Low-pressure casting method and equipment

A low-pressure casting and equipment technology, applied in the field of low-pressure casting, can solve problems such as low yield, shrinkage and porosity of casting structure, and achieve the effects of reducing defects, improving yield, and improving flow control accuracy and pressure control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

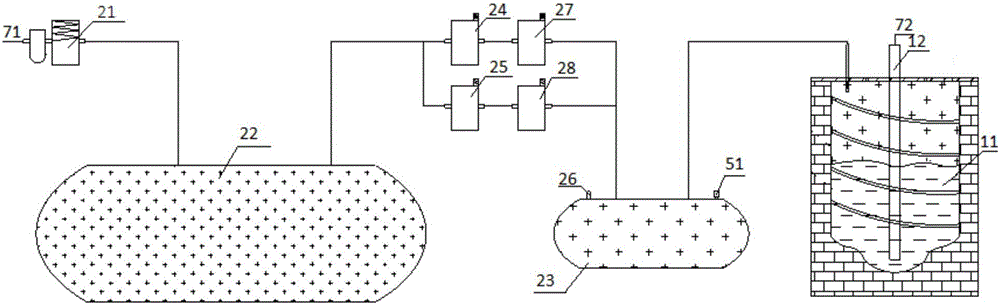

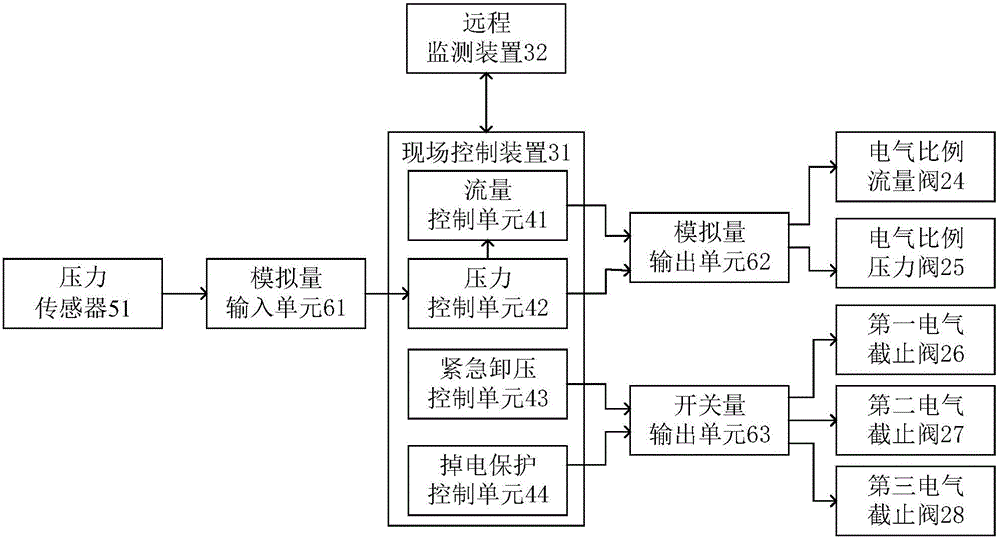

[0050] Such as figure 1 and figure 2 As shown, the low-pressure casting equipment of this embodiment includes a holding furnace 11, a liquid rising pipe 12, a pneumatic circuit and a control system; the liquid rising pipe 12 is arranged in the holding furnace 11 and protrudes from the holding furnace; the air pressure The loop includes a filter decompression valve 21, an air storage tank 22 and a gas pipeline 71; the pneumatic loop also includes a buffer tank 23; the control valve includes an electrical proportional pressure valve 25 and an electrical proportional flow valve 24; the electrical proportional pressure valve 25 is respectively It is connected with the gas storage tank 22 and the buffer tank 23; the electric proportional flow valve 24 is connected with the gas storage tank 22 and the buffer tank 23 respectively; the buffer tank 22 is also connected with the holding furnace 11; the control system includes on-site The control device 31, the on-site control device i...

Embodiment 2

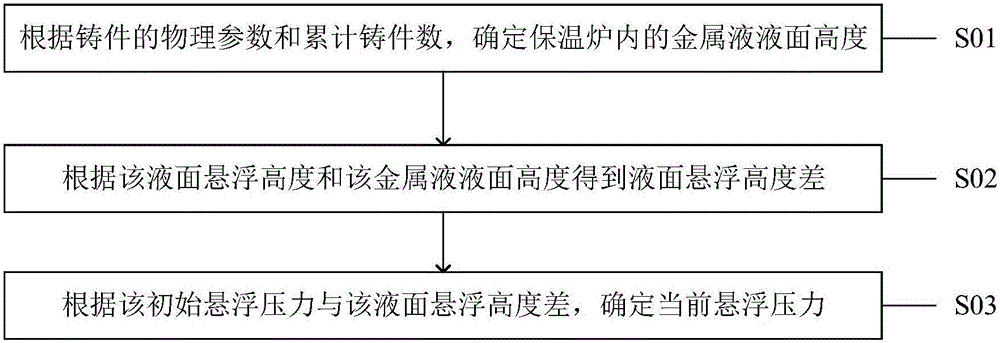

[0087] Such as figure 1 and figure 2 As shown, the low-pressure casting method of this embodiment is based on the low-pressure casting equipment described in Example 1, and includes the following steps:

[0088] The on-site control device generates a flow control command and sends it to the electric proportional flow valve according to the low-pressure casting process parameters, and generates a pressure control command and sends it to the electric proportional pressure valve; the low-pressure casting process parameters include liquid level suspension height, initial suspension pressure, filling velocity, filling pressure, crusting pressure, crusting velocity, crusting time, crystallization pressure, crystallization velocity, or crystallization time; correspondingly,

[0089] The electric proportional pressure valve controls the pressure of the compressed gas in the buffer tank in the suspension step, filling step, crusting step or crystallization step according to the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com