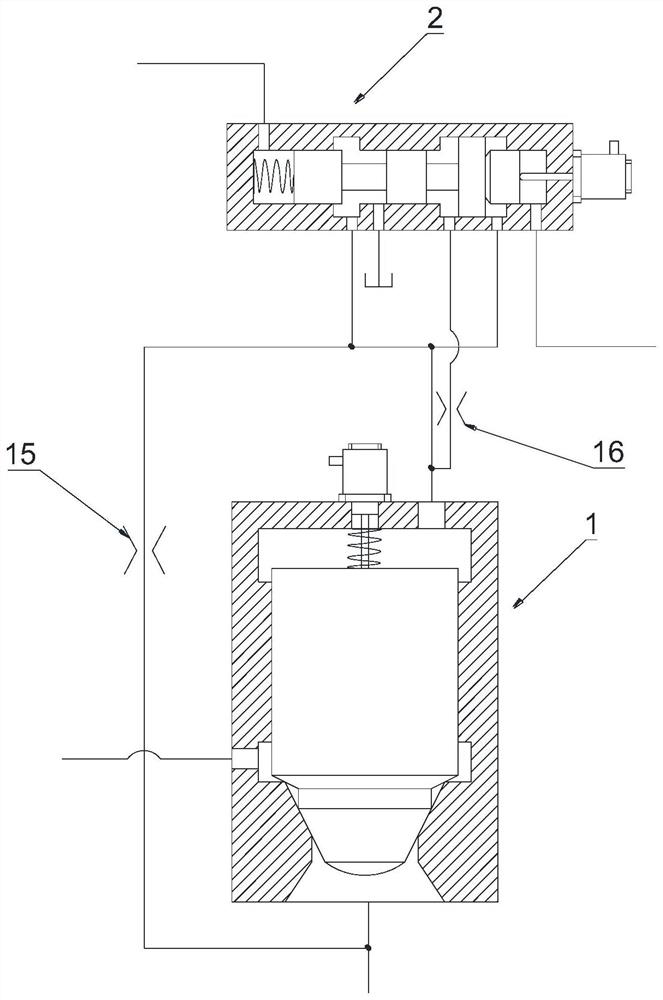

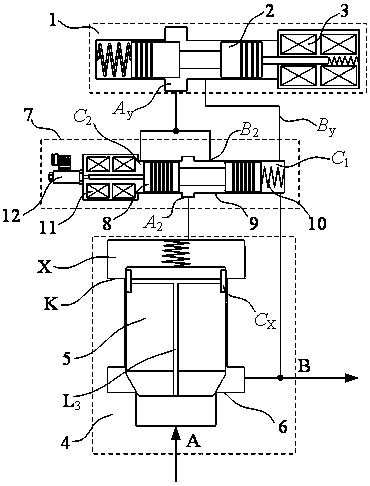

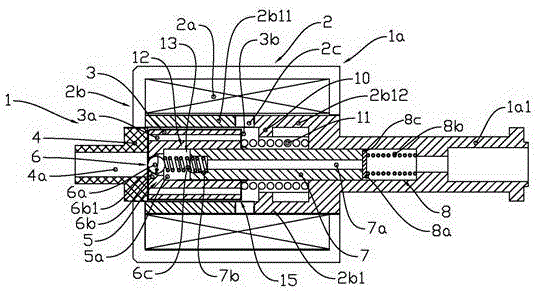

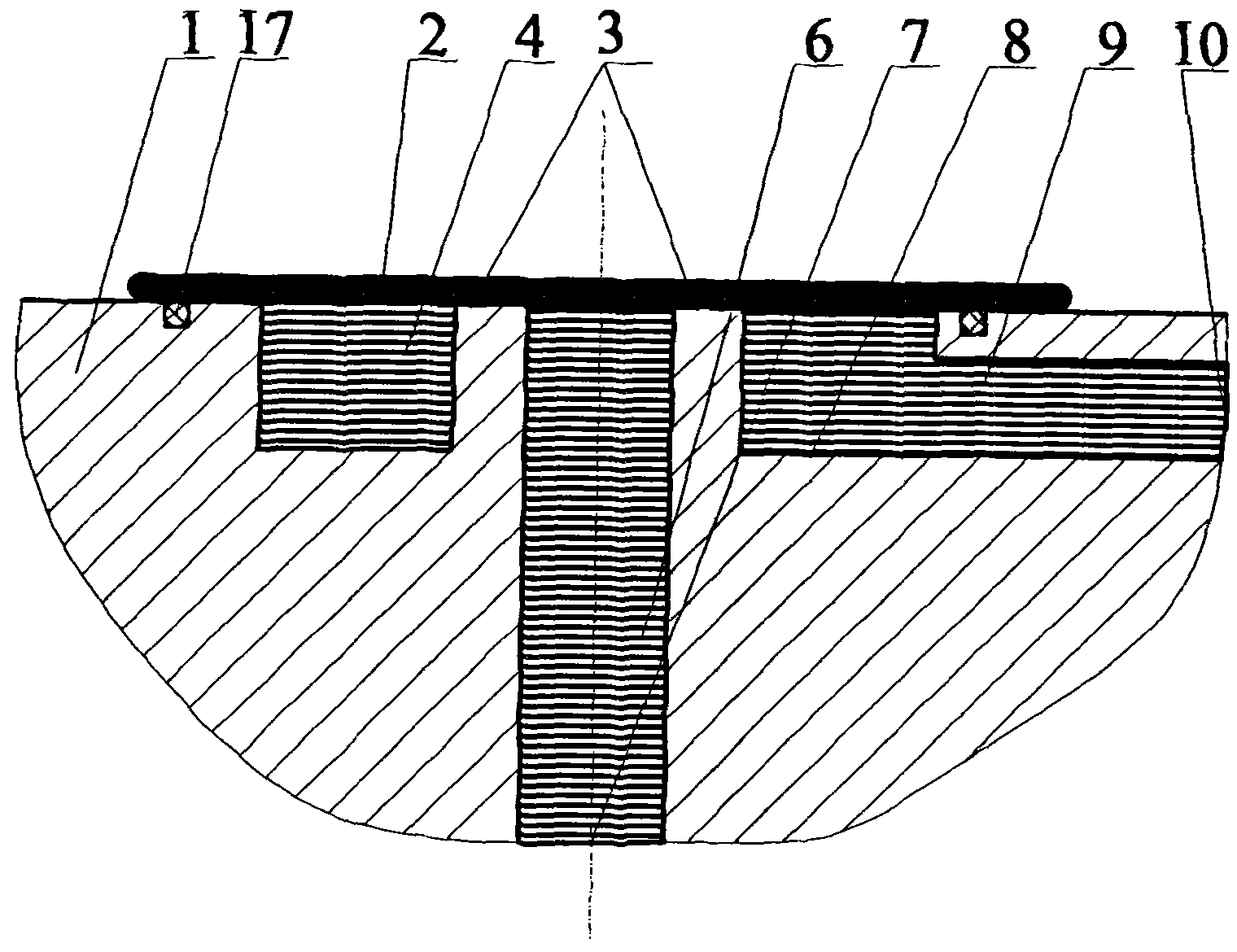

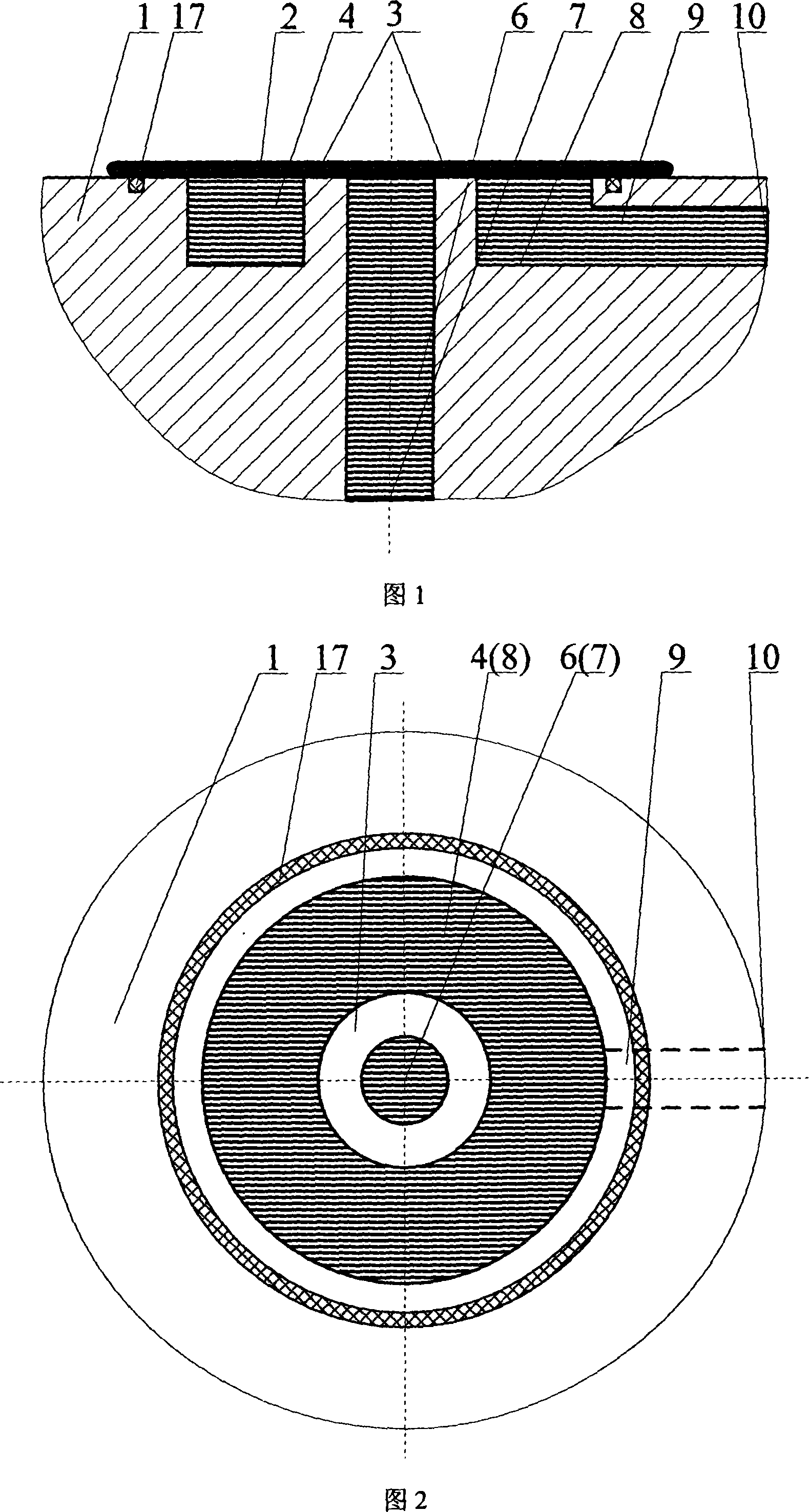

High speed electrohydraulic open and close valve driven directly by ultra-magnetostriction actuator

InactiveCN101225881ASuppresses the effects of output displacementFast dynamic responseOperating means/releasing devices for valvesValve members for heating/coolingMagnetostrictive actuatorSwitching frequency

The invention relates to a high-speed switch valve, in particular to a high-speed electrohydraulic switch valve driven by an giant magnetostrictive actuator, which solves the problems of the prior actuator in the switch valve that the temperature rise of a magnetostrictive rod is restrained, the structure is complicated, the design is not reasonable, the dynamic response speed is slow, the control precision is low and the drive efficiency is low. A coil frame (2) is sleeved on the magnetostrictive rod, a drive coil is wound on the coil frame (2), a liquid flowing inlet (24) is disposed on a side wall of an actuator casing, a liquid flowing outlet (23) is positioned on the side wall of a valve core (9), the liquid flowing inlet (24) is communicated with the liquid flowing outlet (23) through an axial hole (4-1) of the magnetostrictive rod (4) and the actuator casing (1) is sealed with a valve body (8). The high-speed switch valve has the advantages that the temperature rise of the magnetostrictive rod can be restrained, the structure is simple, the design is reasonable, the dynamic response speed is fast, the flow rate control precision is high and the switch frequency is high.

Owner:HARBIN INST OF TECH

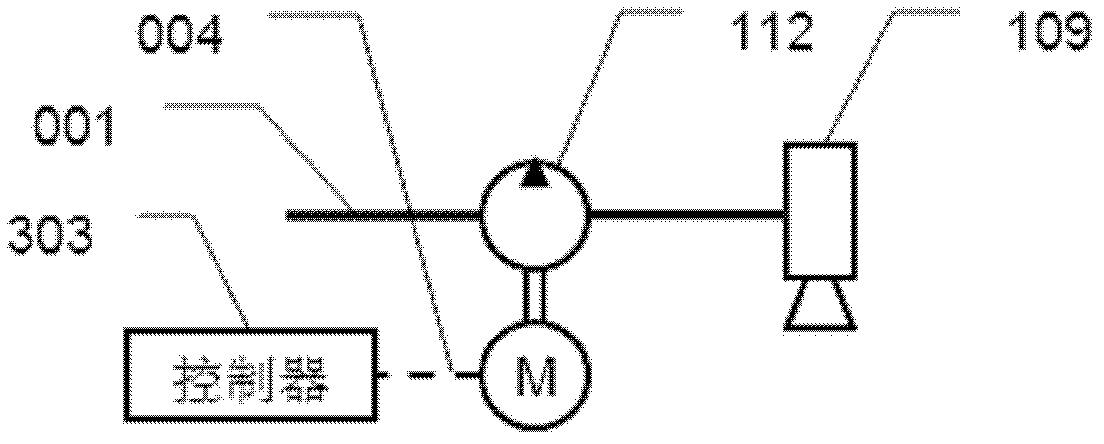

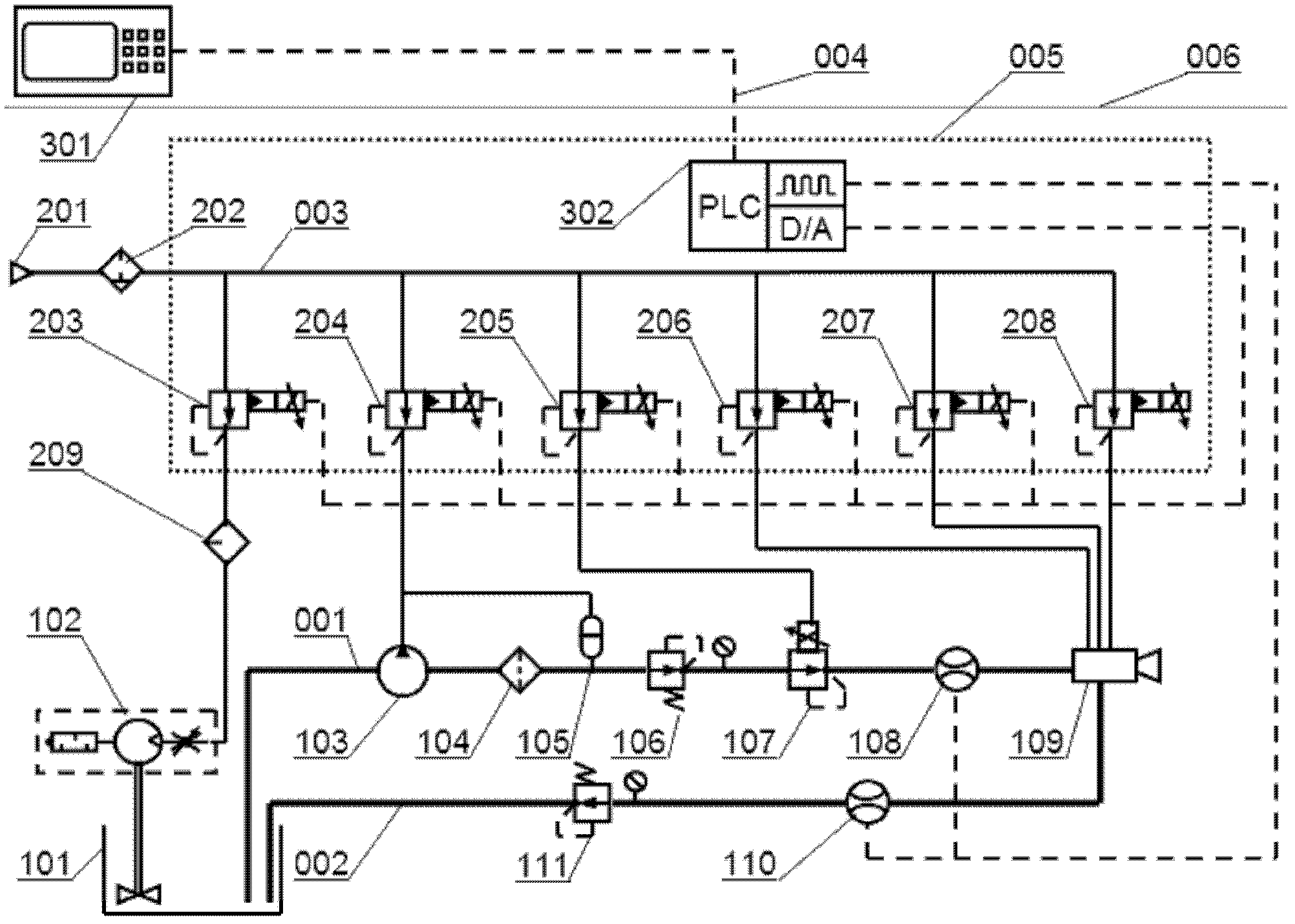

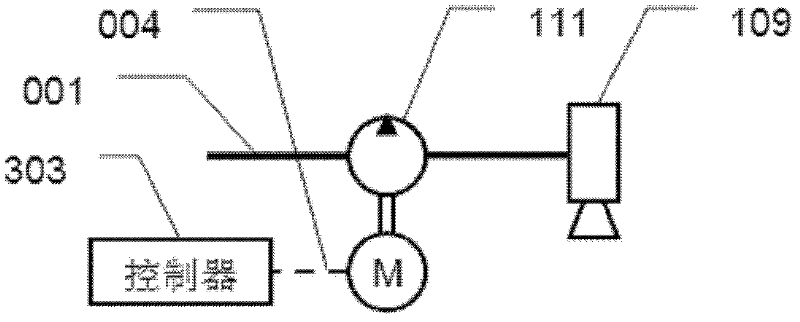

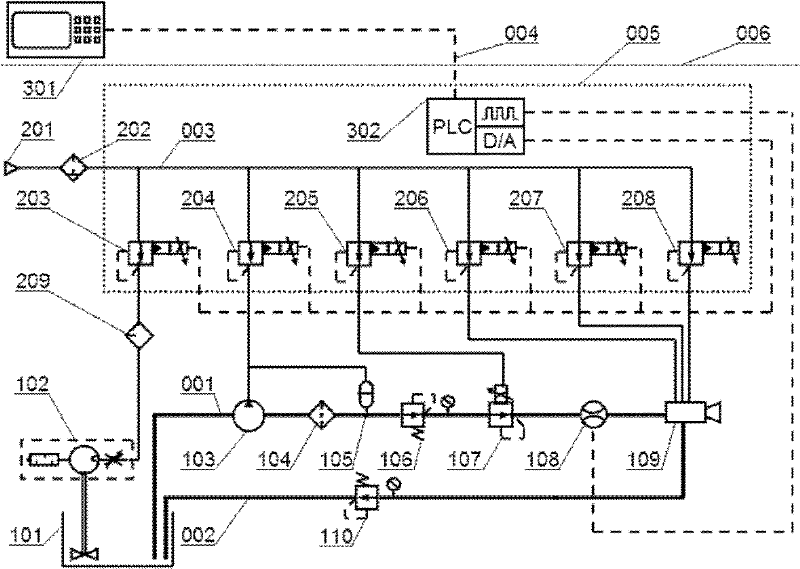

Dual-flow-meter type digital spraying system for robot

InactiveCN102632003ARealize closed-loop controlRealize remote monitoringLiquid spraying apparatusModem deviceProgrammable logic controller

The invention provides a dual-flow meter type digital spraying system for a robot. The dual-flow-meter type digital spraying system partially consists of a fluid part, an air path part and a control part. The fluid part uses a circular feeding mode. Digital flow meters are respectively connected in series with a feeding pipeline and a feeding-back pipeline, so that a feeding flow and a feeding-back flow can be detected in real time. A pneumatic proportional valve is further connected in series with the feeding pipeline, so as to realize long-distance flow adjustment. The air path part is divided into six paths for supplying compressed air to each pneumatic element; electric proportional valves are connected in series with the air paths to realize long-distance adjustment; the control part consists of an upper computer and a PLC (Programmable Logic Controller) and is respectively connected with the electric proportional valves and the flow meters. The dual-flow meter type digital spraying system provided by the invention can be used for real-time flow detection and closed-loop control of a spray gun in a circular feeding mode, and is further provided with a coating pump, a stirrer, a spray gun switch and long-distance adjustment capacities of atomized air and fan width air. Particularly, the dual-flow meter type digital spraying system is applicable to the field of feeding at an in-gun circulating modem and is inconvenient to manual detection flow or a flow decay phenomenon is easy to occur.

Owner:TSINGHUA UNIV

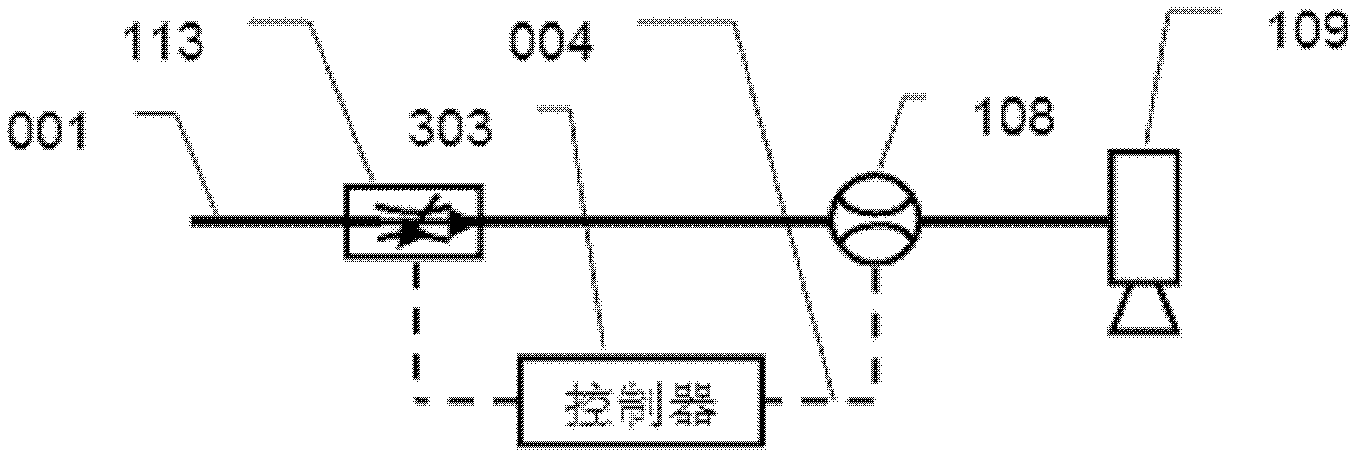

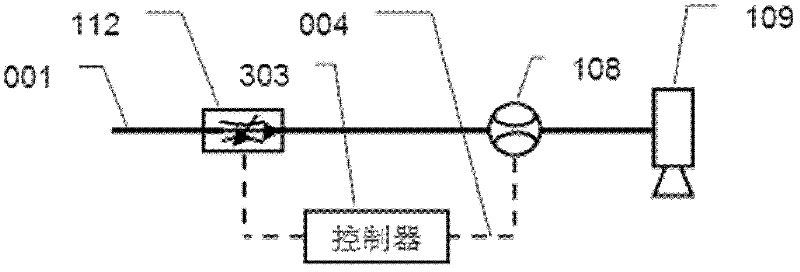

Single flowmeter type digital spraying system for robot

InactiveCN102641803ARealize closed-loop controlRealize remote monitoringLiquid spraying apparatusProgrammable logic controllerClosed loop

A single flowmeter type digital spraying system for a robot is composed of a feed pipeline, a feed back pipeline, an air pipeline and a control part, wherein the feed pipeline conveys a coating to the feed inlet of an automatic spray gun, and a digital flowmeter and a pneumatic proportional valve are connected in series in the pipeline; the feed back pipeline conveys the coating to a coating container from the discharge hole of the automatic spray gun, thereby realizing circulating feed; the air pipeline provides compressed air for various pneumatic elements and an electrical proportional valve is connected in series to the pipeline; and the control part is composed of an upper computer and a PLC (Programmable Logic Controller) controller, which are connected to the electrical proportional valve and the flowmeter, respectively. The system is capable of realizing real-time flow detection and closed-loop control of the automatic spray gun in a circulating feed mode, and also capable of remotely adjusting a coating pump, a stirrer and an automatic spray gun switch as well as atomizing air and fan width air; therefore, the system is especially suitable for the situations in which an inside-gun circulating mode is used for feeding, but the flow cannot be manually detected conveniently or flow decay is easy to occur.

