Electronic expansion valve

A technology of electronic expansion valve and valve body, which is applied in the direction of lifting valve, valve details, valve device, etc., can solve the problems of electronic expansion valve stuck, valve stem bouncing up and down, friction increase, etc., to improve flow control accuracy, flow rate The effect of high control precision and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solutions of the present invention will be further specifically described below through examples.

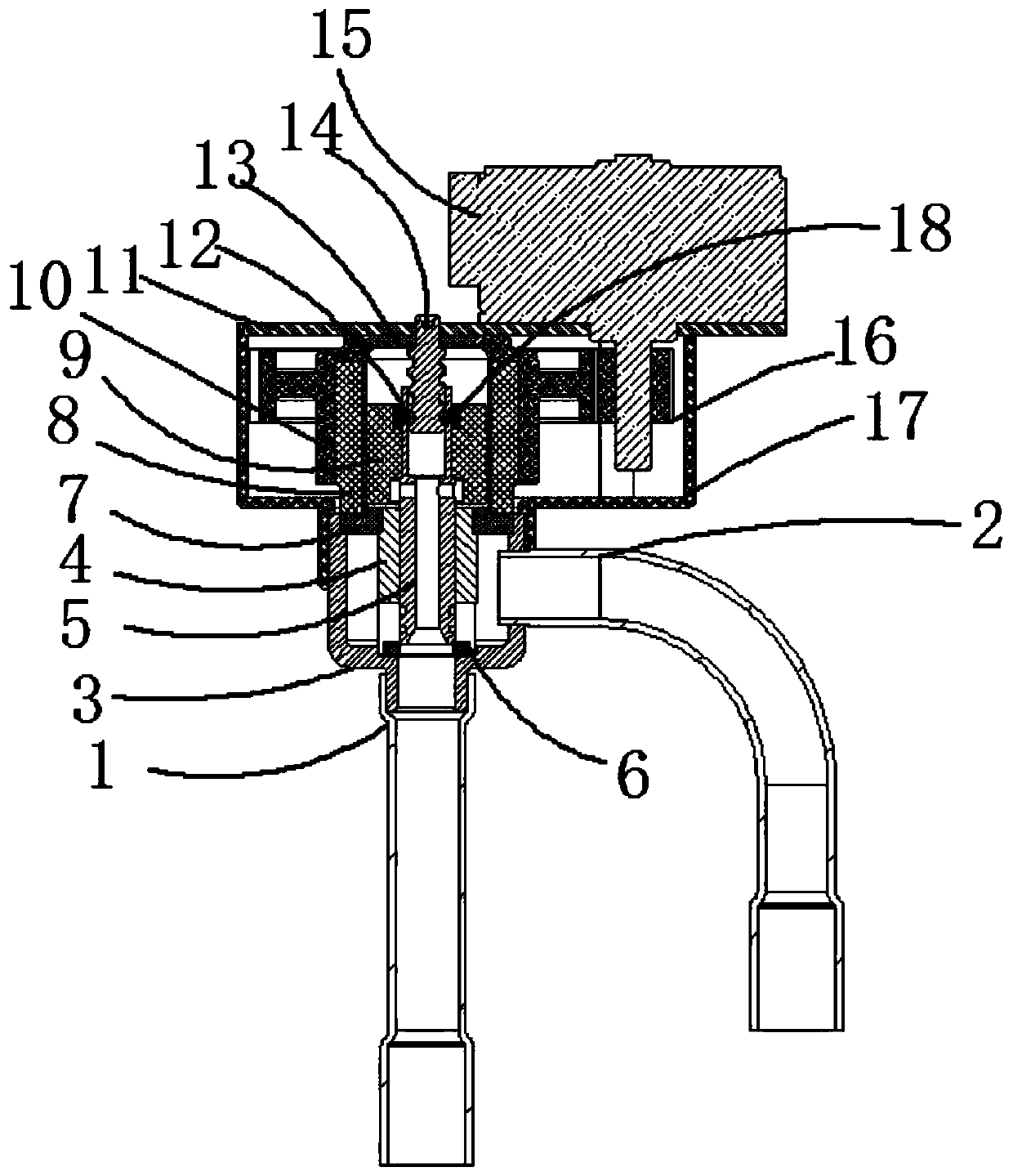

[0058] Such as figure 1 As shown, an electronic expansion valve includes a valve body assembly, an executive assembly and a driving structure.

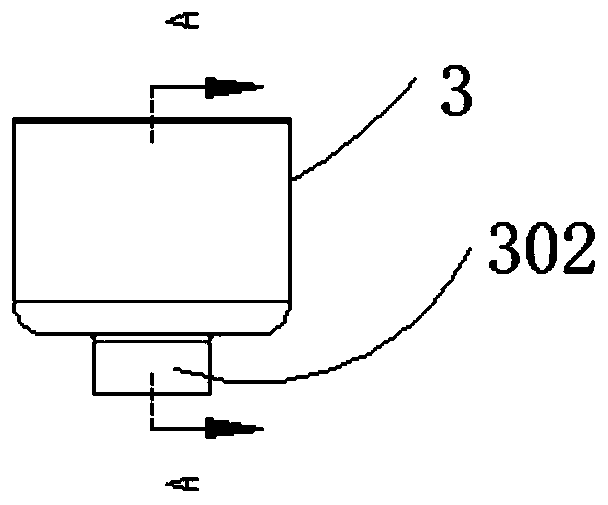

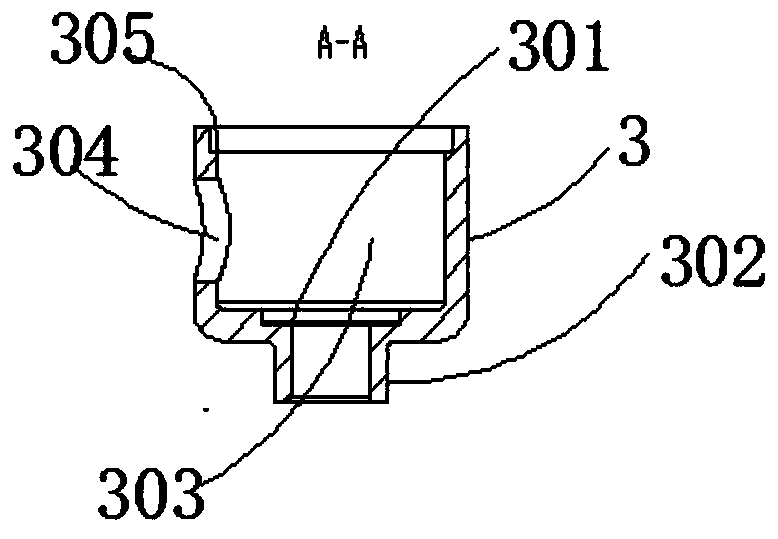

[0059] Among them, such as figure 2 , image 3 , Figure 8 As shown, the valve body assembly includes a valve seat 3, the axial lower part 302 of the valve seat 3 is welded with the B pipe 1, the valve seat side hole 304 is welded with the A pipe 2, and the valve seat 3 An annular channel 303 is formed inside, and the upper end surface of the annular channel 303 forms an inner step 305 of the valve seat, and the inner step 305 of the valve seat is welded together with the disc 702 on the flange 7, and the disc 702 is A stepped circle 703 is formed on the end surface, and the stepped circle 703 is welded together with the matching spacer sleeve 13 , and the outer diameter of the disc 702 is larger than that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com