Flow control method based on non-Newtonian fluid rheological property test system

A technology of non-Newtonian fluid and rheological properties, applied in the field of flow control based on non-Newtonian fluid rheological properties testing system, can solve problems such as insufficient filling, easy wear of filling valve seals, overfilling, etc., to achieve control Real-time, high accuracy of flow control, and the effect of overcoming wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

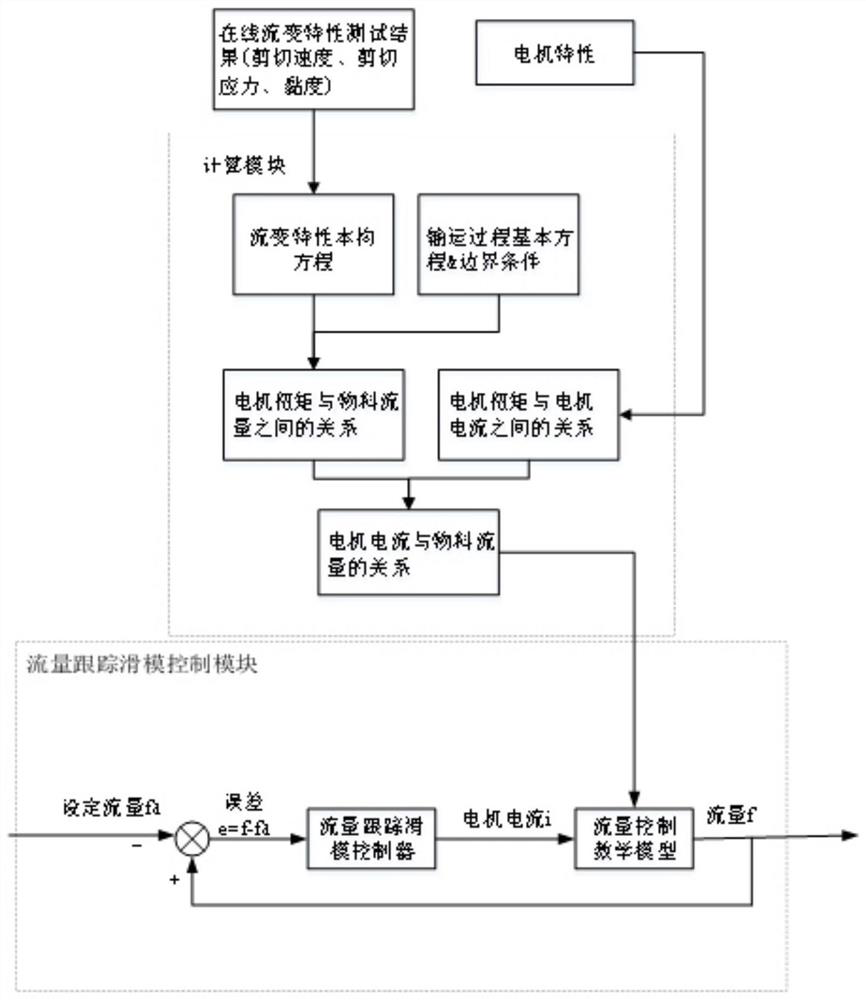

[0031] A flow control method based on a non-Newtonian fluid rheological characteristic testing system, comprising the following steps:

[0032] S1: Transmit the online rheological test results to the calculation module built in the flow intelligent control system. The online rheological property test results include shear velocity, shear stress and viscosity, which are obtained by real-time online measurement and calculation of the non-Newtonian fluid online rheological property test system installed on the production equipment or the production equipment with the function of testing the overall flow rate; the flow rate The intelligent control system includes a rheological data acquisition module, a calculation module, a control module and a human-computer interaction module: the rheological data acquisition module completes the data acquisition work of multiple sensors through the driving software, stamps it with a time stamp, and stores it in the real-time database; the contr...

Embodiment 2

[0043] The flow control of the injection machine (the equipment itself can measure the flow in real time) is an important link related to the quality of the final product. Different flow rates should be used in different stages of injection molding: in the initial stage, the melt should pass through the injection channel at a higher speed ;When the melt enters the cavity mouth, in order to prevent injection, the injection speed should be reduced; during the filling process, the injection speed should be accelerated so that the melt can quickly fill the cavity in the stage; when the mold is about to be filled, in order to prevent overfilling and flash , the injection speed should be reduced. Flow control also affects the total injection volume. If the total injection volume is too small, the product will shrink; if the total injection volume is too large, it will cause product flash, excessive product pressure, etc., and even damage the mold.