Owner:TSINGHUA UNIV

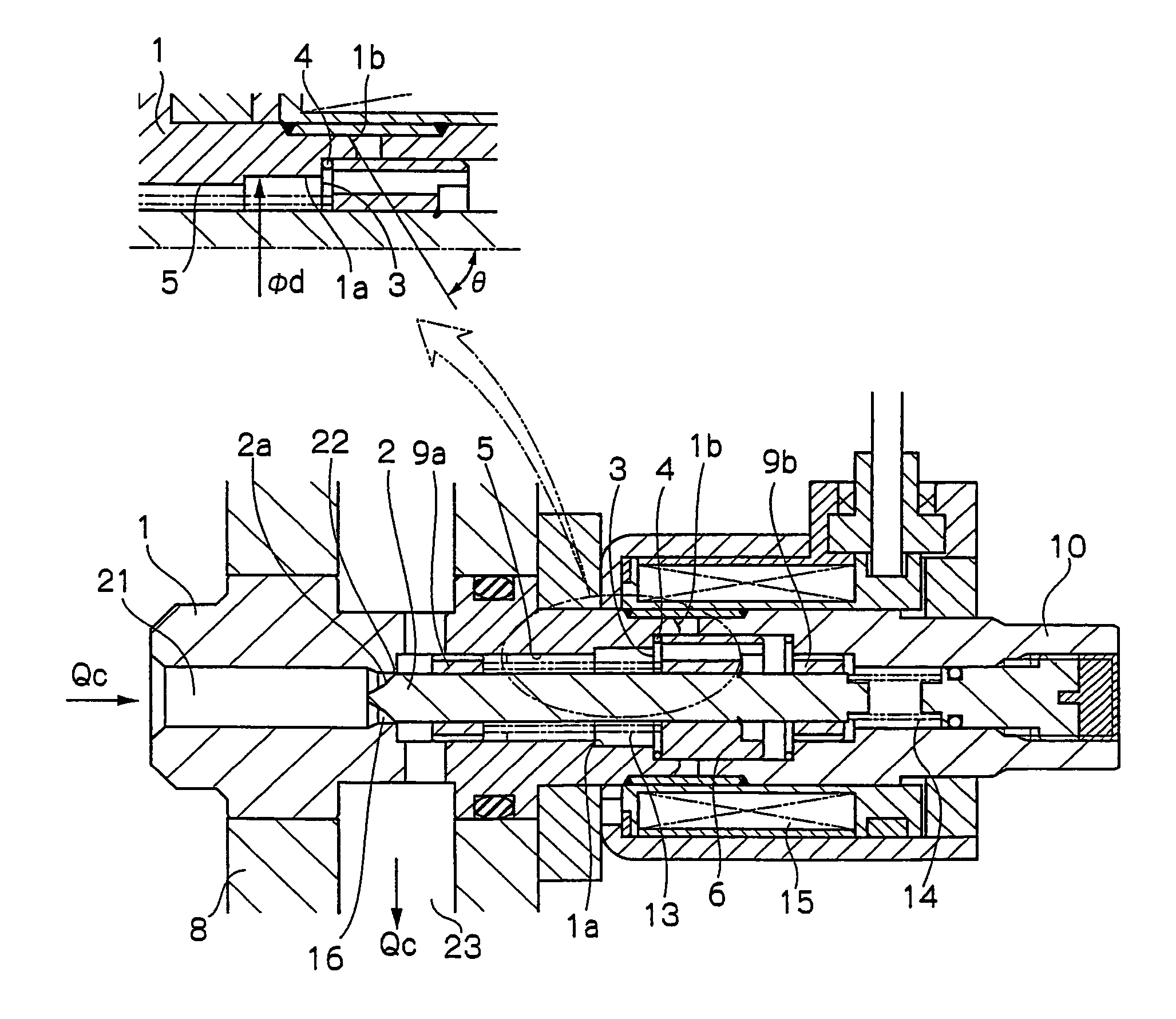

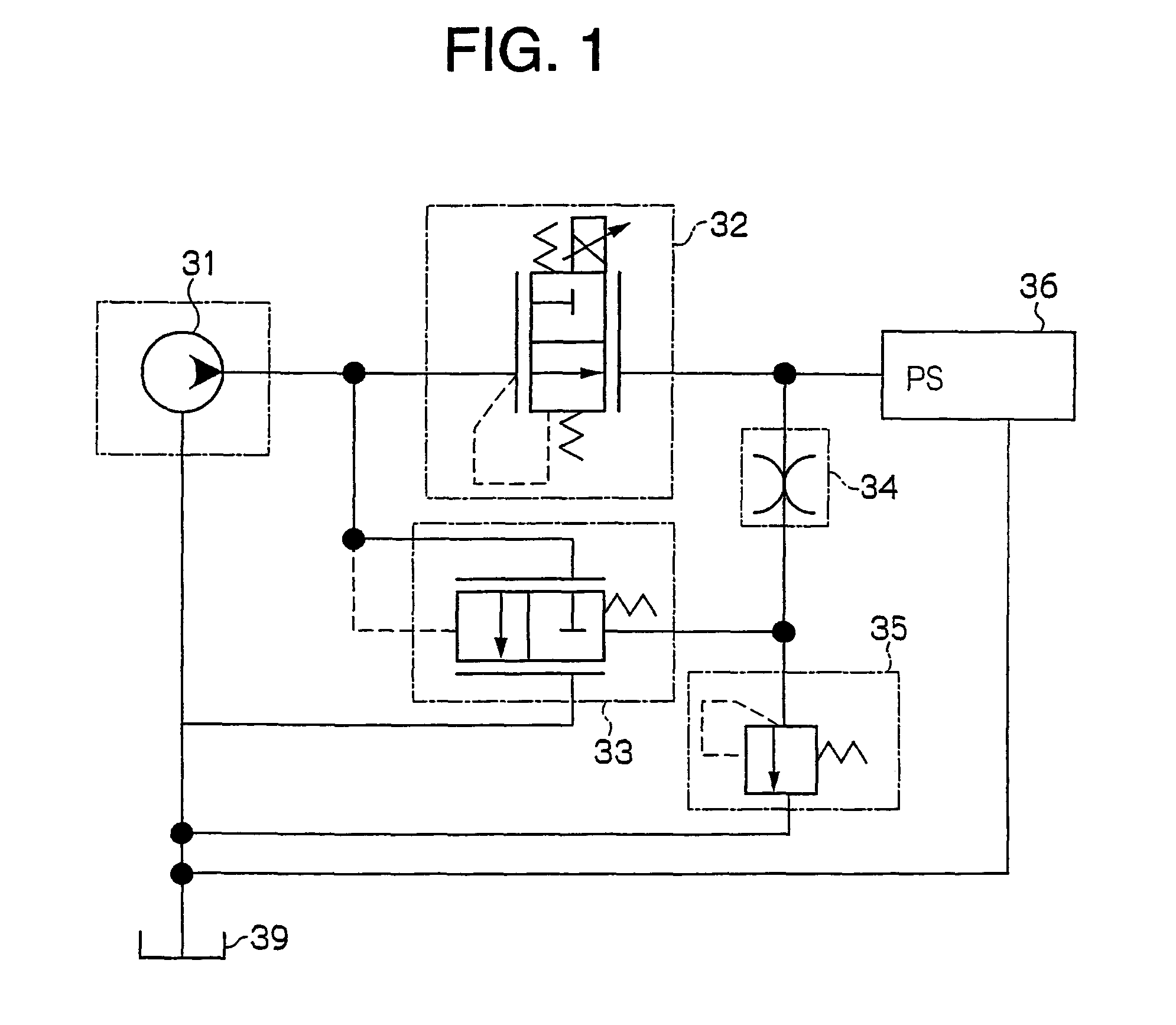

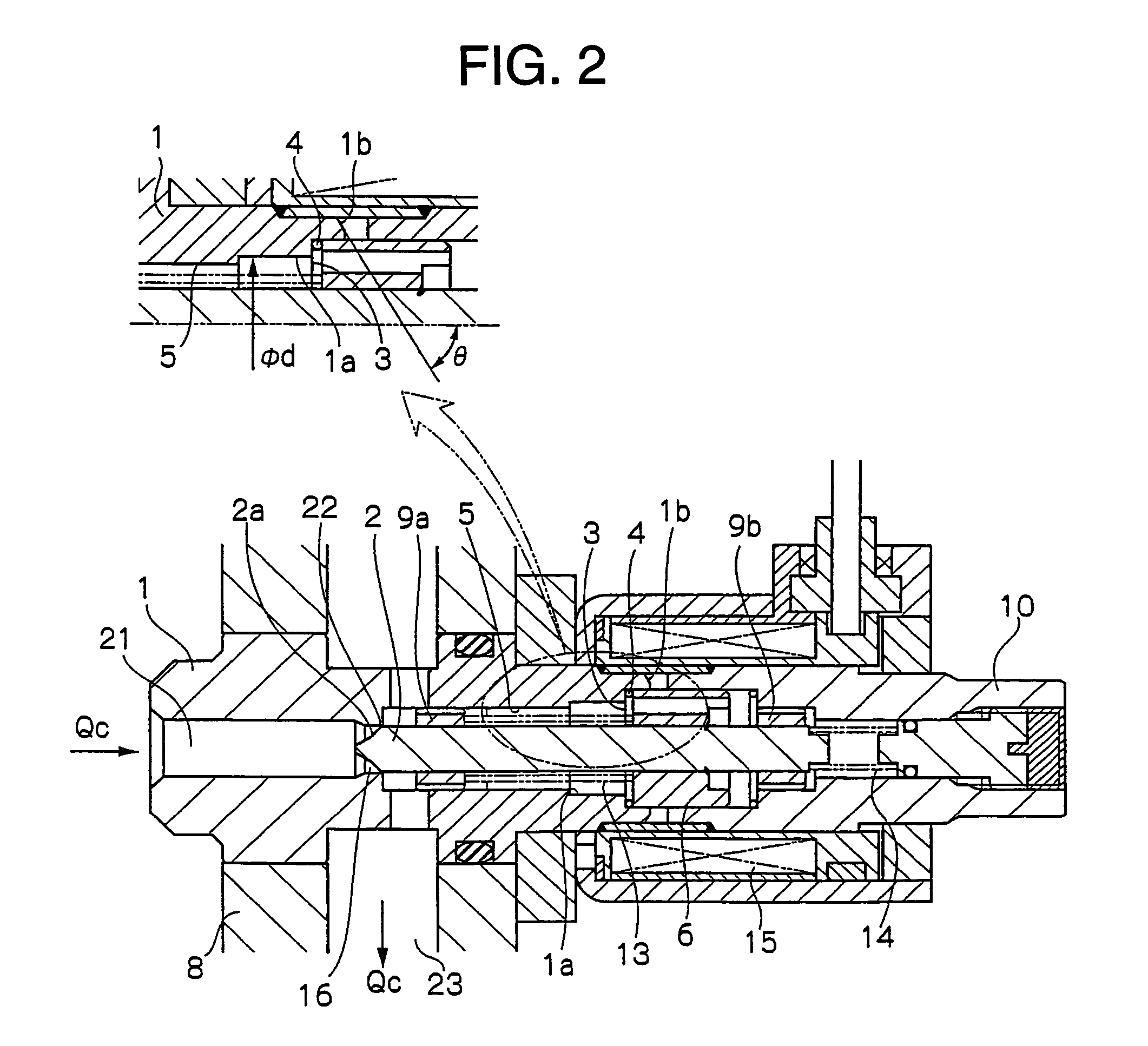

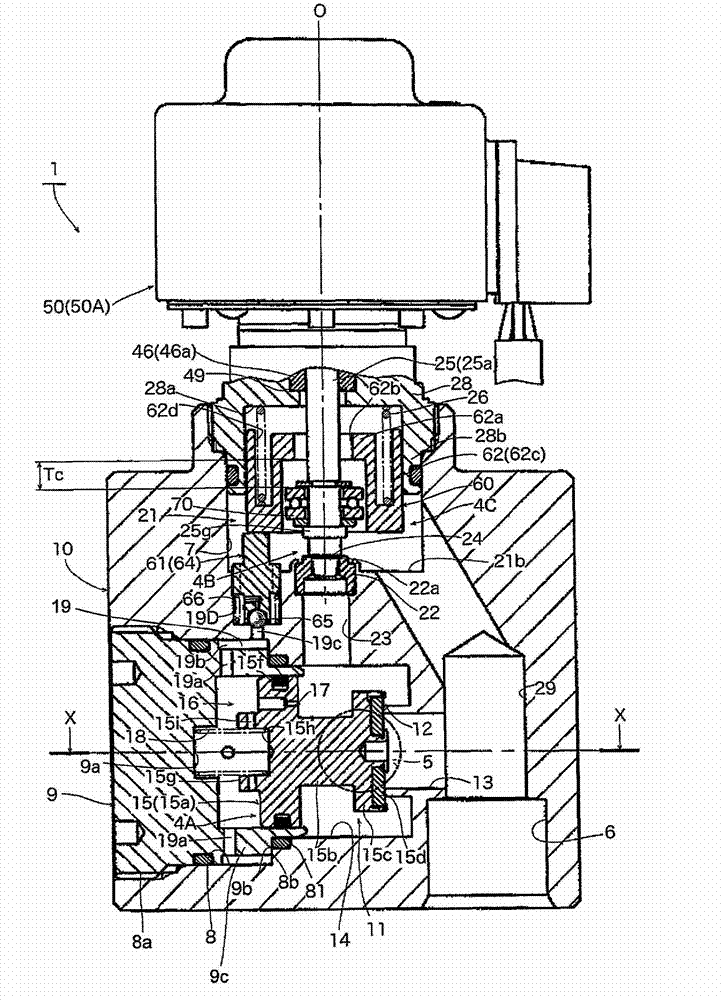

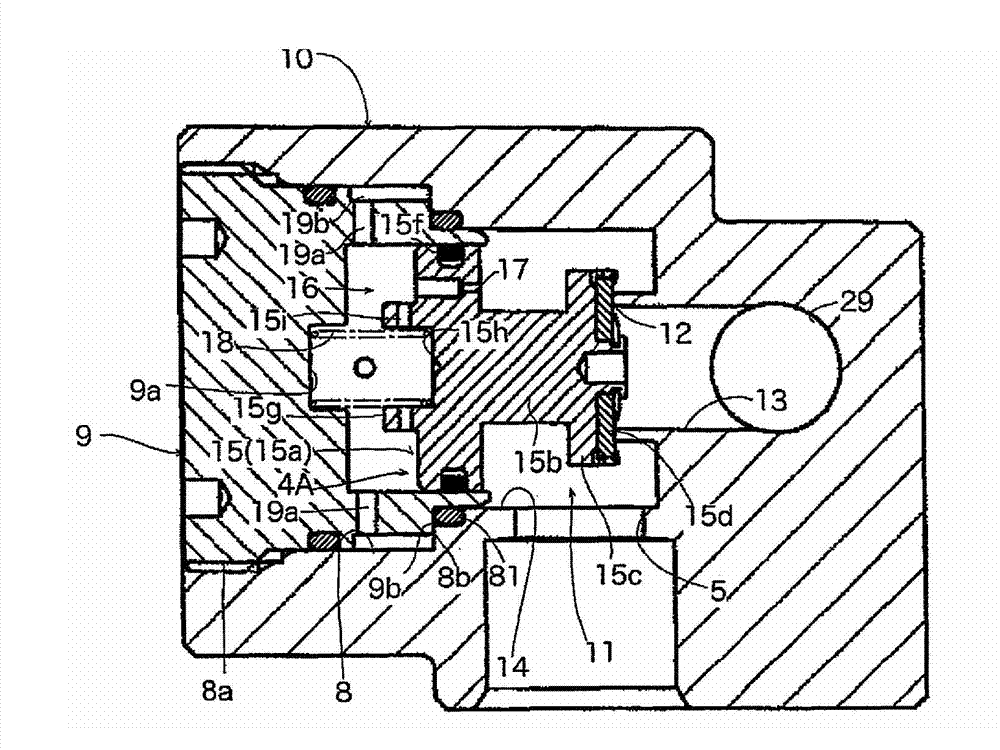

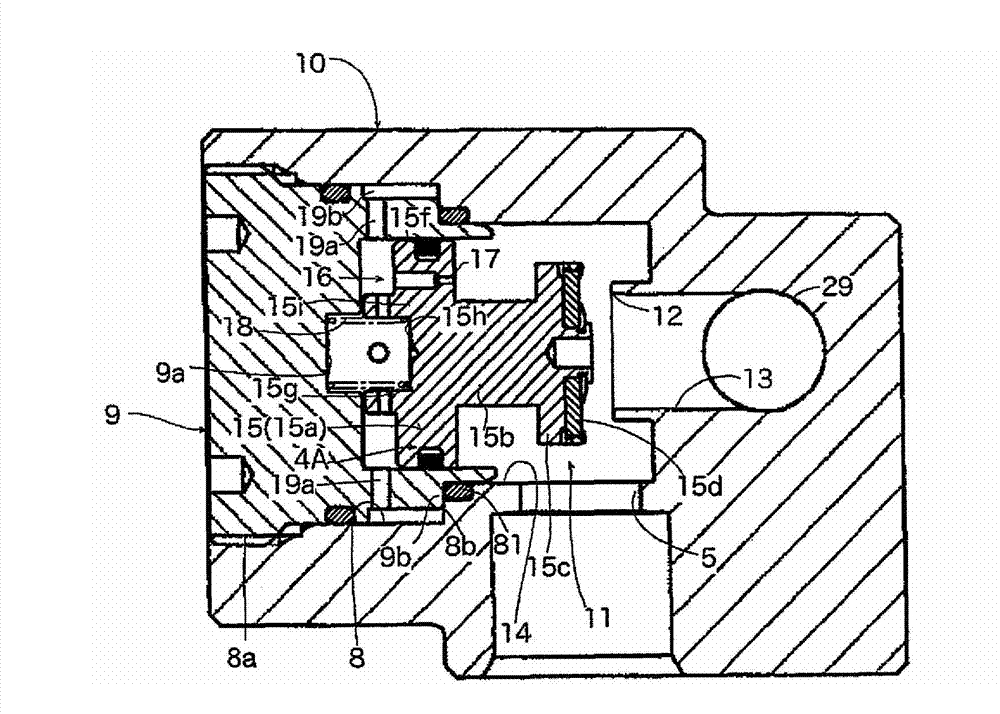

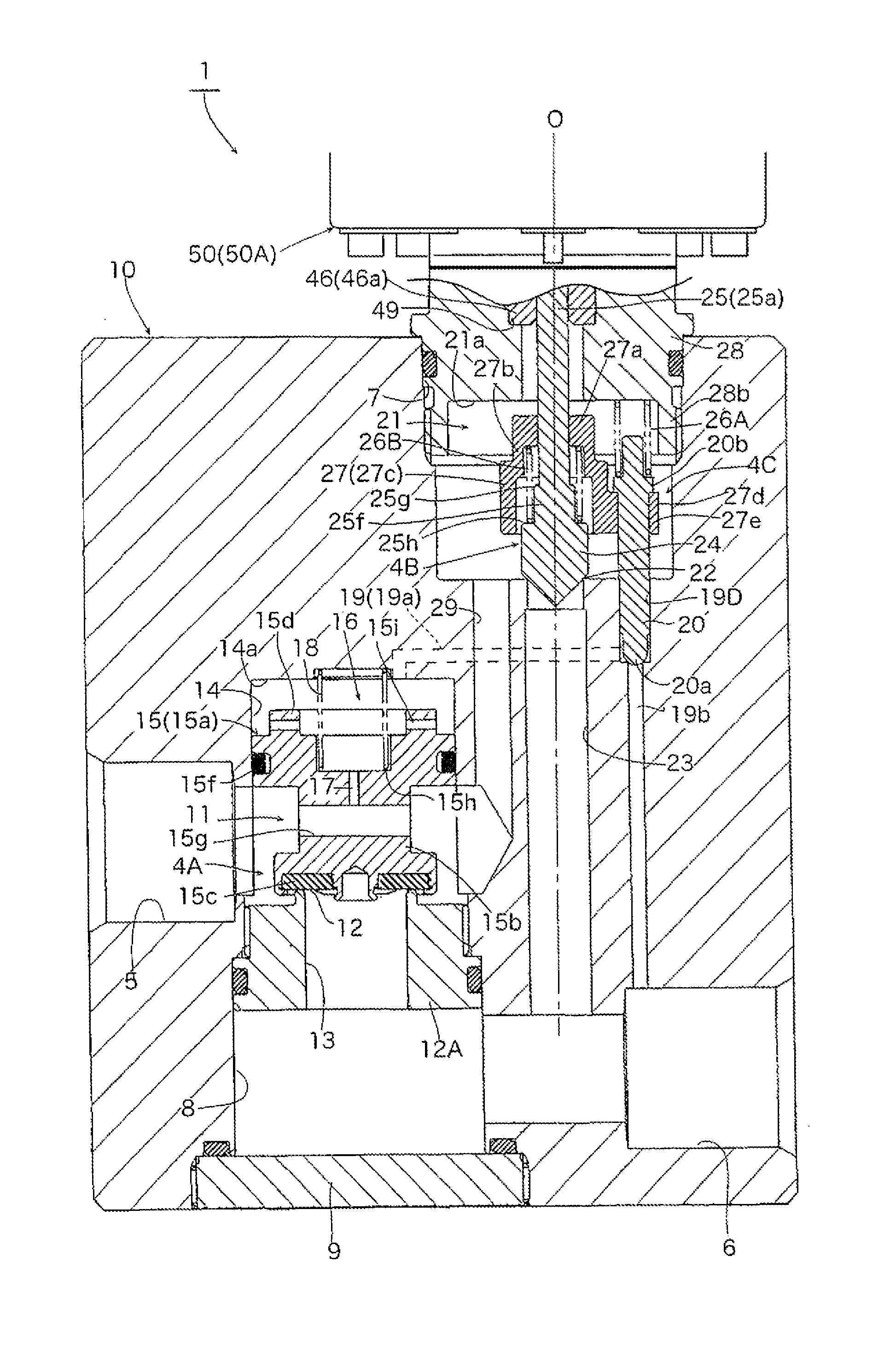

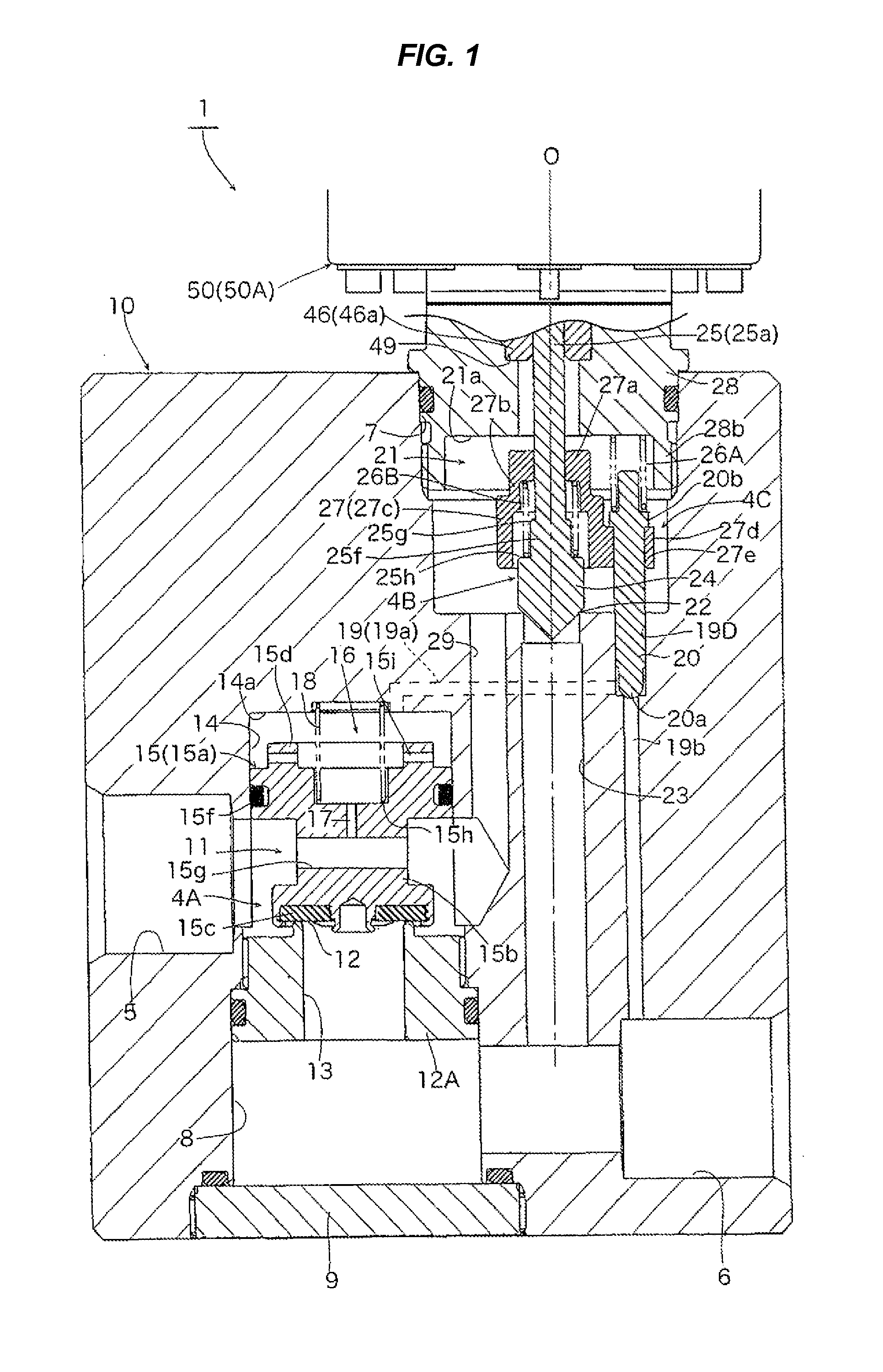

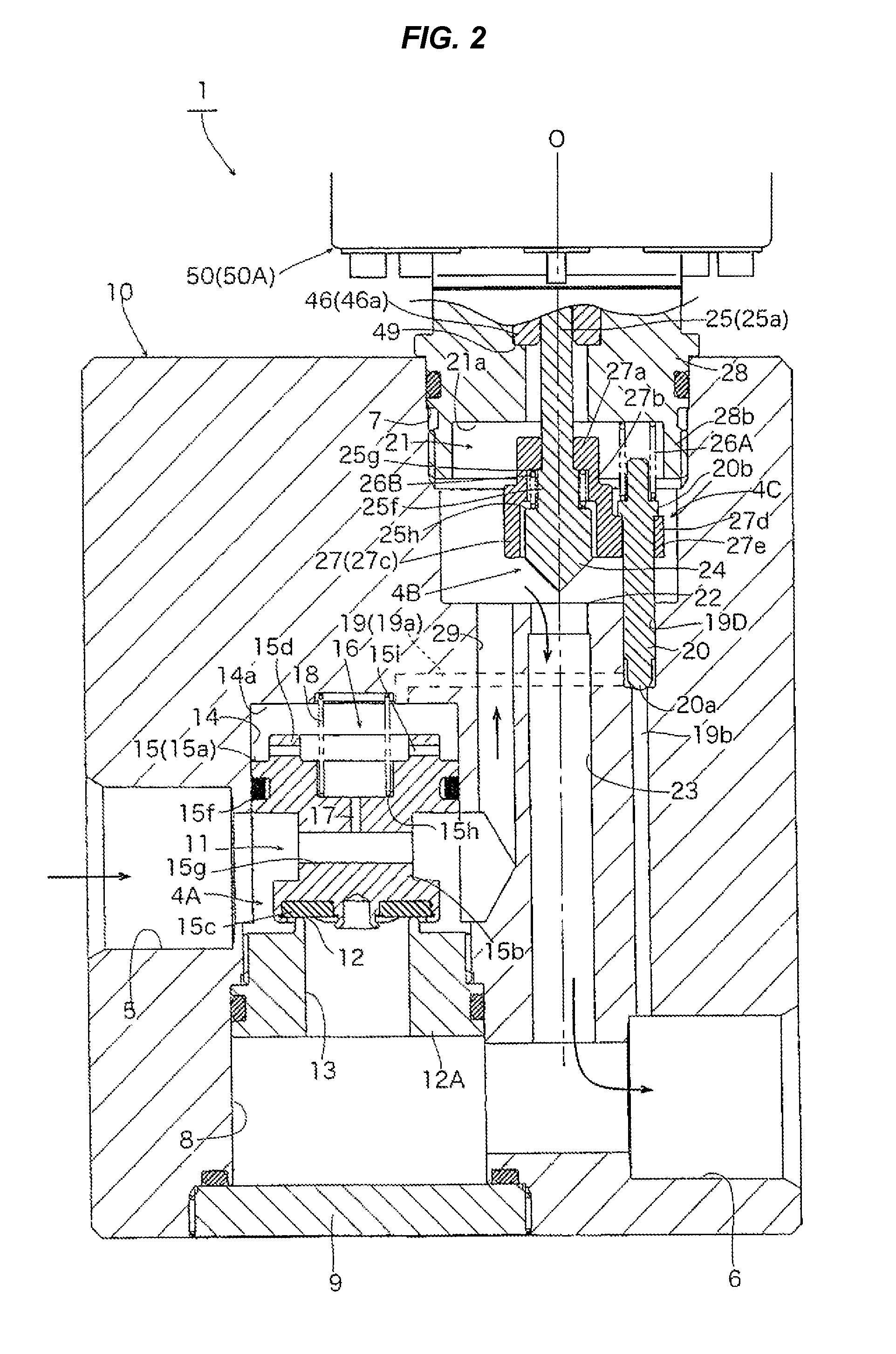

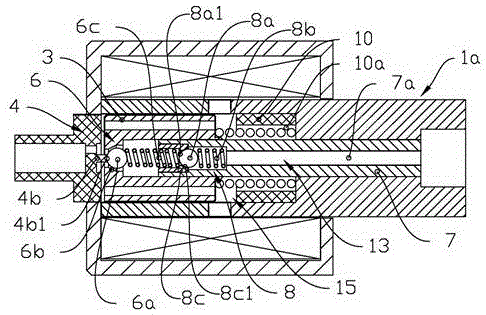

Electromagnetic proportional flow rate control valve

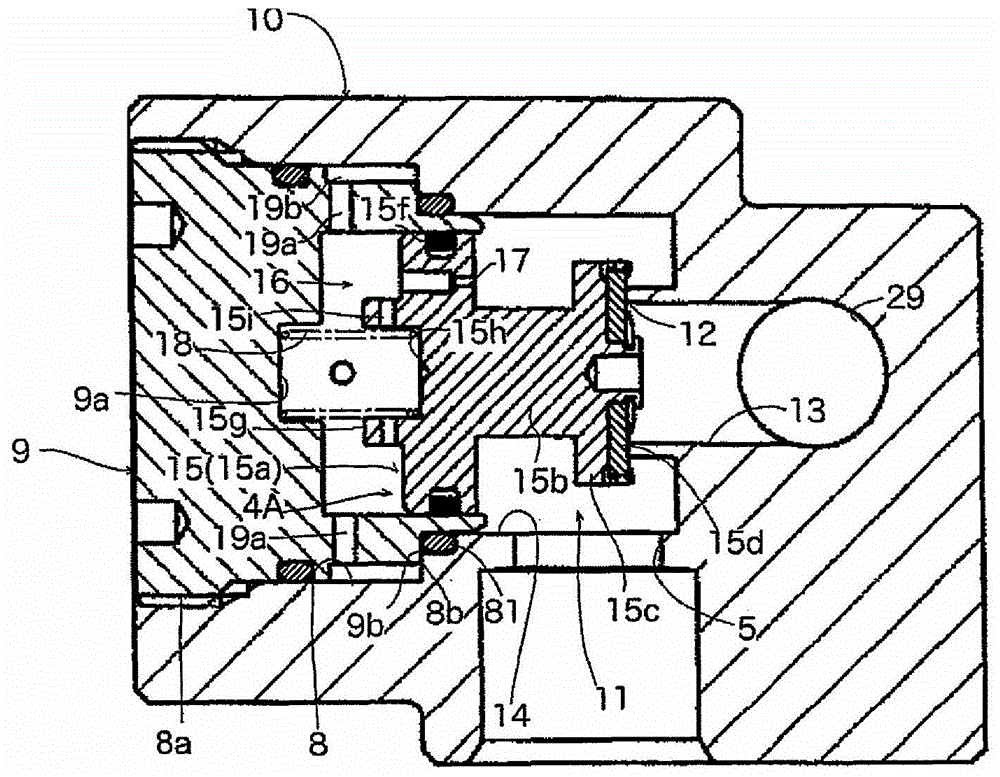

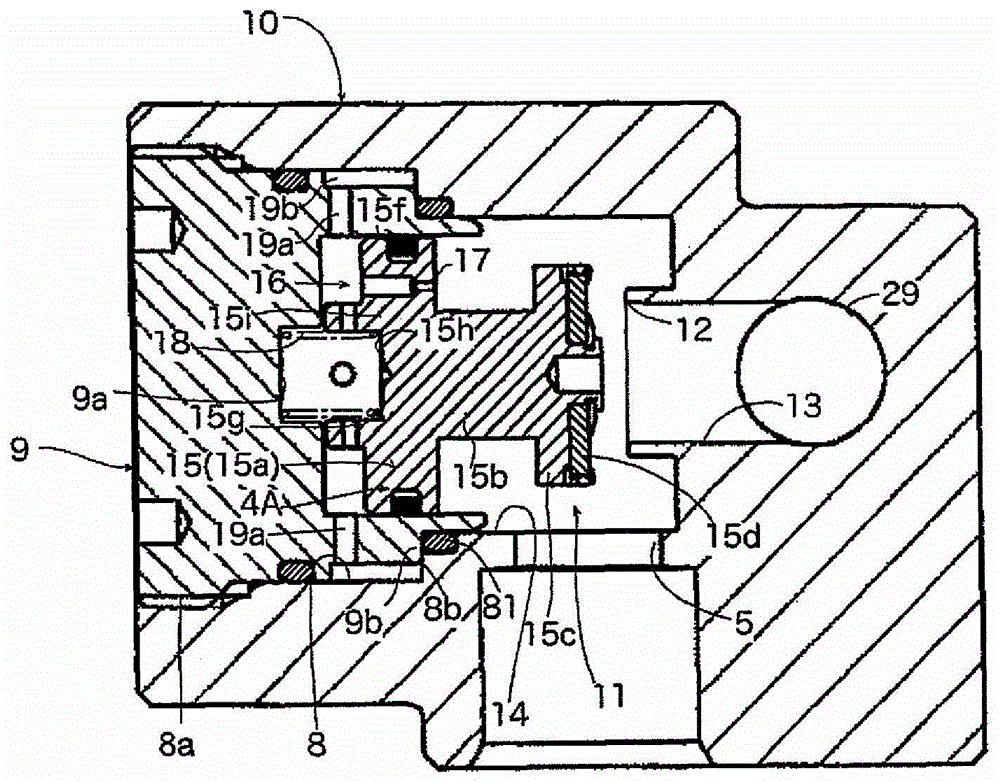

InactiveUS8418723B2Made smallHigh accuracy of flow controlOperating means/releasing devices for valvesServomotorsDriving currentEngineering

Owner:OKI ELECTRIC IND CO LTD

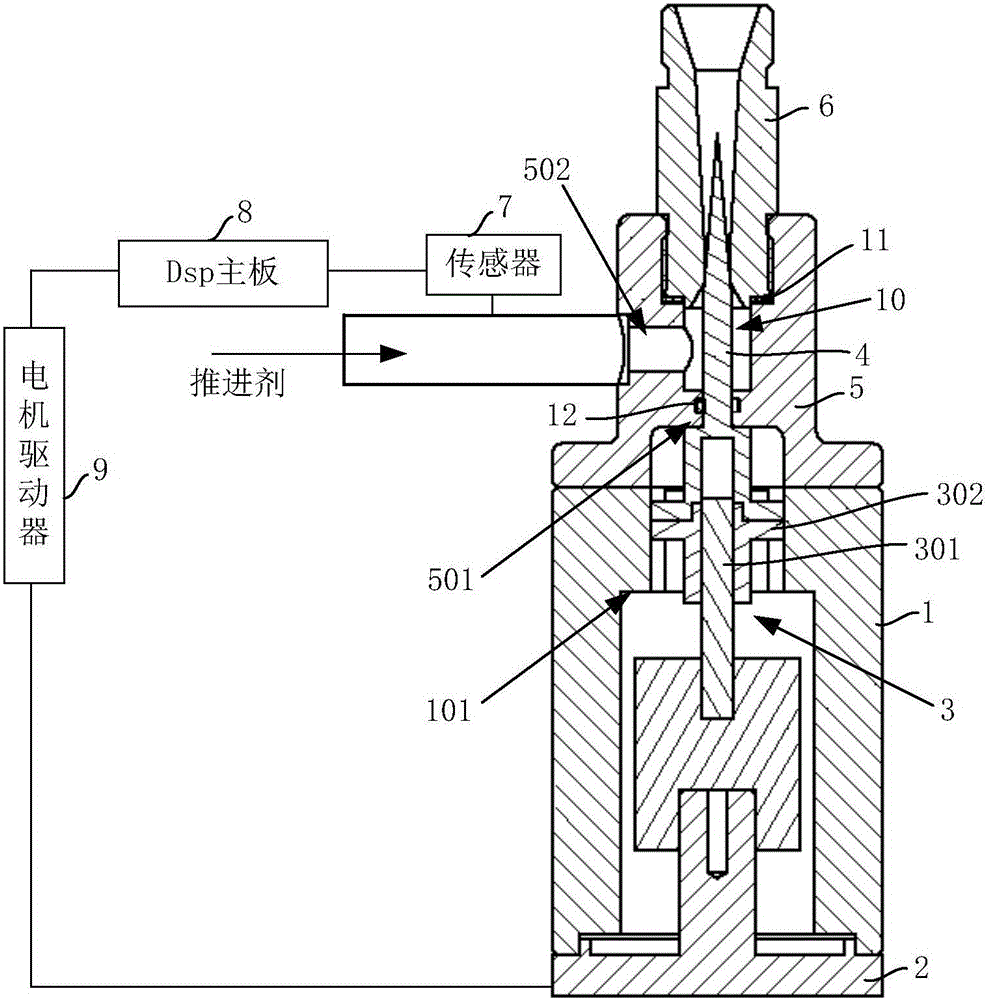

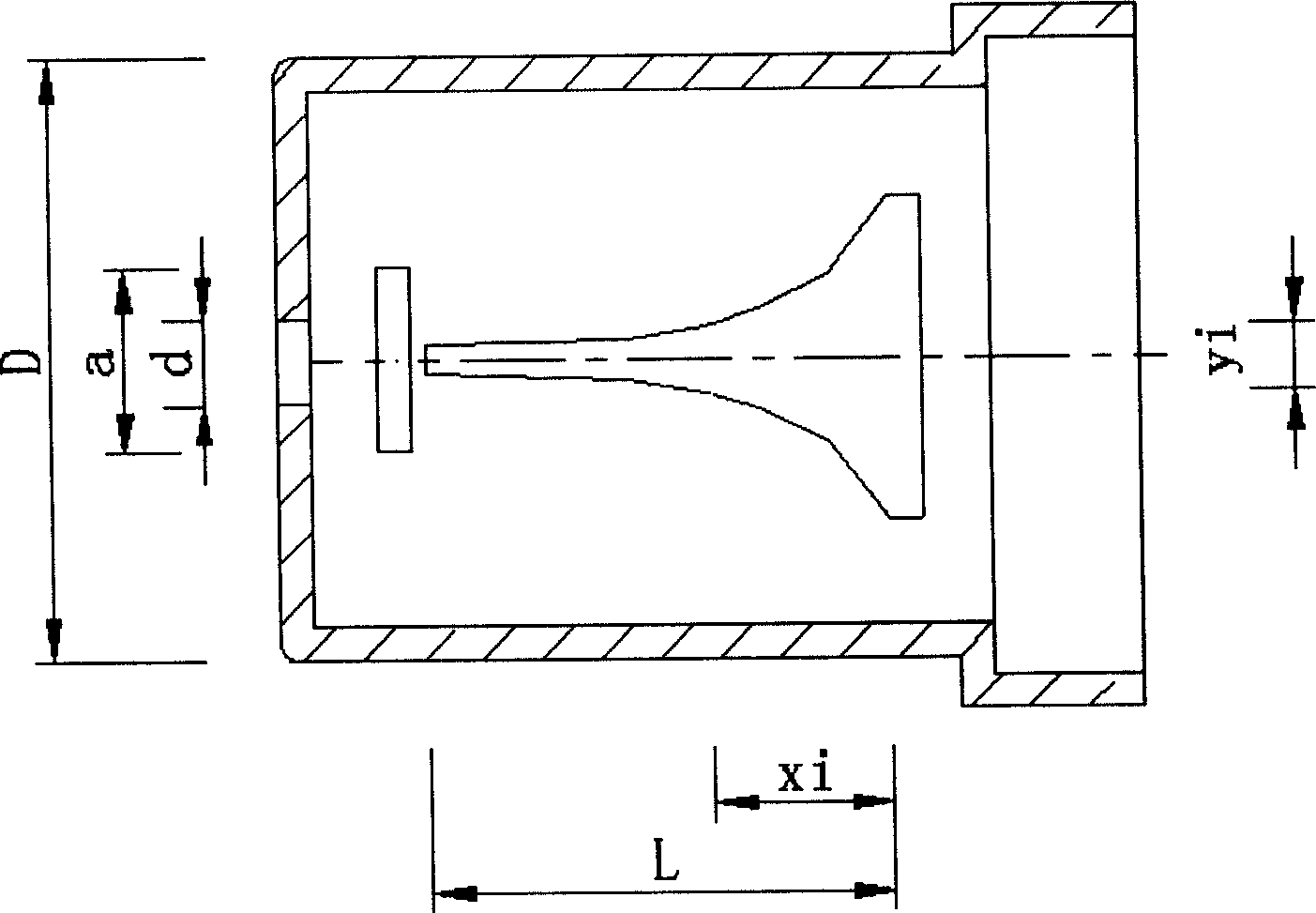

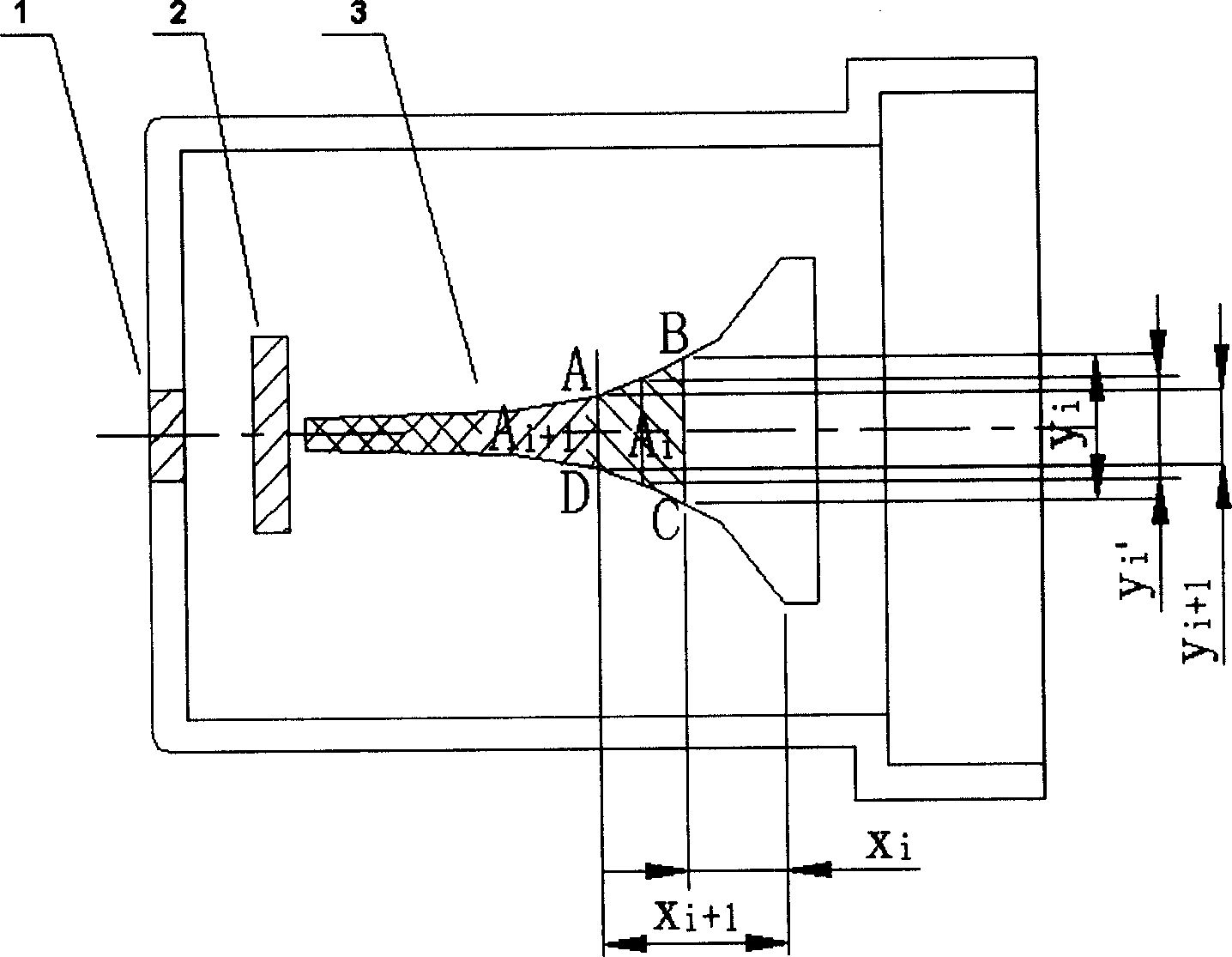

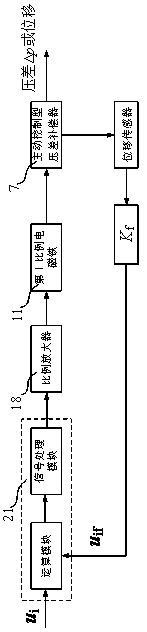

High-precision flow servo control valve

InactiveCN105757304APowerful data processing functionEasy to detectOperating means/releasing devices for valvesEqualizing valvesInlet pressureEngineering

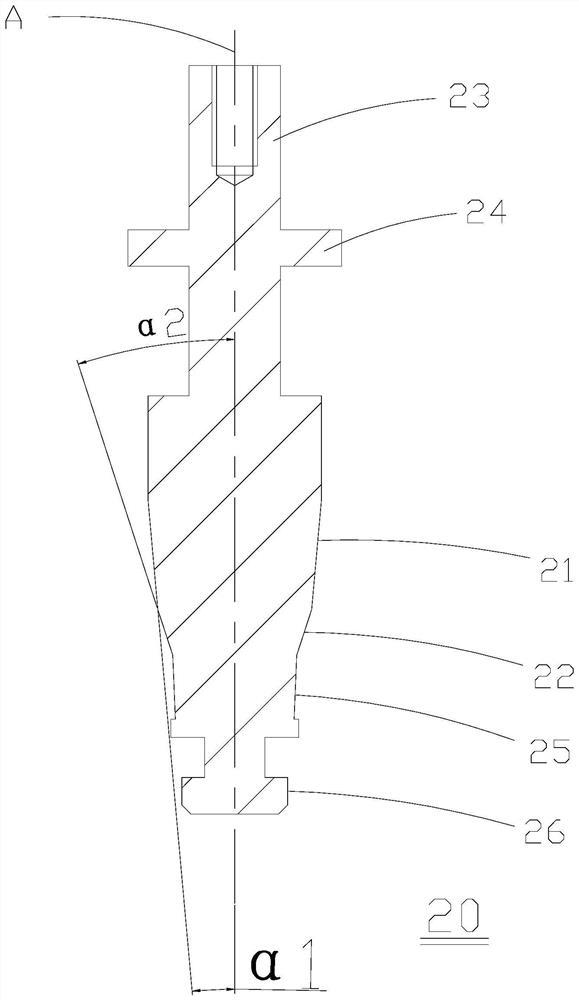

The invention discloses a high-precision flow servo control valve applicable to a liquid pipeline. The high-precision flow servo control valve comprises a servo motor, a ball screw, an adjusting taper and a combined seam type venturi tube. The control valve is compact in design; due to design of the size of the combined seam type venturi tube, the