Constant-volume metering pump

A technology of constant volume metering and pump body, which is applied in the direction of mufflers, engine components, machines/engines, etc. It can solve problems affecting durability, long axial dimension, and difficult manufacturing, and achieve the effect of improving flow control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

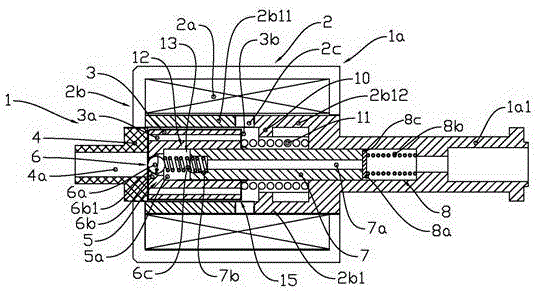

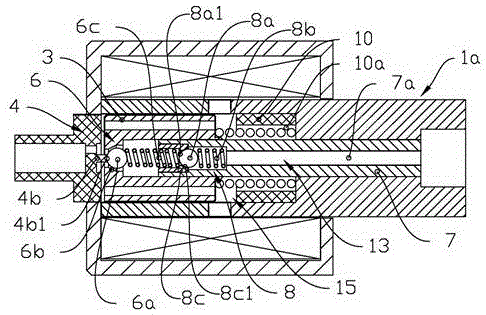

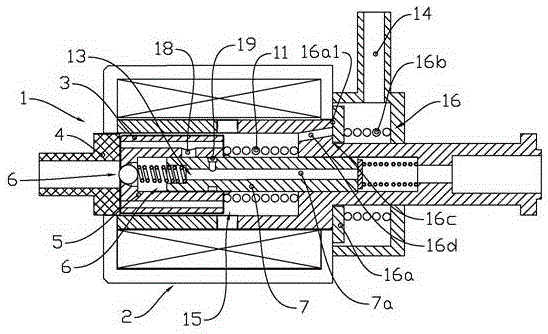

[0047] Such as figure 1 As shown, it is one of the structural diagrams of the embodiment of the constant volume metering pump provided by the present invention. The constant volume metering pump 1 includes a pump body 1a and a solenoid device 2 located in the pump body 1a, a plunger pump 12, and a rear Pump end 4, front pump end 10 and return spring 11.

[0048] The solenoid device 2 has a structure satisfying the basic principle of generating electromagnetic driving force, including a solenoid coil 2a, a yoke 2b, a magnetic isolation ring 2c and an armature 3 driven by electromagnetic force. The yoke 2b is arranged around the coil 2a, and the yoke 2a located inside the coil is an inner yoke 2b1, and the inner yoke 2b1 is divided into an upper inner yoke 2b11 and a lower inner yoke 2b12 by a magnetic spacer ring 2c. The yoke 2b11, the lower inner yoke 2b12 and the spacer ring 2c form a roughly cylindrical space for the reciprocating movement of the armature 3, that is, the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com