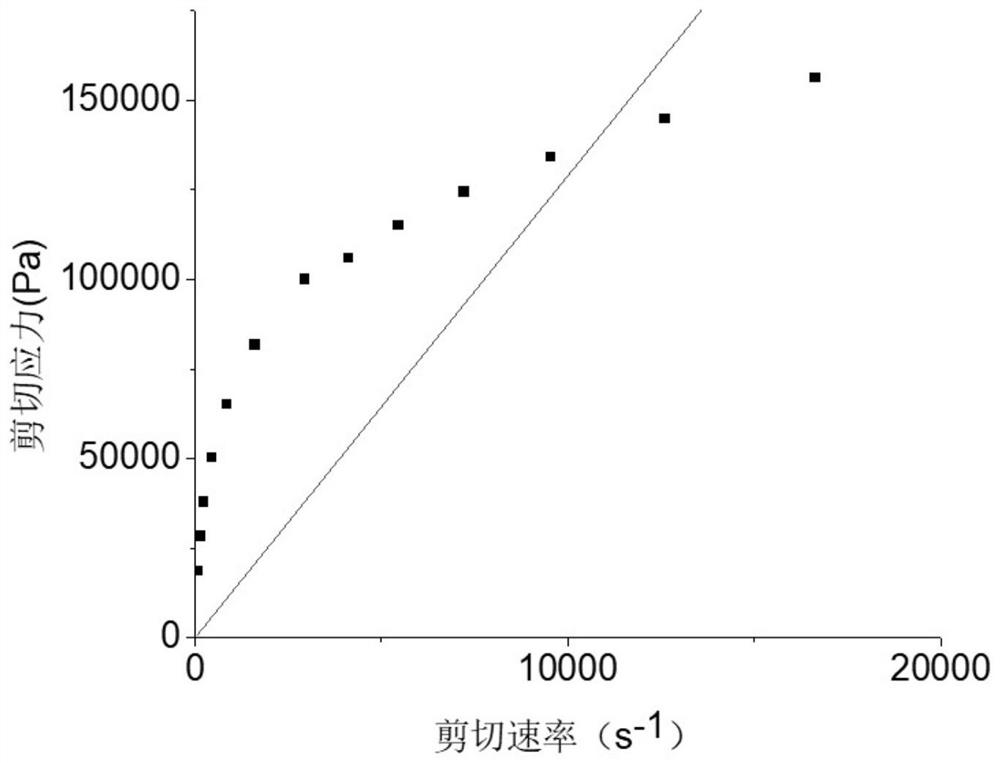

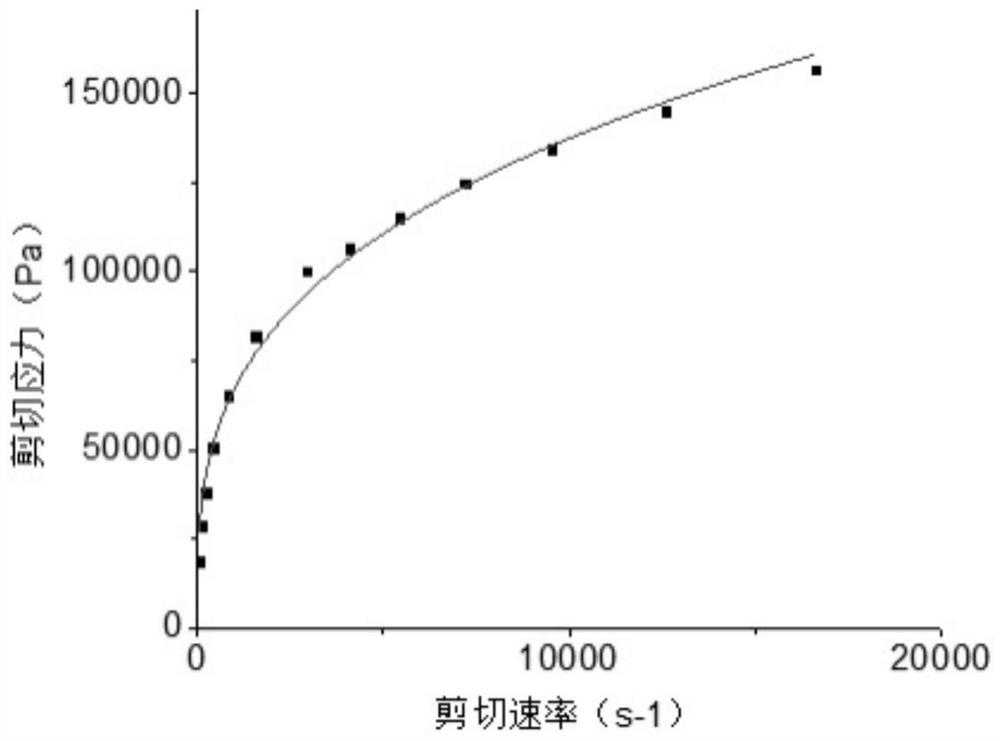

[0044] The plastic melt is inject...

Embodiment 3

[0058] Filling machine (does not have the function of testing the overall flow rate, but is equipped with an online rheological property testing system) in food (edible oil, blended oil, soybean oil, fruit juice, etc.), daily chemicals (detergent, laundry detergent, hand sanitizer, etc.) , lubricating oil (motor oil, glass water, antifreeze, etc.), condiments (soy sauce, vinegar, very delicious, etc.), drinks (mineral water, white wine, red wine, etc.) and other industries are widely used. In order to accurately control the filling volume and reduce the damage to equipment and instruments caused by the shock and vibration of the pipeline when the valve is suddenly opened and closed, it is necessary to accurately control the flow rate. At present, accurate filling is generally carried out by filling valves, which have problems such as easy wear of seals, complex structures, and low efficiency.

[0059] use as Figure 4 The method shown can realize precise control and real-time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com