flow variation and the linearity of the stroke of the adjusting taper are optimized, the precision and the stability of flow control are improved, and the control precision is also improved due to the data processing characteristics of a Dsp mainboard. The venturi tube and a valve body are made of high-strength corrosion-resistant stainless steel, a valve element is made of a copper alloy and is sealed by a nitrile rubber pad, and a limiting block is made of LY12 aluminum alloy. Due to adoption of the combined seam type venturi tube, when the inlet pressure varies within a range of 3-10MPa and the hydrogen peroxide output flow is greater than 100 g / s, the error can be controlled to be within a range of 0.1%, and the flow stability of an aerial conveying system can be ensured.

Owner:BEIHANG UNIV

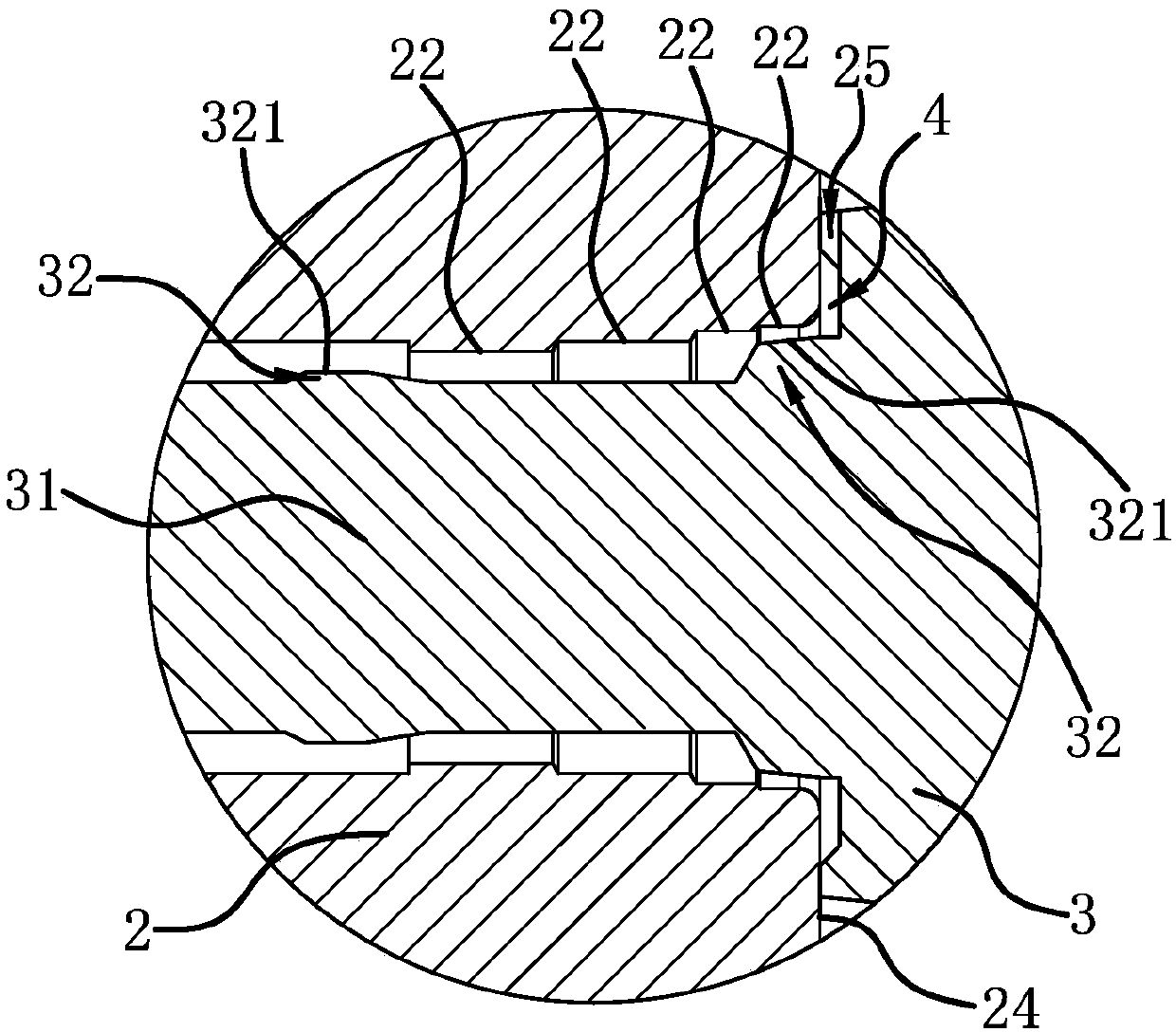

Control valve core device for high-precision automatic flow balancing valve and producing method thereof

InactiveCN1888498ASimple manufacturing methodEasy for CNC machiningEqualizing valvesSafety valvesCoil springEngineering

The inventive control spool means includes a flow control valve cylinder, in which are mounted one by one a flow control spool and a linear helical spring mounted. The flow control spool is hollow and it slides along the inner wall of the flow control valve cylinder. The method of manufacturing the control spool means includes the following steps of choosing the linear helical spring and setting the side-stream channel.

Owner:ZHEJIANG UNIV +1

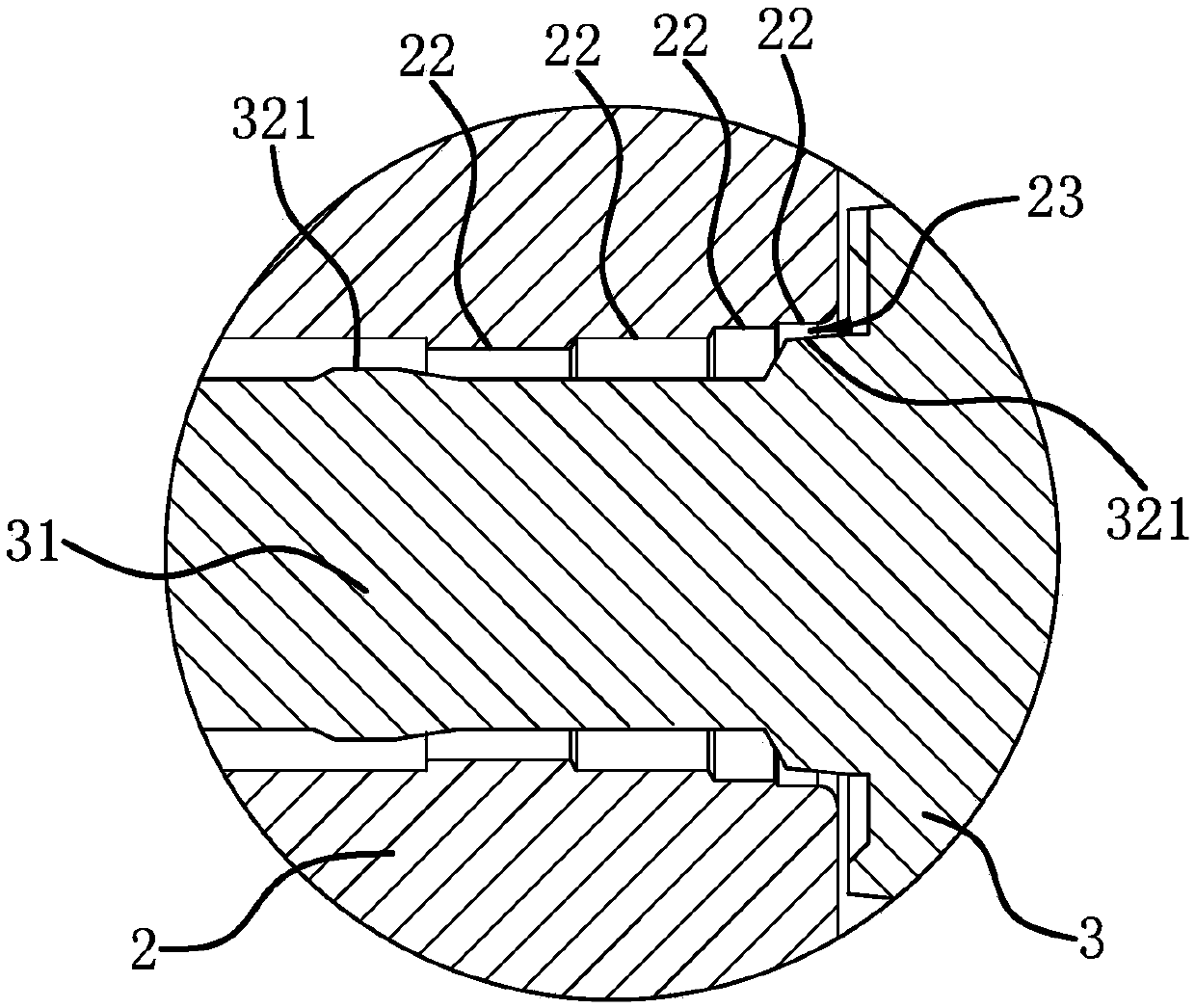

Assembled valve

ActiveCN103245139AHigh accuracy of flow controlImprove sealingOperating means/releasing devices for valvesEfficient regulation technologiesEngineeringMechanical engineering

The present invention relates to an assembled valve. When the lifting amount of a second valve core for low flow control is below a specified amount, a previous guiding valve core arranged on the inner wall of a bush retaining body slidably and freely closes a previous conducting access, a first valve core for a large flow control closes a first valve port, so that a low flow control state for controlling the flow according to the lifting amount of the second valve core is formed. When the lifting amount of the second valve core excesses the specified amount, the previous guiding valve core rises along with the rise of a valve rod, the previous guiding access is opened, and the first valve core opens the first valve port, so that the large flow control state is formed. The previous guiding valve core is inserted in the valve rod slidably, freely and externally, and is applied a downward force by a spring part to close the previous guiding access, and when the lifting amount of the second valve core is increased further from the specified value, a hook is lift on the valve rod. The assembled valve enables the flow control accuracy of the low flow region to be improved, the controllable flow to be increased, and the tightness of the previous guiding access generated by the previous guiding valve core to be improved, so that bad actions are prevented reliably, and the reliability is improved.

Owner:FUJIKOKI MFG CO LTD

Expansion valve

PendingCN107906804AHigh accuracy of flow controlLittle flow changeMechanical apparatusEfficient regulation technologiesEngineeringMechanical engineering

The invention provides an expansion valve, belongs to the technical field of valves and solves the problem of low control accuracy of the existing expansion valve. The expansion valve comprises a valve element I and a cylindrical valve element II, wherein the valve element I is provided with a run-through throttling hole; a cylinder insertion head which can be inserted into the throttling hole isarranged on the end surface of the valve element II; the outer diameter of the insertion head is smaller than that of the valve element II; at least two straight cylinder surfaces with different diameters are arranged on the inner wall of the throttling hole from the hole opening to the inside; at least two ring-shaped throttling walls with different diameters are arranged on the outer wall of theinsertion head; when the insertion head is inserted into the throttling hole, the throttling walls are opposite to the straight cylinder surfaces and form throttling channels. The expansion valve ishigher in flow control accuracy.

Owner:WENLING HENGFA AIRCONDITION COMPONENTS

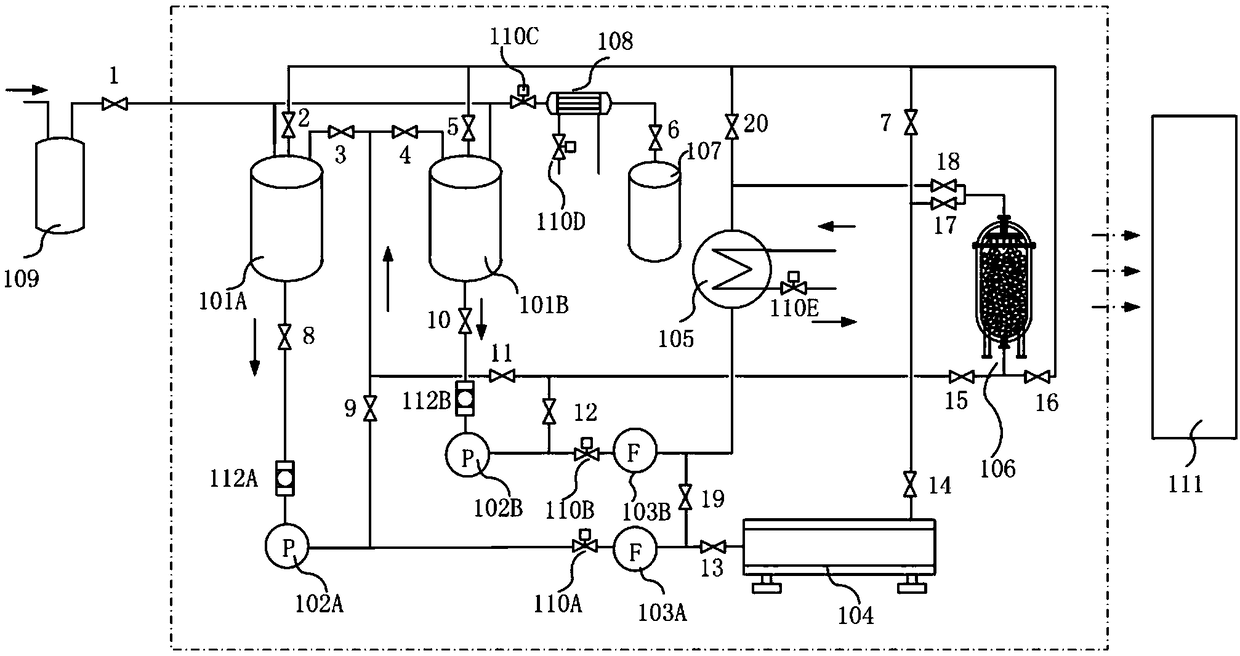

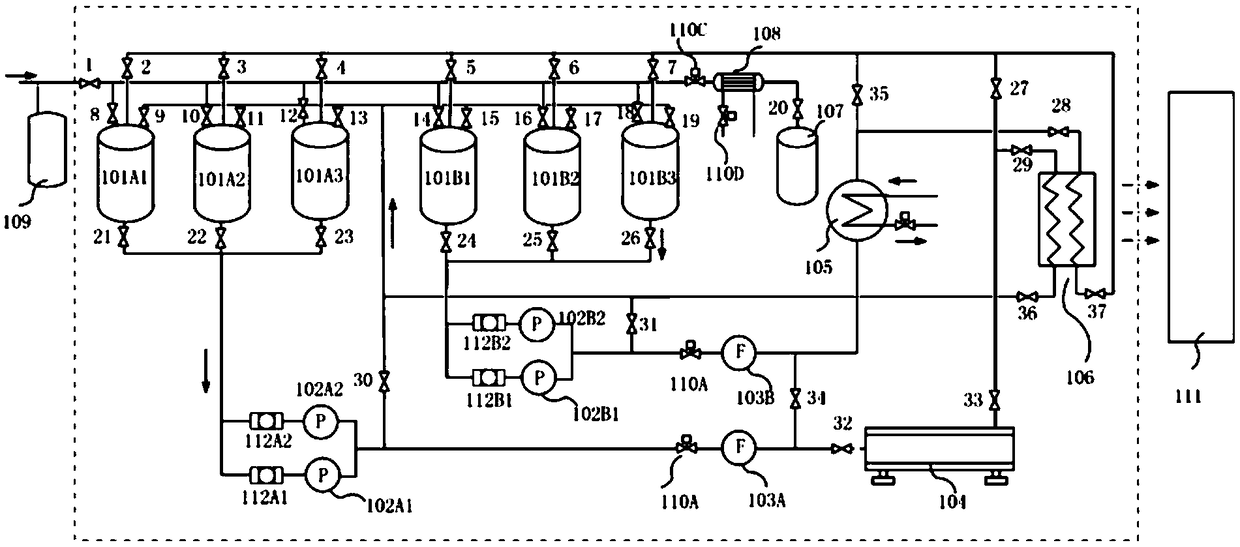

Heat performance test system

ActiveCN108918175AExtended operating temperature rangeWide power rangeStructural/machines measurementControl systemEngineering

The invention discloses a heat performance test system, which can perform test experiment and performance estimation on the heat storage / release performance of a heat storage device with high power and a wide temperature range and the heat exchange performance of a large-sized heat exchanger. The system consists of a test and control system, a heat energy production and storage system, a pressurestabilizing system, a tested device assembly, a pump valve assembly and the like, and can implement a test under a relatively wide temperature and pressure range. The system can also simulate outputting of unstable heat energy such as regenerable energy and implement a performance test and an operation strategy research on a large-scale medium and high-temperature heat storage device array, and can meet work such as a research and development test on key components of a compressed air energy storage system.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

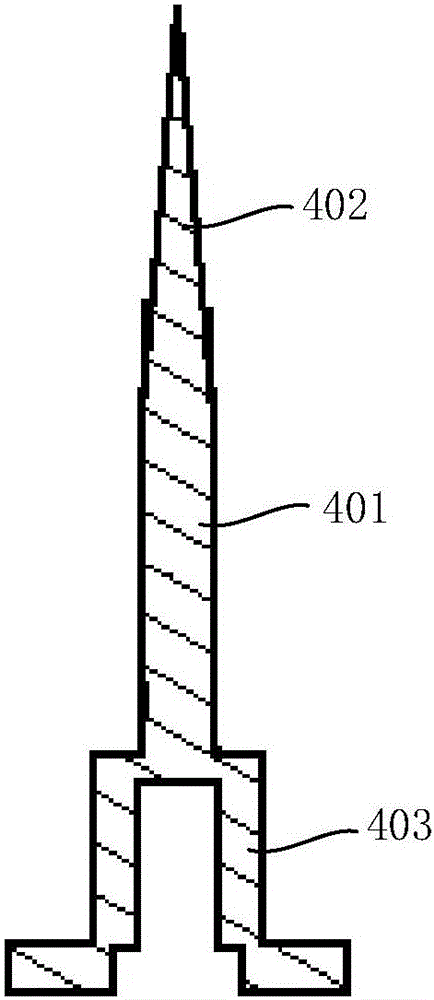

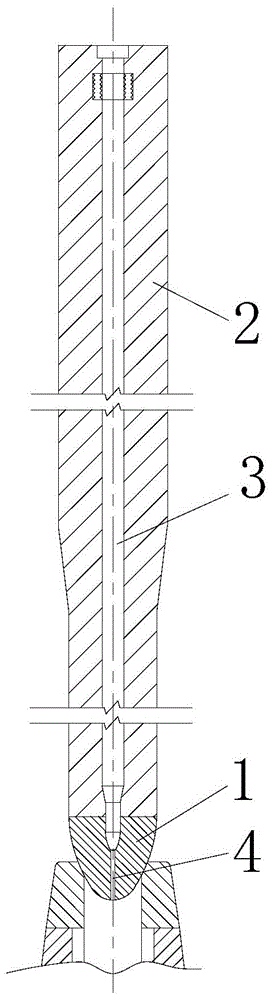

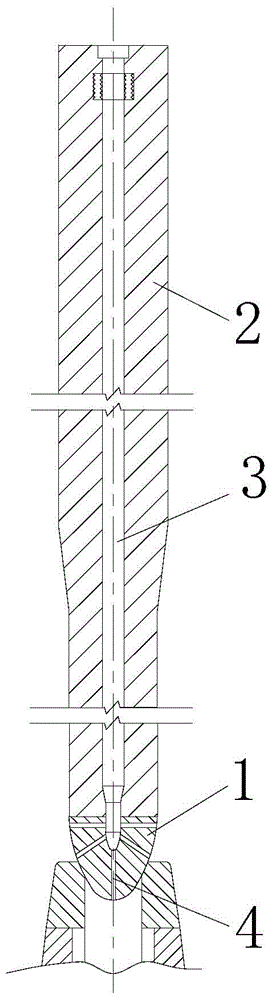

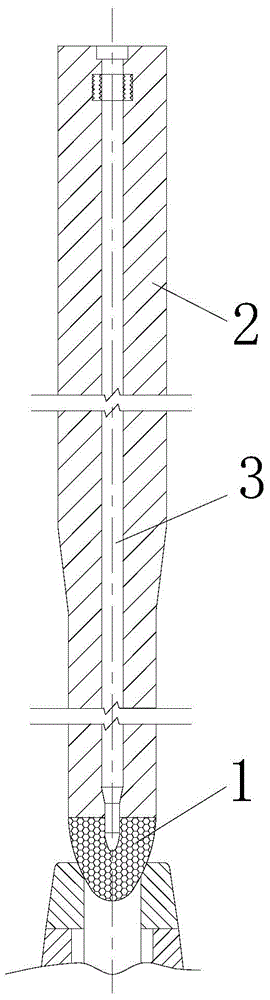

Diffusing argon blowing stopper rod for continuous casting and manufacturing method for stopper rod

The invention relates to a diffusing argon blowing stopper rod for continuous casting and a manufacturing method for the stopper rod. The stopper rod is formed by a stopper rod body and a stopper rod head fixed on the front end of the stopper rod body, wherein an argon channel to the stopper rod head is formed in the stopper rod body; the stopper rod head is made from porous material; and argon is diffusedly blown into molten steel via porous material. The manufacturing method comprises material preparation, mixture, formation, sintering, machinery processing, coating and packing. Compared with the prior art, the beneficial effects of the diffusing argon blowing stopper rod for continuous casting and the manufacturing method for the stopper rod are that air guide holes are unnecessary for the stopper rod head; argon is blown via the porous material having great apparent porosity, so argon can be evenly blown and impurities accumulated on the stopper rod head can be removed; control current precision can be improved; compared with a common stopper rod, effects on liquid level fluctuation of a crystallizer by large bubbles due to concentrated argon blowing can be avoided, so argon blowing effect can be enhanced; the stopper rod head having apparent porosity greater than 20%is made from with addition of ignition lost agent to raw material; and simple manufacturing method is provided and low cost is achieved.

Owner:UNIV OF SCI & TECH LIAONING +1

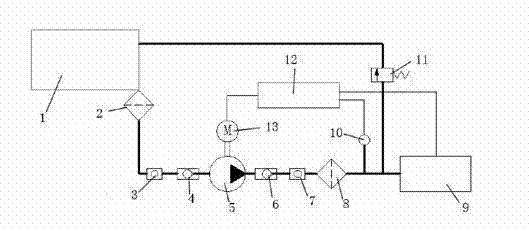

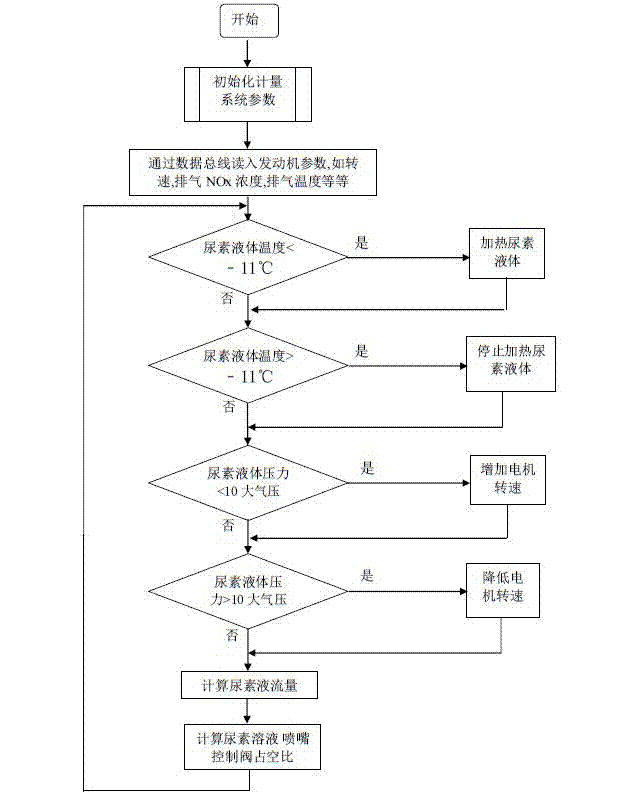

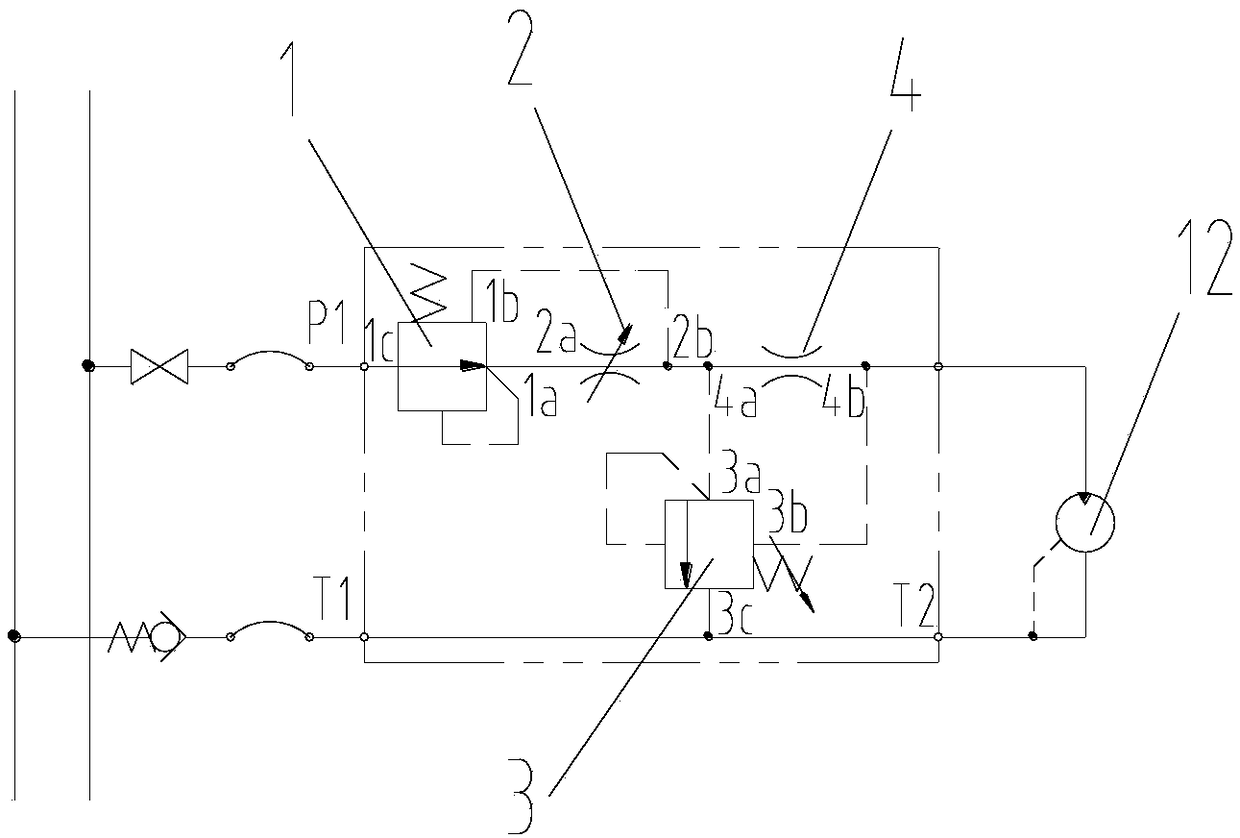

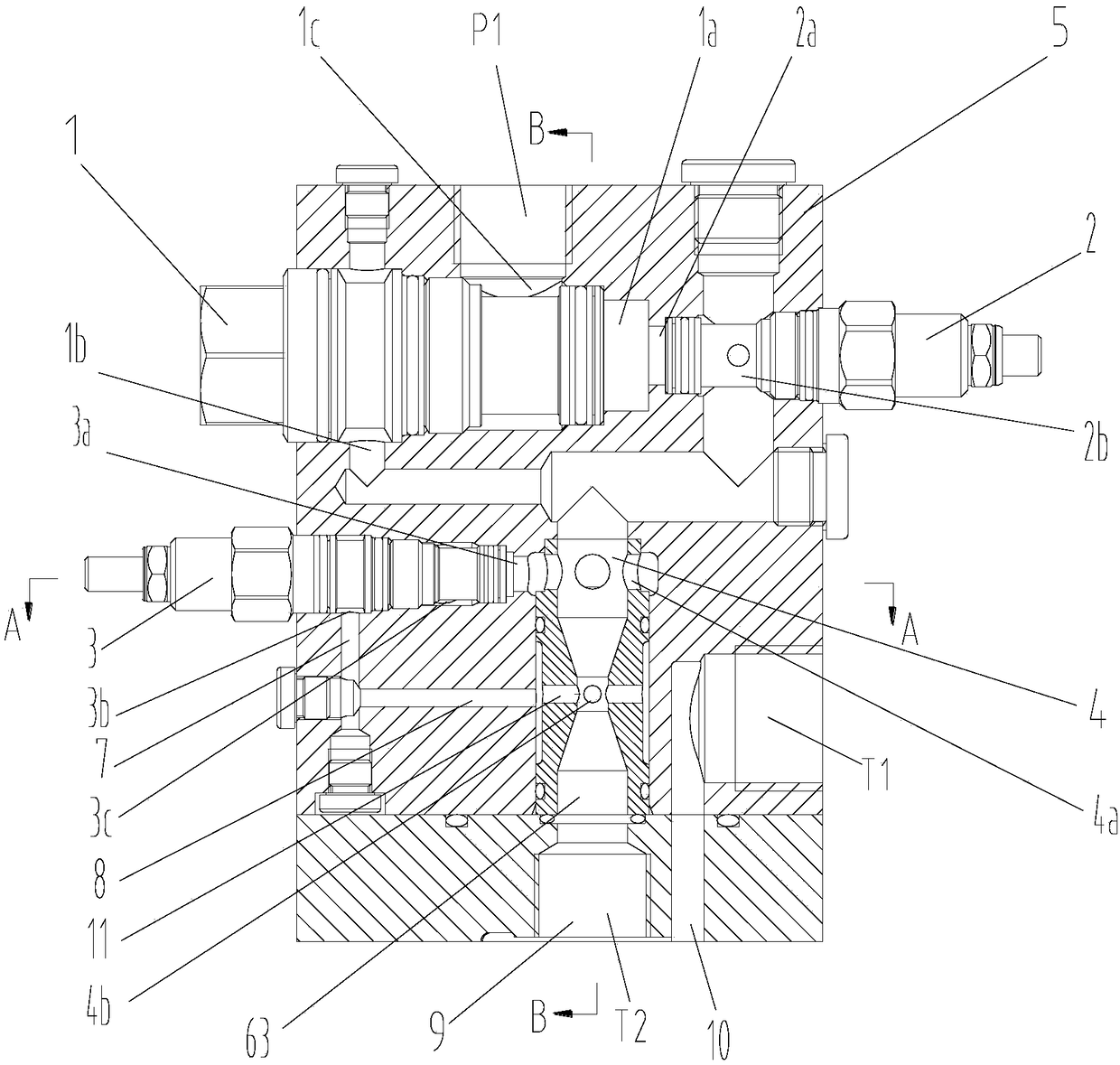

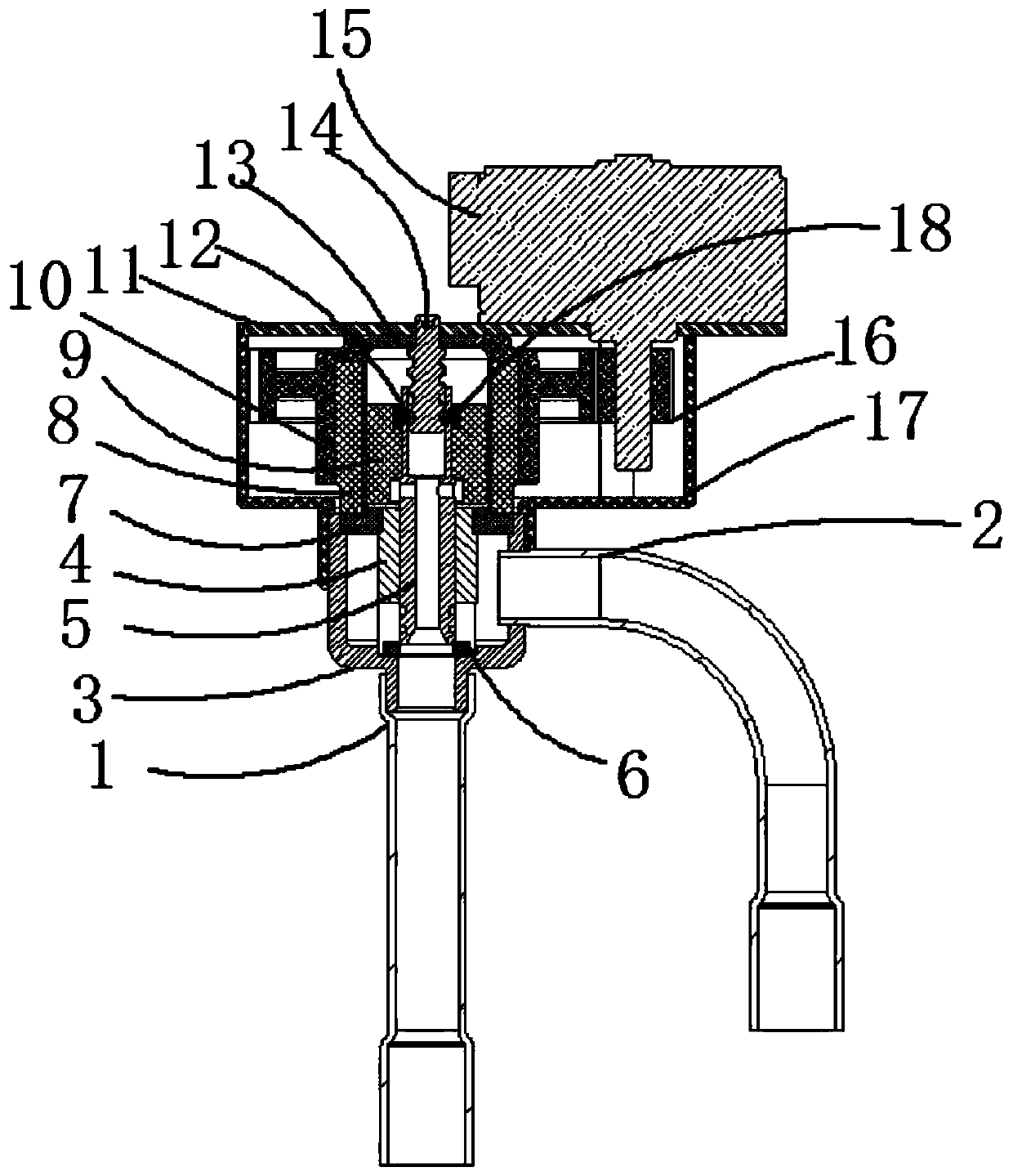

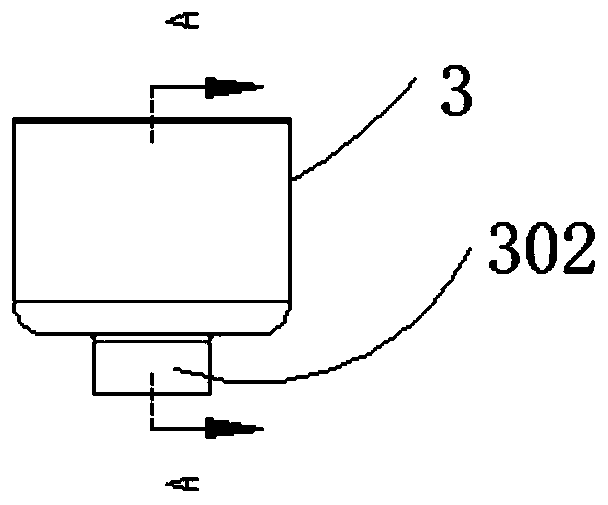

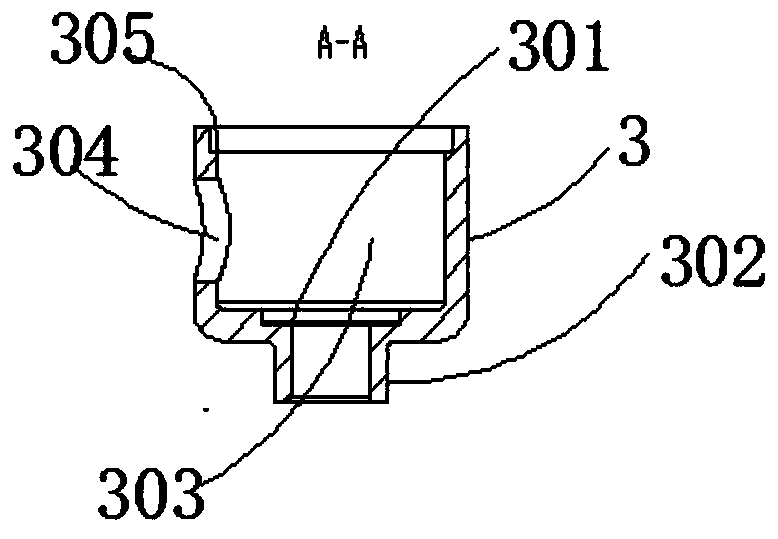

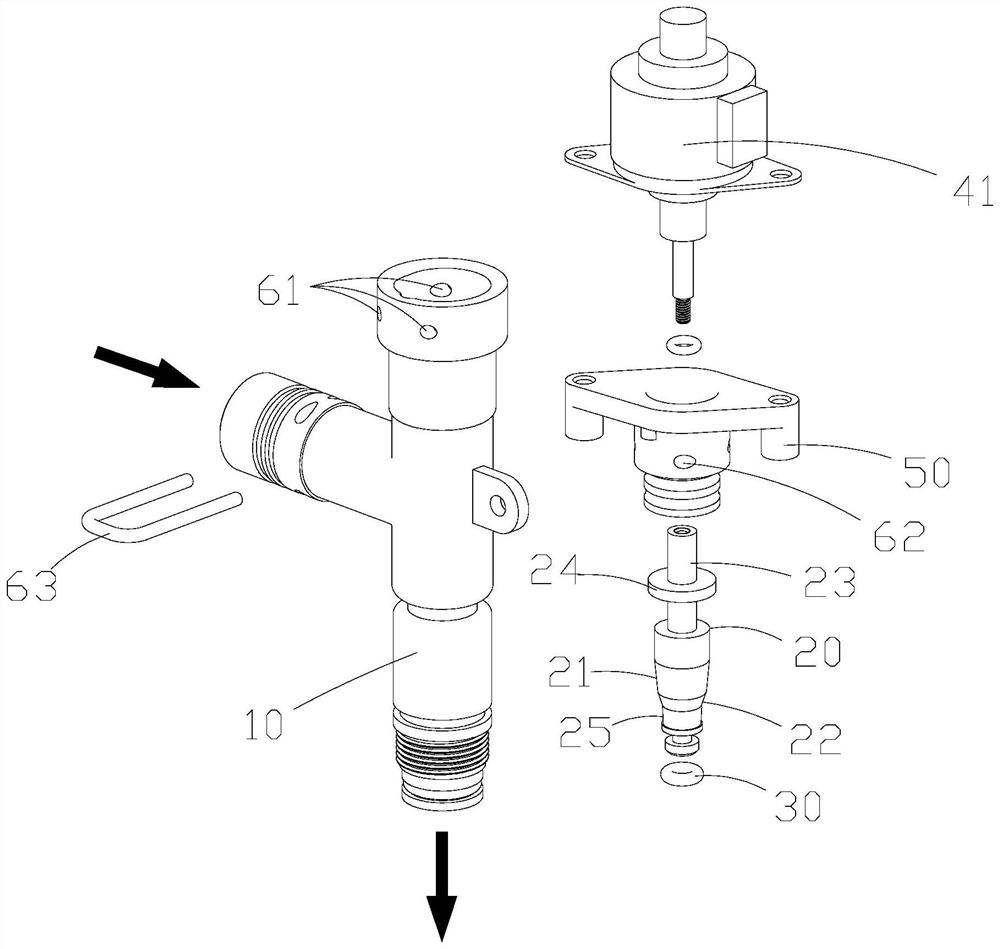

Urea solution metering injector and control method thereof

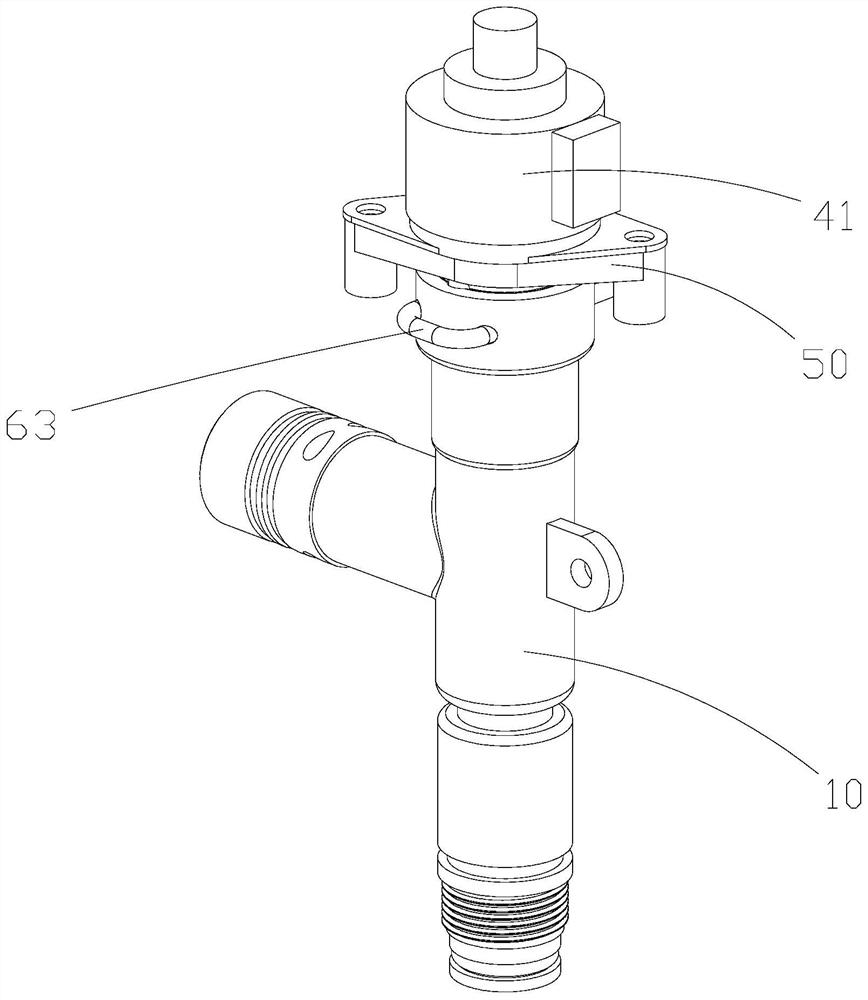

InactiveCN103114896ASmall pressure fluctuationsHigh control precisionInternal combustion piston enginesExhaust apparatusInjectorUrea

The invention discloses a urea solution metering injector which comprises a pump, a urea cylinder, a step motor and a nozzle. An outlet of the urea cylinder is connected to an entry end of the pump sequentially through a pre-filter, a first volume-variable member and a first one-way valve, a discharge end of the pump is connected to the nozzle sequentially through a second one-way valve, a second volume-variable member and a filter, and the step motor is connected to the pump. A pressure valve is disposed between the filter and the nozzle. A sensor is disposed between the nozzle and the filter. The step motor is connected with a control unit which is connected with the sensor and the nozzle. The control unit is used for controlling pressure and starting time of urea solution from the nozzle according to the speed of the step motor. Each of the pre-filter, the filter, the first one-way valve, the second one-way valve, the pump and the step motor is provided with a heating unit.

Owner:JIANGSU UNIV

Hydraulic speed regulating valve and hydraulic system

ActiveCN108194440AEasy to adjustSimple structureServomotor componentsServomotorsEngineeringDrive motor

The invention discloses a hydraulic speed regulating valve and a hydraulic system, and belongs to the field of hydraulic valve assemblies. The hydraulic speed regulating valve comprises a pressure reducing valve, a throttling valve, an overflow valve and a Venturi tube; an oil outlet of the pressure reducing valve communicates with an oil inlet of the throttling valve; an oil drainage port of thepressure reducing valve communicates with an oil outlet of the throttling valve; an oil inlet of the overflow valve communicates with the oil outlet of the throttling valve; the oil outlet of the throttling valve communicates with an oil inlet of the Venturi tube; a control oil port of the overflow valve communicates with the throat of the Venturi tube; and opening pressure of the overflow valve meets a formula as shown in the specification. The hydraulic speed regulating valve is little in pressure loss, and the hydraulic oil flow accurately adjusted by the hydraulic speed regulating valve isthe same as the rated flow of a portable pump driving motor.

Owner:WUHAN MARINE MACHINERY PLANT

Vehicle-mounted physical parameter tester of geological heat of ground source heat pump

InactiveCN102095751ACompact structureEasy to use and flexibleMaterial heat developmentResponse methodEngineering

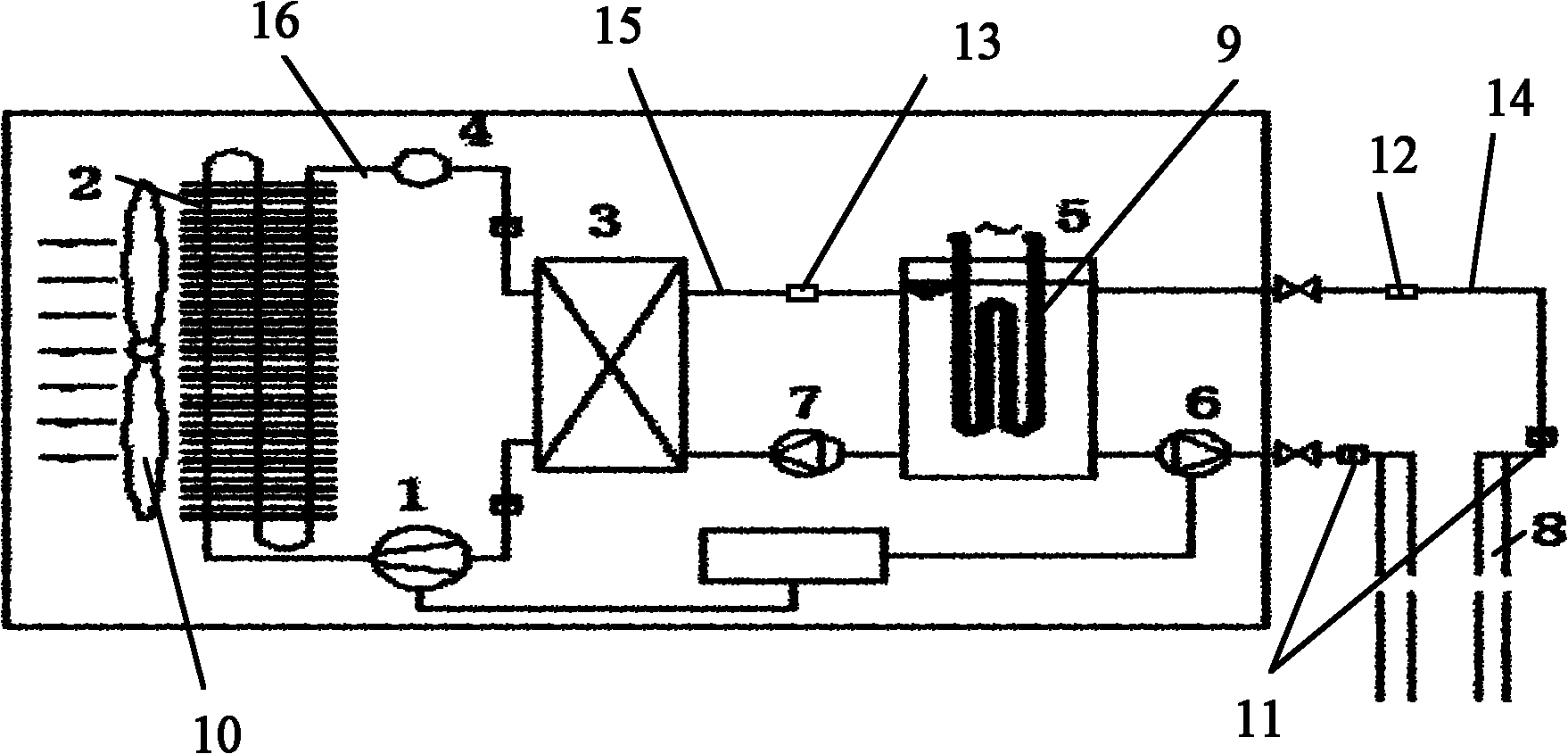

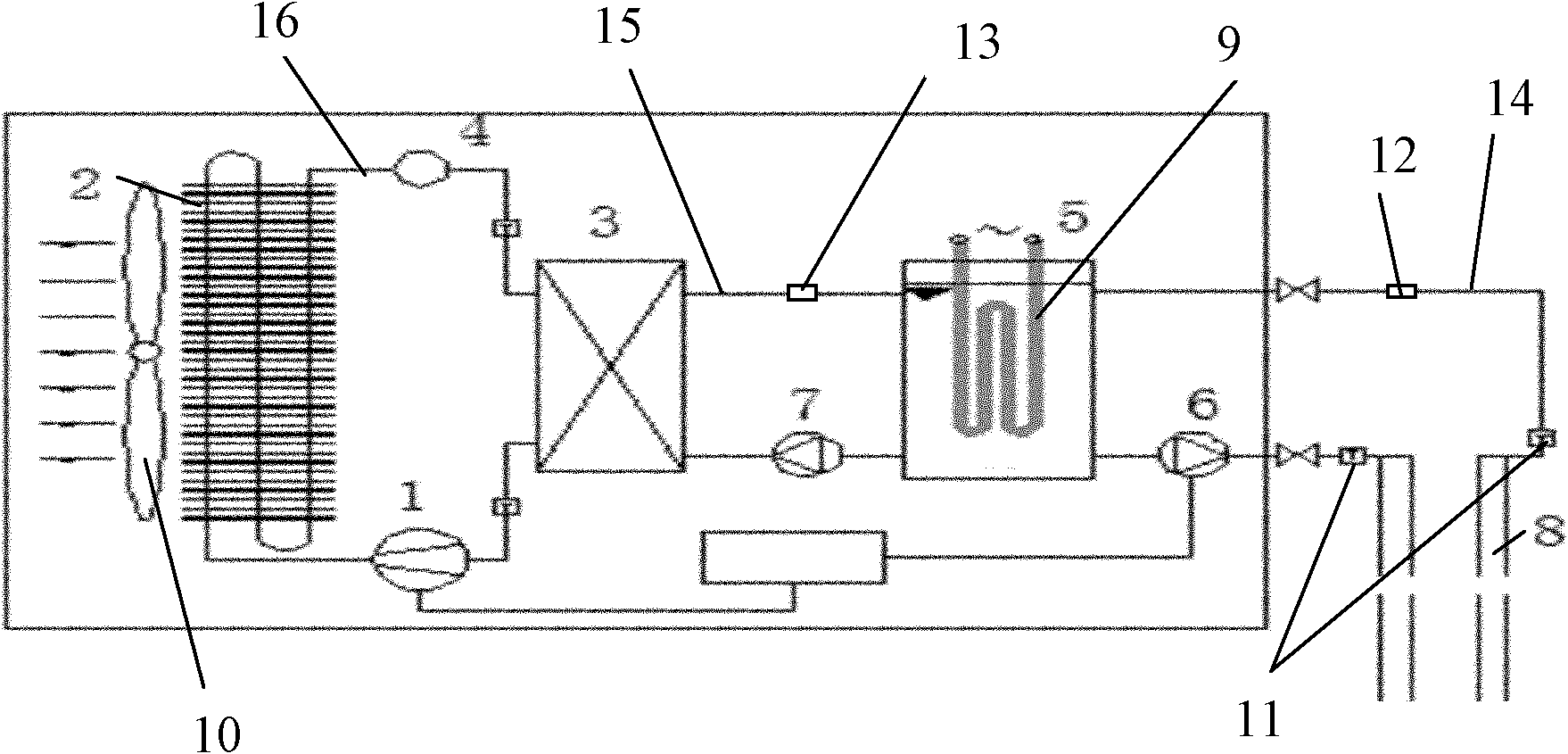

The invention discloses a vehicle-mounted physical parameter tester of geological heat of a ground source heat pump. The physical parameter tester comprises a heat-insulating water tank, an electrical heating tube, a circulating pump for a buried tube, a circulating pump for an evaporator, an air-cooled heat pump unit consisting of the evaporator, a compressor, a condenser, an expansion valve and a fan, and a controller. In the vehicle-mounted physical parameter tester of the geological heat of the ground source heat pump, the cold and heat source is provided by the air-cooled heat pump unit, so the whole tester has a compact structure, can be placed on a vehicle, and is very flexible and convenient to use. In addition, the cold and heat source mainly comes from air, so that other cooling and heating facilities are not needed. During testing, only a group of heat exchangers for the buried tube are needed to be buried, so that the testing cost can be greatly reduced. As the tester can be used for cooling (preparing cold water) and heating (preparing hot water), only one tester can meet the testing requirements of a thermal response method and a simulation method. Therefore, the tester is dual-purpose, and has a wide application range. In addition, the tester has high automation degree.

Owner:天津美意机电设备工程有限公司

Electronic expansion valve

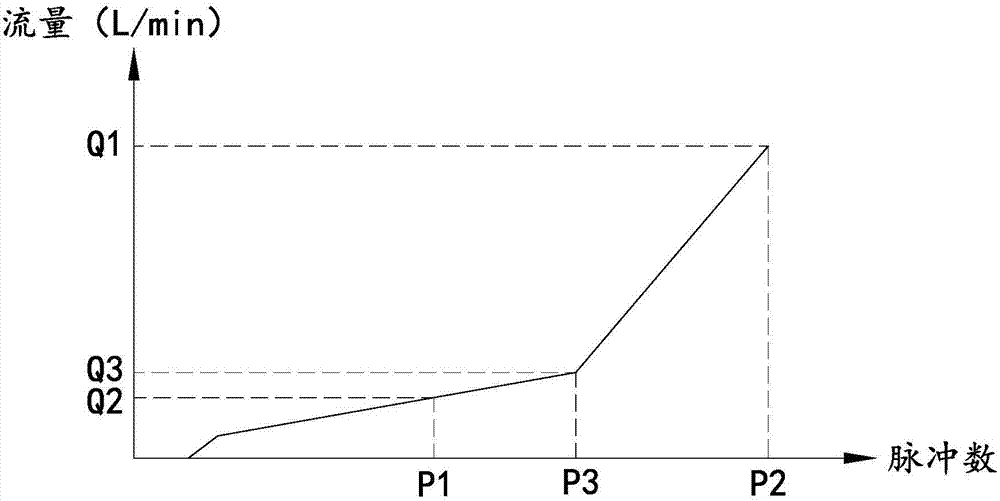

InactiveCN107461498AHigh accuracy of flow controlHigh guiding precisionEfficient regulation technologiesFluid circulation arrangementEngineeringMechanical engineering

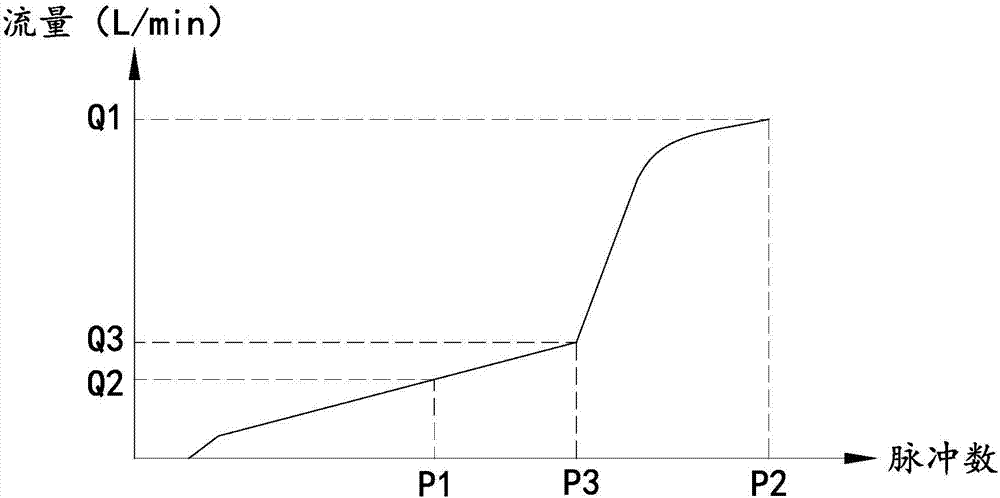

The invention discloses an electronic expansion valve, belongs to the field of electromagnetic valves, and solves the problem that a traditional electronic expansion valve cannot obtain the flow curve in application of one special system. The electronic expansion valve comprises a valve body, a valve needle module, and a driving device for driving the valve needle module to move; and the electronic expansion valve controls the driving device according to received pulse signals. The electronic expansion valve further comprises a valve base element mounted on the valve needle module; a small valve port is formed in the valve base element; a large valve port is formed in the valve body; the driving device drives the valve needle module to move to control the openness of the small valve port; and the driving device drives the valve base element to move through the valve needle module so as to control the openness of the large valve port. The electronic expansion valve effectively realizes special flow curve control so as to realize application of the special system.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

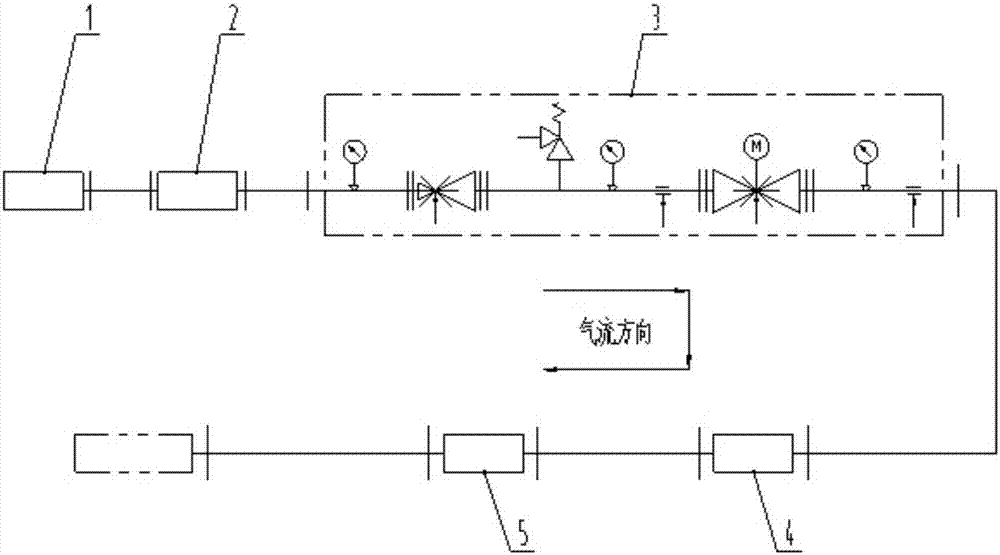

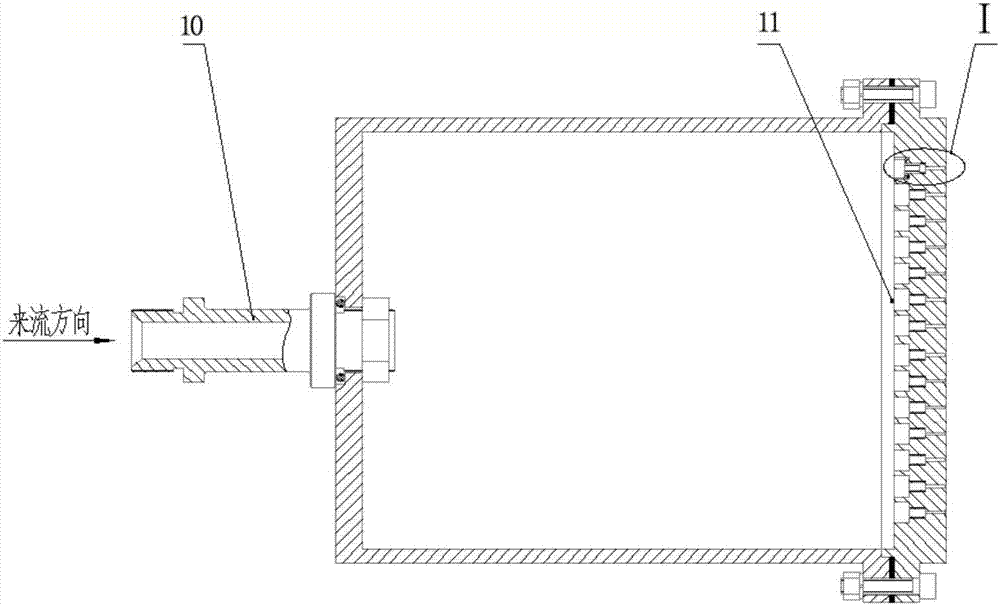

High-precision micro-jet test pipeline device

PendingCN107367368AGuaranteed uptimeHigh accuracy of flow controlAerodynamic testingJet flowInlet channel

The invention relates to a high-precision micro-jet test pipeline device. The high-precision micro-jet test pipeline device comprises a flowmeter, a pressure lowering and stabilizing valve group, a multi-position digital valve and a pressure stability cavity, wherein high-pressure gas is connected with the flowmeter, the flowmeter is connected with the pressure lowering and stabilizing valve group, the pressure lowering and stabilizing valve group is connected with the multi-position digital valve, the multi-position digital valve is connected with the pressure stabilizing cavity, the pressure stabilizing cavity is connected with a test piece jet hole plate, the multi-position digital valve comprises an air inlet and collecting chamber, a plurality of Laval nozzles, a plurality of electromagnetic valves and an air discharge and collecting chamber, the air inlet and collecting chamber is provided with a plurality of air outlets, one Laval nozzle is mounted at each air outlet, each Laval nozzle is connected with one electromagnetic valve, the air discharge and collecting chamber is provided with corresponding number of air inlets, and each electromagnetic valve is connected with the air inlet at the corresponding positon of the air discharge and collecting chamber. The high-precision micro-jet test pipeline device has the advantages that when the high-precision micro-jet test pipeline device is applied to an air inlet channel micro-jet flow controlled wind tunnel test, the device is stable in operation, jet flow is adjustable in a range of 0-0.032kg / s, and the device is high in flow control and measuring precision.

Owner:中国航空工业集团公司哈尔滨空气动力研究所

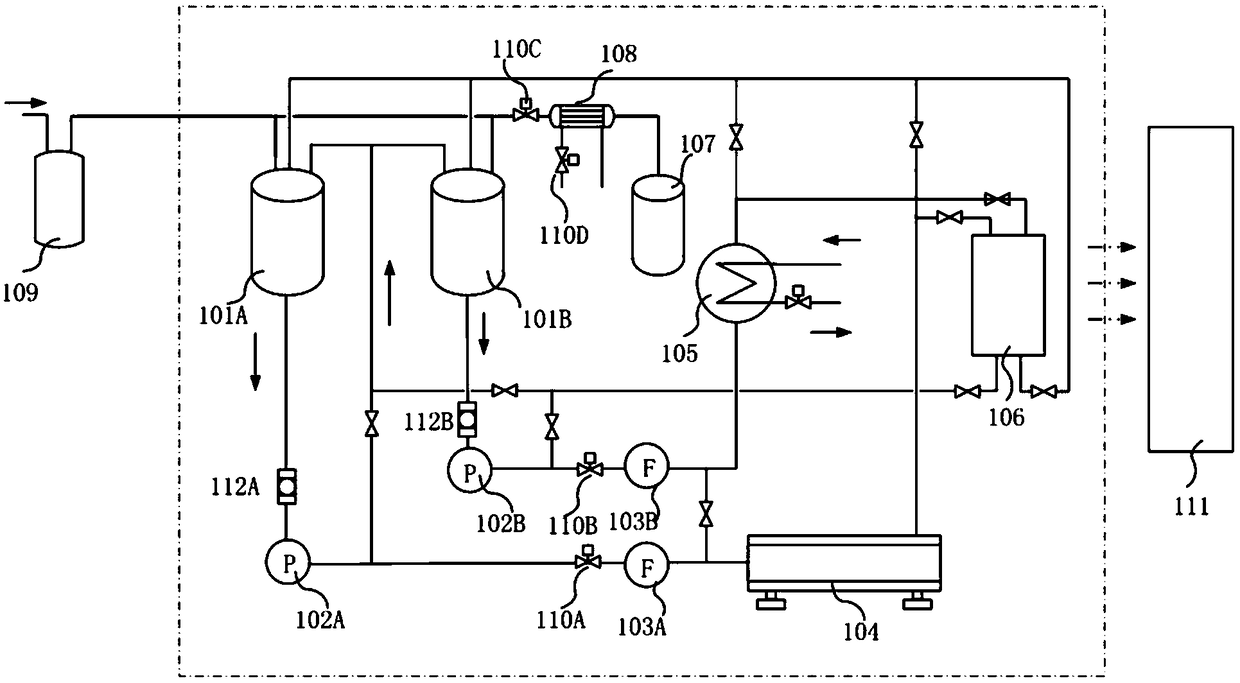

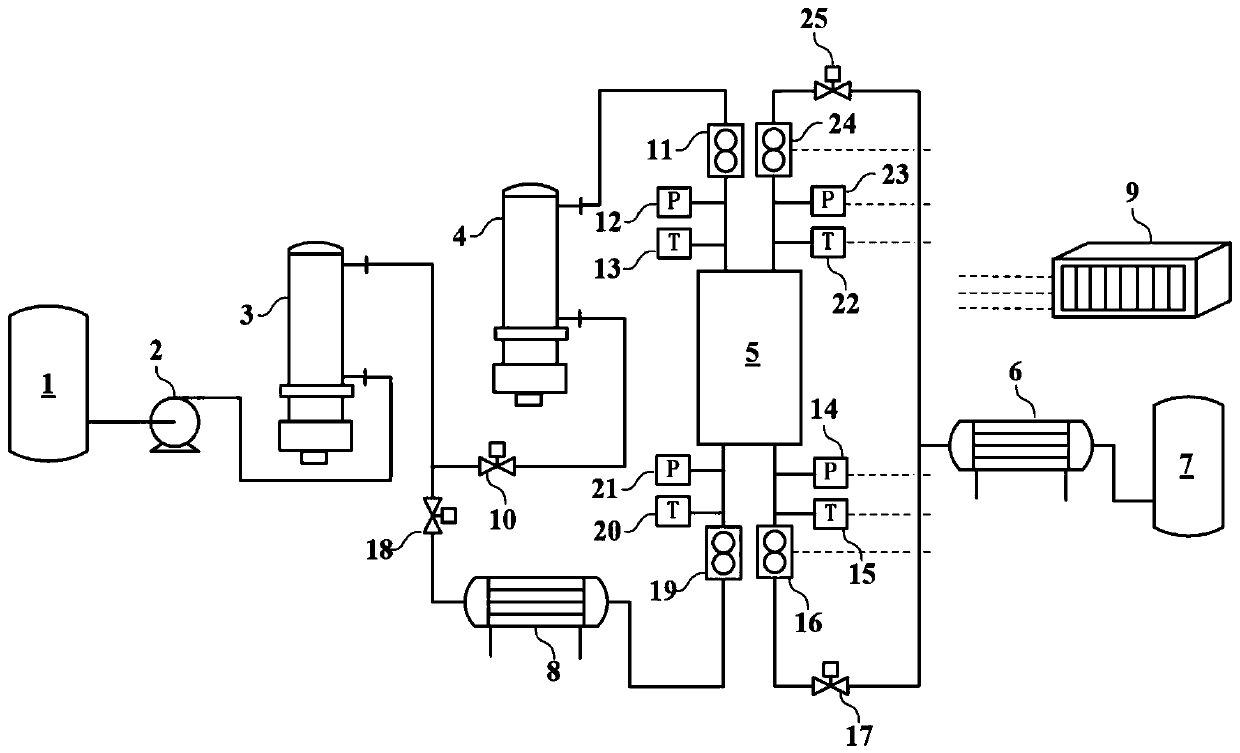

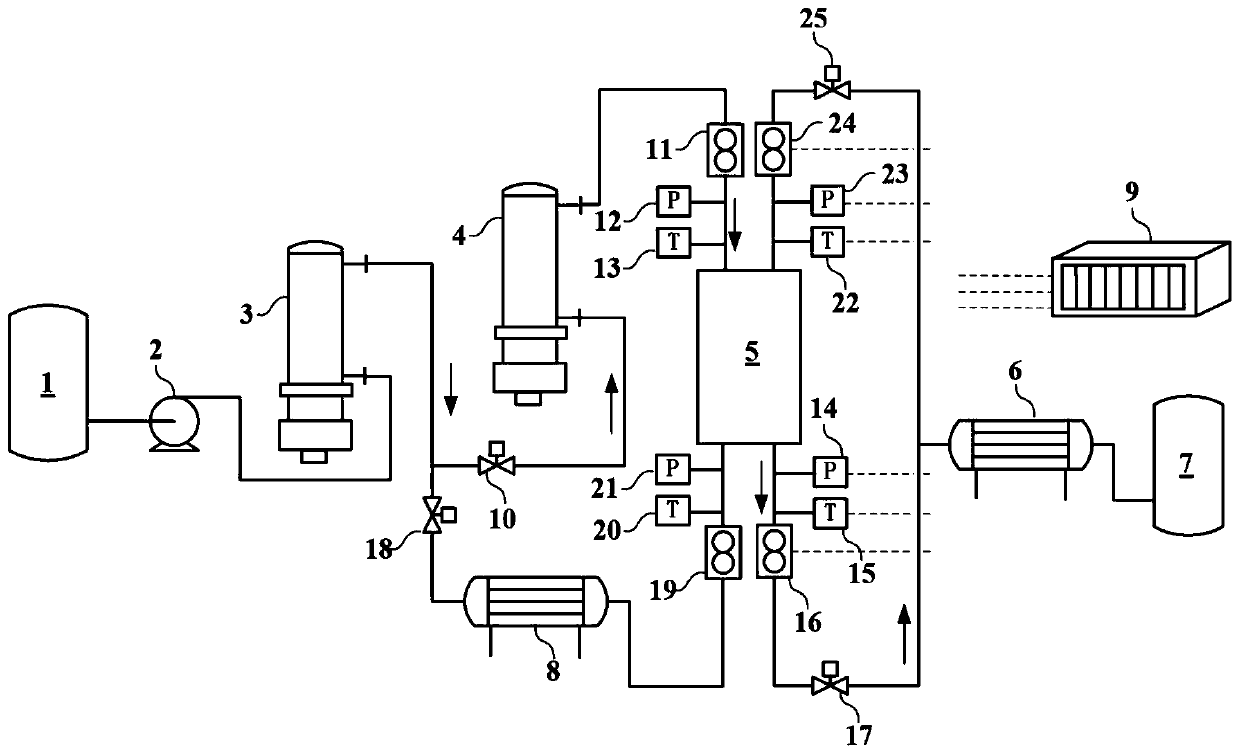

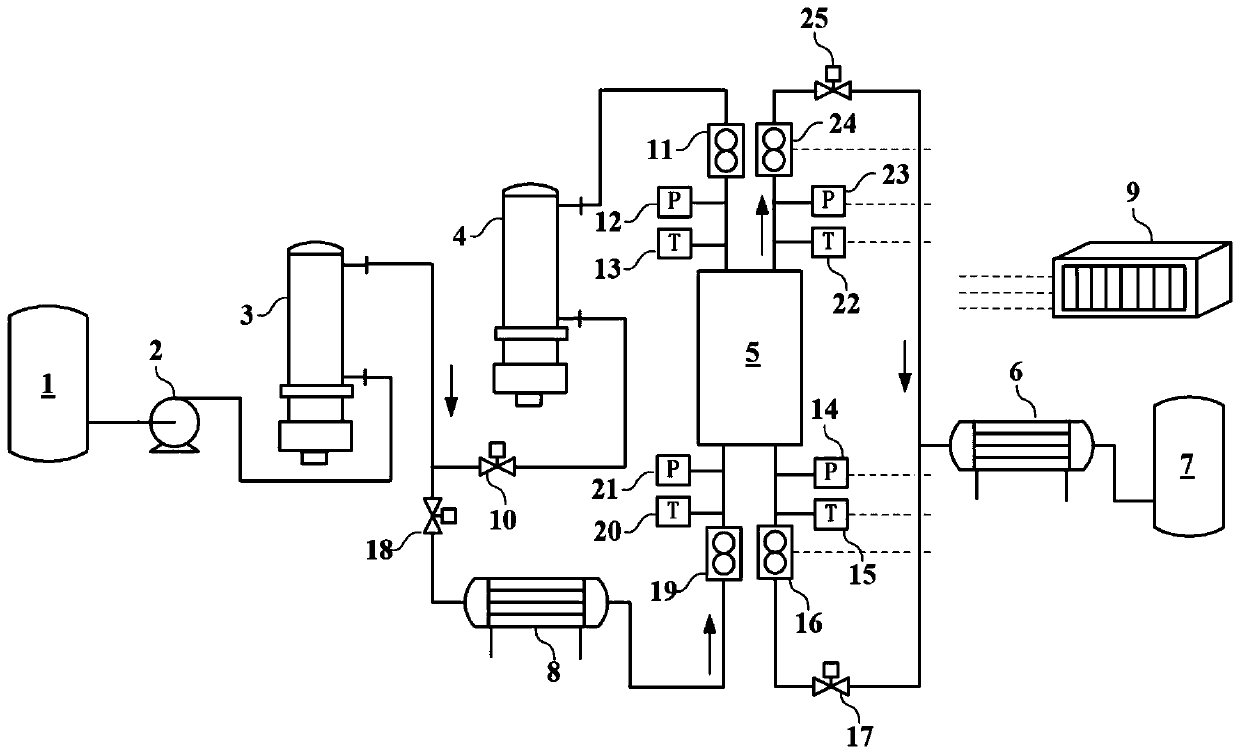

Performance test system of heat storage equipment taking steam as working medium

ActiveCN111307479AHigh pressure accuracyHigh accuracy of flow controlStructural/machines measurementControl systemData acquisition

The invention discloses a performance test system of heat storage equipment taking steam as a working medium. The system can carry out performance test experiment and evaluation on the heat storage performance of the heat storage equipment taking the steam as the medium. The system is composed of an electric steam generator, an electric superheater, a heat exchanger, a data acquisition and controlsystem, tested equipment, a pump valve assembly, a state parameter measuring instrument and the like. According to the system, high-temperature steam heat storage / release conditions of different scales and working condition parameters can be realized, unstable heat energy working conditions such as industrial waste heat can be simulated, and research, development and test of heat storage key components in the compressed air energy storage system can be met.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

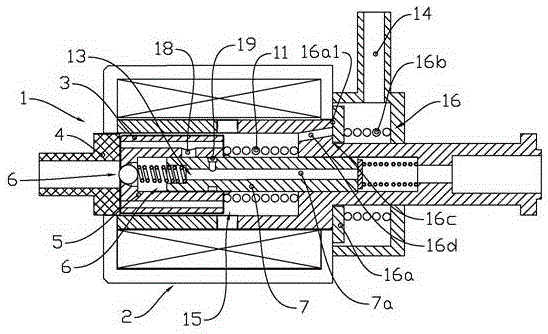

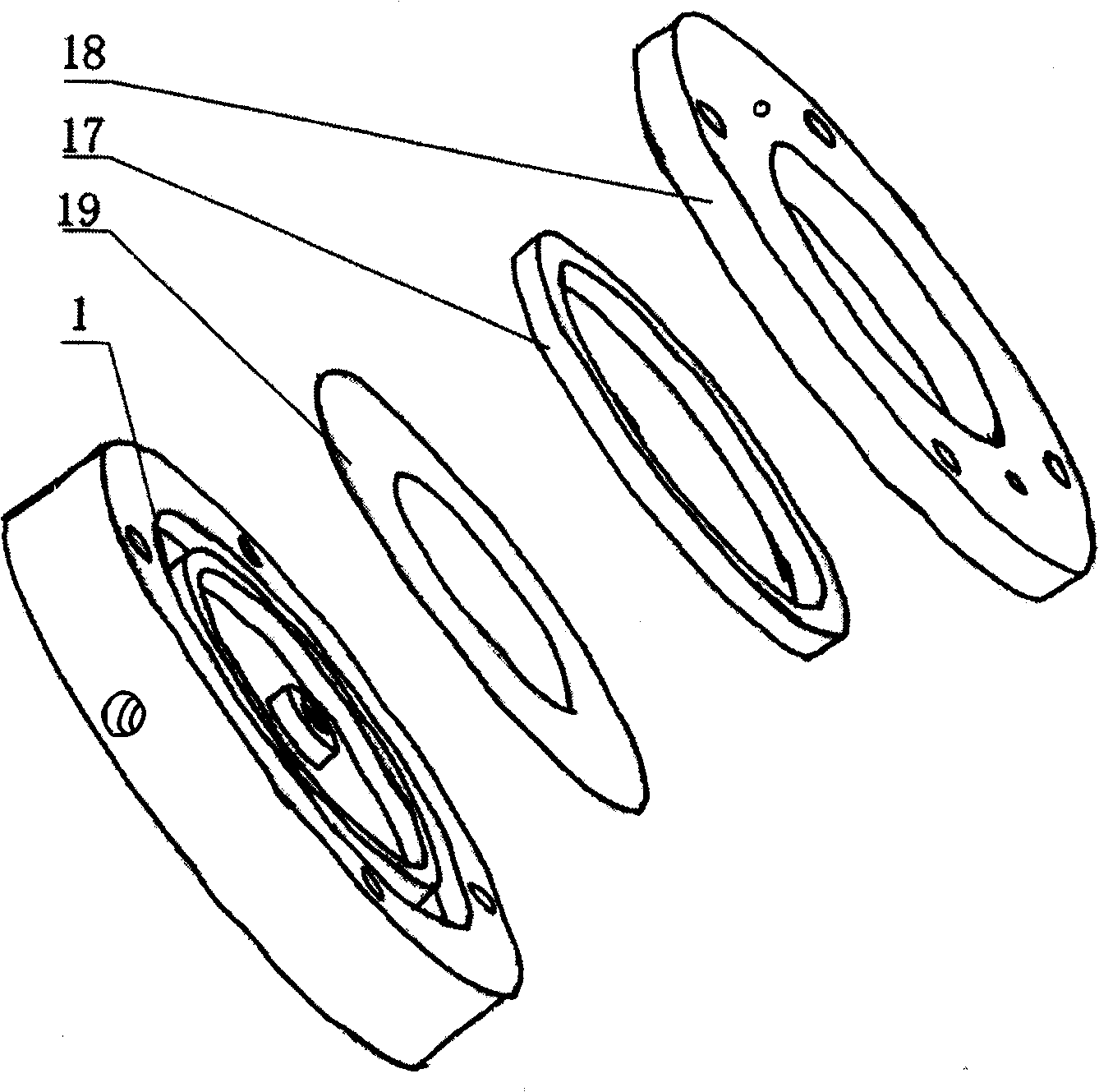

Composite valve

ActiveUS20130153056A1High accuracy of flow controlIncrease flow rateOperating means/releasing devices for valvesEfficient regulation technologiesPilot valveRate control

A composite valve has a communication path, a second valve port and a pilot passage. First and second valve bodies are arranged to be moved up and down in the same direction, and are away from each other only at a predetermined distance. In the case that a lift amount of the second valve body for a small flow rate control is equal to or less than a predetermined amount, said pilot passage and a first valve port are respectively closed by a pilot valve body and the first valve body, thereby taking a small flow rate control state. In the case that the lift amount of said second valve body goes beyond said predetermined amount, said pilot valve body is moved up by the upward movement of a valve shaft to open said pilot passage, thereby taking a large flow rate control state.

Owner:FUJIKOKI CORP

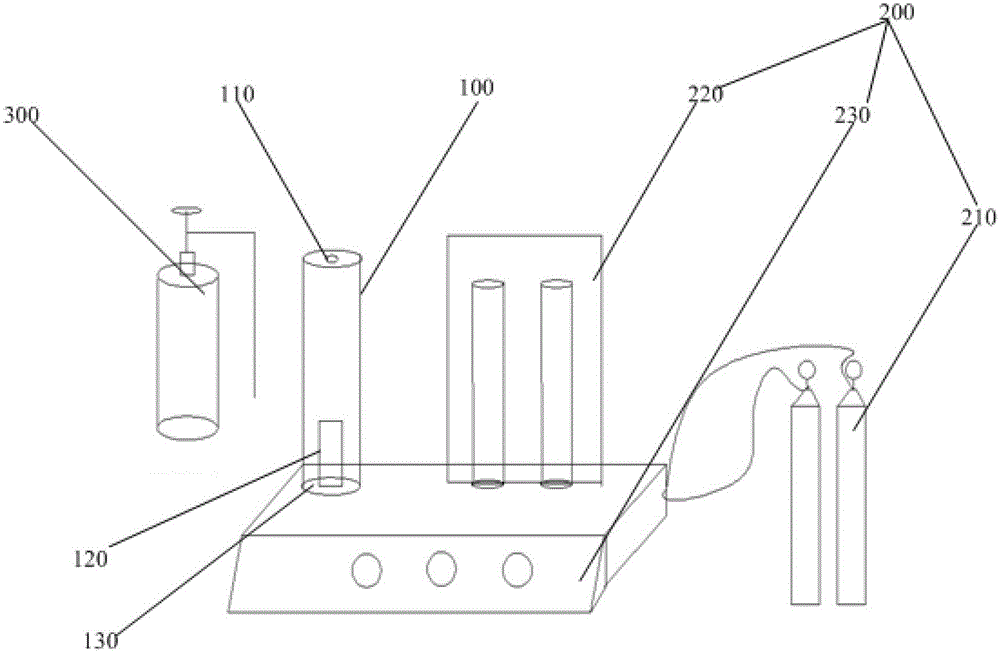

Oxygen index test system

ActiveCN103149321AHigh accuracy of flow controlEasy to operateChemical analysis using combustionIndex testCombustion

The invention discloses an oxygen index test system which comprises a combustion tube, a flow control system and an ignition device, wherein the combustion tube is used for holding materials to be tested; the flow control system is connected with the combustion tube and used for introducing gas to the combustion tube and controlling the oxygen content of the introduced gas; and the ignition device is inserted into the combustion tube and used for igniting the materials to be tested. The oxygen index test system disclosed by the invention has the advantages of high flow control precision, good control of ignition position, simpleness in operation and accurate detection result.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL +1

Differential pressure compensation valve with fast and stable main valve opening degree

InactiveCN111608980AEliminate sudden changes in trafficImprove stabilityServomotor componentsEqualizing valvesValve openingPilot valve

The invention provides a differential pressure compensation valve with a fast and stable main valve opening degree. The differential pressure compensation valve with the fast and stable main valve opening degree is used for realizing the compensation of various disturbance factors in the control of a large flow multi-way valve by the differential pressure compensation valve, with the help of the structural design of a valve element of a main valve, the pressure before and after the main valve is fast and stable, pressure fluctuation is reduced, and noise is reduced. The differential pressure compensation main valve and a differential pressure compensation pilot valve are included. The differential pressure compensation main valve comprises a main valve body and the valve element of the main valve. An oil inlet and an oil outlet are formed in the main valve body, the oil inlet communicates with an internal main valve cavity through a valve port, the valve element of the main valve is arranged in the main valve cavity, and the differential pressure compensation pilot valve comprises a pilot valve body and a valve element of the pilot valve. A pilot valve cavity is formed in the pilotvalve body, and the valve element of the pilot valve is arranged in the pilot valve cavity.

Owner:杨新超

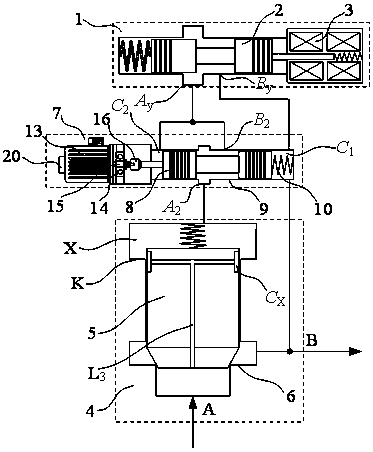

Pilot type proportional flow valve and control method

InactiveCN111396422AIncrease the flow control rangeImprove intelligenceFluid-pressure actuator testingServomotor componentsLinear controlLoop control

The invention relates to a pilot type proportional flow valve. The valve comprises a proportional pilot valve communicating with a pilot cavity of a main valve, wherein a differential pressure compensator is arranged between the main valve and the proportional pilot valve, the differential pressure compensator compensates inlet and outlet differential pressure of the proportional pilot valve, thedifferential pressure compensator is an active control type differential pressure compensator, a valve element linear control device and a valve element displacement real-time detection device are arranged, a signal output port of the valve element displacement real-time detection device is connected with a processor, and the processor is connected with and controls the valve element linear control device. The valve solves the problems of large fluctuation of flow and poor stability caused by small pressure change due to the fact that a valve port adopts a method of correcting closed-loop control flow by a differential pressure sensor, the control precision of a pressure sensor is limited, the pressure sensor needs a large working range, but the compensation differential pressure is relatively small and is in the same order of magnitude as a system in pressure fluctuation.

Owner:TAIYUAN UNIV OF TECH

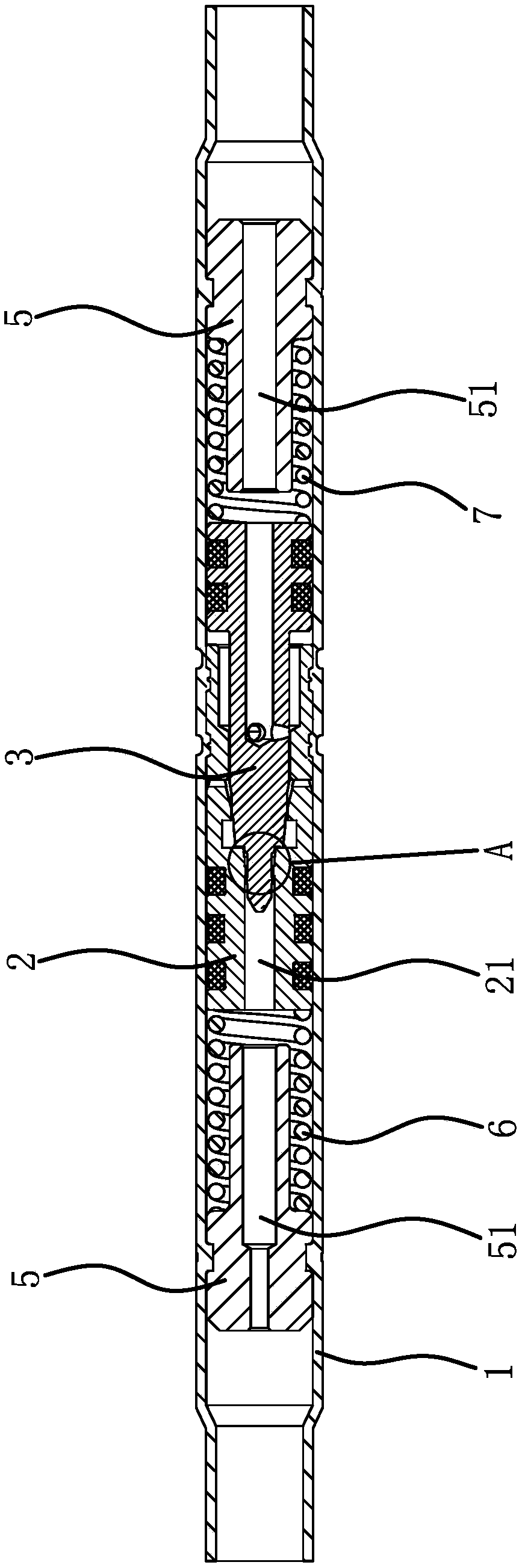

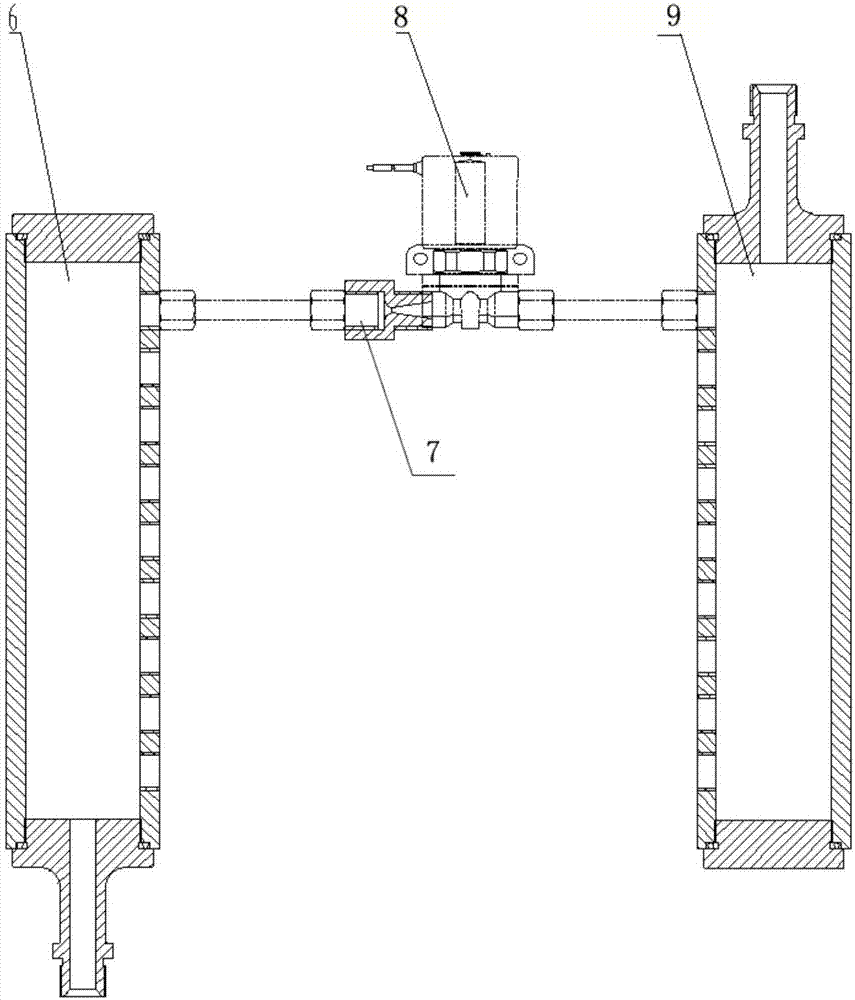

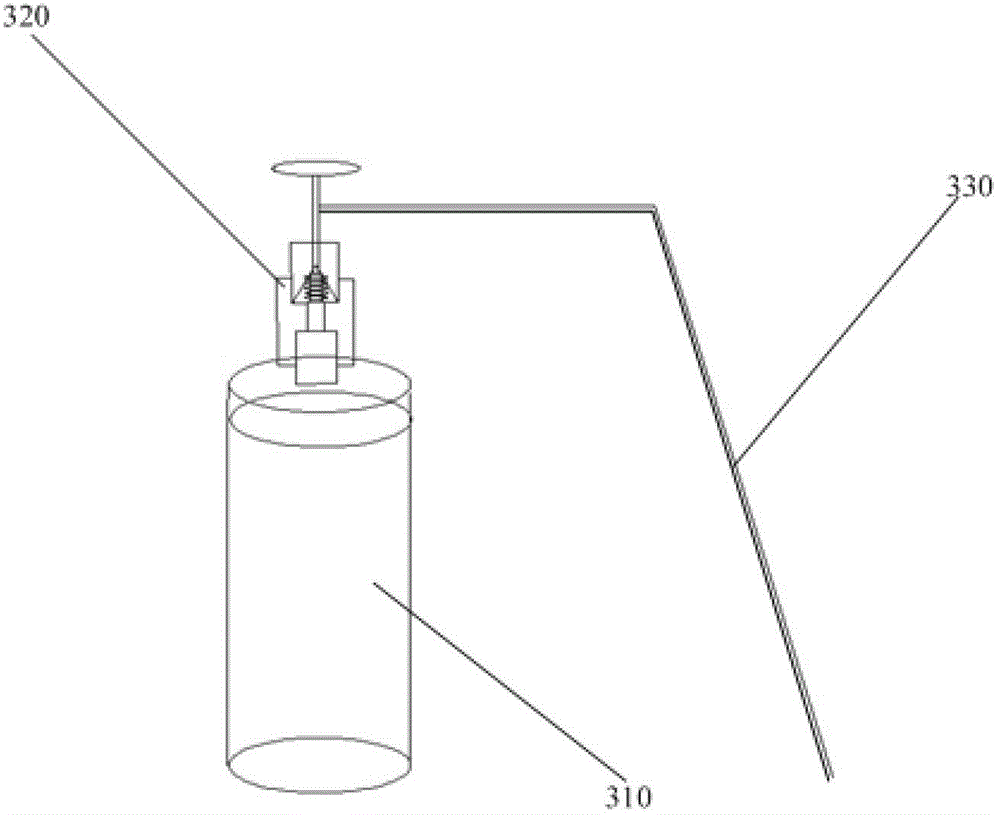

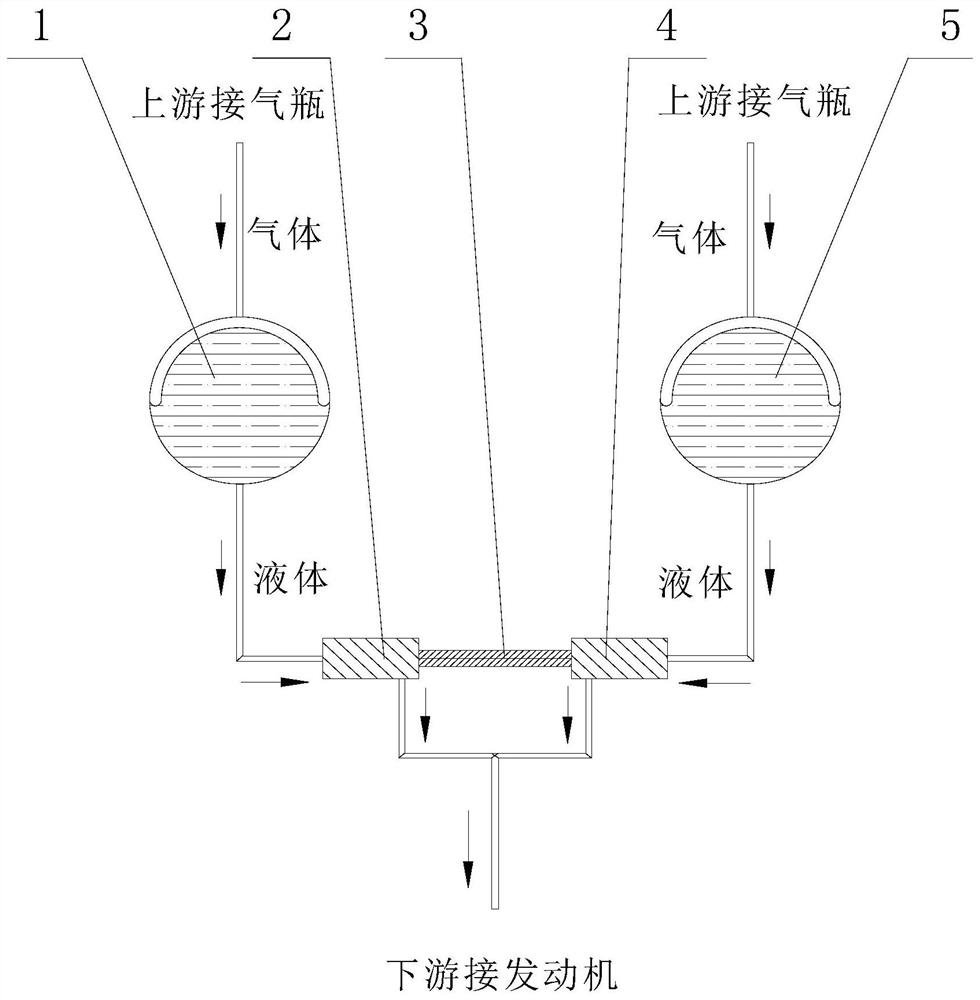

Device for balanced discharge of parallel storage tanks

InactiveCN111731514AGuaranteed control accuracyHigh control precisionCosmonautic vehiclesCosmonautic propulsion system apparatusMechanical engineeringMechanics

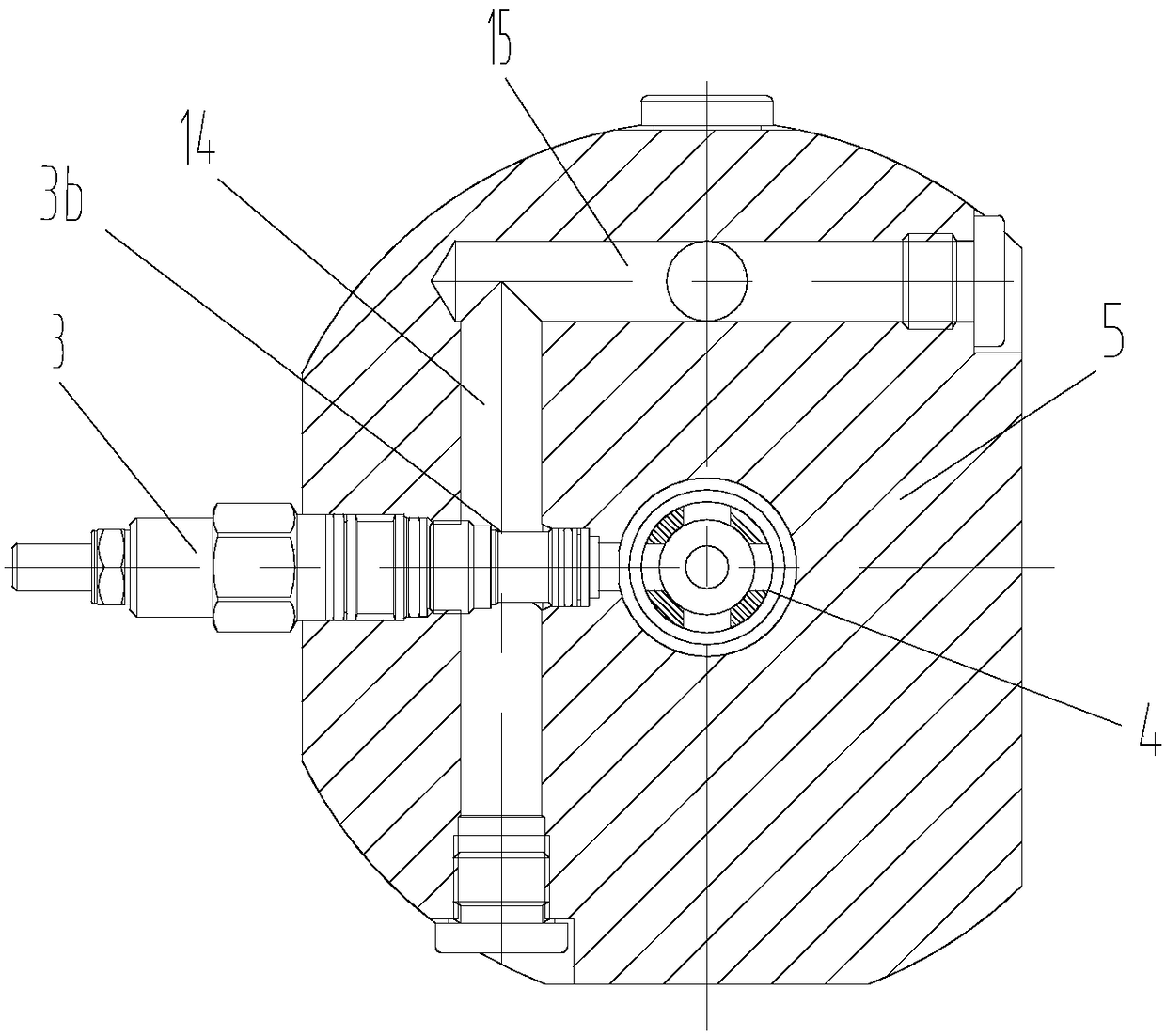

The invention provides a device for balanced discharge of parallel storage tanks. The device comprises a volumetric flow meter A (2), a volumetric flow meter B (4) and a rigid interconnection mechanism (3), whereina main shaft of the volumetric flow meter A (2) is connected with a main shaft of the volumetric flow meter B (4) through the rigid interconnection mechanism (3). The device for balanceddischarge of parallel storage tanks has the advantages of being high in flow control precision, wide in pressure application range and high in viscosity adaptability, flow calibration can be completed in a single-machine state, system pipeline matching and system cold flow testing do not need to be conducted, system testing and structural layout are simplified, and product reliability is greatlyimproved.

Owner:SHANGHAI INST OF SPACE PROPULSION

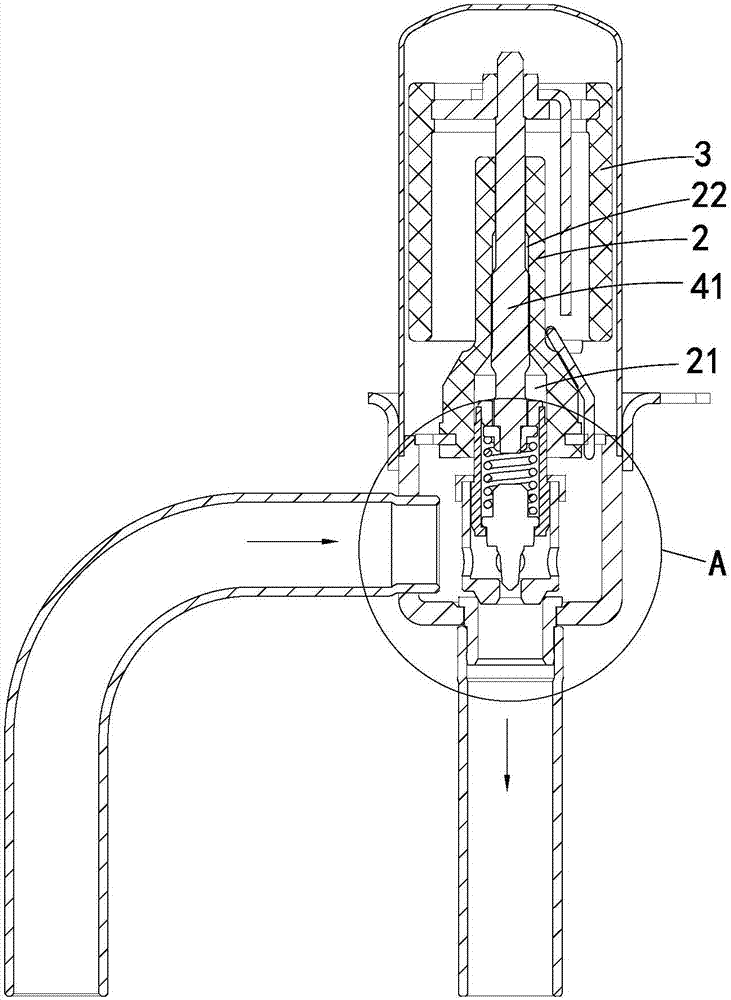

Constant-volume metering pump

ActiveCN106285855AHigh accuracy of flow controlLimited outputExhaust apparatusSilencing apparatusMetering pumpBiomedical engineering

The invention provides a constant-volume metering pump. The constant-volume metering pump comprises a pump body, a solenoid device and a plunger pump, wherein the solenoid device and the plunger pump are located in the pump body. The solenoid device comprises an armature. The plunger pump comprises a sleeve, a plunger, an input valve and an output valve. The sleeve comprises a sleeve inner hole, and the sleeve inner hole is in close fit with the outer surface of the plunger and can slide freely. The interior of the pump body is divided into a low pressure space and a pressure feed space by the plunger pump. Liquid enters the pressure feed space from the low pressure space through the input valve, and then is discharged through the output valve. The constant-volume metering pump is characterized in that the sleeve and the armature are connected and kept reciprocating synchronously, the solenoid driving device drives the sleeve and the plunger to move relatively to enable the liquid to be discharged, and the liquid discharging amount obtained through relative movement between the sleeve and the plunger is limited by the geometric structure.

Owner:福爱电子(贵州)有限公司

Microfluid active control valve with toroid boundary

InactiveCN101303085BReduce controlHigh accuracy of flow controlDiaphragm valvesOperating means/releasing devices for valvesHysteresisHigh flux

The invention discloses an active control valve of a micro fluid, which is provided with torus boundaries. A through hole, of which the radius is R, and a circular cylindrical cavity which is coaxial with the through hole are processed on a valve body, and the torus boundaries are formed naturally. A film executive element not only forms a closed fluid cavity which is connected with a liquid outlet through a liquid output channel with the circular cylindrical cavity but also contacts with the torus boundaries to separate a liquid input channel and the liquid output channel. The film executiveelement is caused to make vibration or distortion to change the distance from the torus boundaries by an external control single when the valve at a natural state is closed, thus realizing the opening, closing and degrees of the valve. The active control valve of the invention can realize the control of an extreme small flux, thereby reaching an extreme high flux control precision; and the opening and close of the valve is actively controlled by the film executive elements can reduce the hysteresis of the valve, thus improving working efficiency and guaranteeing that the film executive element has certain predeformation to provide stanching property; besides, no locomotive mechanical part has advantages of quick response and good reliability and durability.

Owner:CHONGQING UNIV

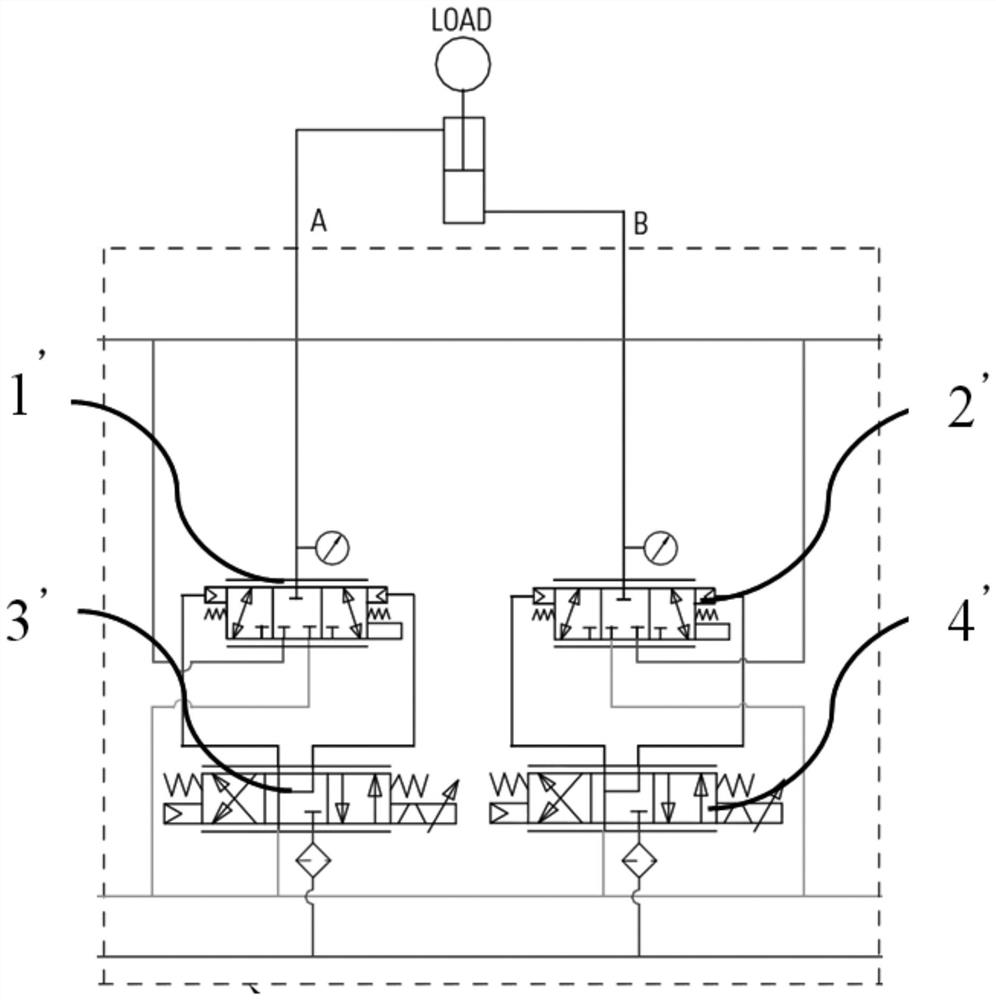

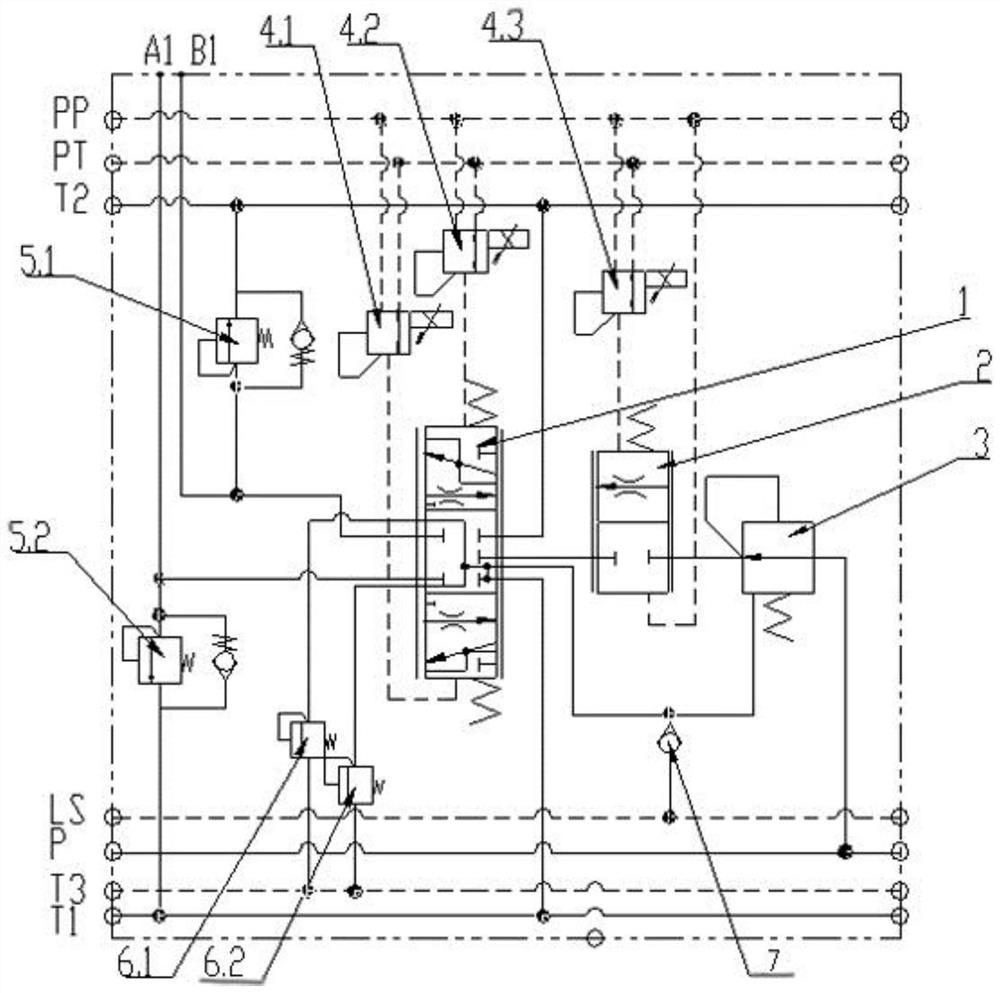

Working link and valve port independent control type multi-way valve and engineering machinery

ActiveCN114165495ASolve the problem of mechanical solid connection of inlet and outletAddressing Control ComplexityServomotor componentsFluid-pressure actuator componentsArea networkControl manner

The invention relates to a working unit, a valve port independent control type multi-way valve and engineering machinery, the working unit can realize independent control of an oil inlet and an oil outlet, and manual, electro-hydraulic proportional and CAN (Controller Area Network) bus control modes can be adopted. The problem of mechanical fixed connection of an oil inlet and an oil outlet of a traditional multi-way valve is solved, and the control freedom degree is increased; the problems that an existing valve with an independent valve port is complex in control and unstable in control are solved, the structure is simple, the flow control precision is high, the cost is low, and switching between the valve with the independent valve port and a traditional upstream compensation load sensitive multi-way valve can be achieved. With the development of the sensor technology and the control technology, control methods of flow calculation control, pressure calculation control and the like can be achieved on the premise that the structure of the valve body is not changed, the second main valve element is replaced with the plug, the form of a throttling opening in the first main valve element is changed, and therefore the valve body structure is simplified. The function of the upstream compensation load-sensitive multi-way valve of a traditional structure can be achieved through the working unit, and therefore the performance of the multi-way valve with the independently-controlled valve port and even the performance of engineering machinery are improved.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD

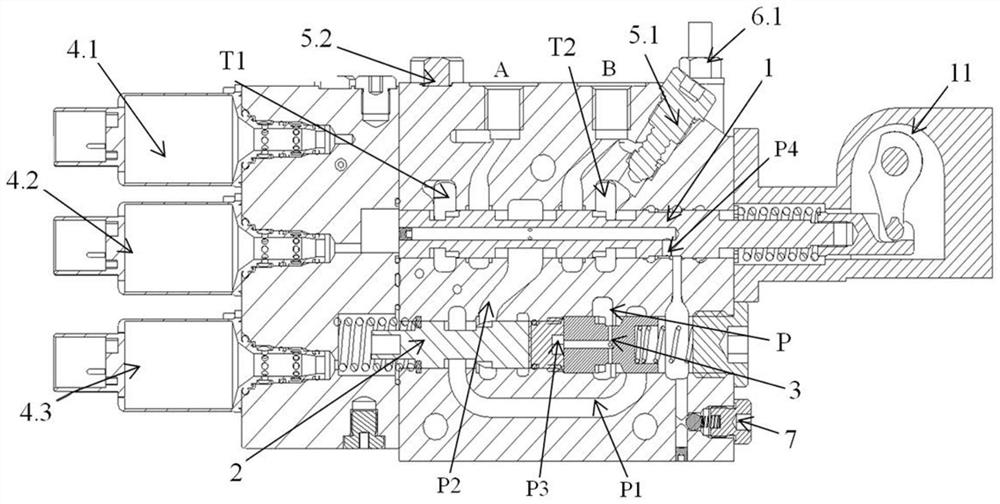

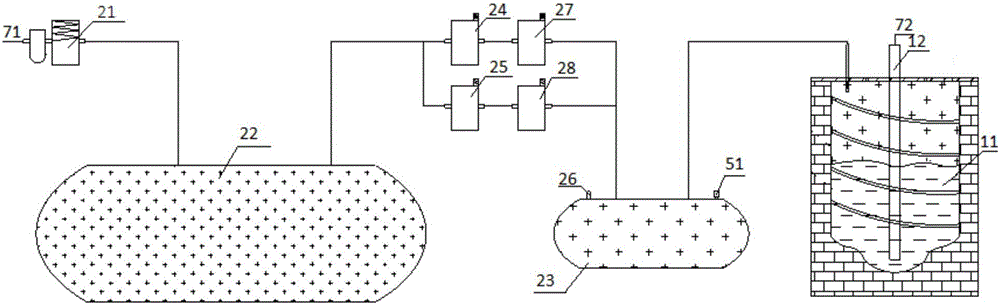

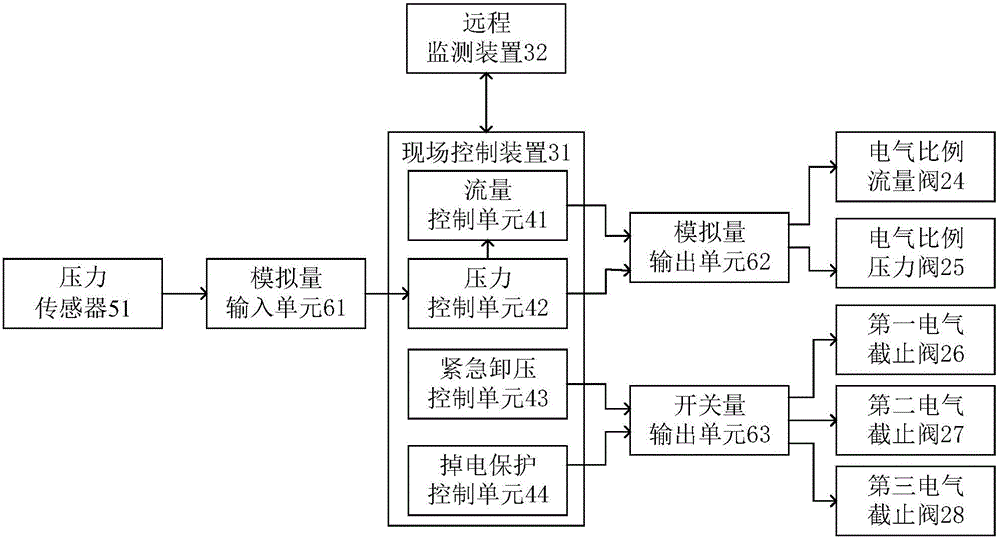

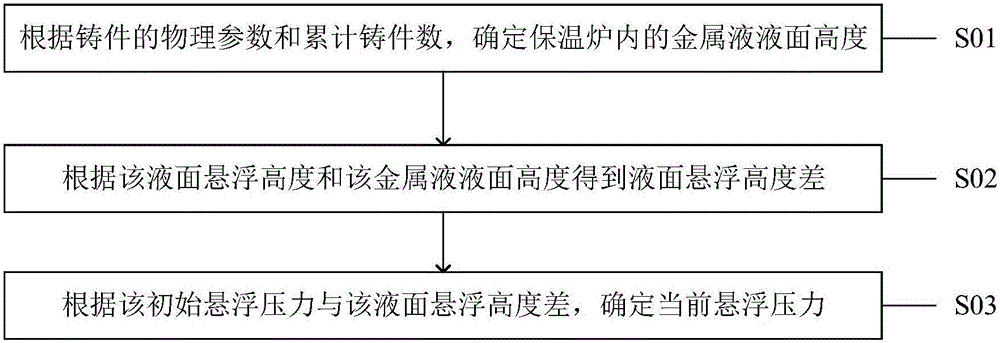

Low-pressure casting method and equipment

ActiveCN105689689AHigh accuracy of flow controlHigh precision of pressure controlPneumatic circuitControl system

The invention belongs to the technical field of low-pressure casting, and particularly relates to a low-pressure casting method and equipment. The low-pressure casting equipment comprises a heat preserving furnace, a riser tube, a pneumatic circuit and a control system, wherein the pneumatic circuit comprises a gas storage tank and a control valve, and further comprises a buffer tank; the control valve comprises an electro-pneumatic proportional pressure valve and an electro-pneumatic proportional flow valve; the electro-pneumatic proportional pressure valve is connected with the gas storage tank and the buffer tank; the electro-pneumatic proportional flow valve is connected with the gas storage tank and the buffer tank; the buffer tank is further connected with the heat preserving furnace; the control system comprises an on-site control device; the on-site control device comprises a pressure control unit and a flow control unit; the pressure control unit is connected with the electro-pneumatic proportional pressure valve; the flow control unit is connected with the electro-pneumatic proportional flow valve. The low-pressure casting method and equipment have the advantage that pressure of compressed gas can be adjusted precisely in a casting process, so as to reduce defects of a casting structure and improve yield.

Owner:致能科技有限公司

Electronic expansion valve

PendingCN110230722ALow costEasy to installOperating means/releasing devices for valvesEfficient regulation technologiesGear driveMotor drive

The invention discloses an electronic expansion valve, in particular to the magnetic-coupling anti-clamping-stagnation electronic expansion valve with high flow control precision. The electronic expansion valve is characterized by comprising a valve body assembly, an execution assembly and a drive structure, wherein the valve body assembly comprises a valve seat; the lower part of the axial direction and the lateral direction of the valve seat are welded with a pipe B and a pipe A; a flange plate is welded to the upper end surface of the valve seat; and the upper surface of a tilting pan and an isolation sleeve pipe are welded together. The drive structure comprises a stepping motor, wherein a driving gear on an output shaft of the stepping motor drives a driven gear sleeved in the isolation sleeve pipe, and an outer magnetic ring on the driven gear drives an inner magnetic ring in the isolation sleeve pipe, so that the execution assembly is driven to rotate. The electronic expansion valve provided by the invention not only is excellent in performance, but also is low in cost.

Owner:ZHUJI YIBA ELECTRONICS VALVE

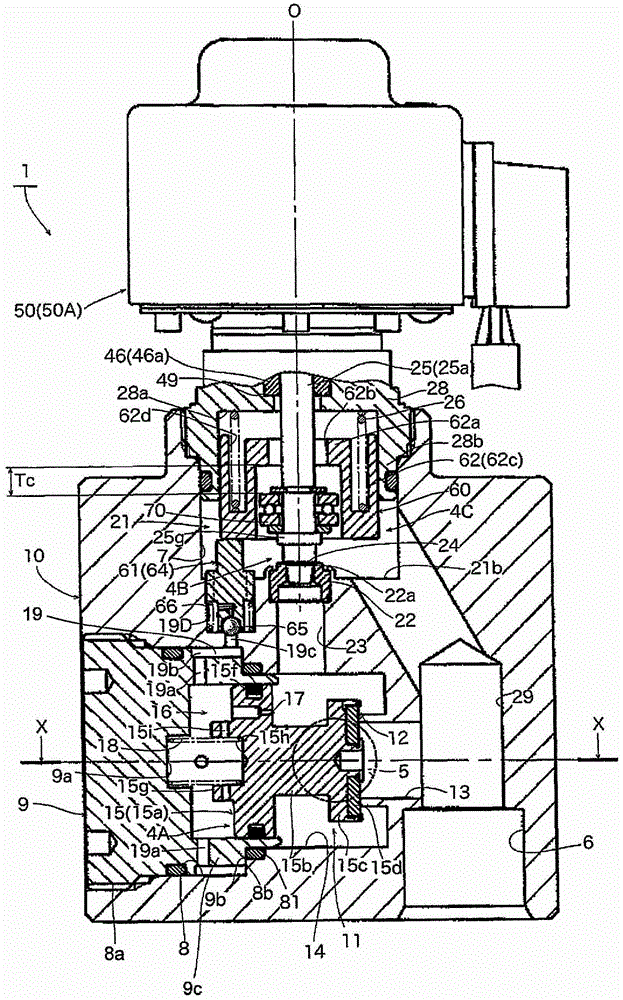

Combination valve

ActiveCN103245139BHigh accuracy of flow controlImprove sealingOperating means/releasing devices for valvesFluid circulation arrangementEngineeringPilot valve

The invention provides a composite valve which can achieve both an improvement of a flow rate control precision in a small flow rate region and an increase of a controllable flow rate (a reduction of a pressure loss), and can enhance a sealing performance of a pilot passage by a pilot valve body, whereby it is possible to securely prevent a malfunction and it is possible to enhance a reliability. When a lift amount of a second valve body (24) for a small flow rate control is equal to or less than a predetermined amount (Tc), a pilot passage (19) is closed by a pilot valve body (60) which is slidable on an inner wall of a bush retention body (28), and a first valve port (13) is closed by a first valve body (15) for a large flow rate control, thereby taking a small flow rate control state in which a flow rate is controlled in correspondence to a lift amount of the second valve body (24). When the lift amount of the second valve body (24) goes beyond the predetermined amount (Tc), a pilot valve body (20) is raised in correspondence to a rising motion of a valve shaft (25) so as to open the pilot passage (19), thereby taking a large flow rate control state in which the first valve body (15) opens the first valve port (13). The pilot valve body (60) is outward inserted slidably to the valve shaft (25), and is energized downward by a spring member (26) so as to close the pilot passage (19). Further, when the lift amount of the second valve body (24) is increased more than the predetermined amount Tc, the pilot valve body (60) is caught on the valve shaft (25) so as to be pulled up.

Owner:FUJIKOKI MFG CO LTD

Flow adjusting device

PendingCN114811065AStable structureHigh accuracy of flow controlOperating means/releasing devices for valvesLift valveStream flowEnvironmental engineering

The invention discloses a flow adjusting device which comprises a body, the body is provided with a water inlet channel and a water outlet channel, a water inlet hole is formed in the portion, between the water inlet channel and the water outlet channel, of the body, a moving shaft used for adjusting flow is arranged in the body, and the moving shaft can be connected with the water inlet hole in a matched mode. According to the kitchen and bath water treatment device, the structure is simple and stable, the flow control precision is high, and the kitchen and bath water treatment device is suitable for kitchen and bath water treatment products.

Owner:XIAMEN RUNNER IND CORP

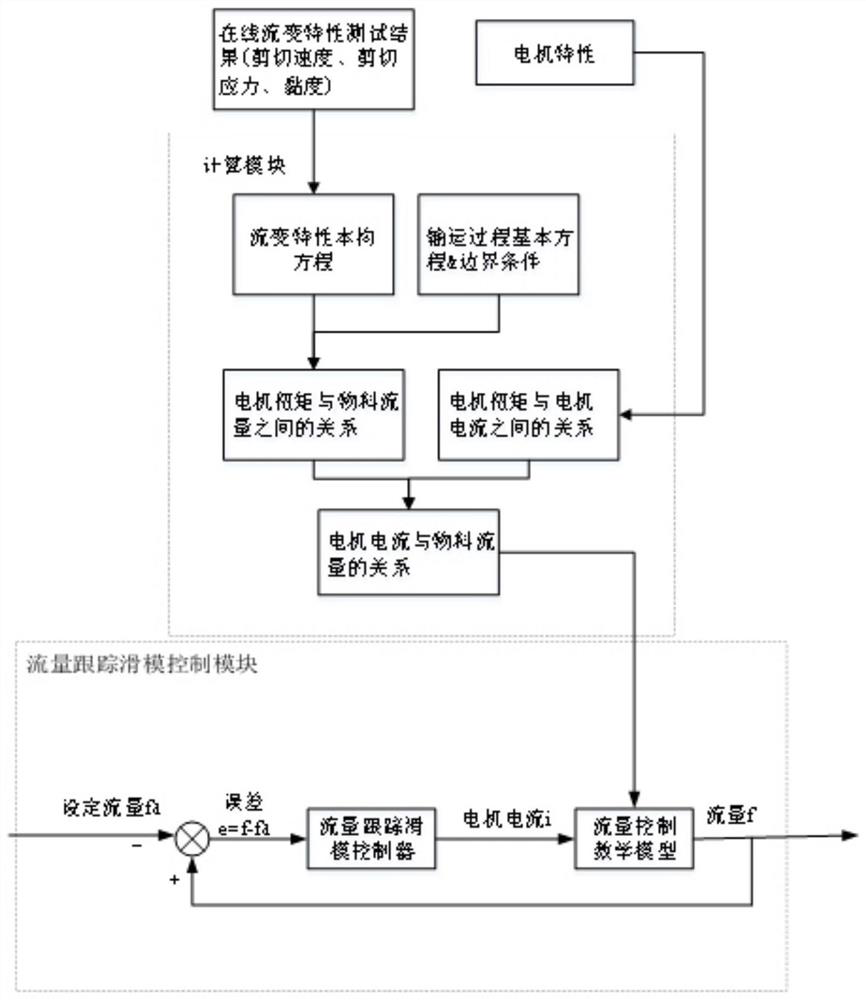

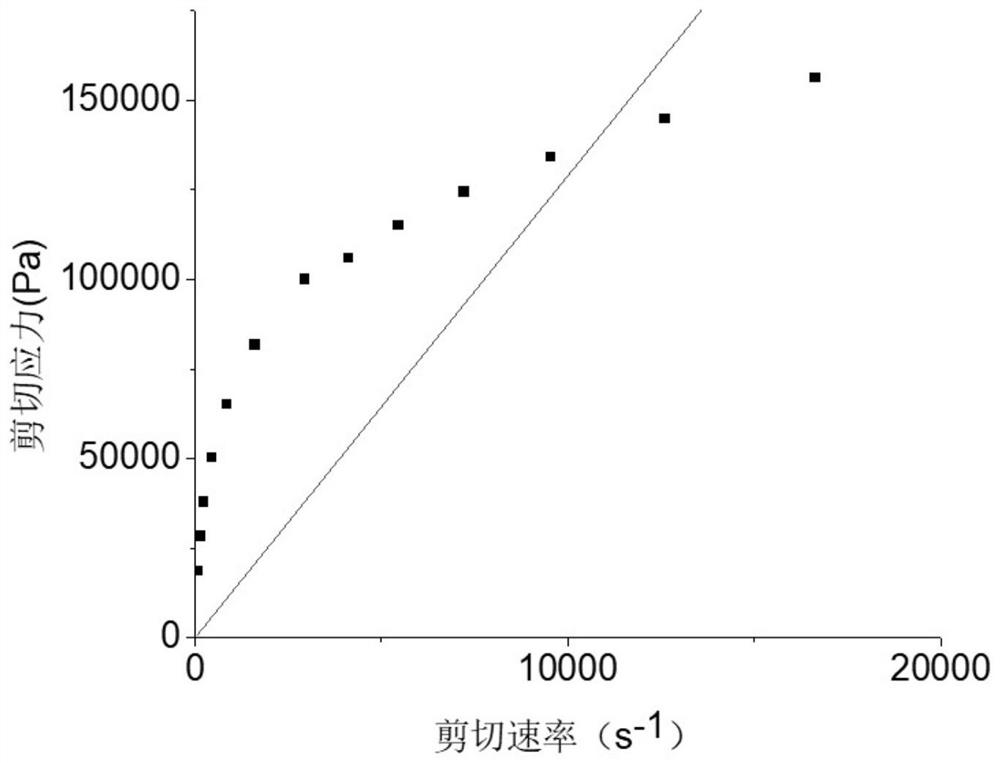

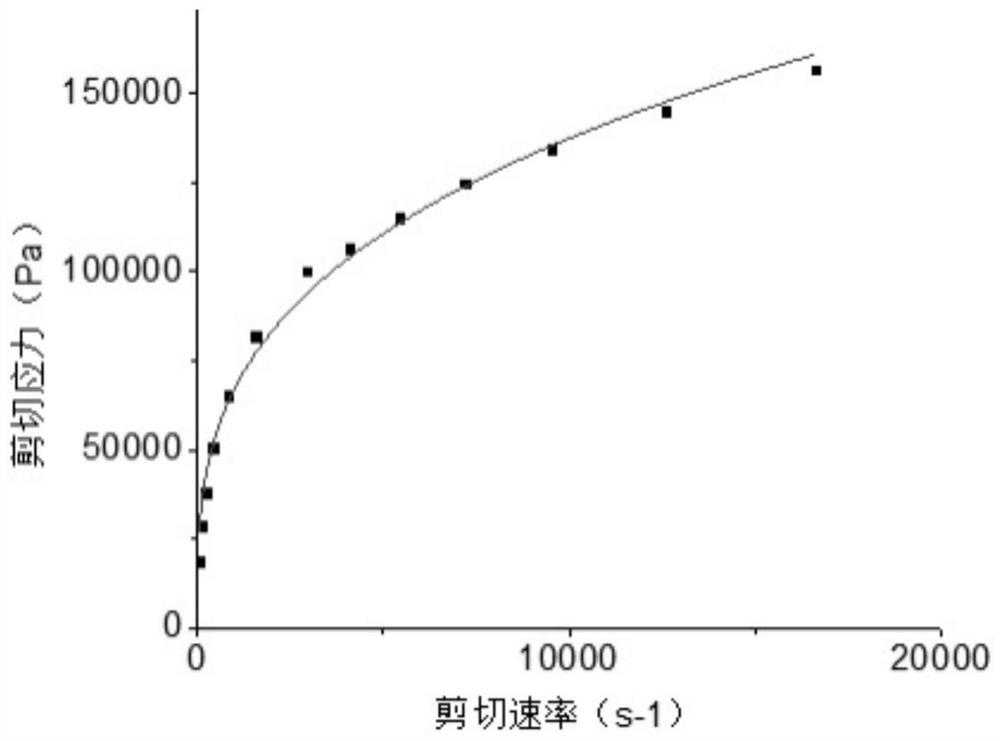

Flow control method based on non-Newtonian fluid rheological property test system

ActiveCN113533135AHigh accuracy of flow controlReal-time controlDirect flow property measurementMathematical modelStream flow

A flow control method based on a non-Newtonian fluid rheological property test system belongs to the field of flow control of non-Newtonian fluid, and comprises the following steps: S1, an online rheological property test result is transmitted to a built-in calculation module of a flow intelligent control system; S2, the calculation module obtains a real-time rheological characteristic constitutive equation of the material according to the rheological property test result; s3, the calculation module calculates the corresponding relation between the motor current and the non-Newtonian fluid material flow; s4, a flow control mathematical model is obtained according to the corresponding relation in the S3, and the flow control mathematical model is built in a control module; and S5, the control module compares the actual flow fed back with the set flow and adjusts parameters of the mathematical model, so that the flow is rapidly and accurately controlled. The flow of a certain position of production equipment is accurately controlled through movement of the motor, so that the flow control accuracy of non-Newtonian fluid is high, the control is real-time, and the problems that a filling sealing piece of a conventional filling valve is easy to wear, the structure is complex and the efficiency is low are solved.

Owner:HUNAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com